Course Overview:

The MRAC01- WORKSHOP 3.2 course focuses on dynamic and improvisational workflows that are used on real-time control of Industrial Robots. Therefore in this course students learned how to use Industrial robots through experimentation of rapid trial and error, hands-on discovery, and real-time problem-solving .uring this workshop, students engaged in a series of exercises involving Python coding and the use of RobotStudio®, aiming to implement communication between ABB IRB 6700 robots. Additionally, they explored the creation of conditionals and functions that activate real-time robot movement along toolpaths and trajectories.

Topics covered include:

● Introduction to live coding principles

● Overview of tools & frameworks for real-time robot control

● Strategies for improvisational workflows with robots

● Safety considerations & best practices for dynamic environments

● Hands-on coding exercises & experimentation

Assignment Objective:

Development of a project that is based on the simultaneous real-time control of two ABB IRB 6700 robots with the use of RobotStudio®.

The primary objective of this project was the development of a system enabling simultaneous real-time control of two ABB IRB 6700 robots using RobotStudio®. To achieve this, students first had to familiarize themselves with the aforementioned robotic control applications and subsequently develop a functional system within a structured four-day schedule, with implementation taking place over two days.

Concept:

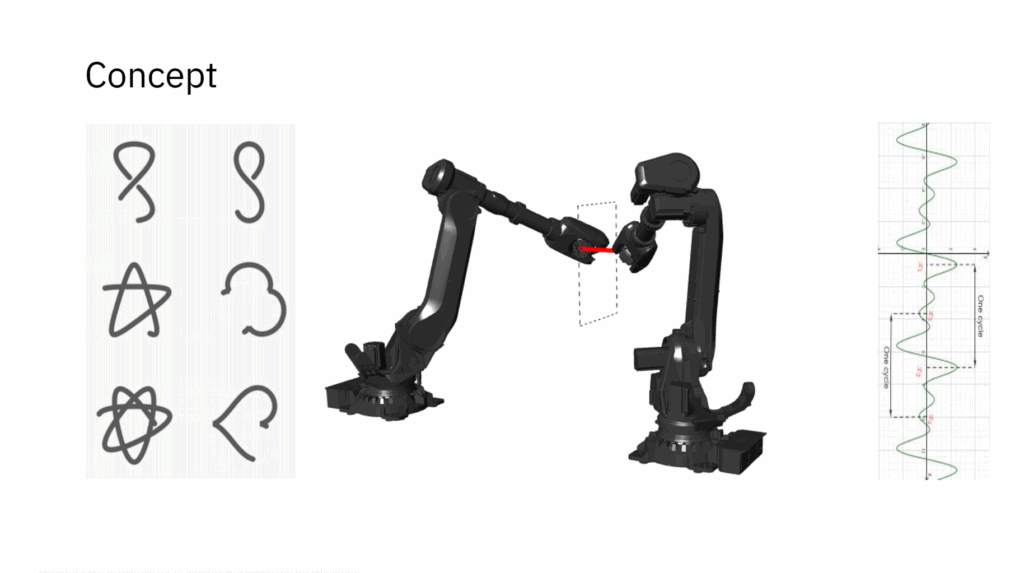

The concept of the Red String of Fate, originating in East Asian mythology, suggests that two individuals destined to meet are connected by an invisible red thread. In our case, this symbolic idea is applied to robotics, representing the intricate relationship between the movements of our two robots, named Filemona and Mortadella. Their synchronized paths and interconnected actions embody a technical parallel to the soulmate thread concept.

Within this framework, the robots can follow a multitude of interdependent geometric trajectories, enabling synchronized movements that dynamically respond to each other.

Main Questions:

For the successful realization of this geometric relationship and robotic control system, several critical questions must first be addressed. These inquiries concern feasibility, efficiency, and optimization strategies for achieving real-time synchronization.

Challenges:

Undertaking such an ambitious project presented a range of challenges. The most significant obstacle was establishing seamless data communication across various platforms. A considerable portion of the development phase was dedicated to testing different methods for facilitating connectivity between Grasshopper, VS Code, and RobotStudio®, using communication protocols such as Open Sound Control (OSC).

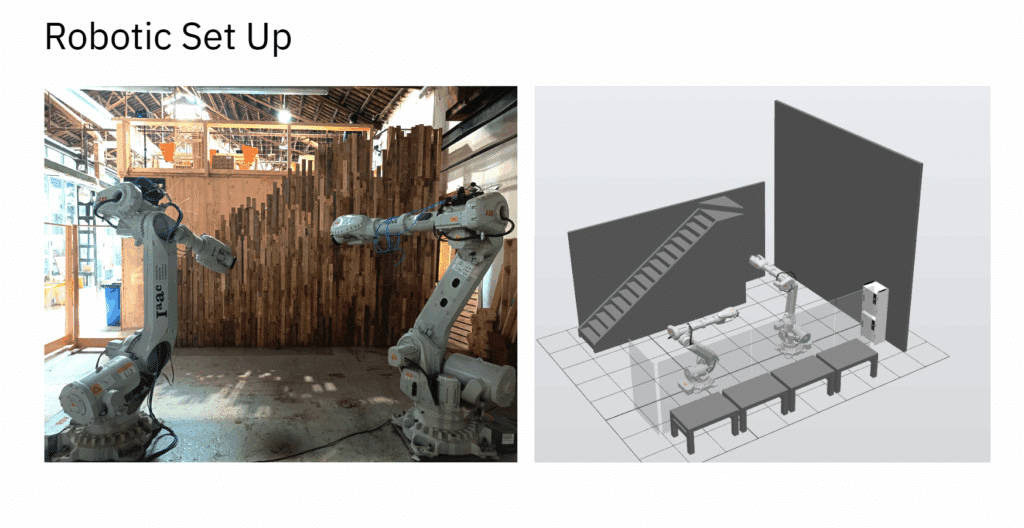

The setup process for live robot operation required extensive preparation to ensure adherence to essential safety measures. Given that the IRB 6700 robots are large, heavy industrial tools, any uncontrolled movement could pose serious injury risks to individuals within the setup environment. In the accompanying image, we observe the physical setup in IAAC’s laboratory on the left, and its digital counterpart within RobotStudio® on the right, where robot movements are simulated to predict and prevent potential accidents or collisions.

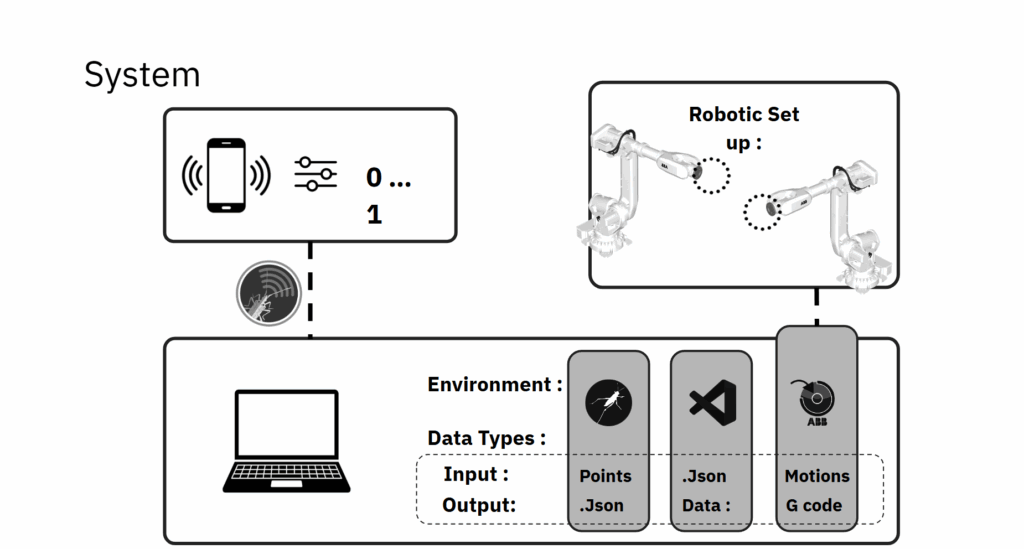

System:

Final Thoughts:

This project underscores the complexities involved in real-time robotic synchronization. The interplay between physical execution and digital simulation proved vital, highlighting the necessity of predictive modeling for risk mitigation. Through this experience, students gained valuable insights into cross-platform communication, real-time data exchange, and robotic control safety measures.

Key Takeaways:

Several distinct and significant lessons emerged from this workshop, including:

This workshop not only deepened students’ technical understanding but also refined their ability to manage complex, interdisciplinary projects requiring precision, collaboration, and innovative problem-solving.