Concept

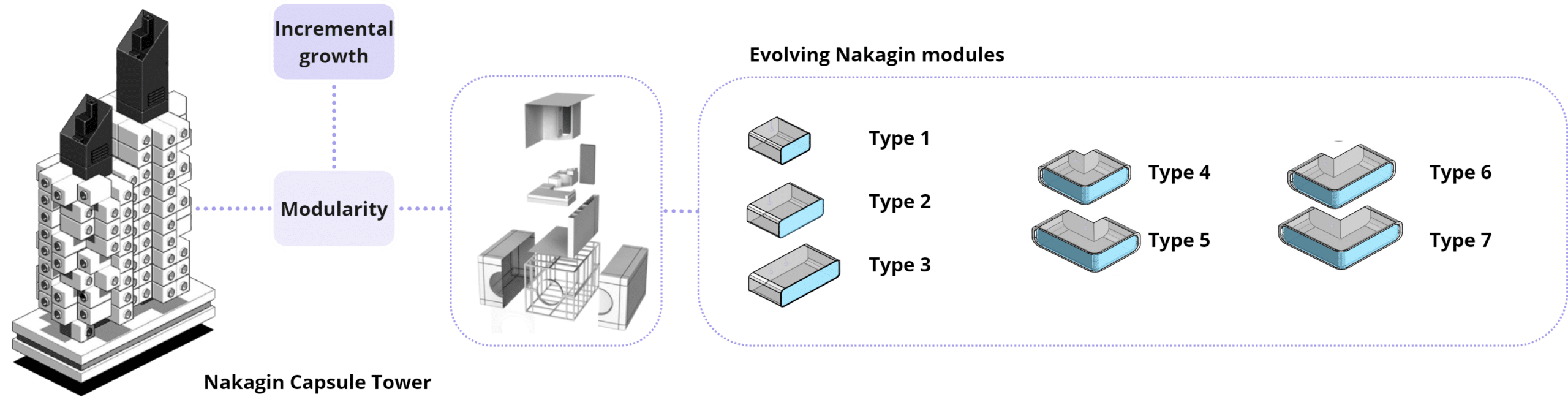

Our project reimagines the modular, adaptable spirit of the Nakagin Capsule Tower for contemporary sustainable architecture. Drawing inspiration from Kisho Kurokawa’s Metabolist vision—where buildings function as dynamic systems composed of interchangeable units—we developed a parametric and highly flexible building system. The core concept centers on a central concrete core, providing stability and integrated infrastructure. Steel bracings are used for enhanced lateral support, referencing the megastructure principles of the original tower. Around this core, lightweight, prefabricated living modules are attached—each fully replaceable, customizable, and manufactured for minimal environmental impact.

This system not only honors the Nakagin Capsule Tower’s legacy of modular living and organic adaptability but also updates it through the use of modern materials and digital parametric tools, enabling rapid customization and future expansion to meet evolving urban and ecological needs.

This design strategy prioritizes adaptability, easy customization, and future scalability—enabling the building to be updated or modified beyond its original lifespan, while minimizing environmental impact. Drawing inspiration from the visionary principles of Metabolist architecture, which emphasized modularity, resilience, and the potential for urban forms to evolve like living organisms, our approach fuses these concepts with contemporary sustainable building practices.

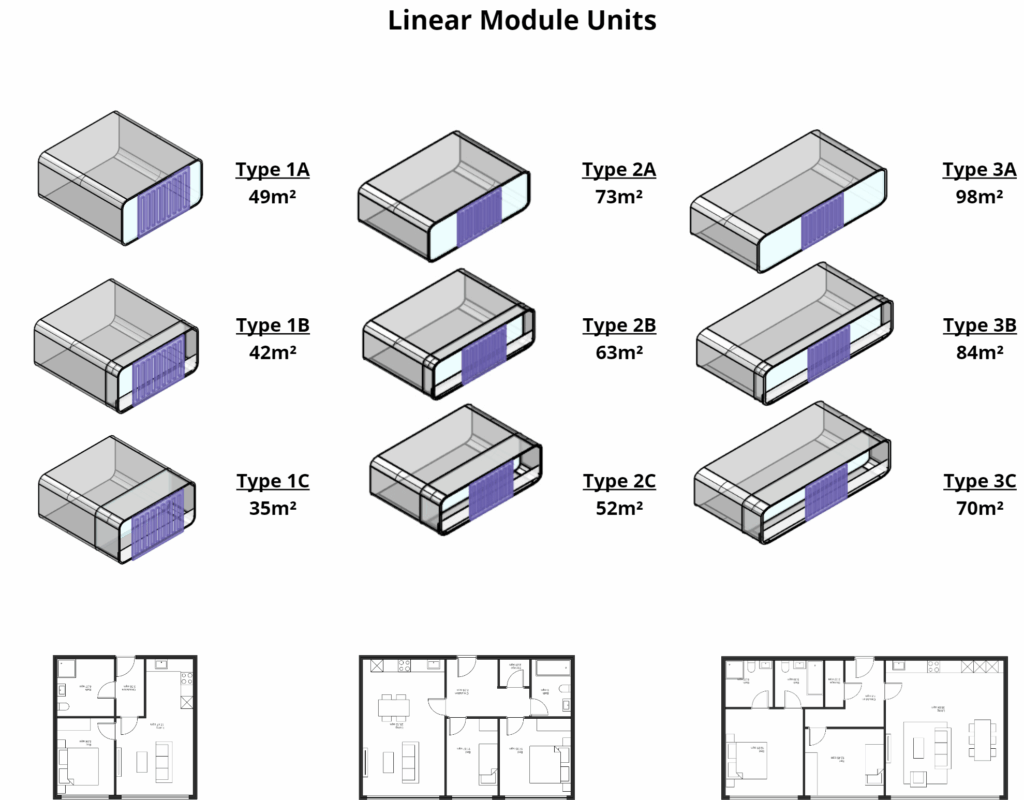

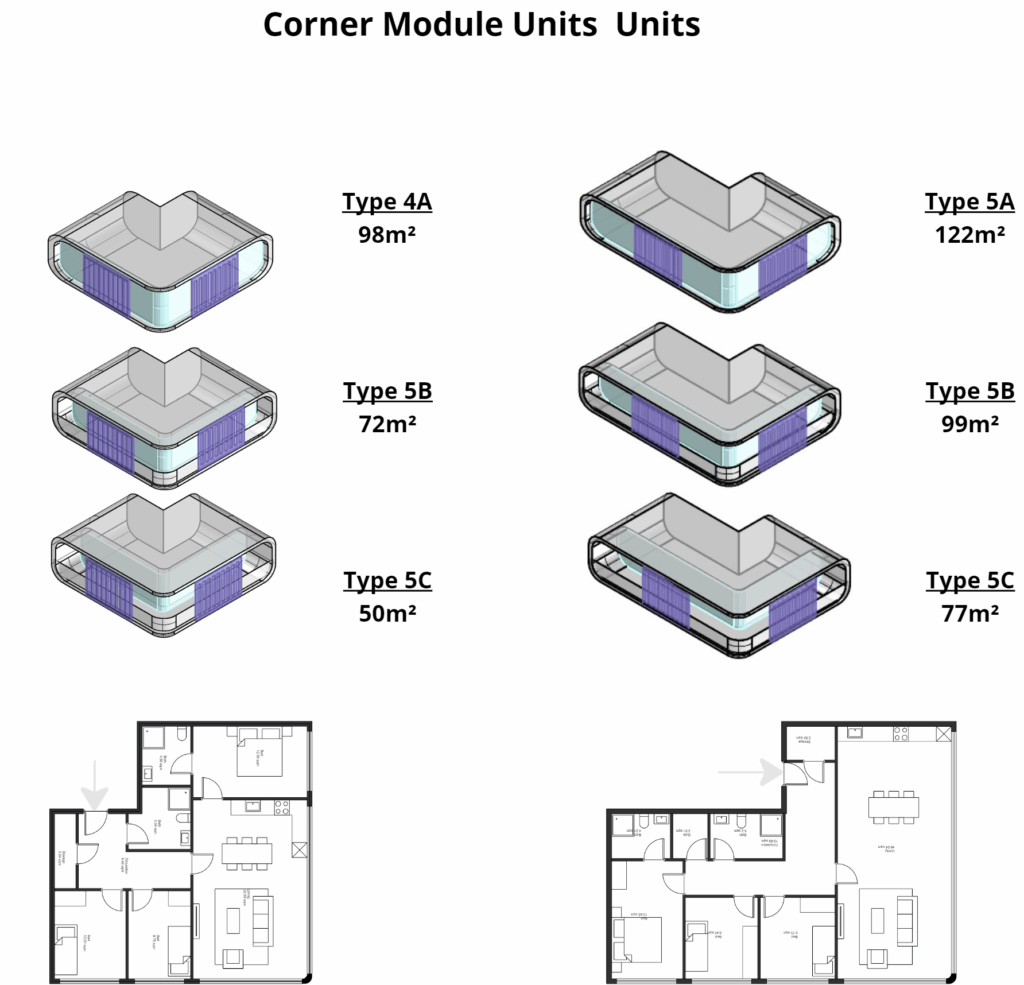

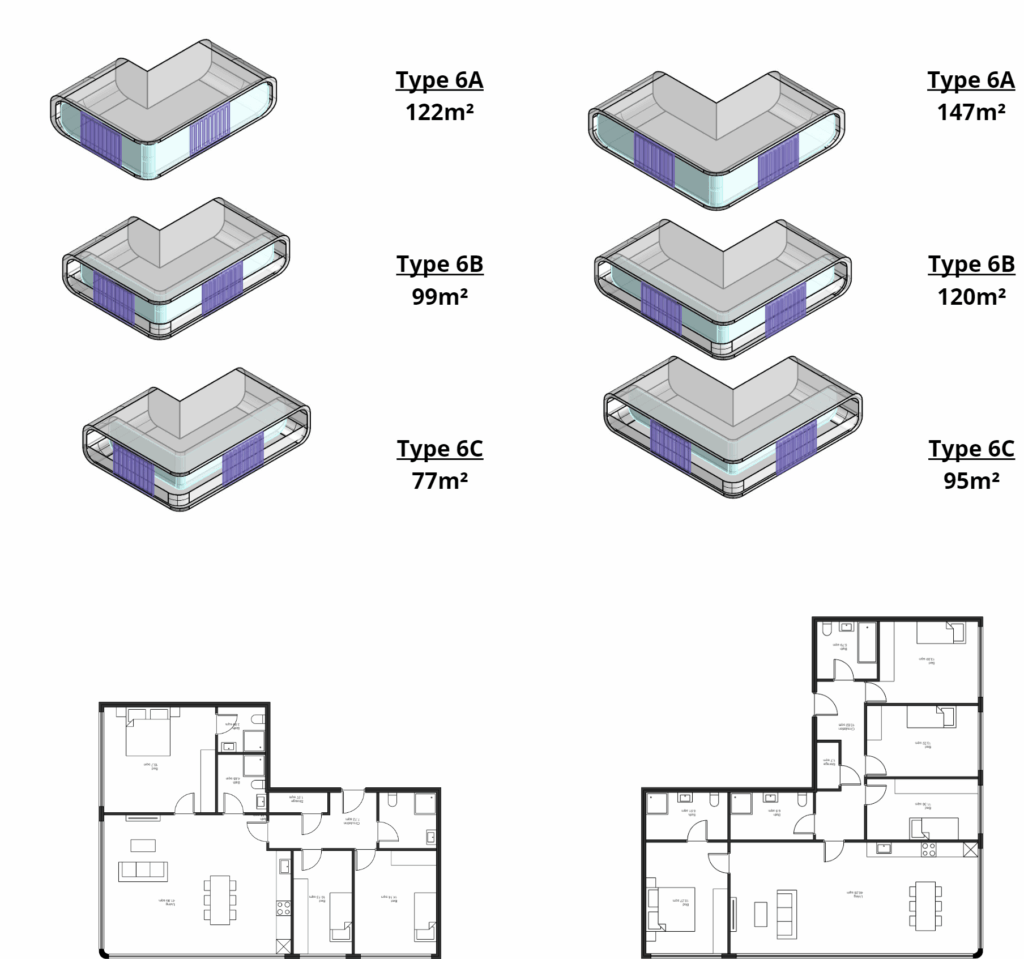

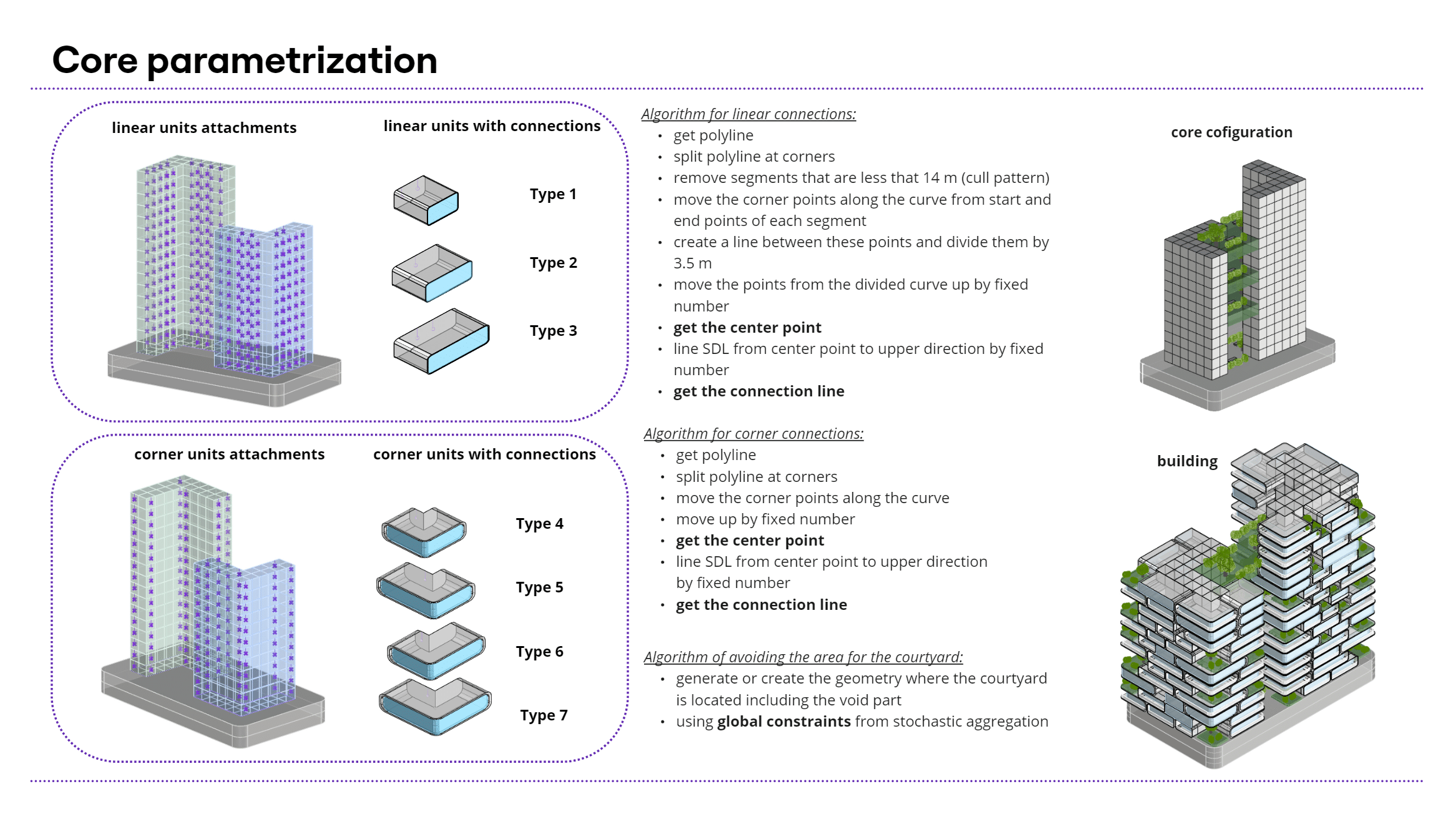

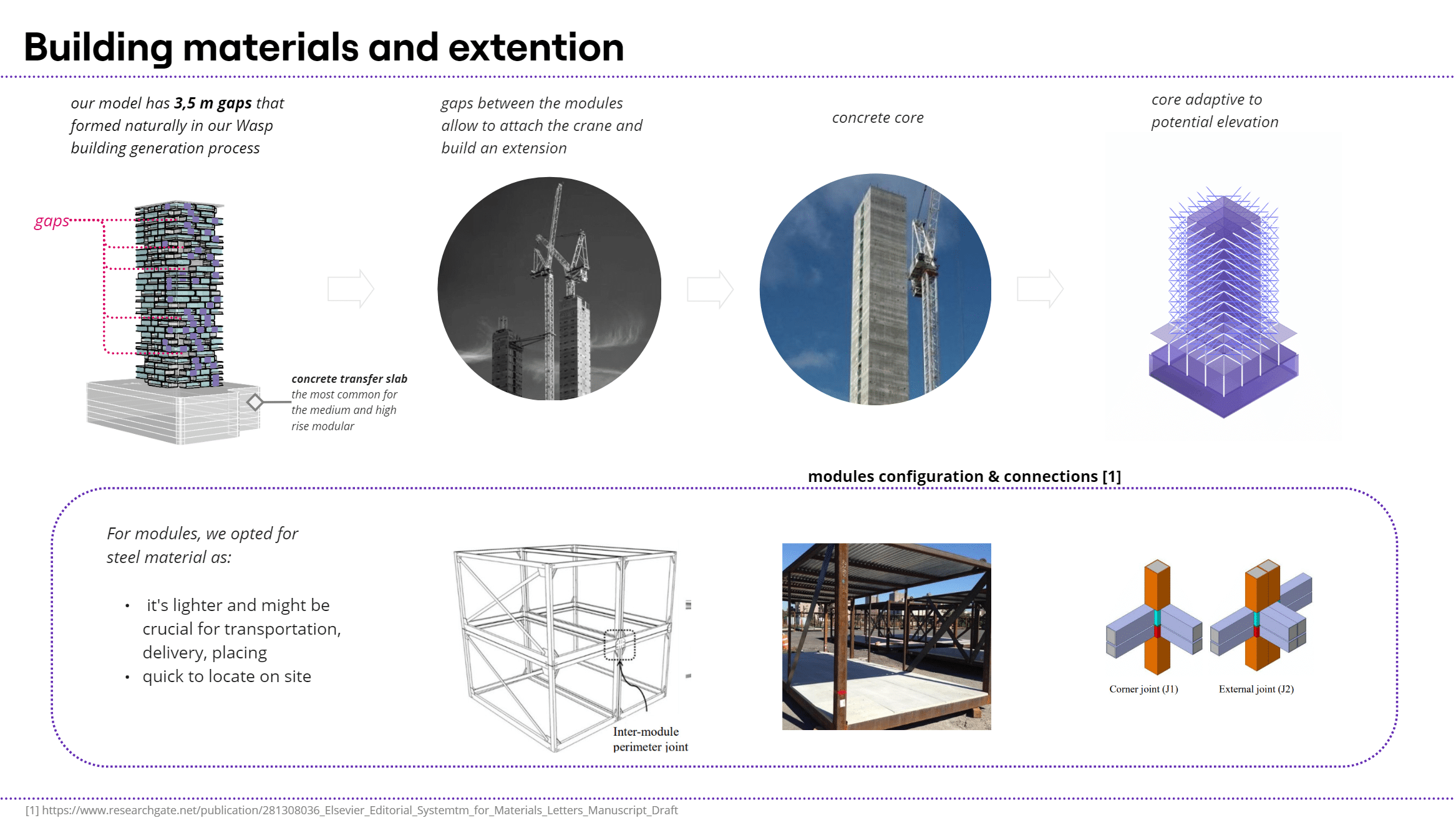

The core system is built around a parametric model, with modules configured and attached using the Wasp algorithm in Grasshopper. This enables adaptive arrangement to any rectangular core and accommodates variation in floor numbers, reflecting the Metabolist ideal of long-term, service-oriented frameworks populated by replaceable units. Seven principal module types—corner and linear—are manufactured from lightweight GFRP materials; each can be independently attached to, or replaced from, the central core, supporting both operational flexibility and lifecycle extension.

A distinctive feature of our generation process is the emergence of natural gaps, typically 3.5 meters wide, between certain modules. These gaps, determined algorithmically, not only facilitate access for cranes during extension and maintenance, but also echo Metabolist strategies of spatial articulation and infrastructural resilience. The use of prefabricated, replaceable modules meets contemporary demands for efficient, low-impact construction and paves the way for ongoing upgrades, upgrades, and user customization.

By marrying the systemic thinking of metabolic architecture with sustainable design innovations, the resulting building typology is capable of responding dynamically to changing social, environmental, or technological imperatives—both today and in the future.

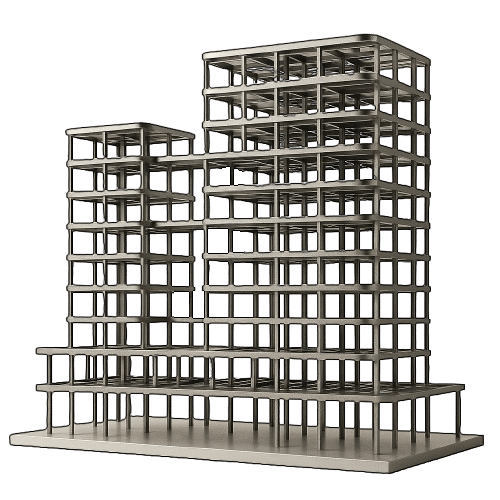

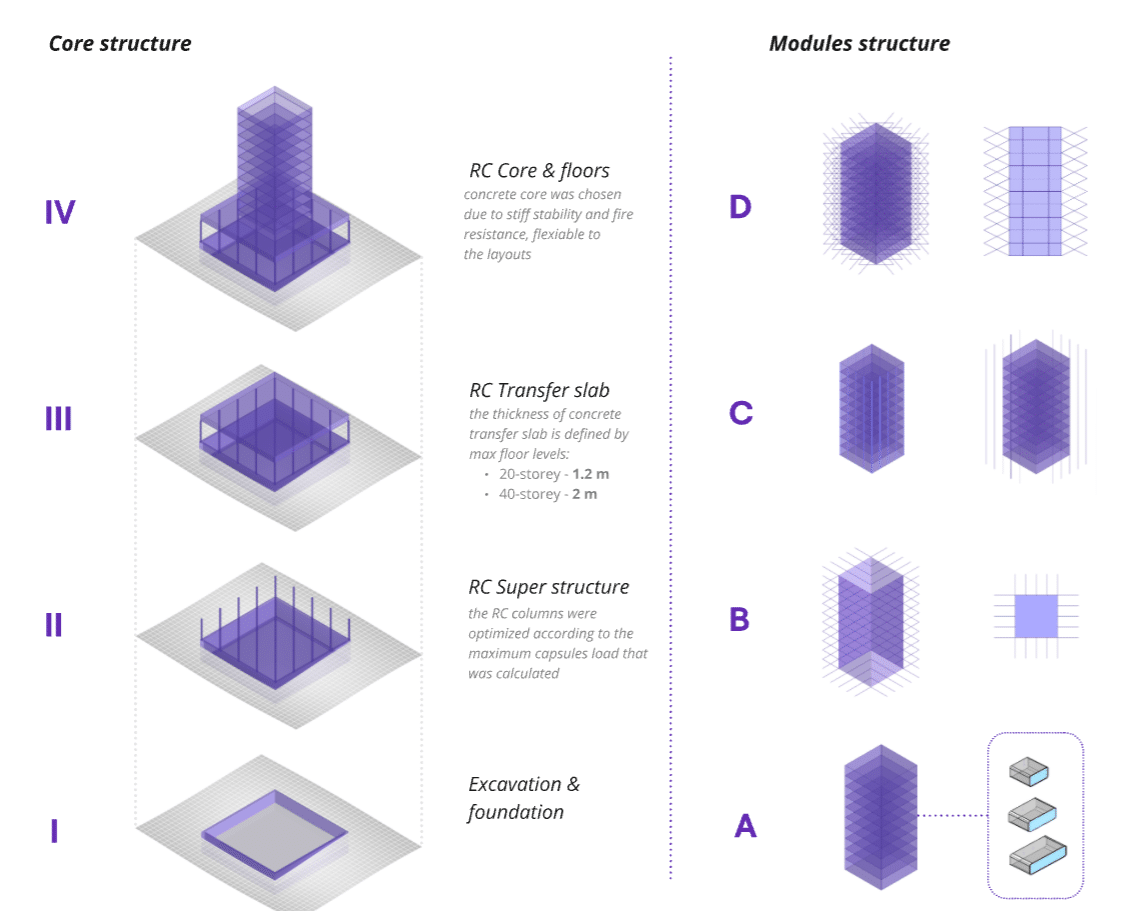

The structural model

Our basic model consists of 2 modules: core and modules structure.

The core structure:

- foundation

- super structure columns

- transfer slab

- core and floors

The modules structure:

- horizontal columns (B)

- vertical columns (C)

- horizontal bracings (D)

- vertical bracings (D)

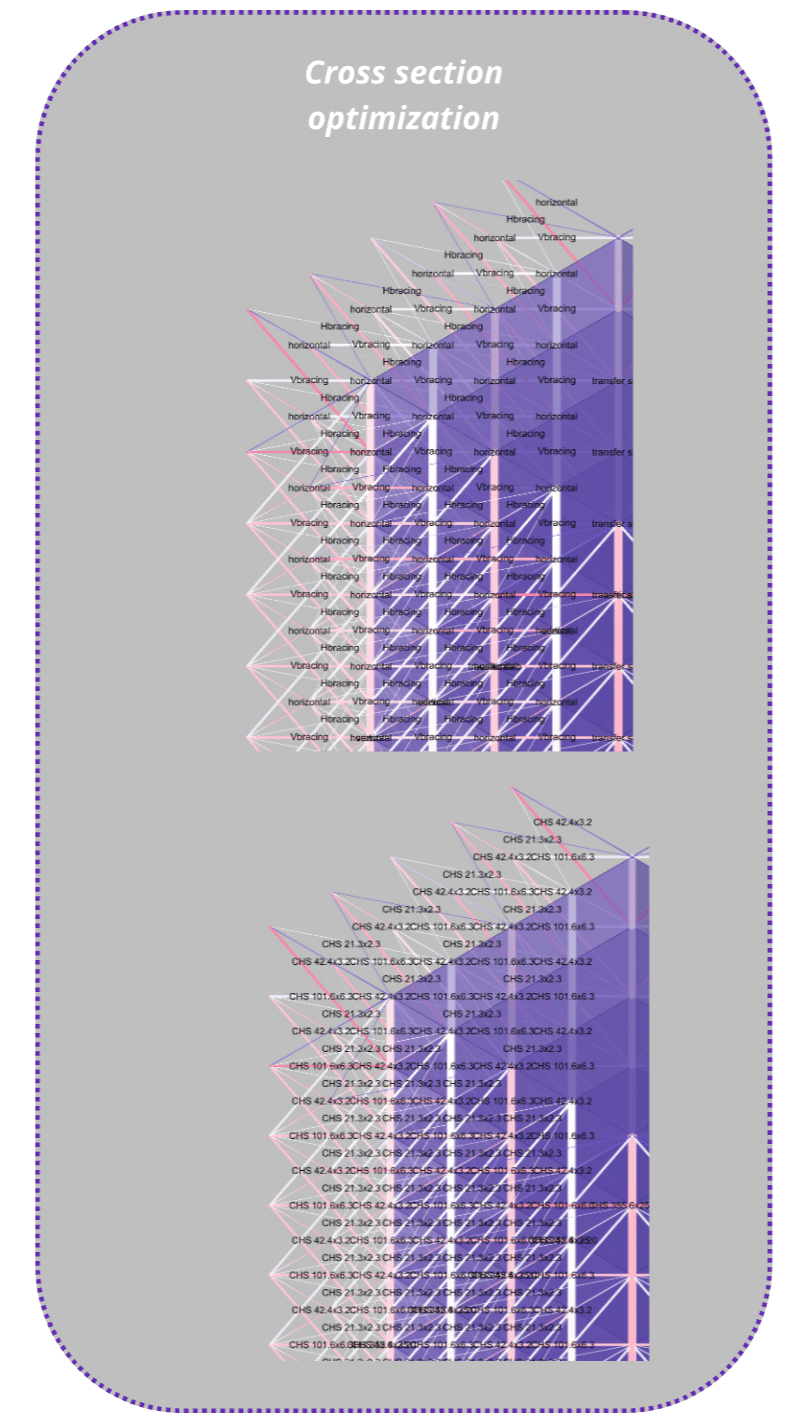

All columns and the transfer slab underwent cross-sectional optimization to maximize structural stability while minimizing material usage. This approach ensures efficient load distribution and enhances the overall strength of the building with economical use of resources.

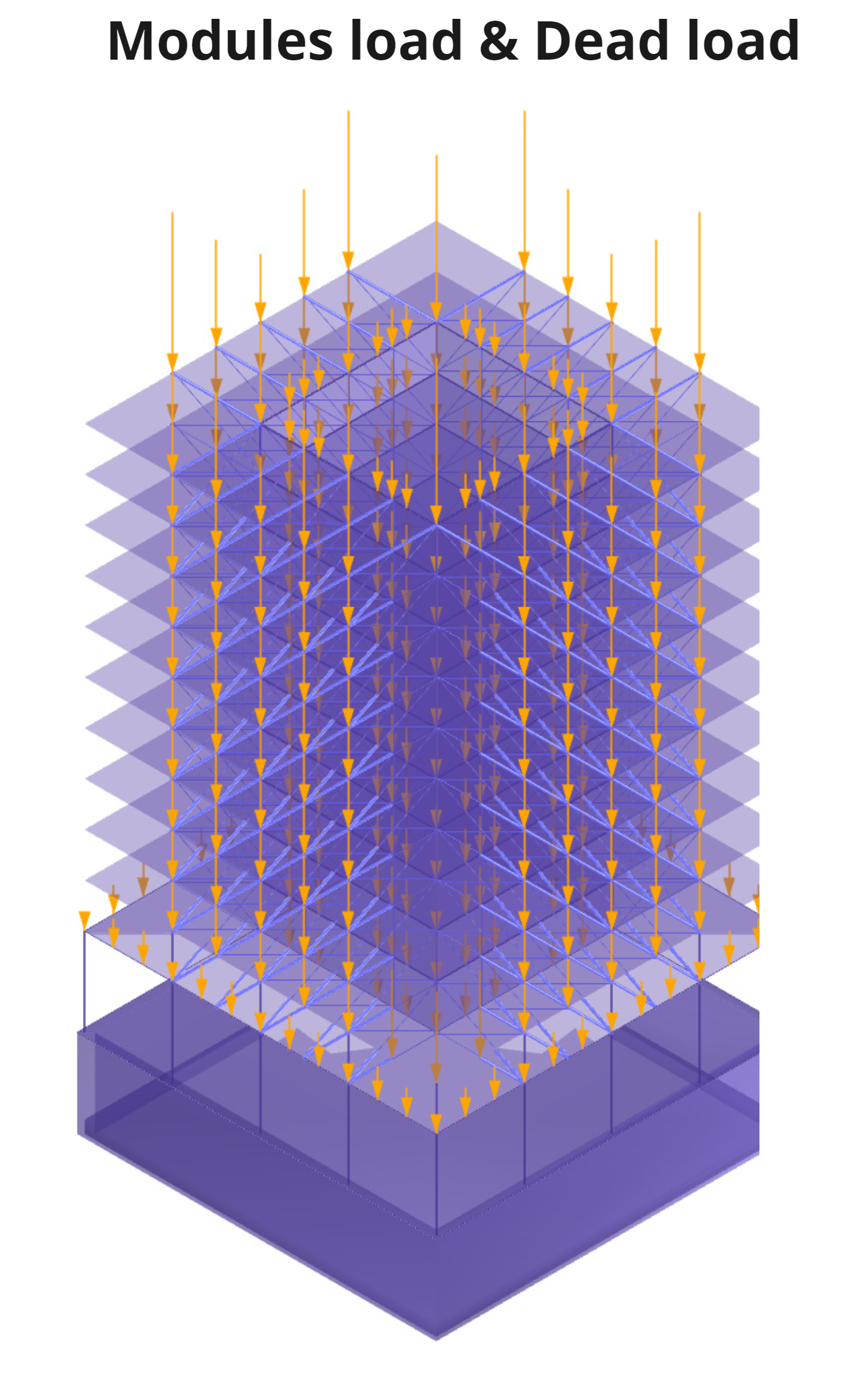

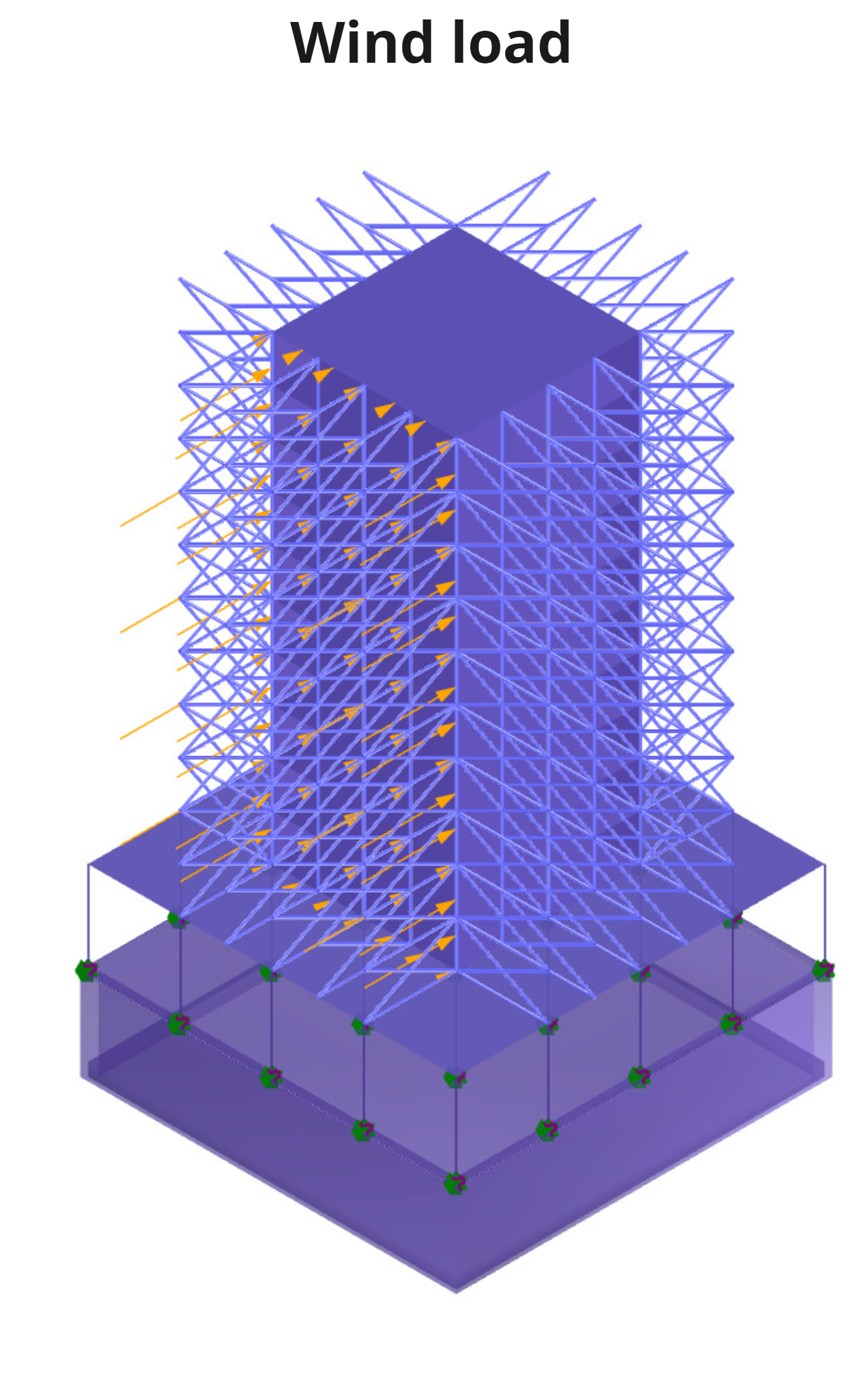

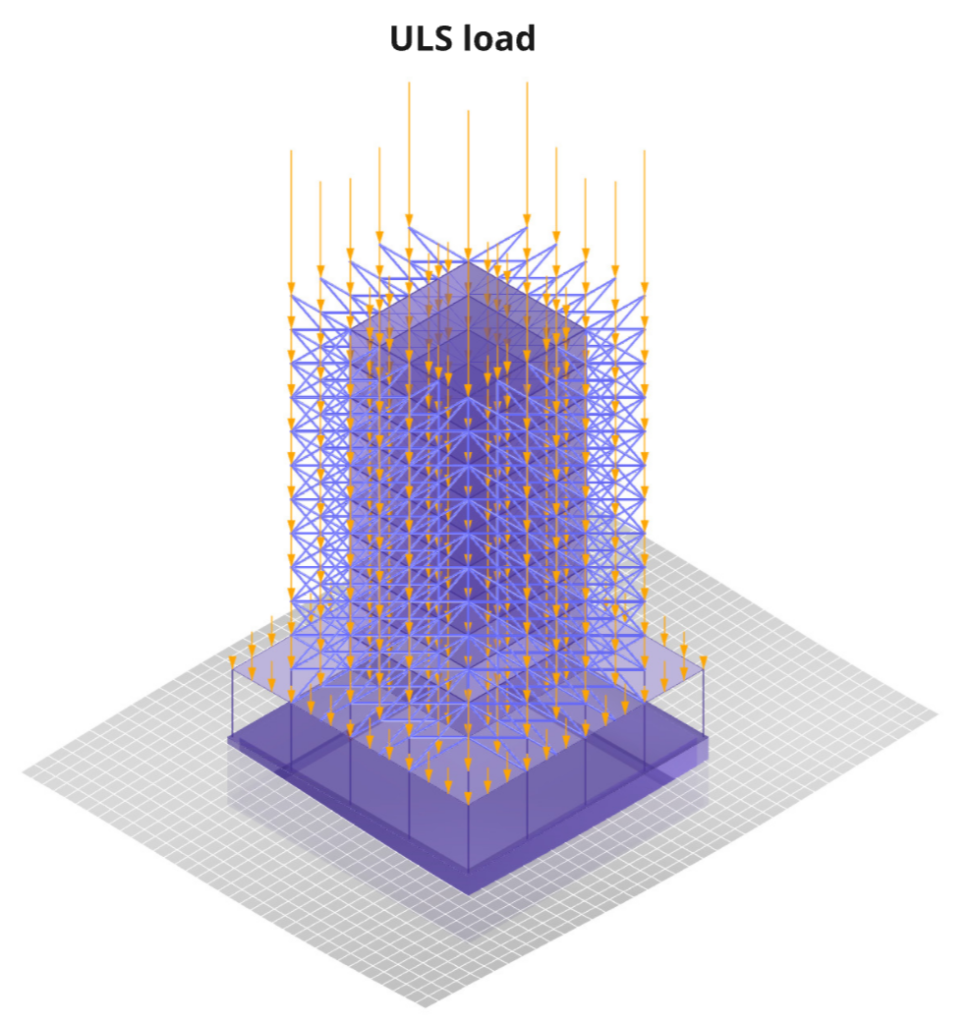

Loads

The loads applied to our structural building model:

- Gravity (g)

- Modules load (gm) 5 kN/sq.m.

- Dead load (gq) 2 kN/sq.m.

- Wind load (qw) 1 kN/sq.m.

- ULS = 1.35 (g + gm + gq) + 1.5qw

- 1.35x for dead loads

- 1.5x for live loads

We have create sets of 4 element sets in Karamba, such as vertical columns, horizontal columns, vertical bracings and horizontal bracing and run a cross section optimization for each group with 100% ULS as maximum utilization.

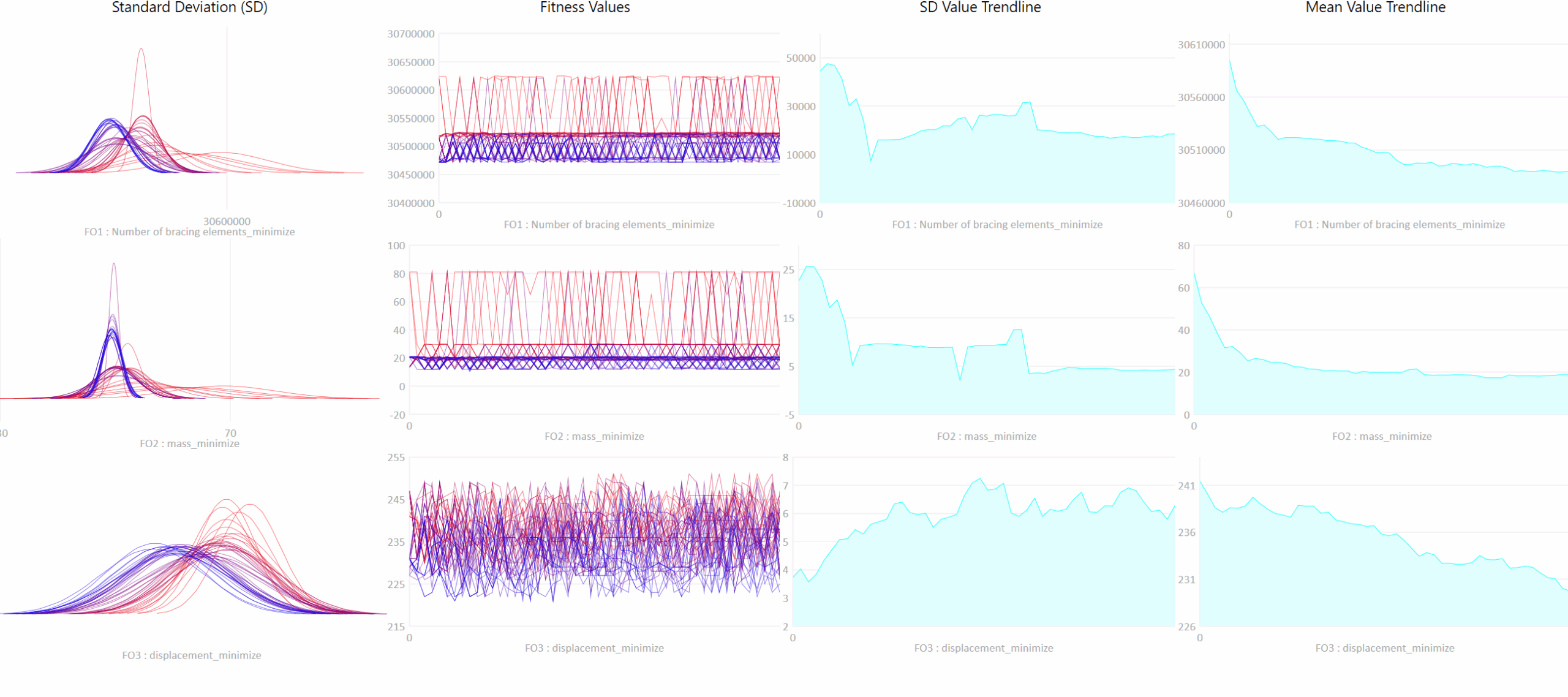

Design exploration & optimization

We explored several structural design options aiming to achieve the lowest mass and displacement while maximizing the utilization of structural elements. Displacement was measured in centimeters, and mass in kilograms. An element utilization graph was generated based on the Ultimate Limit State (ULS) load case.

Among the options, Option C—where the module structure consisted only of vertical and horizontal columns without any bracing—demonstrated the highest structural element utilization. However, it also resulted in the greatest overall mass.

Our analysis showed that bracing elements are more effective structurally. Although bracing increases the total number of elements, the optimized cross-sectional areas of these braces are smaller, which leads to reduced displacement, a lighter overall structure, and consequently, a smaller carbon footprint. Based on these findings, Options E and F were selected for further optimization.

The optimization process focused on the steel structure of the modules, seeking to minimize steel usage while maintaining minimal displacement. Starting with 400 vertical bracing elements, we aimed to reduce this number by half by selectively culling 200 elements using a genetic algorithm based on a gene pool representing the structural genomic data.

For this optimization, we employed the multi-objective Wallacei solver with the following goals:

- Minimize displacement

- Minimize CO2 emissions associated with material usage

- Minimize the number of bracing elements

Results & further development

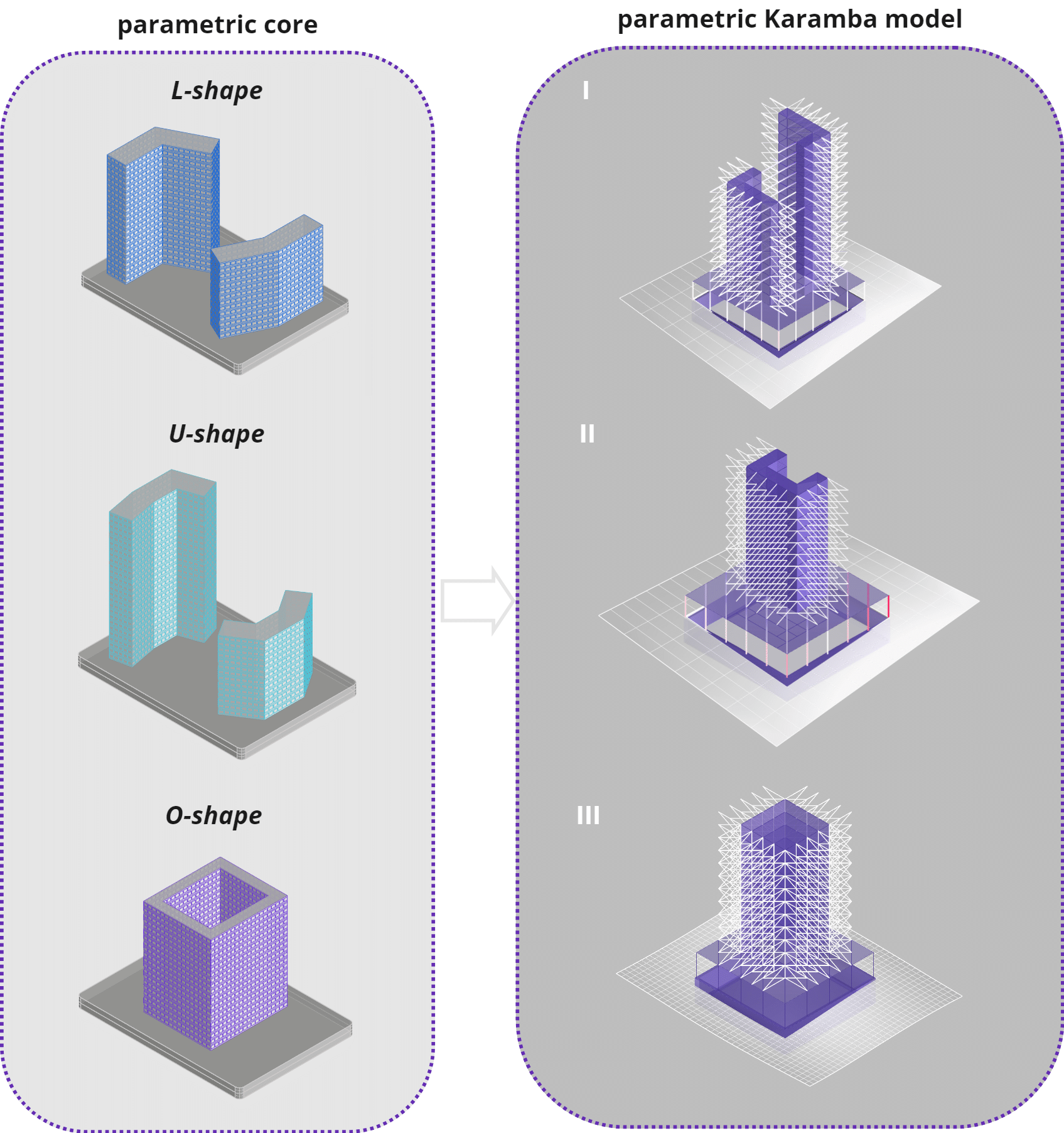

We have developed a parametric structural model in Karamba3D that adapts seamlessly to various core geometries, including L-, U-, and O-shaped configurations, accommodating any number of floors. This flexible model is designed for customization and can be further refined or expanded depending on specific project requirements.

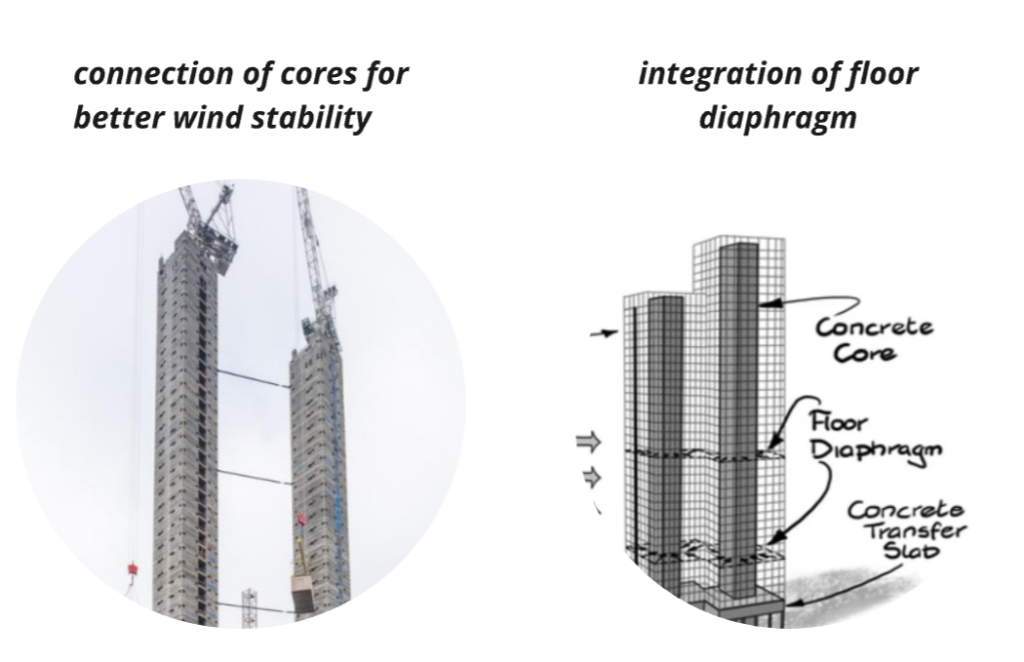

For high-rise configurations or complex building arrangements—such as cases with two adjacent cores—additional structural elements can be integrated. For example, steel connections linking the two cores can be introduced, which also create shared green spaces between them. Moreover, to enhance overall stiffness and stability, floor diaphragms may be incorporated at intervals of every 10 to 20 floors, improving lateral load distribution and structural robustness.

This adaptable parametric framework ensures structural efficiency while providing designers with the flexibility needed for innovative and resilient architectural solutions.