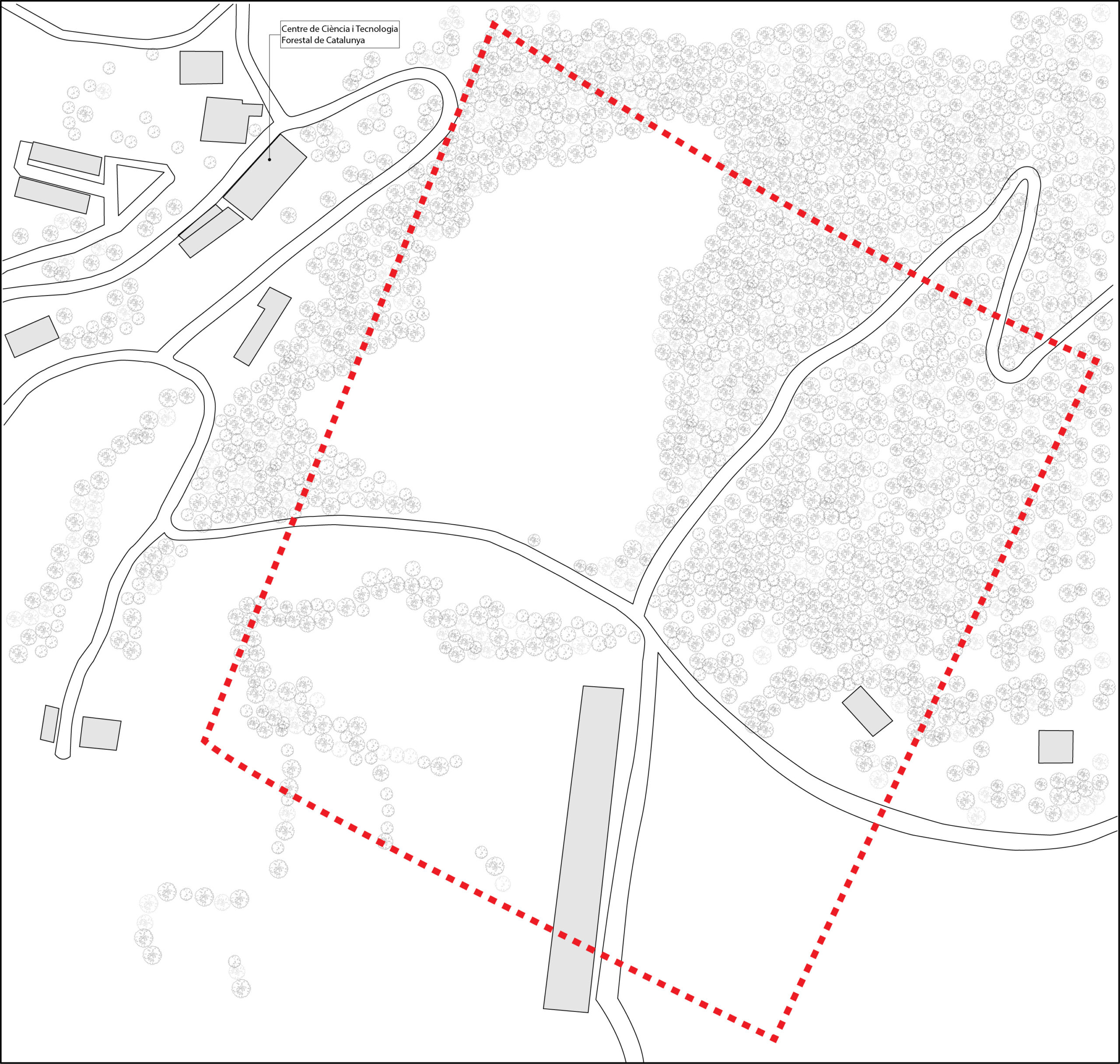

Location

SOLSONA, SPAIN

Elevation: 700 m above sea level

Climate: Continental / highlands

Manifesto

From the Pyrenees to Barcelona, the journey wood takes can become a means to bridge the knowledge gap between forests and the timber industry. Solsona, located in the middle of this journey, housing our timber saw mill, can become a place of community and respect for these forests, while engaging people with what happens at large in their region.

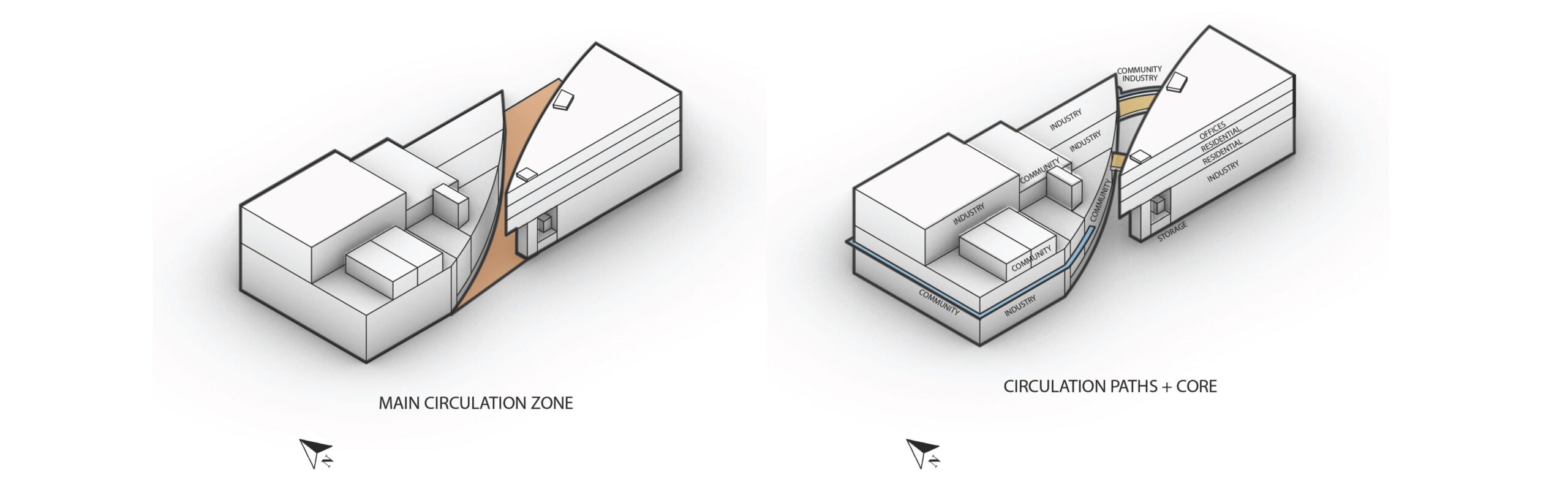

Nestled along the side of a forest, the circulation and structure of our building is equally influenced by wood as it is by people. The industry, contained predominantly on the first floor, is designed around the pathways of lumber, and on display to any guests who visit. Visitors and staff alike can circulate around the building, seeing the process at all stages.

Our structure is divided into two predominant parts in order to incorporate key passive design strategies for the local climate. Ventilation is allowed throughout, with the design of our main central channel and the use of natural materials such as hempcrete help in multiple areas with their thermal inertia. It provides comfort and also use within the manufacturing process of lumber.

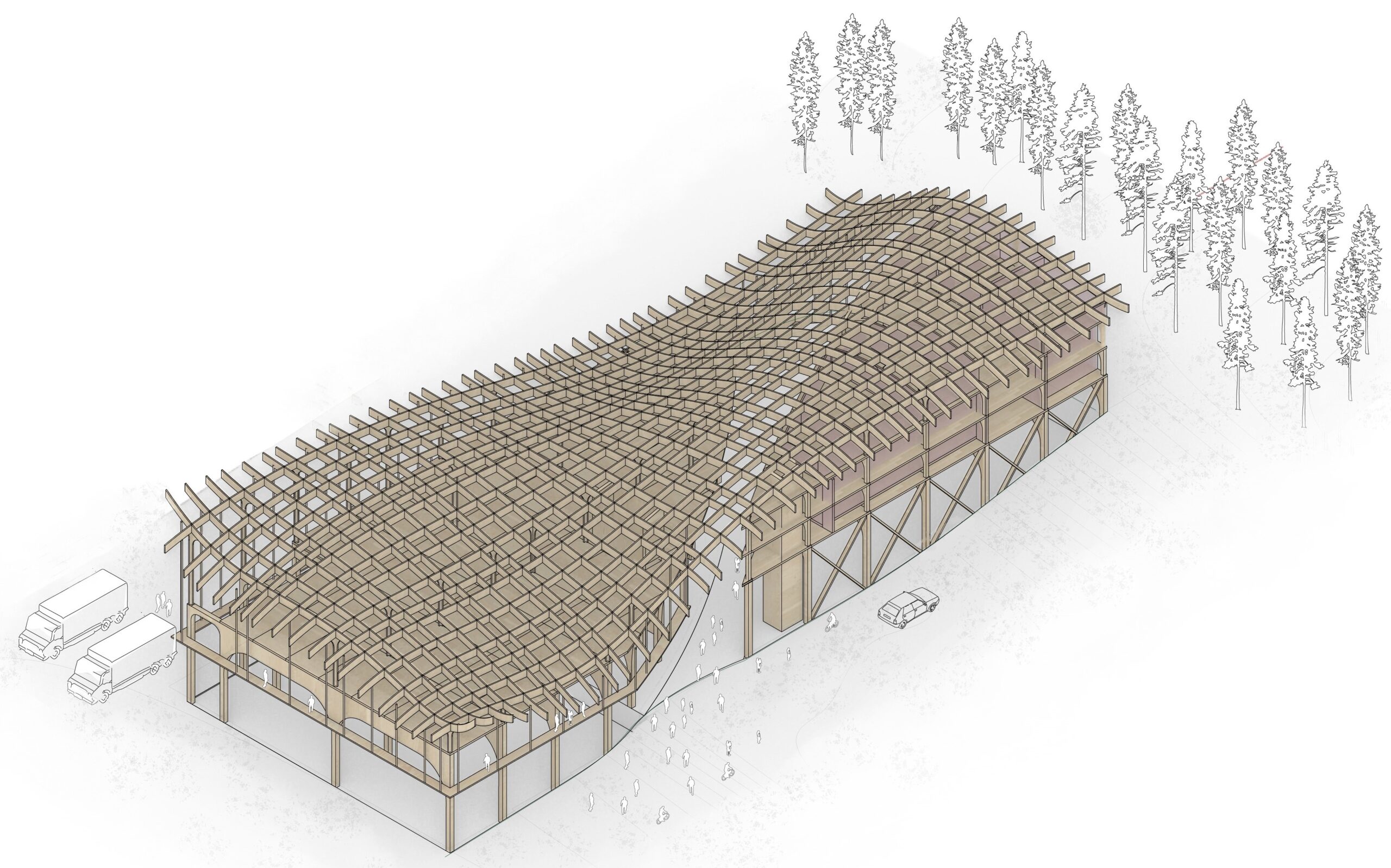

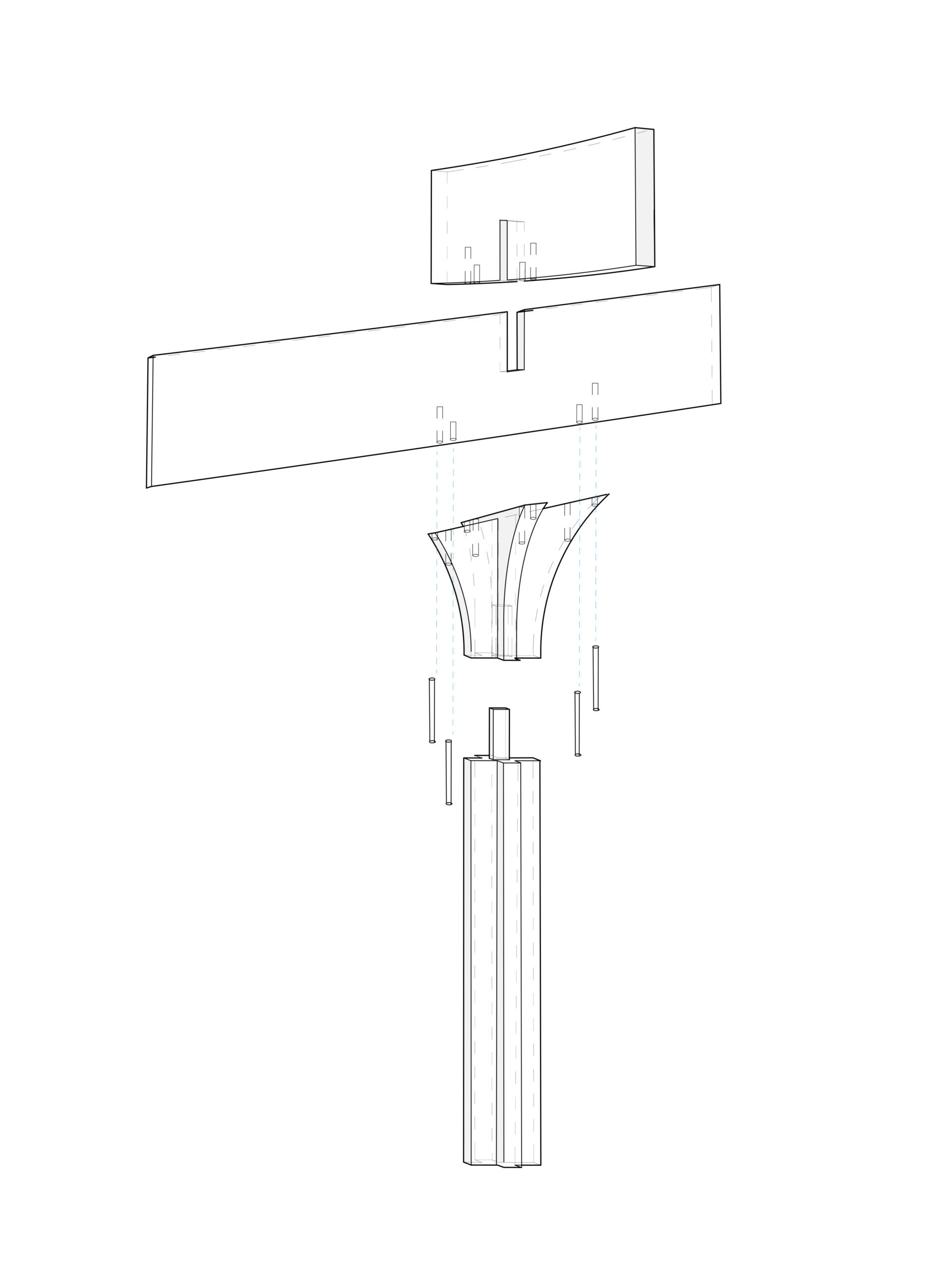

As a homage to the forests, the main elements of our structural system, arches and columns, attempt to replicate the more natural organic forms we see outside. At the same time, the roof grid is equally as organic, creating its own topography communicating with the landscape of Solsona and acting as a building envelope and thermal regulator.

Program

Our sawmill factory’s layout is designed to streamline log processing operations. The first floor houses the entire industrial program, dedicated to machinery and production. The second and third floors, located in the right-side building, are designated for residential areas. These floors are positioned away from the noisy machinery, ensuring a quieter and more comfortable living environment for residents. Finally, the fourth floor is reserved for office spaces.

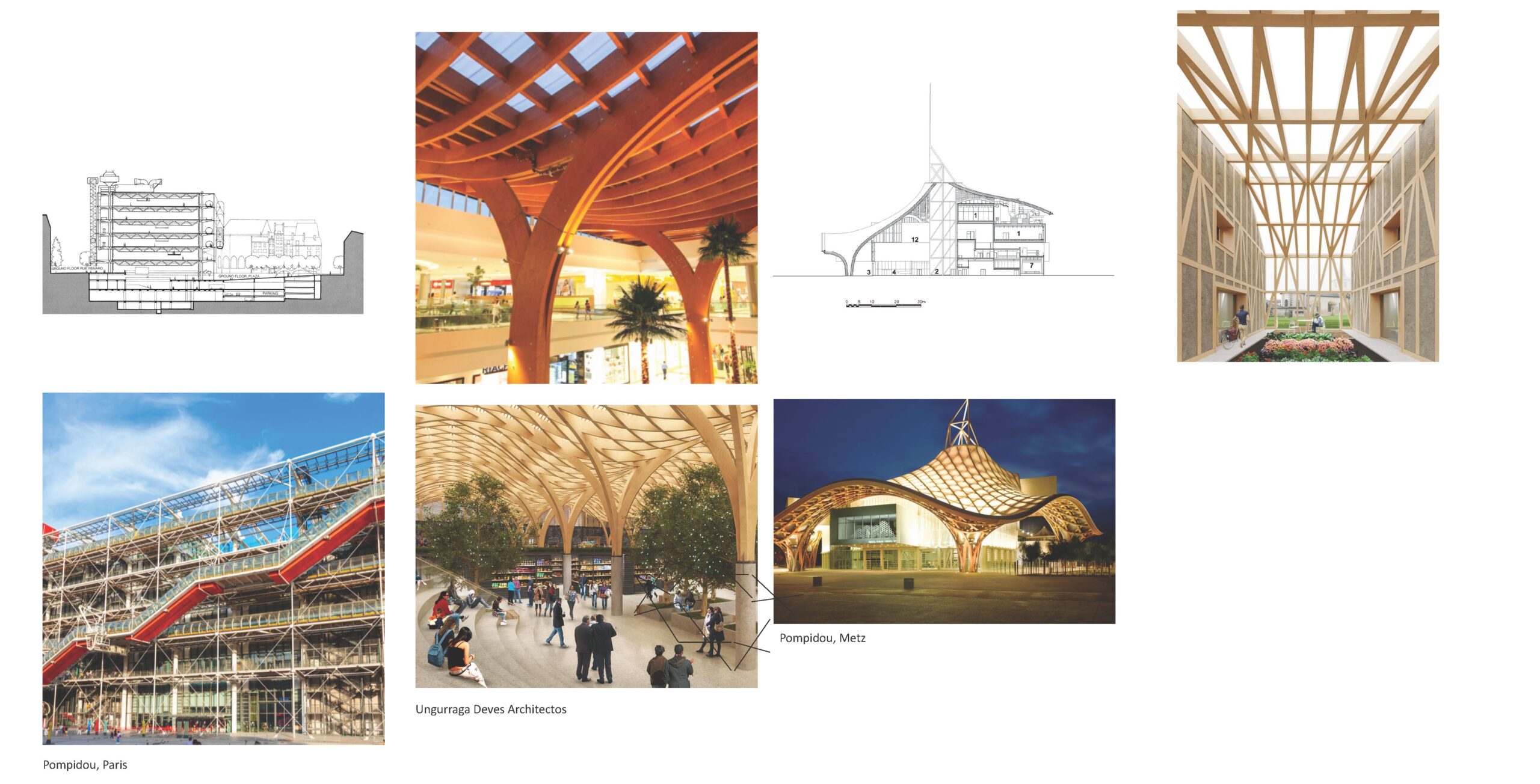

Case Studies

Framing Plans / Axons

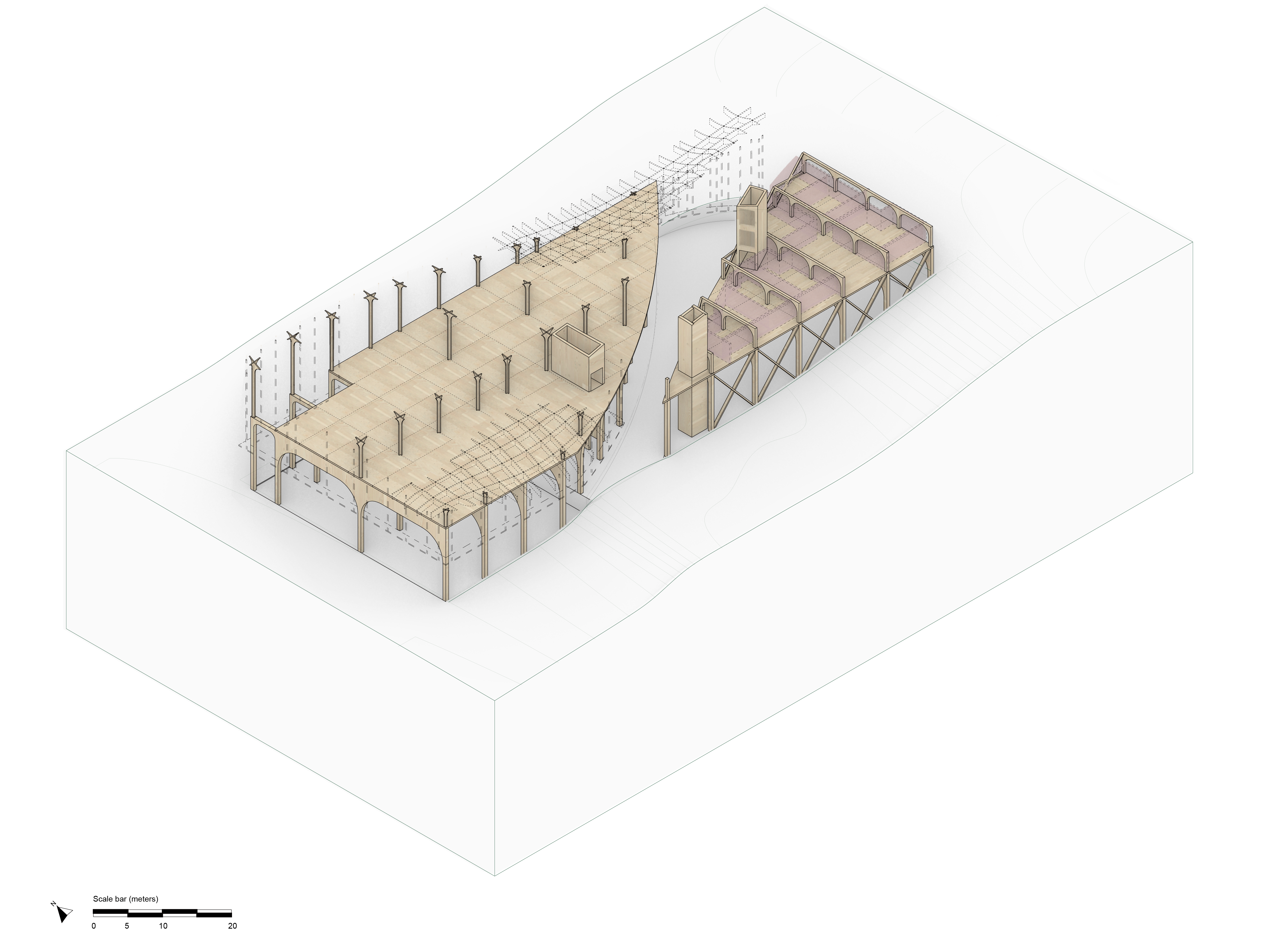

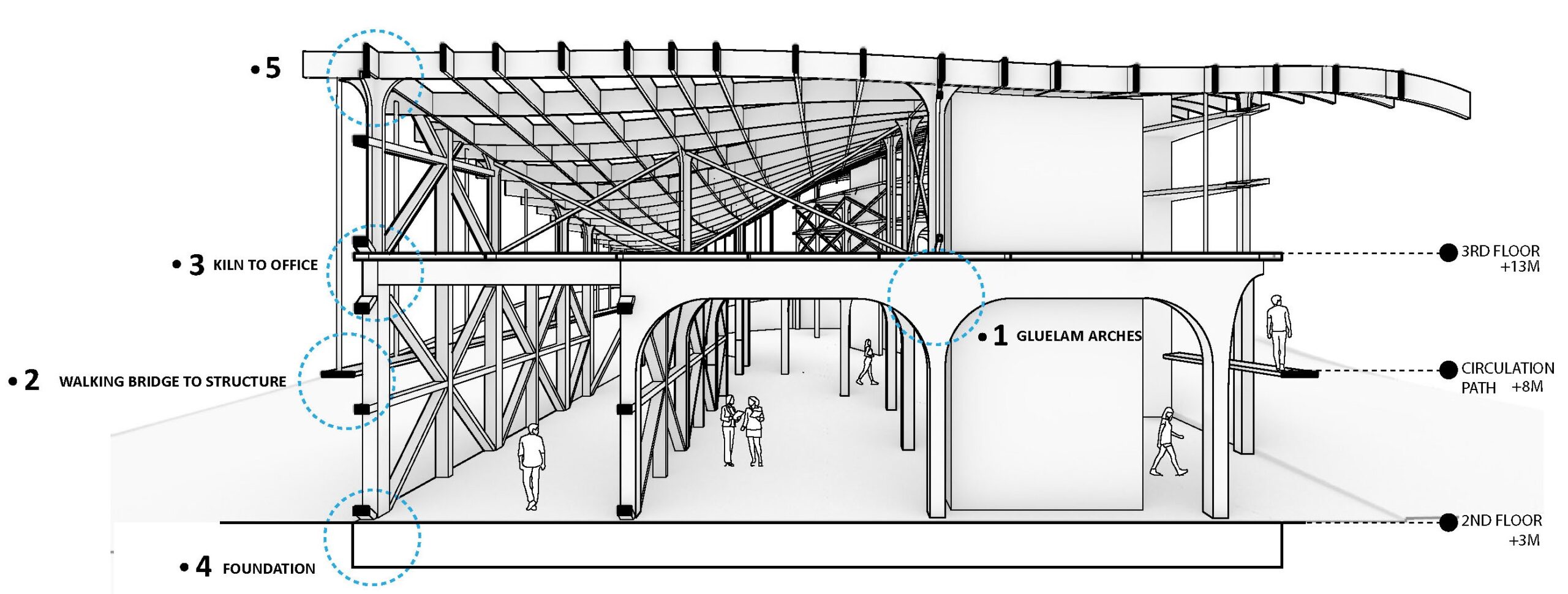

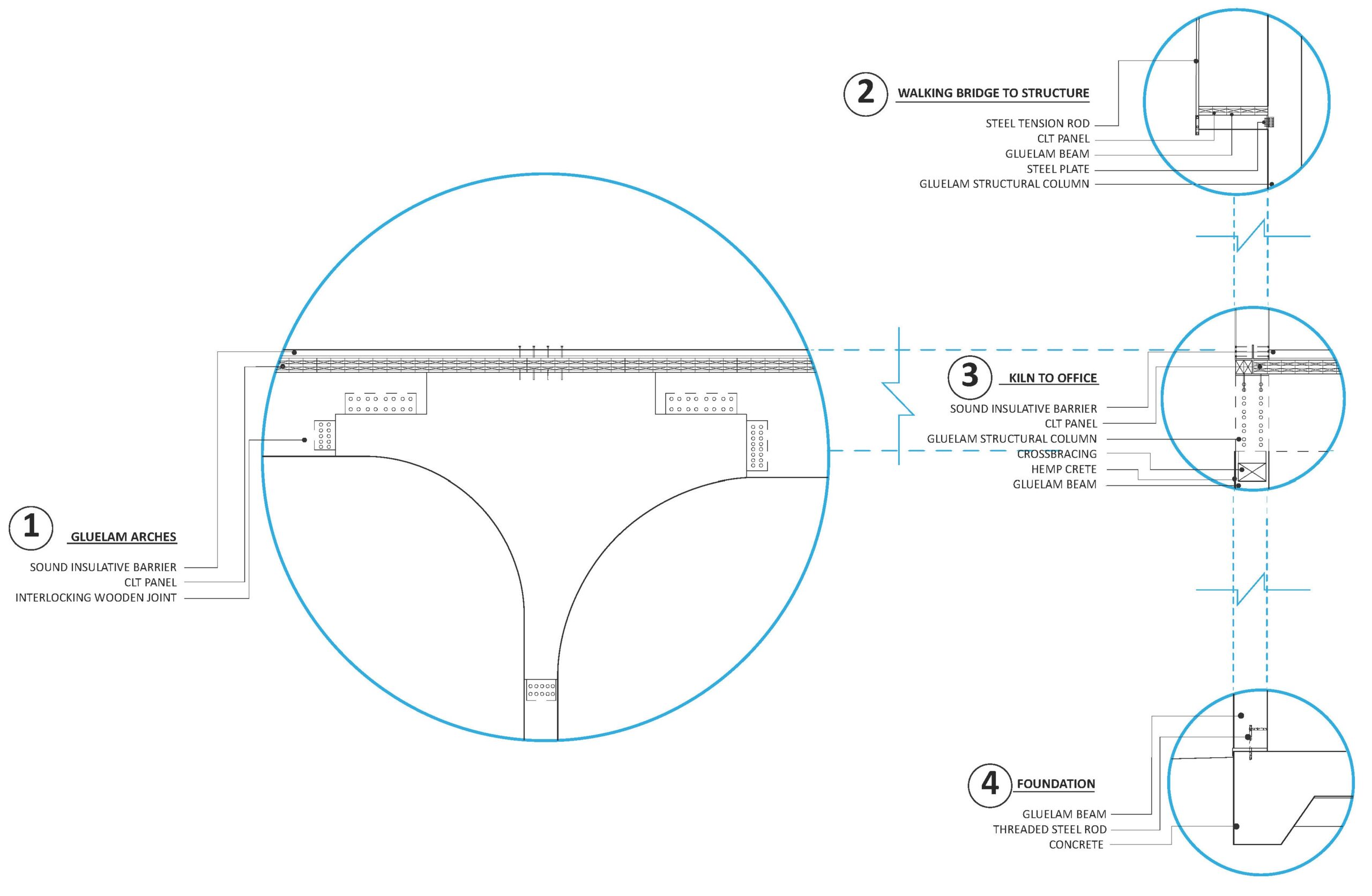

The framing system throughout the building features a combination of glulam arches and columns, providing structural support. CLT bracing and CLT panels are used for the cores of both buildings, while CLT panels are also employed for the flooring, enhancing the overall stability and efficiency of the structure.

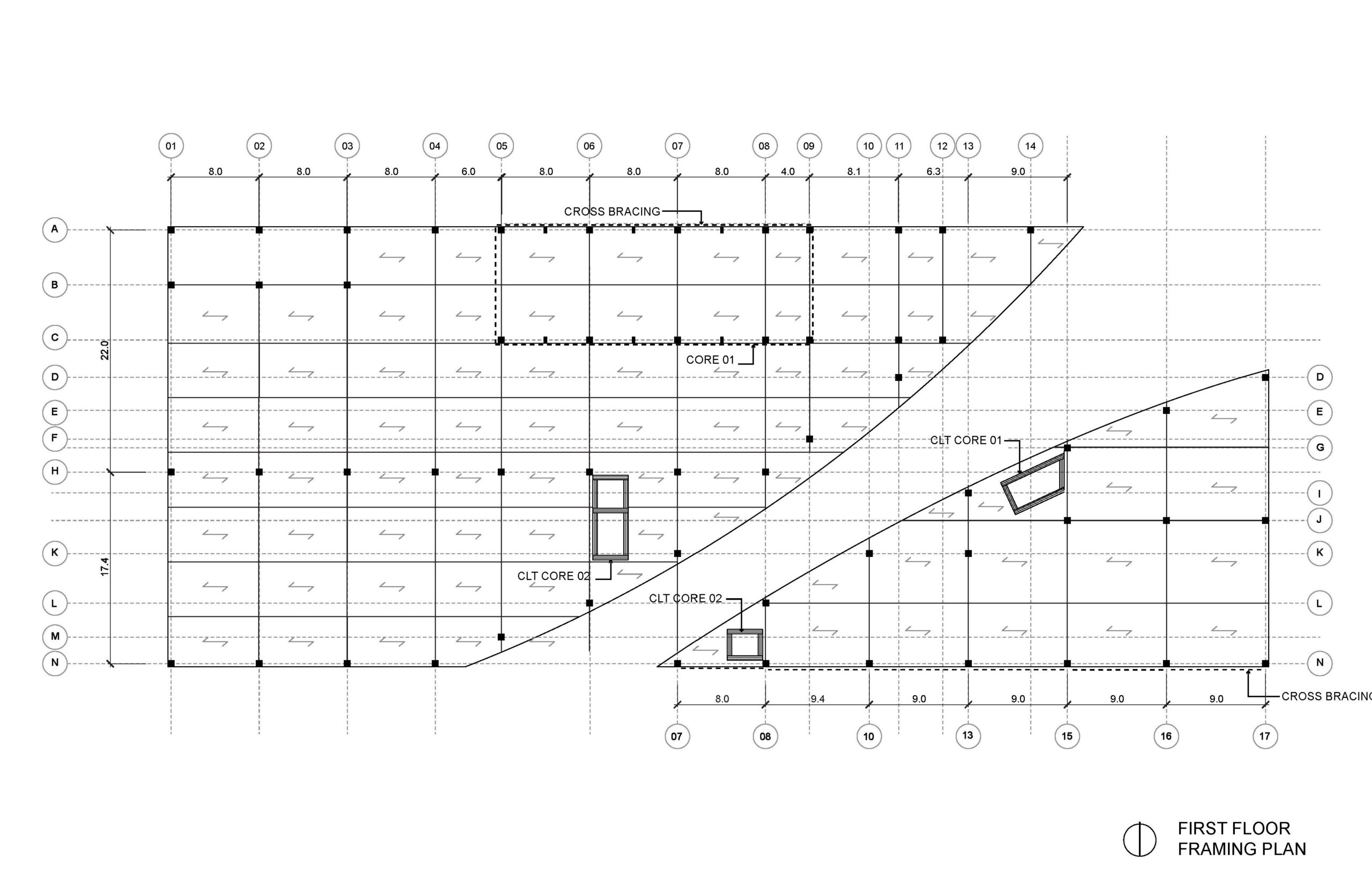

First floor:

The structural system on the first floor features arch columns with long spans, specifically designed to support the large machinery required for our sawmill operations. Within the kiln area ( west building), which is integral to the log processing, we’ve utilized the thick walls for cross bracing, allowing them to function as a core element of the structure. This cross bracing extends to the second floor, providing essential diagonal support throughout the building. Throughout both buildings, the cores are formed by CLT panels, offering additional structural strength and serving as a key component of the overall framework.

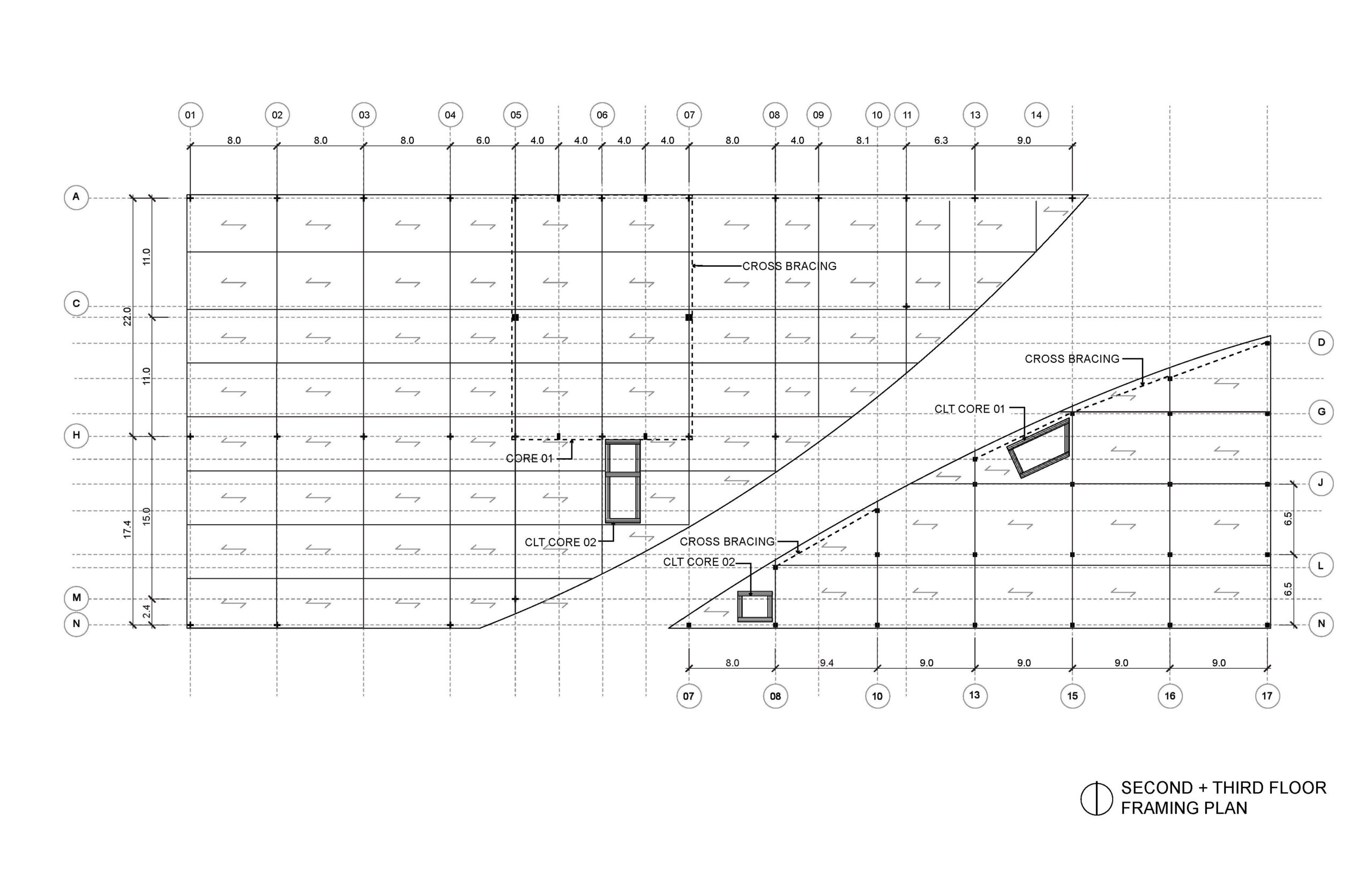

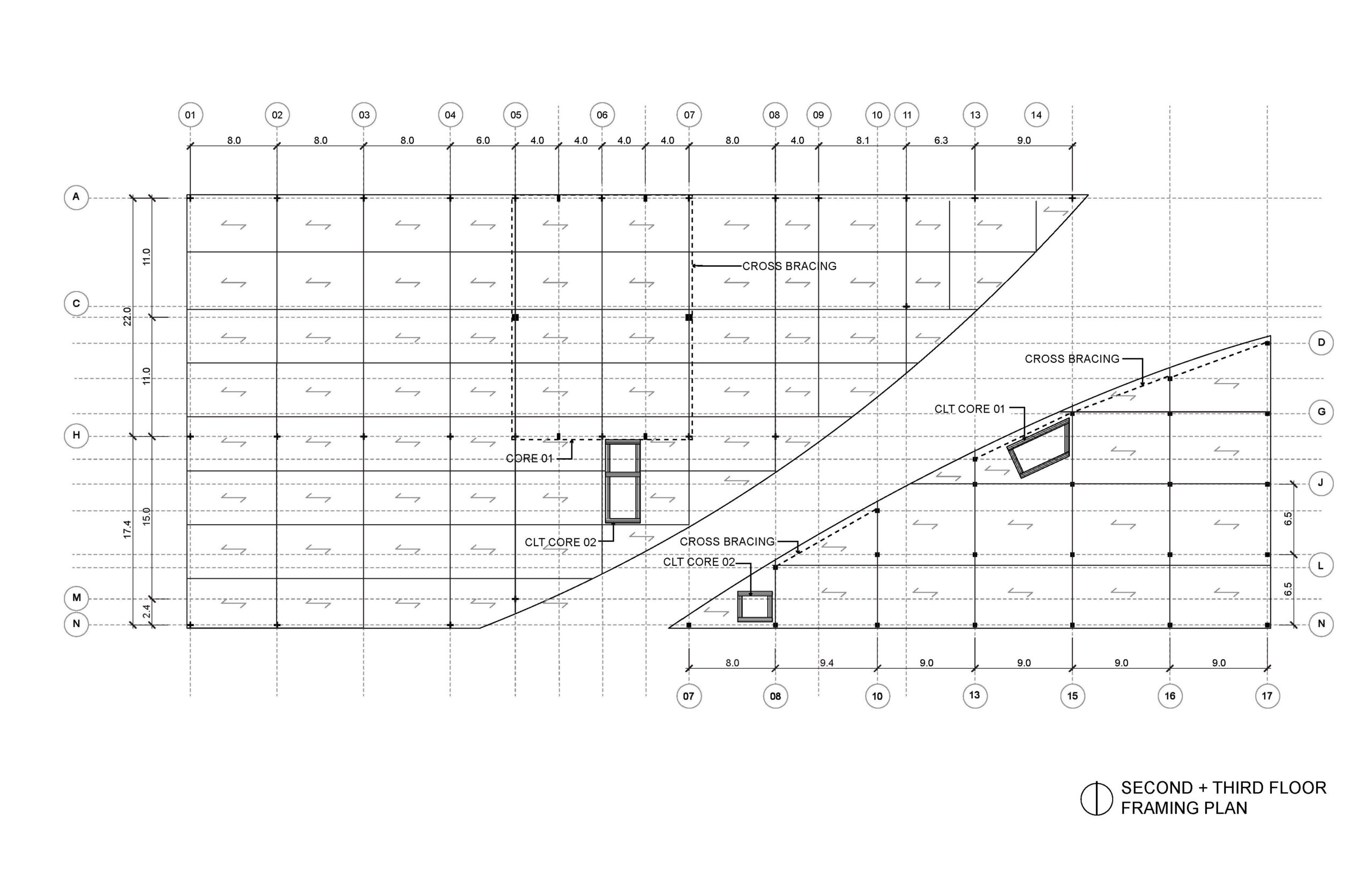

Second Floor:

In the west building, the structural system consists of glulam columns that are connected to the roof structure, providing strong vertical support. The cross bracing from the first floor, located in the kiln area, continues through to the second floor, ensuring stability and reinforcing the overall structure. In the east building, which is designated for residential use, the arch columns have a shorter span to accommodate the lighter load requirements of the floor.

Third Floor:

The third floor mirrors the structural layout of the second floor in the east building, maintaining the same design with shorter span arch columns to support the lighter residential load. The core remains consistent, with CLT panels providing strength and stability throughout. The west building, however, does not have a third floor, as it was designed with only two levels to accommodate the industrial program on the lower floors.

Fourth Floor:

The structural layout on the fourth floor closely follows that of the second floor in the west building, with columns supporting the roof structure. This floor is dedicated to office spaces, providing a quiet and functional environment separate from the industrial activities below. The glulam columns continue to provide strong vertical support, ensuring the stability of the building while allowing for an open, flexible office layout.

Milling Process Diagram:

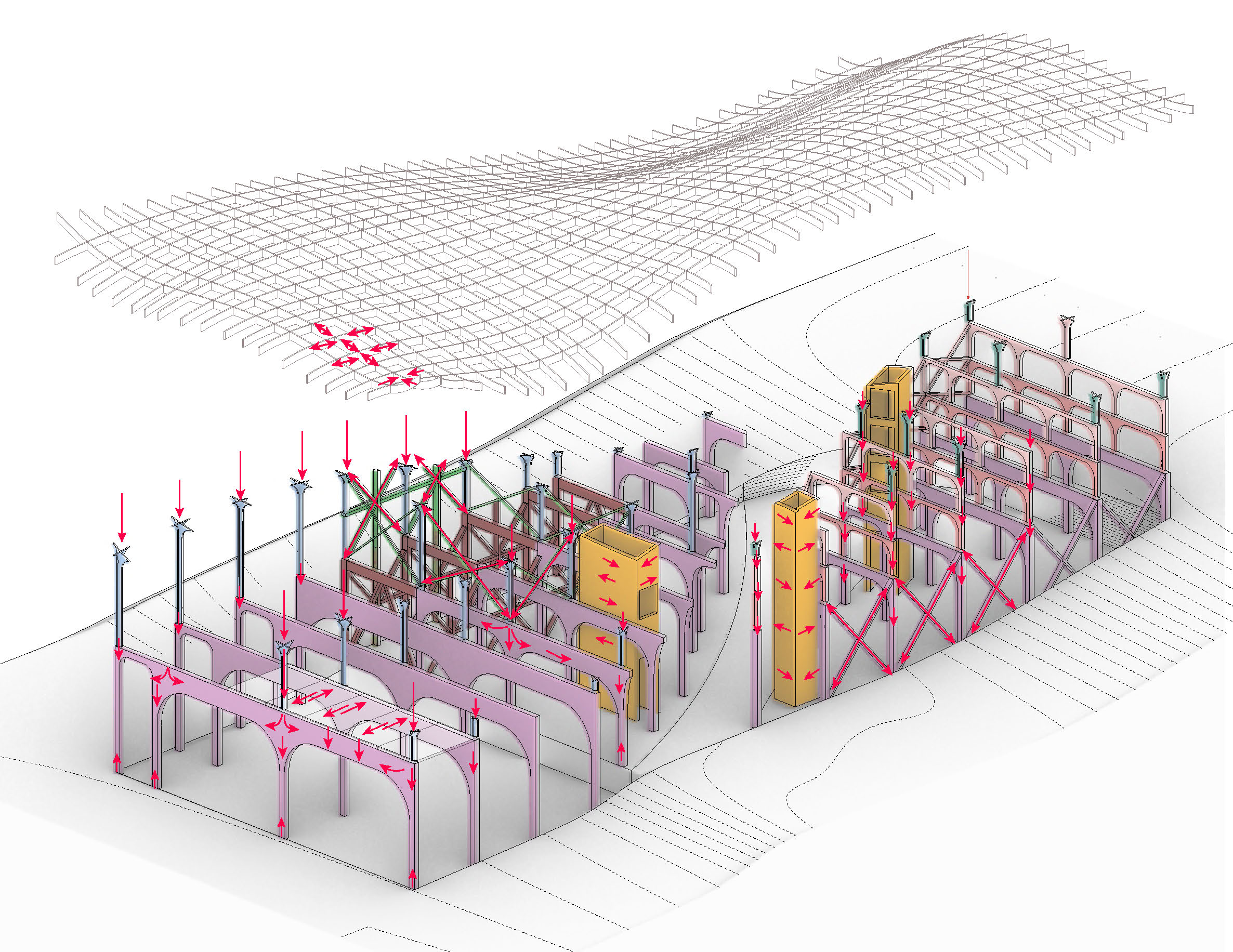

Load Transfer Diagram

The load transfer diagram details how loads are distributed throughout the building’s structure. The wooden waffle structure of the roof transfers the load, indicated by red arrows, which are then carried by the glulam columns. These columns direct the load to the arch columns, where it is further dispersed. The CLT flooring spreads the load horizontally, with arrows illustrating the distribution. The CLT panels in the cores transfer the load in two directions, both vertically and horizontally. The cross bracing distributes loads diagonally, providing additional stability and support across the structure.

Section:

Details:

Model Pictures: