Objective

The goal of this module was to take the final decisions in order to match the building design to the integrated facilities that optimize the circular economy in timber production, balancing large-scale industrial processes with small-scale habitational solutions and an holistic urban system.

Chain of production

Timber V4ult is the fourth in a chain of production that includes a Forest Management Center, a Timber Sawmill, a CLT Factory and a Timber Research Center.

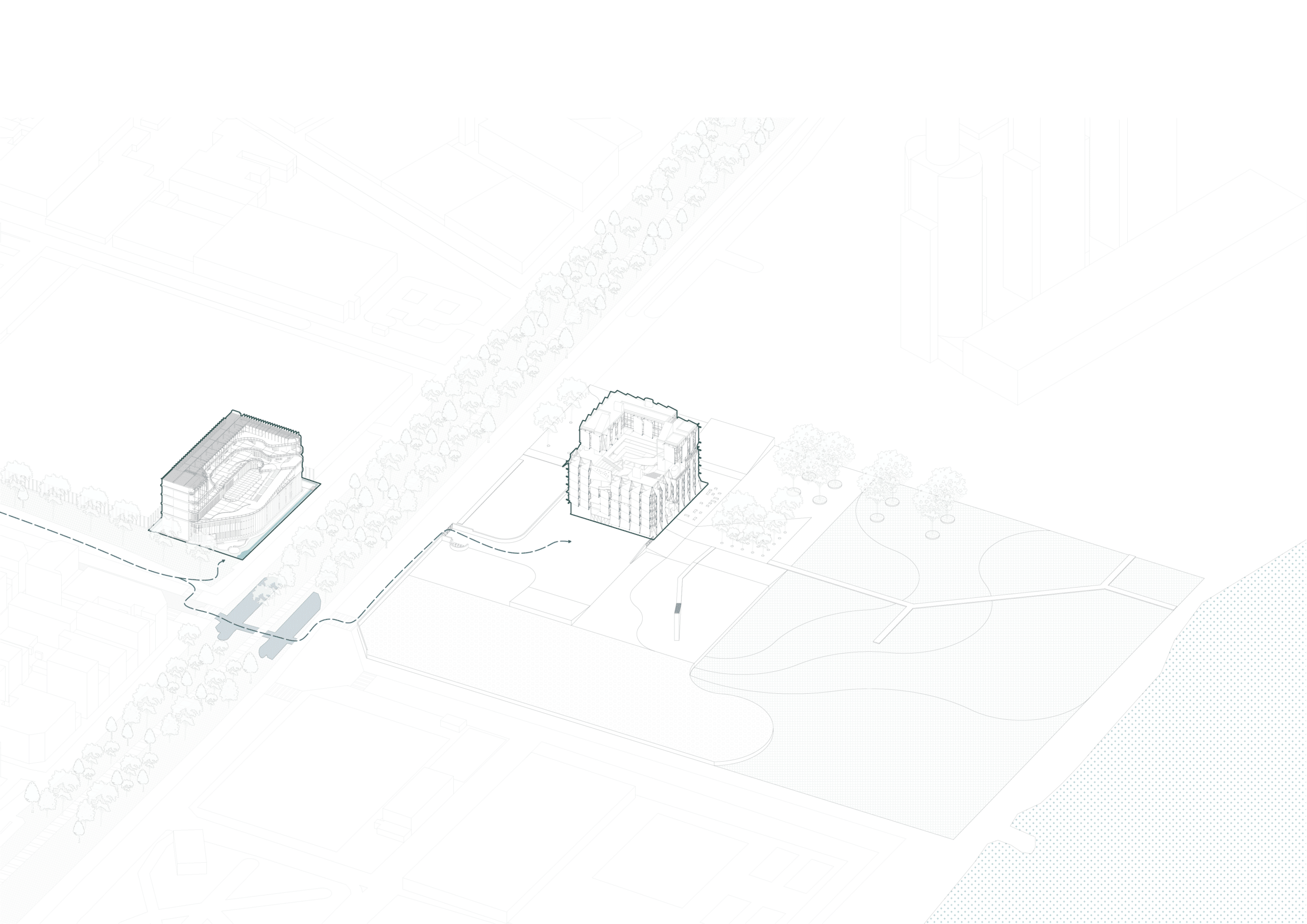

Situation

Location of Timber V4ult, on the left, right across the street from Group 5’s The N.E.S.T. The buildings are integrated through a urban design that brings green spaces to the city, spreading across the rambla-like garden that goes from the left side until the flooding area of the second one.

Form Development

Evolution of the Building

The design of a building is an organic project that adapts according to the perspectives and challenges of different disciplines. From the initial concepts to the adaptation of specific techniques, each area brings adjustments that enrich the original proposal. In this case, we see the design transform during the different module disciplines.

Programme and Circulation

Urban Intervention: Green Spaces

One of our main goals was to begin replicating what stages 1-3 of our production chain have: a direct contact to nature. By revitalizing the area nearby with new greenery, implementing more than 140m of bioswales and imagining green surfaces on each floor – including in the ground floor’s internal patio – we aim to improve air quality, reduce heat island effect and create a pleasant area for workers, residents and citizens.

Thermodynamics and Envelopes

Aiming towards a building that require less artificial climatization, we designed the main facades to incorporate fixed fins, angled in a way that blocks direct sunlight during summer and allow it’s entrance during winter. They are made of timber and have a white alumina coating on the exterior face, to help reflect the light. On the ground floor, where our pre fabrication facility takes place, a second layer was created to help control the temperature and provide more security. Two 3 meters high operable glass louvers on the bottom and top, divided by a fixed 4m glass panel between them. On the opposite facade there are large operable windows. Those create a sweep effect with the first one, cooling the building during the summer and helping remove the dust. During winter, both can be closed and the glass creates a greenhouse effect to keep the interior warm.

Materiality

Material Passport Pyramid

Water System

The system harvests 683.000 liters of rainwater yearly. Only 58% of the water comes from the grid.

Energy System

661m² of photovoltaic panels generates roughly 35% of the power consumption, reducing 80 tons of CO2 yearly.

Structural System

Our structural system is made out of CLT and GLT. 3 to 5 different columns compose into a single element to create a tree-inspired structure, connecting to beams. There are three CLT structural cores, the main vertical circulation core, on the left, the fire escape on the top right and a water shaft on the bottom right.

Kindly refer to the previous blog posts about Timber V4ult:

THERMODYNAMICS FABRICATIONS: https://blog.iaac.net/sunscape-lounge-thermodynamic-fabrications/

ECOSYSTEMIC STRUCTURES: https://blog.iaac.net/timber-v4ult-ecosystemic-structures/

METABOLIC BUILDING SYSTEMS – ENERGY: https://blog.iaac.net/timber-v4ult-energy-systems/

METABOLIC BUILDING SYSTEMS – WATER: https://blog.iaac.net/wp-admin/post.php?post=116204&action=edit

RESILIENT ENVELOPES: https://blog.iaac.net/resilient-envelopes-timber-v4ult/