THE PNEUMATICAL ⤰ INCRUSTATION

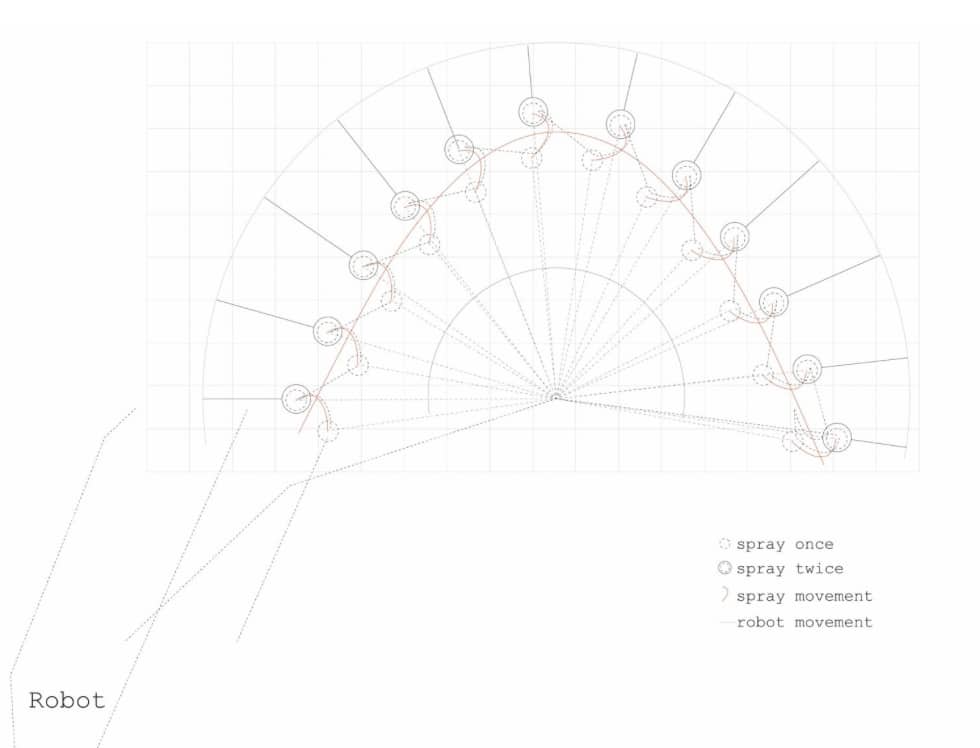

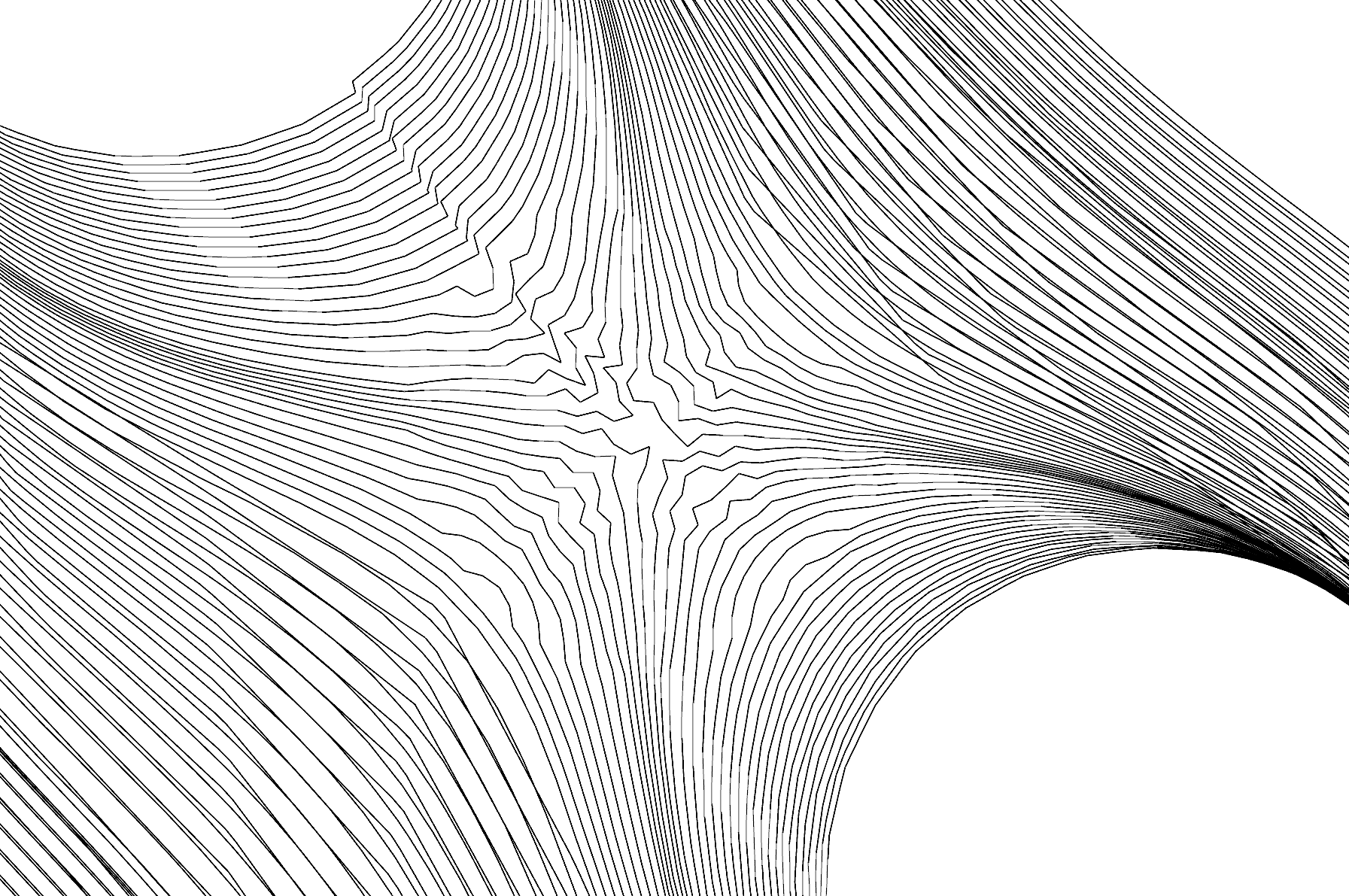

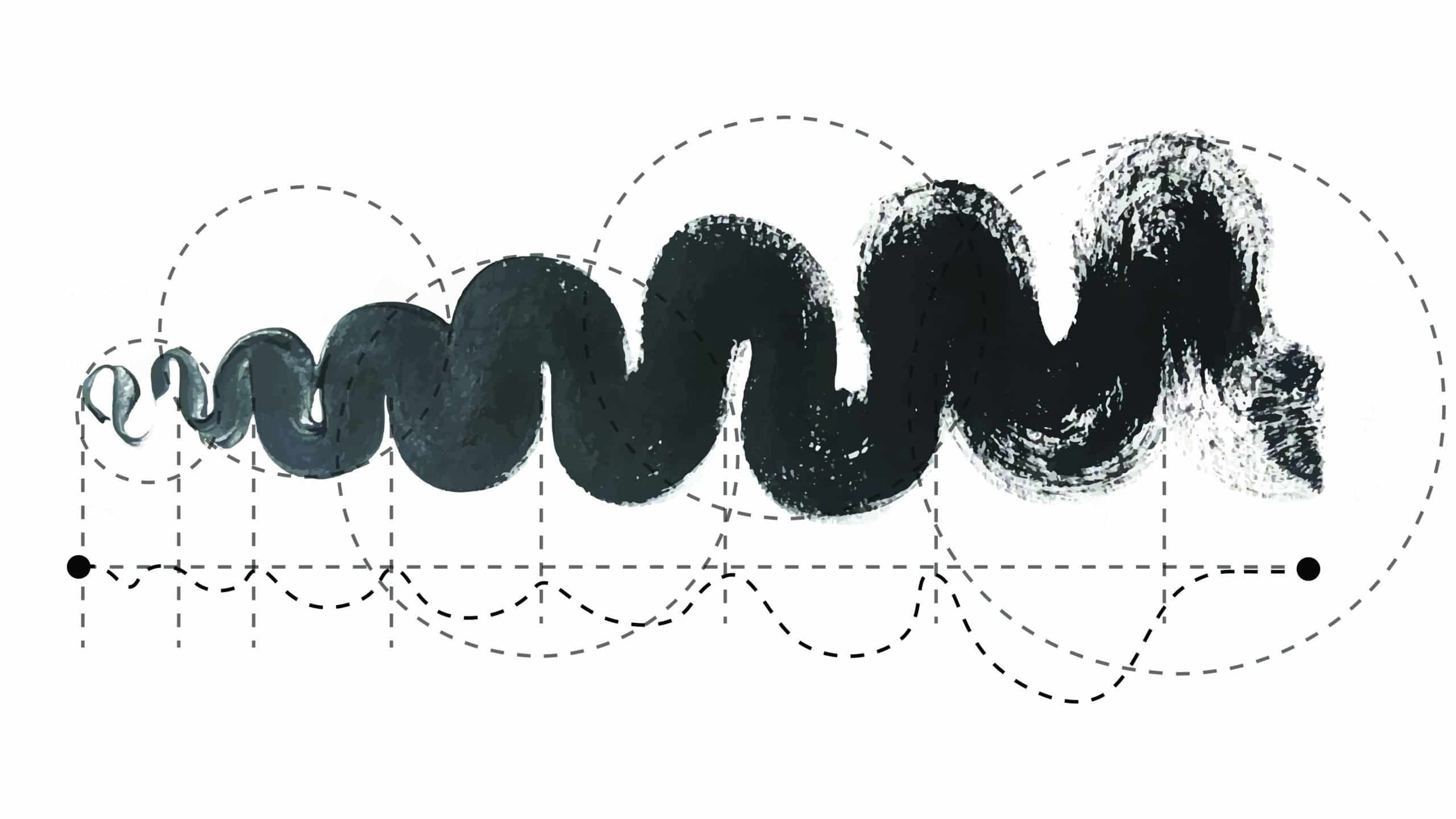

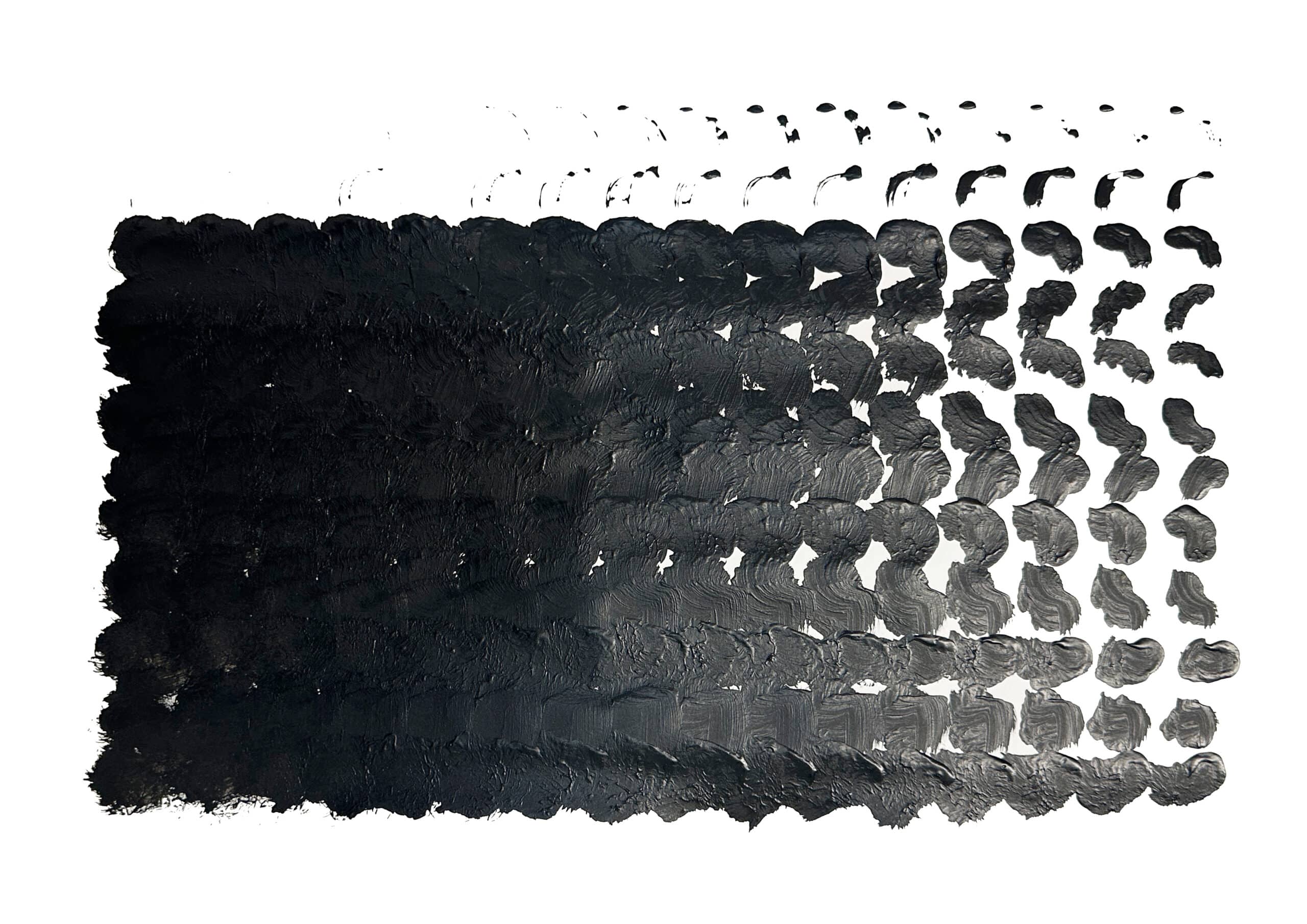

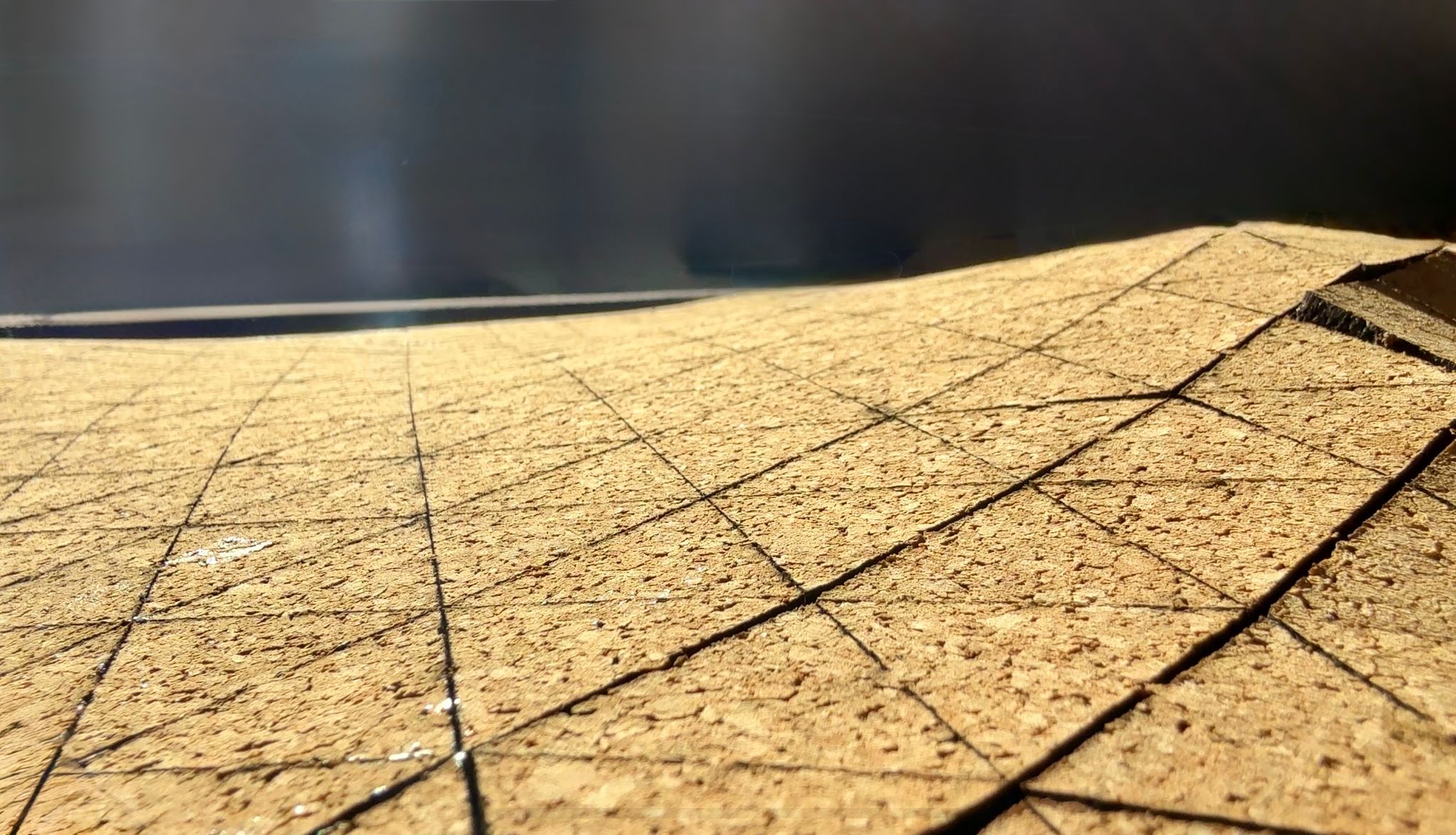

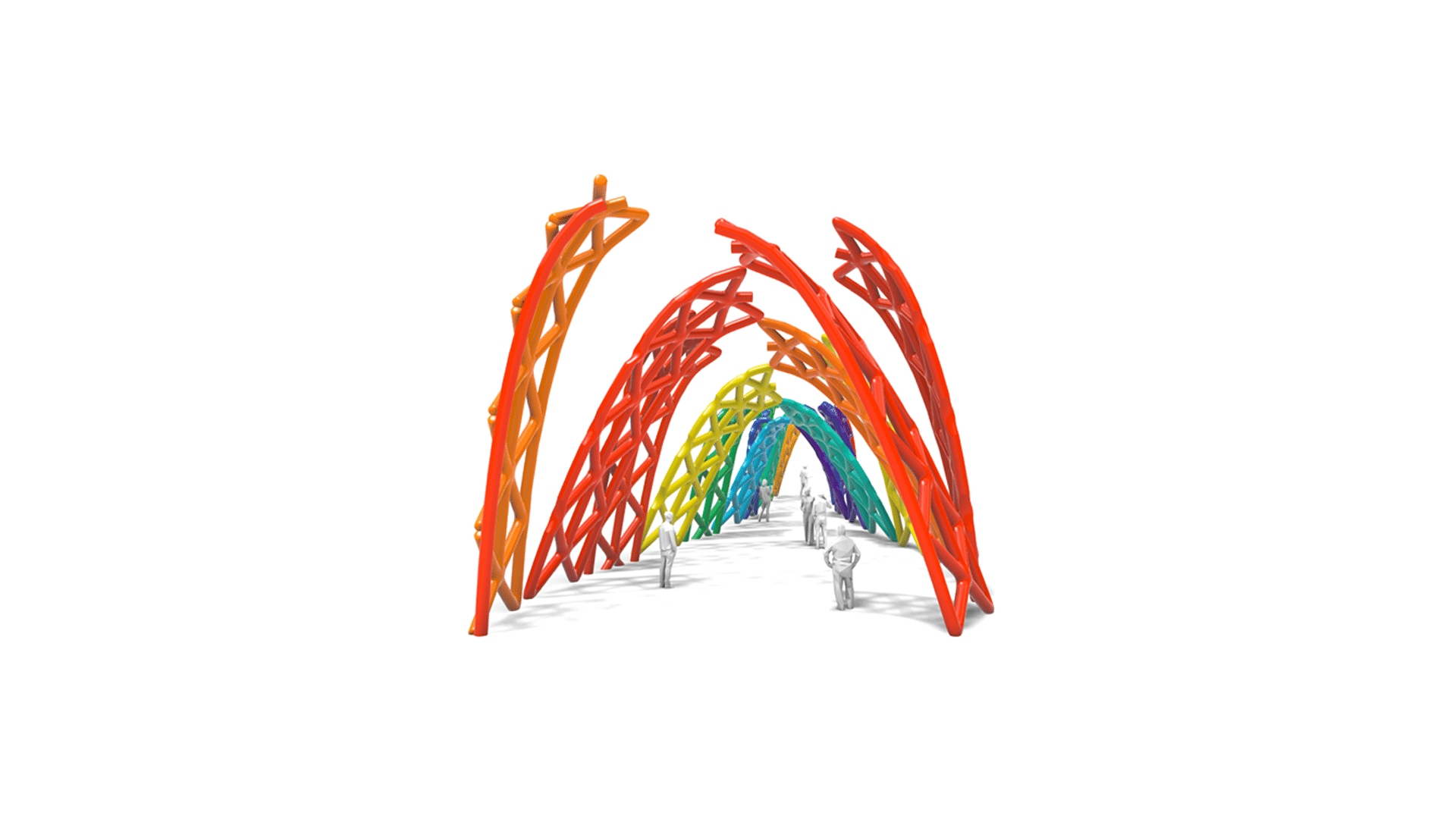

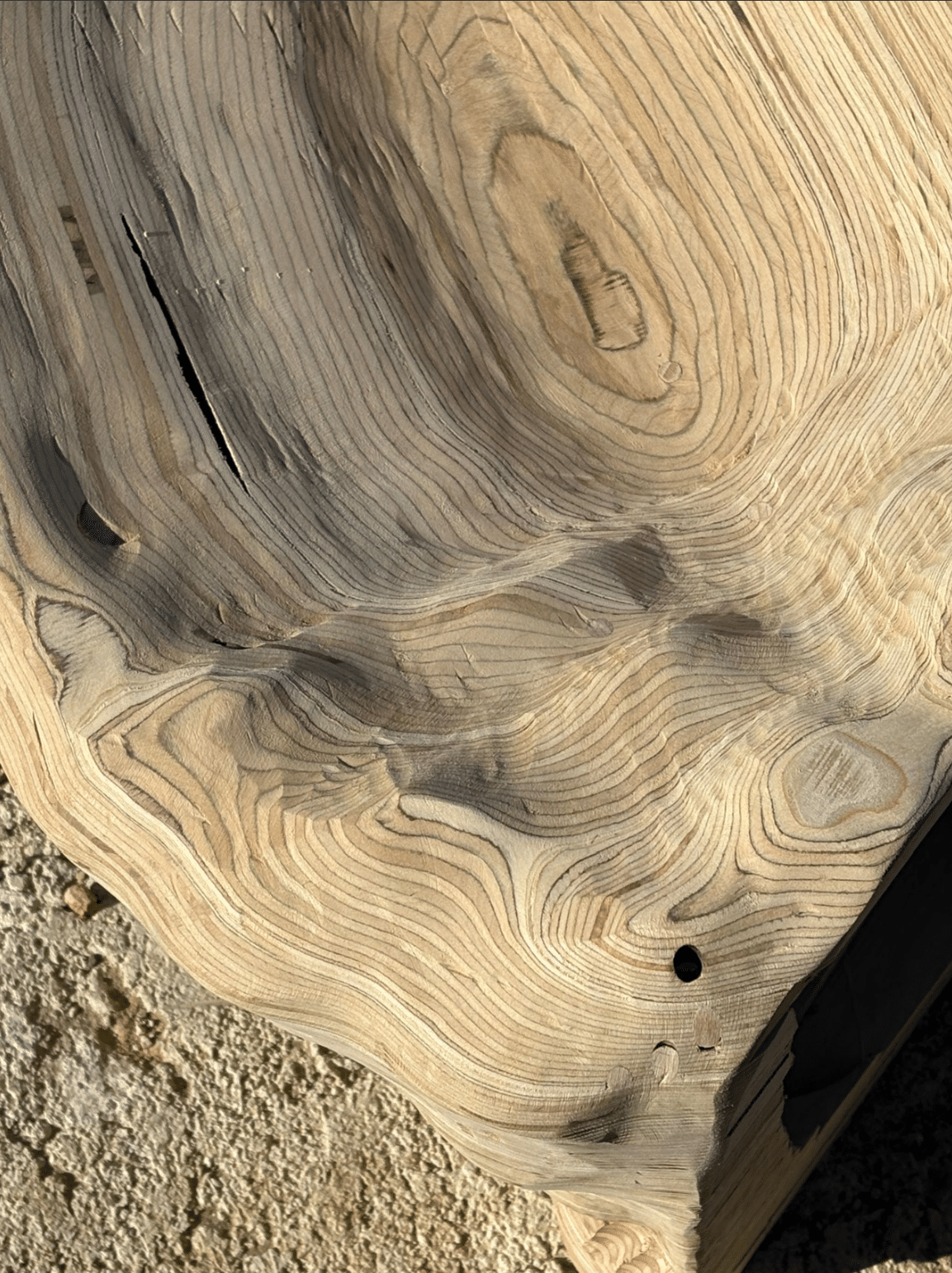

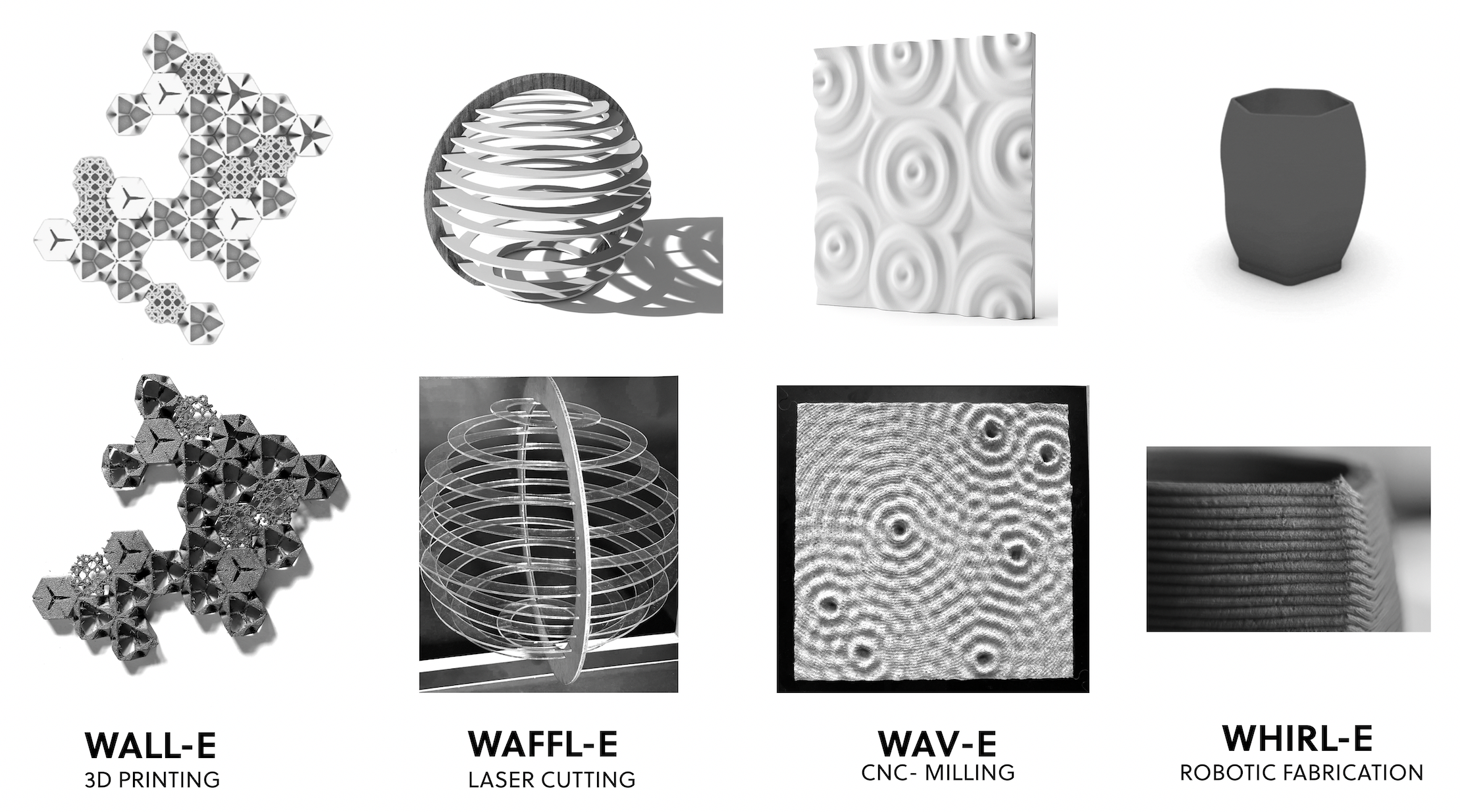

Solid vs. Soft How can an object low in inherent solidity still be structurally present and define architectural space? This question lies at the heart of The Pneumatical Incrustation. Developed for the Complex Forming Seminar, this project explores the fundamental contrast between the solid and the soft. The goal was to investigate how “soft” forms … Read more