This term, we explored three Digital fabrication techniques: CNC Milling, Laser Cutting, and 3D Printing. Our objective was to create A Cabin Integrating and investigating the characteristics of each technique.

Concept

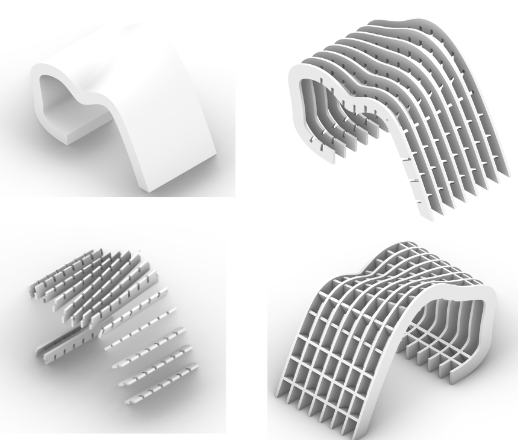

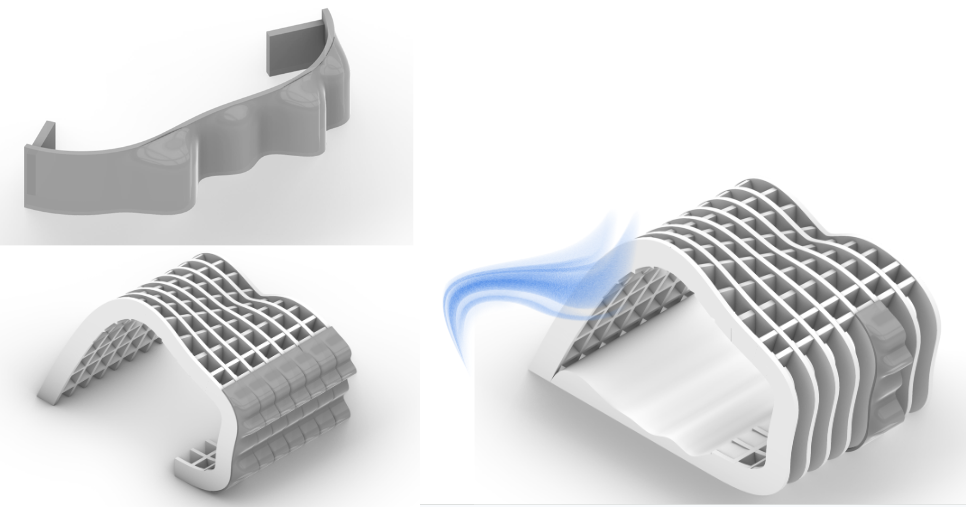

The waffle cabin, designed for future human use, is tailored for different terrains, including beach, desert, forest, and plain regions. The primary structure of the cabin, based on a waffle design, makes it exceptionally strong and durable. With its fluid, streamlined appearance, the cabin aligns with the aesthetic of future design language. The back section is enclosed with a recessed wall, allowing objects to be placed within its niches. Additionally, a rear air inlet vent is integrated, enabling air circulation to be controlled through advanced technology. The wavy floor design, covered with a soft or fabric layer, offers a comfortable surface for sitting or lying down. Altogether, the waffle cabin combines functionality and aesthetics to create a unique living space.

Laser Cutting

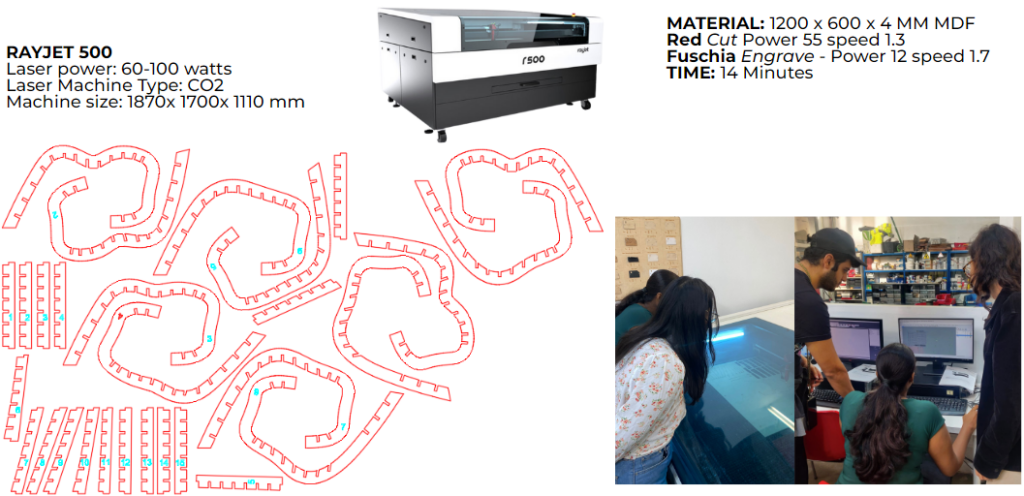

Laser cutting technology was used for the skeleton of the waffle structure with MDF. This approach enhances both aesthetic and structural efficiency. Each element was designed to facilitate both assembly and disassembly, resulting in a modular construction system.

Parameters:

Material : Medium Density Fiberboard 4mm

Technique : Laser cutting

Joint type : Waffle

Design

Production

Prototype

3D Printing

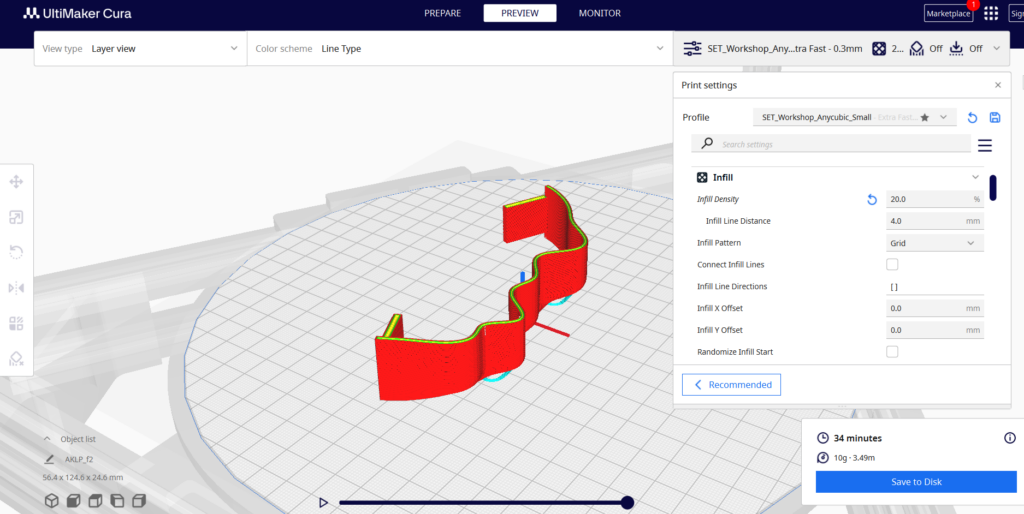

3D printing technology was used to fabricate the components of the facade helping with air flow. The Modular Panel can easily be attached to the waffle structure.

Parameters:

Printer : Anycubic Kossel Linear Plus

FIlament: PLA

Colour: White

Time: 34 Minutes

Design

Production

Prototype

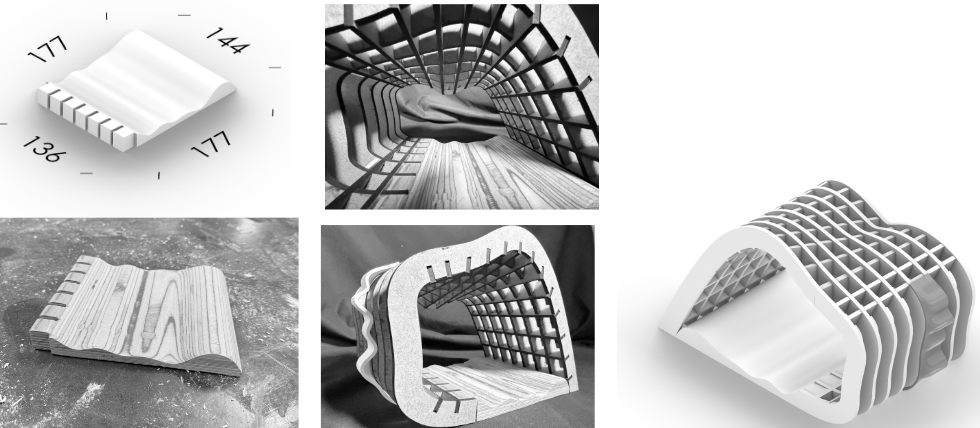

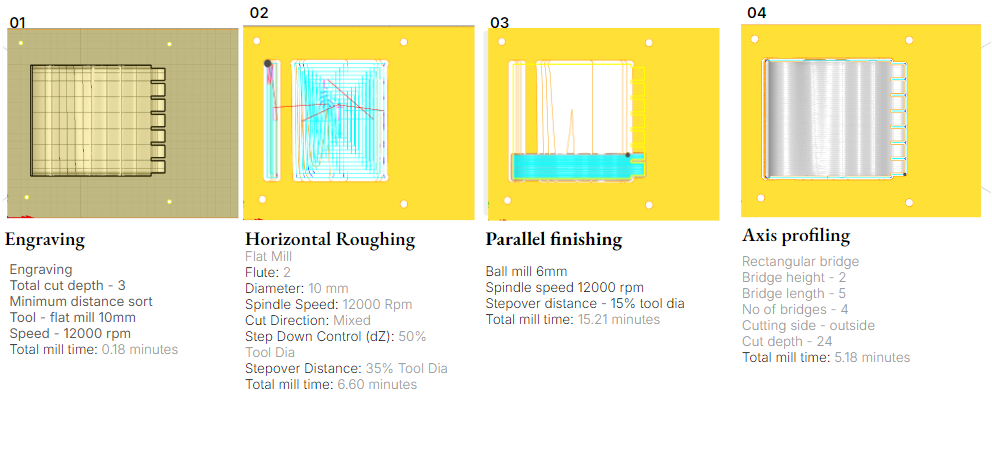

CNC MILLING

The design intention was to create inbuilt furniture seamlessly merging with the structure itself, through groves which would get interlocked to the waffle.

Parameters:

Material : 24mm Plywood

Machine : TREX CNC

Post Processor : CNC_STEP_BCN TREX

Set up Time: 27.18 Minutes

Design

Production

Prototype

FINAL PROTOTYPE