Upcycled Timber Retrofit Strategies for a

Climate-Conscious Transformation of the Venus

Building.

Context

Why Retrofitting Matters

Buildings account for nearly 30% of global carbon emissions, with most of today’s housing stock expected to remain in use beyond 2050. In this context, the built environment becomes both a challenge and an opportunity for climate action.

Retrofitting allows us to improve performance without demolishing existing structures—preserving embodied energy, social ties, and cultural continuity, while reducing emissions at scale.

Regional Focus

Barcelona’s Retrofitting Potential

Mediterranean cities like Barcelona experience high levels of solar irradiation and rising cooling demands. Many buildings constructed between the 1950s and 1980s are poorly insulated and energy inefficient.

Retrofitting these structures is not only a sustainability strategy, but a practical urban necessity. The city is already investing in neighborhood upgrades—this project aligns with and amplifies that momentum.

Material Strategy

Timber as Climate Action

Timber has the rare capacity to store carbon while also replacing high-emission materials like concrete. When sourced from waste streams—such as sawmill offcuts or workshop scrap—it becomes an even more sustainable choice.

This project treats wood waste not as residue, but as resource—proving that with the right tools and vision, discarded materials can drive architectural innovation.

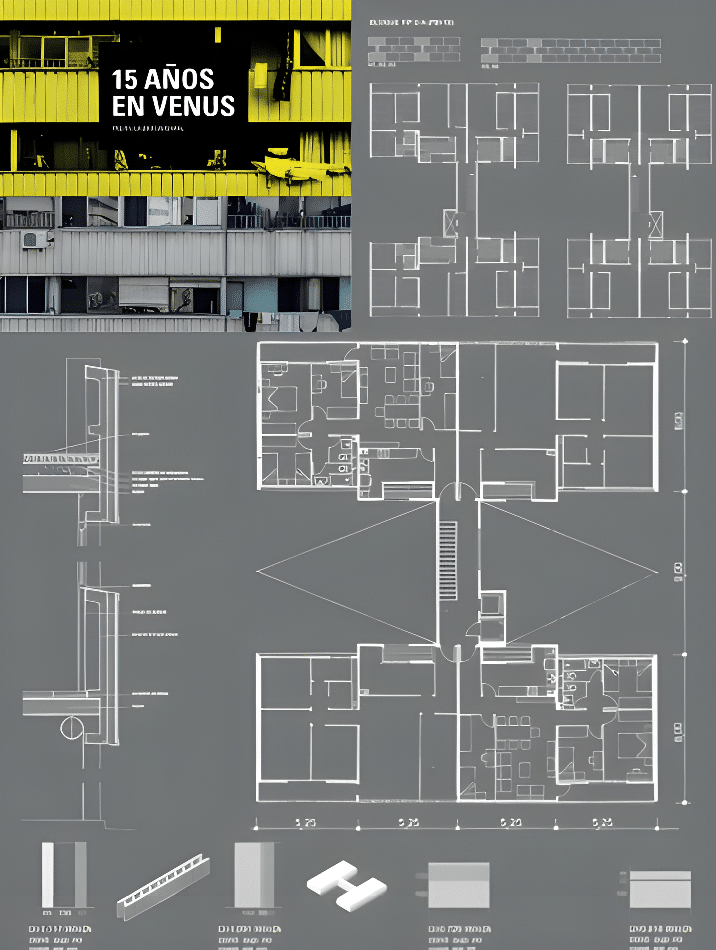

Case Study

The Venus Building

The Venus Building in Besòs i Maresme represents a broader typology of modular, repetitive social housing built during Barcelona’s rapid post-war expansion.

Its standardized layout, deteriorating condition, and socio-political visibility make it the ideal testbed for a flexible and replicable retrofit solution focused on energy, identity, and dignity.

Design Goal

Modular System, Circular Logic

Our objective was to design a prefabricated façade system using irregular timber offcuts. The goal was not just to wrap the building, but to engage with it—adapting to its structure, improving its performance, and respecting its social role.

Each module responds to environmental, economic, and technical criteria while supporting a circular material lifecycle.

System Prototypes

Three Modules, One Vision

The system is composed of three prefabricated prototypes:

- WoodSkin: a textured, rhythmic assembly from offcuts

- MosaicWaste: a dense collage of reclaimed wood

- TimberScript: CNC-joined curved elements for wood identity

Each prototype explores a different aesthetic and technical logic, demonstrating the range and richness of waste-based design.

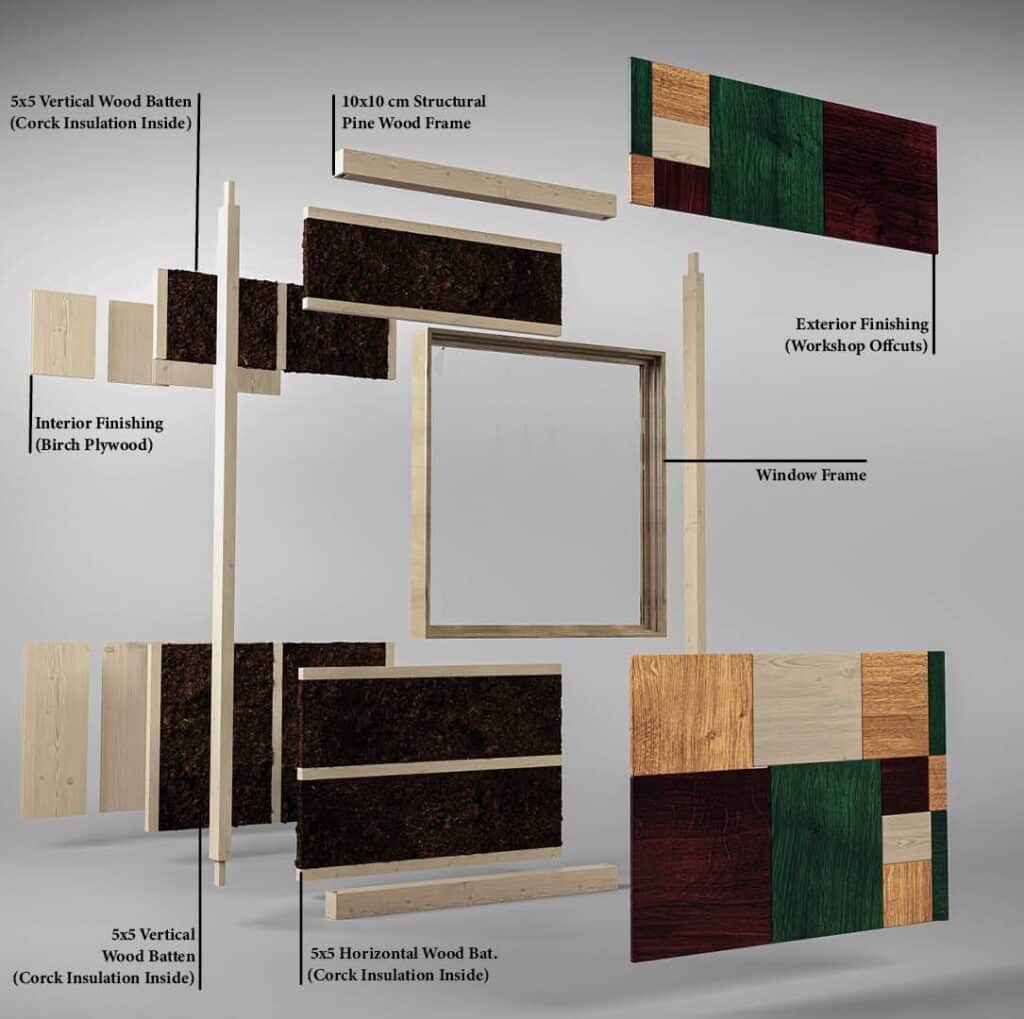

Layering Texture with Waste Offcuts

Module A: WoodSkin Panel

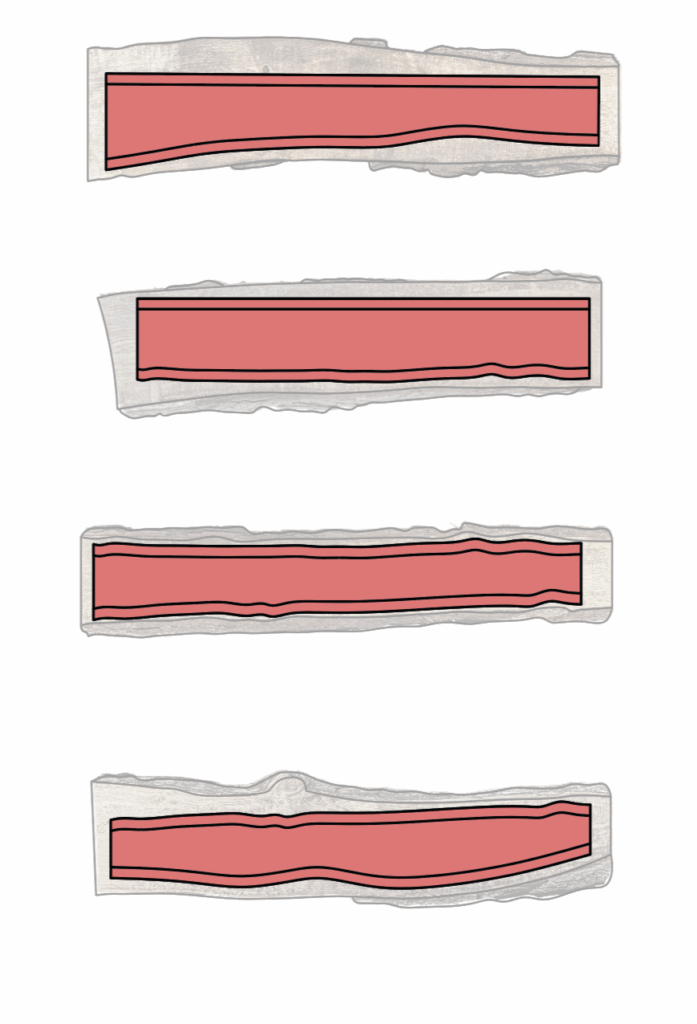

WoodSkin explores the expressive power of flat, bark-lined workshop offcuts by arranging them in stratified, repeating bands that form a new “skin” for the building. These timber pieces often retain traces of bark—a literal and symbolic reminder of their origin—which becomes part of the panel’s tactile and visual identity.

The panel’s composition is driven by a horizontal layering system that sorts offcuts by thickness and length, stacking them to form a textured rhythm. This surface variation isn’t just aesthetic—it modulates solar shading and light reflection, improving the building’s microclimate.

Our digital workflow uses a greedy-fit algorithm to optimize placement: longer pieces are prioritized to maximize coverage and minimize cuts. All offcuts are trimmed with a miter saw and mounted with screw fixings onto a lightweight pine frame.

The resulting panel reinterprets the bark as architectural language—transforming the tree’s outermost layer into a building envelope that is both protective and revealing. The raw character of each strip is preserved, and the building gains a skin with material memory.

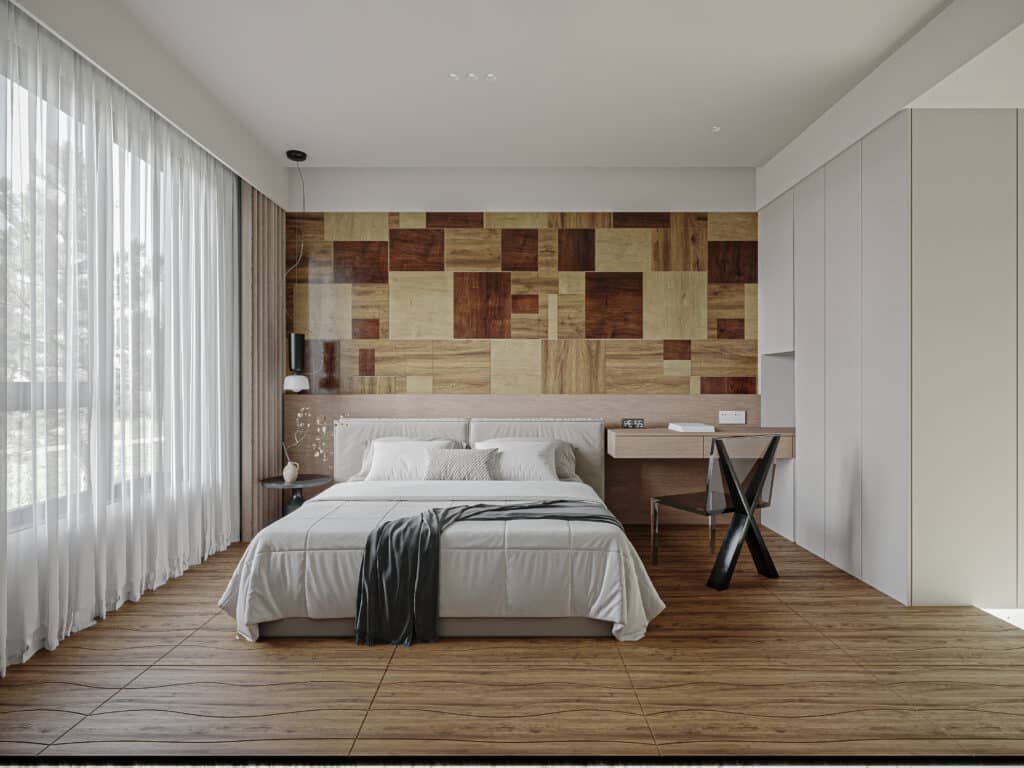

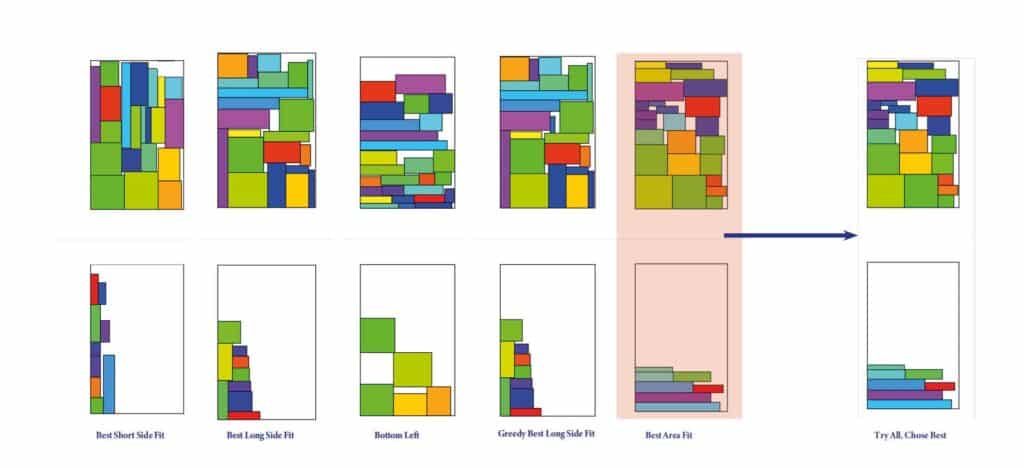

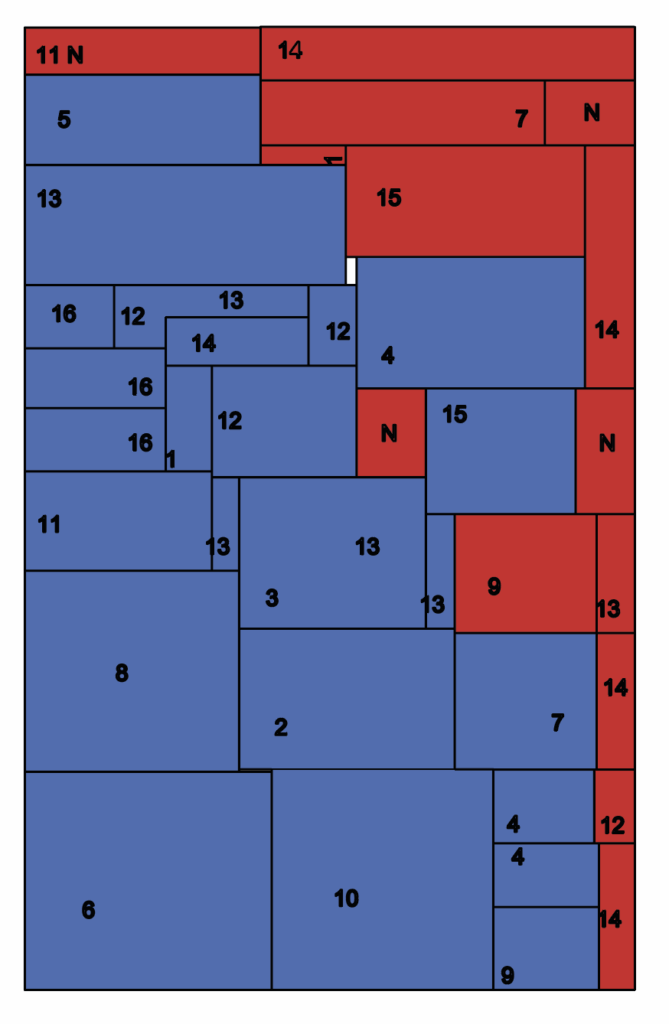

Module B: MosaicWaste Panel

Composing Density from Disorder

MosaicWaste addresses a different material condition: irregular, randomly shaped offcuts—fragments with diverse grain, form, and angle. These elements were too inconsistent for linear assembly, so we designed a packing algorithm to place them in a dense, interlocking layout.

The system uses a “best-fit” logic that compares different placement strategies (e.g. Long-Side Fit, Area Fit, Bottom-Left Fit), selects the optimal one, and assigns each piece a unique slot within the panel. Any gaps were filled using CNC-milled trimmings from the leftover fragments, reinforcing the zero-waste principle.

Visually, the panel reads like a wooden collage—honest and expressive. The layering of tones, grains, and angles results in a rich façade element that celebrates imperfection. Structurally, all elements were screw-mounted onto a standardized wood frame thanks to wooden slabs obtained from dismantling a pallet. Cork insulation is placed behind to ensure insulation.

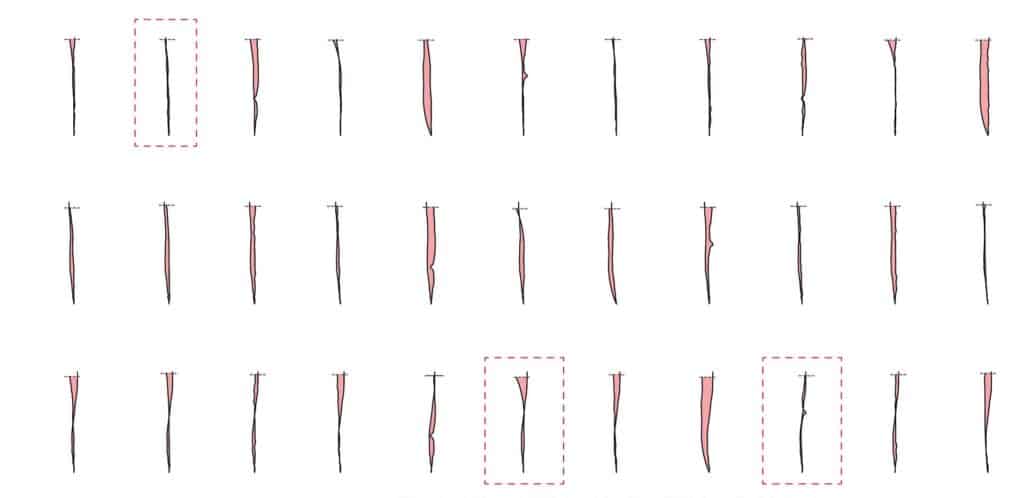

Module C: ForestScript Panel

Joining the Curve with CNC Logic

TimberScript is a synthesis of material expression and computational precision. This prototype began with bark-edged offcuts that retained their natural curvature. These curves were scanned, vectorized, and catalogued in a digital library. We then developed a custom algorithm that performs intersection mapping to compare curve pairs and score them by geometric similarity.

From a various number of combinations, the algorithm filtered those with the highest match value. Each selected pair was then digitally prepared for CNC joinery, which included creating alignment pockets and subtractive locking points. The physical joints were milled with tolerance precision to allow seamless assembly while keeping structural grip.

The final effect is a flowing, interwoven timber script—every joint preserving the original grain curve, forming a facade element that is at once structural, ornamental, and narrative. The module is installed as a facade panel, but we imagined it as a possible flooring or interior panel system as well.

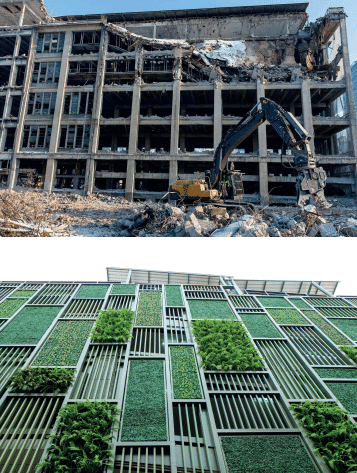

Architectural Impact & Façade Transformation

From Anonymous Envelope to Material Identity

The original Venus Building façade was repetitive, flat, and deteriorated—a neutral skin with no engagement to climate or character. Through the introduction of timber modules, the building gains a new spatial rhythm, solar modulation, and material expressiveness.

Each prototype panel interacts differently with light and shadow, offering moments of depth, density, or curvature. Together, they create an adaptive envelope that is both performative and symbolic—transforming waste into presence.

This retrofit model can be scaled to other buildings with similar structural logic, offering not just thermal improvement, but a redefinition of architectural language in mass housing contexts.

Future Potential & System Scalability

Retrofitting the City, One Module at a Time

This system was designed for the Venus Building, but its logic extends far beyond. The use of standard substructures, digitally-fitted modules, and waste-sourcing flexibility means it can adapt to a wide range of building typologies.

With policy alignment (e.g. EU’s Renovation Wave), localized sourcing, and community participation, this approach could be scaled across neighborhoods—transforming cities from within.

By working with waste, we reduce extraction. By working with what’s already built, we reduce erasure. And by designing with modularity, we open paths for maintenance, upgrading, and long-term sustainability—not just once, but cyclically.