This term’s digital fabrication explorations investigated the expressive and technical potential of multiple fabrication methods laser cutting, CNC milling, robotic clay extrusion, and 3D printing. While each technique demanded a different workflow and material logic, a common thread emerged: the use of material duality to create depth, contrast, and spatial effect. By combining two materials such as plywood and cork, or Acrylic and MDF we were able to produce hybrid prototypes that emphasize texture, light interaction, and structural behavior. Across these studies, the aim was to translate geometric ideas into physical form through systematic digital modelling and machine-specific fabrication strategies, gradually building an understanding of how computational design engages with material performance.

CNC Milling

Nature Meets Order

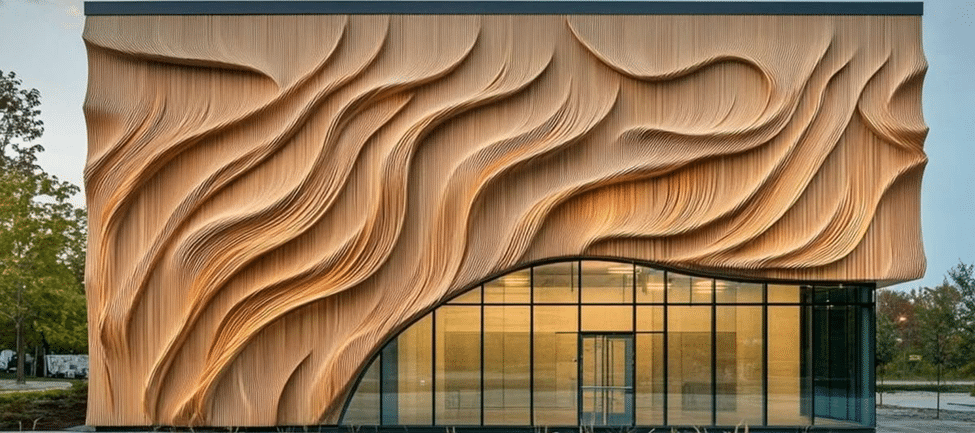

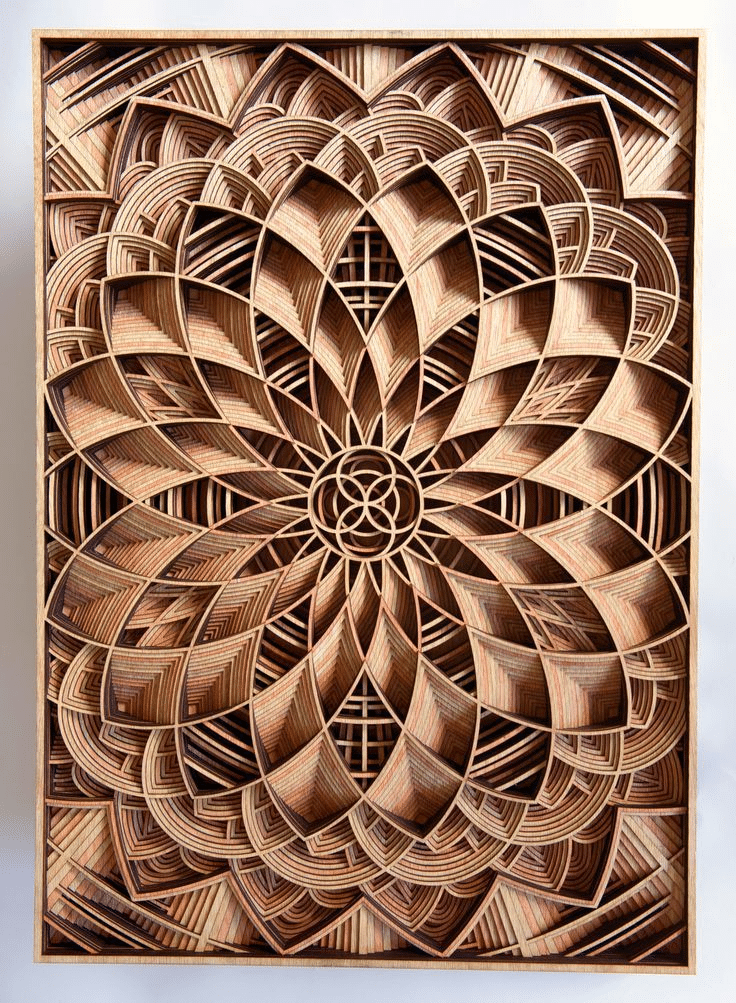

This architectural model explores the relationship between organic fluidity and structured order. The CNC-milled plywood forms represent a dynamic natural landscape, while the linear cork base reflects human-imposed structure and control. Their intersection reveals how natural terrains and architectural systems coexist, highlighting the tension and harmony between fluid forms and geometric order.

Inspirations :

Prototype :

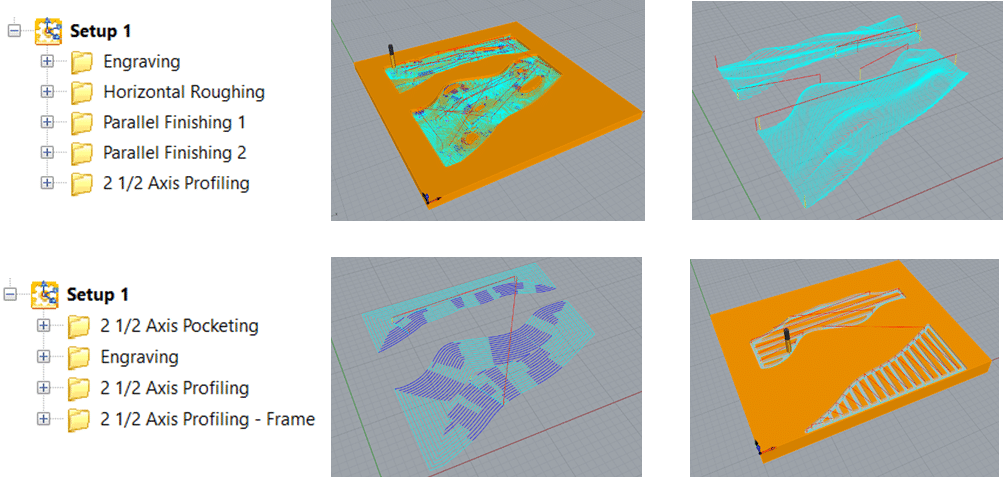

This CNC-milled prototype explores how subtractive fabrication can transform plywood and cork into a fluid, topographic surface. Inspired by contemporary façades that use layered wood to create flowing, wave-like forms, the design carves smooth contours into plywood while exposing the vertical grain of cork to produce contrast in texture and depth. Through simple 3 axis milling, the panel demonstrates how material directionality and layered milling strategies can generate dynamic surfaces that evoke movement, shadow, and sculptural expression.

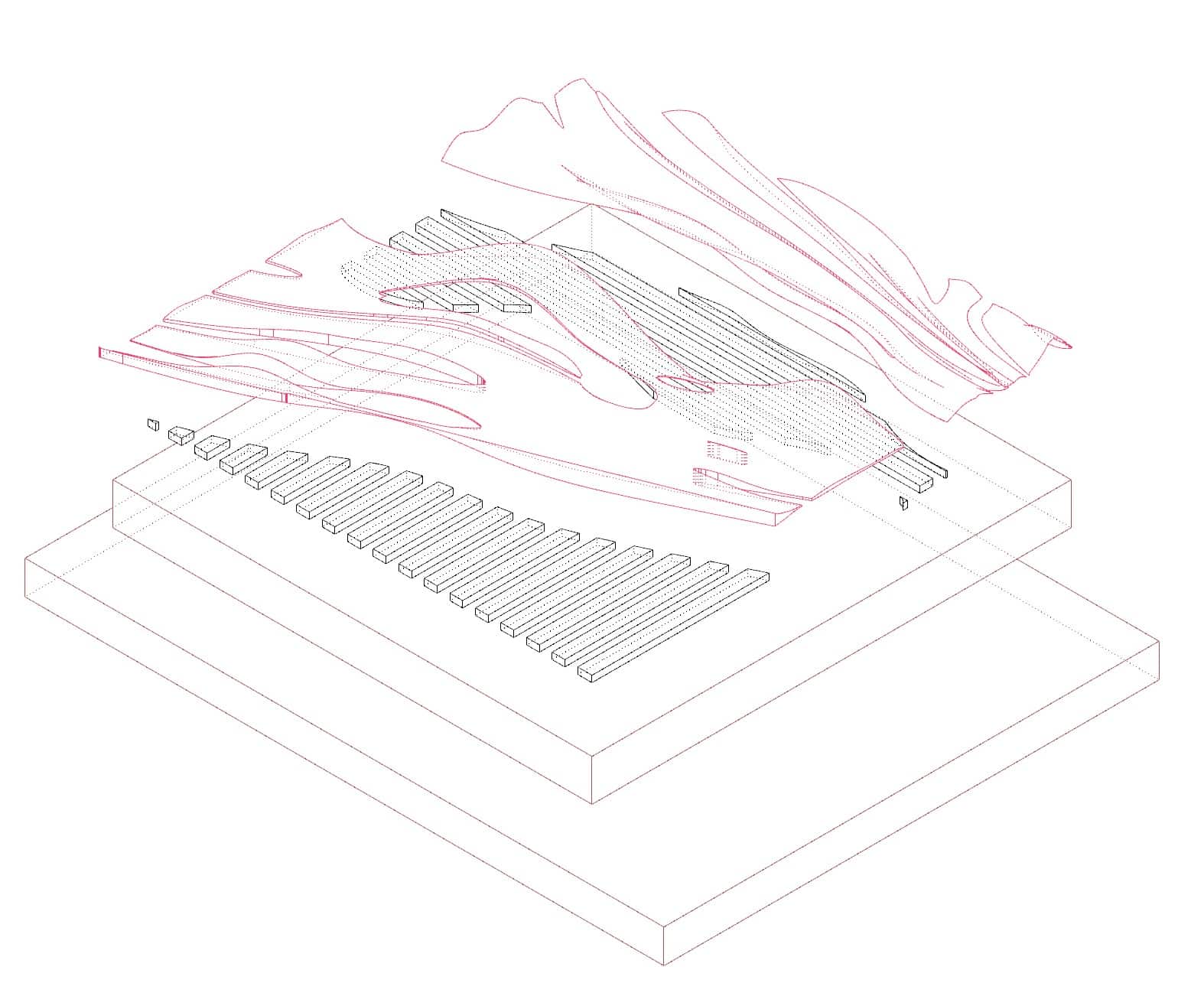

Final design diagrams :

Technical Steps and Strategies :

Final design :

3D Printing

Kinetic Convergence

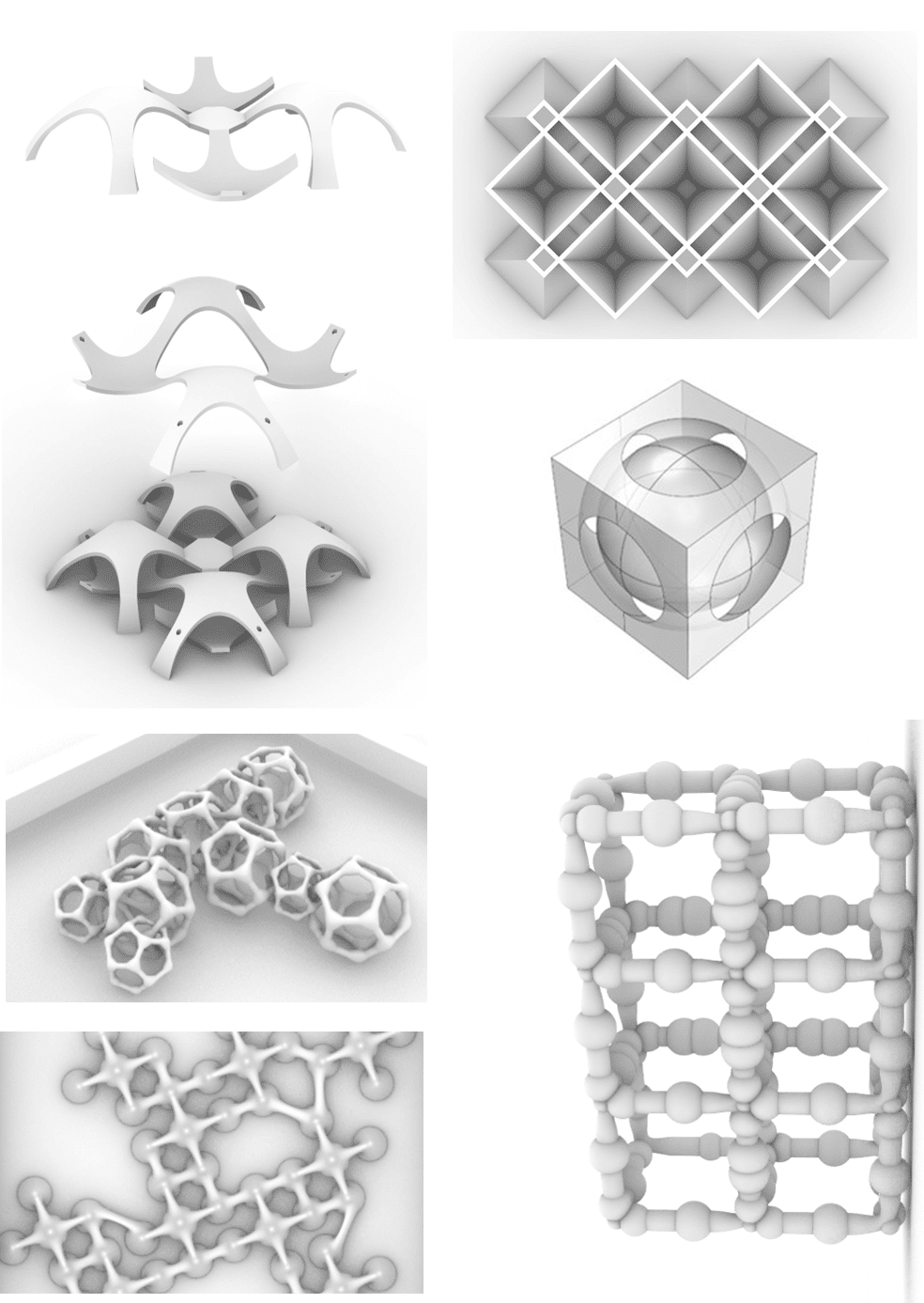

This project explores modularity, curvature, and motion through a series of additive manufacturing prototypes. Inspired by wave-based surfaces and interlocking minimal geometries, the process involved developing multiple experimental units—ranging from spherical voids and saddle modules to concave lattice grids. The final design combines these explorations into a hybrid object composed of a kinetic outer frame with a rolling ball and a central interconnected structure. Through iterative modeling and precise FDM 3D printing, the project demonstrates how additive manufacturing supports complex assemblies, embedded movement, and finely tuned tolerances, resulting in a playful yet structurally coherent spatial system.

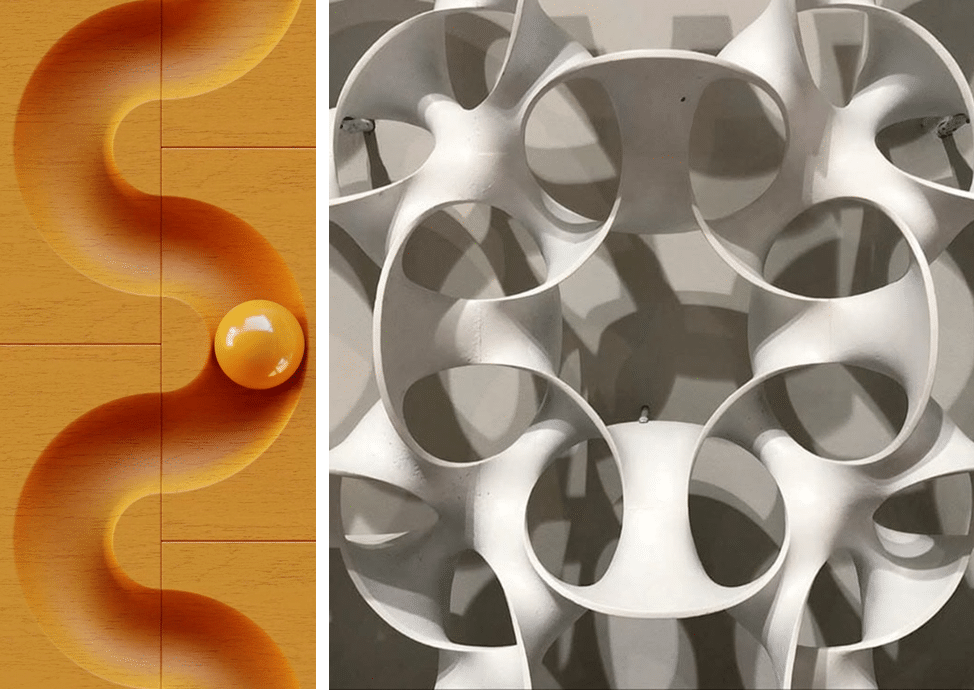

Inspirations…

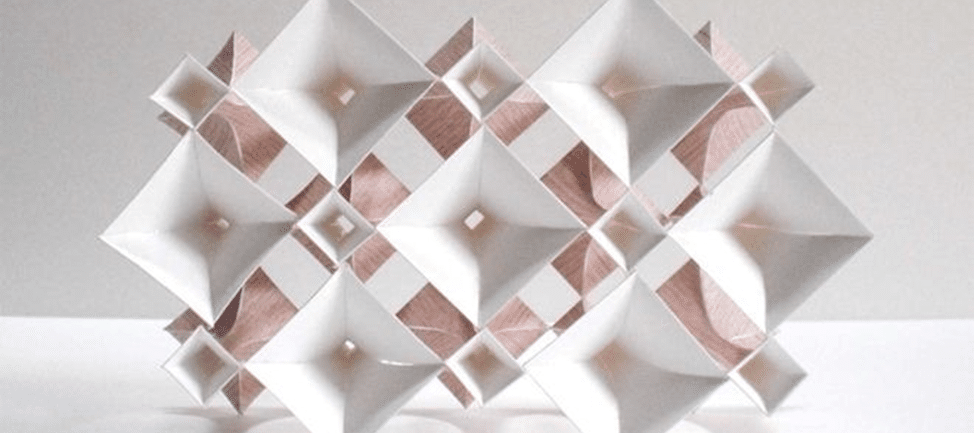

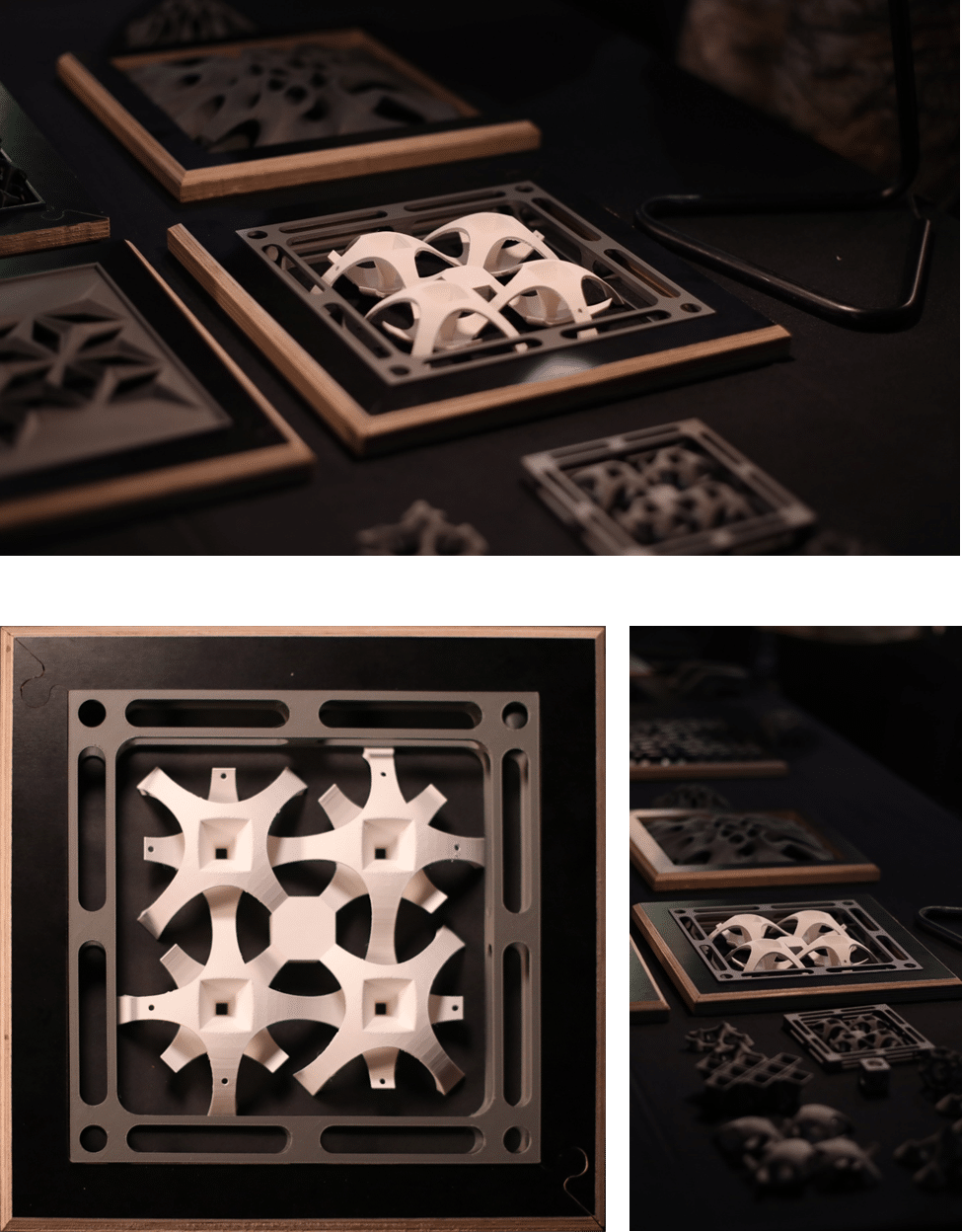

Prototype

The project began with an exploration of curved geometries inspired by smooth wave patterns and minimal surface systems. Through multiple prototypes, different spatial logics were tested: spherical voids carved out of cubes, diamond-grid concavities, and shell-based interlocking units. These studies informed both the central geometry and the motion-based frame.

Final design :

The final design combines the strongest aspects of these prototypes. A rigid outer frame incorporates a continuous sinusoidal channel, enabling a ball to roll freely and introducing an interactive, tactile element. At the center, a cluster of interconnected saddle modules forms a spatial sculpture assembled from repeated units. The two components together create a playful yet architecturally expressive object, demonstrating how additive manufacturing supports both precision assembly and embedded motion.

Final Module :

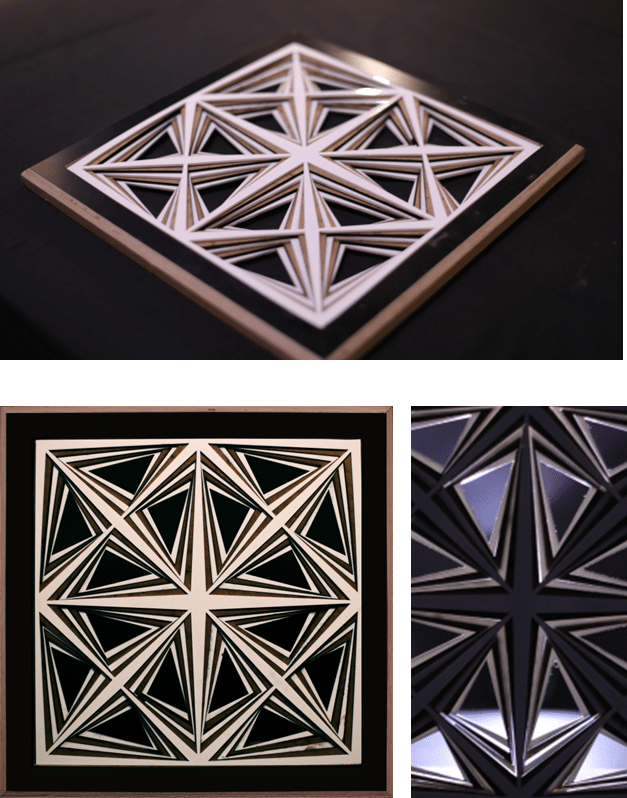

Laser Cutting

Geometry of Light

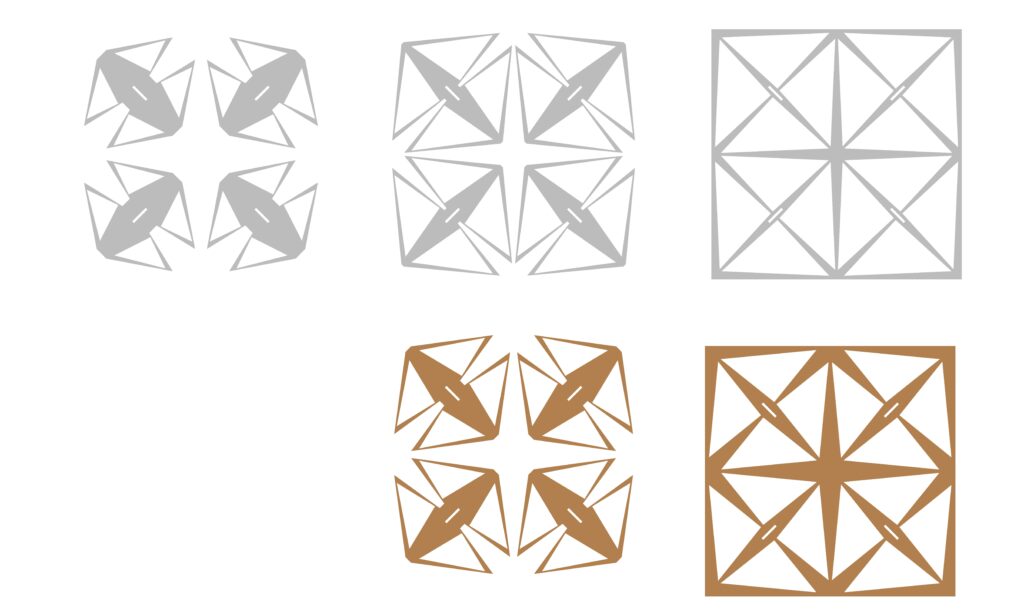

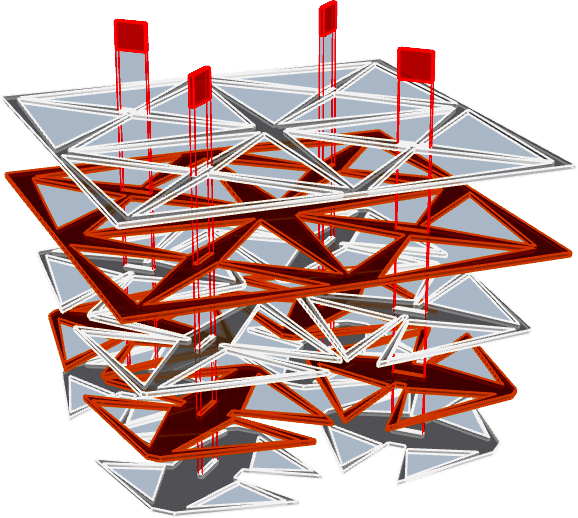

This project investigates how stacked laser-cut layers can generate a performative façade element that modulates light and creates spatial depth. Inspired by porous architectural lattices and multi-layered geometric roofs, the design uses repeated triangular modules cut in 2D and assembled into a three-dimensional relief. The layered composition filters daylight, producing dynamic shadows and varying levels of transparency throughout the day. By transforming simple laser-cut components into a volumetric pattern, the prototype demonstrates an efficient and scalable approach for creating lightweight façade systems that integrate environmental performance with expressive geometry.

Inspirations…

Prototype :

Final design technical diagram :

The façade prototype is developed using laser-cut stacking as the primary fabrication technique. Starting from a parametric triangular grid, individual modules were cut in successive layers of Acrylic and MDF, each slightly offset to introduce depth and shadow. When assembled, the layers form a three-dimensional tessellation that echoes the geometric porosity seen in contemporary patterned roofs and vernacular screens.

Under controlled lighting, the model casts sharp, evolving shadow patterns, demonstrating its performance as a light-modulating façade. The system’s modularity enables scalability, while its material efficiency—achieved through repeated 2D cuts—makes it an accessible method for prototyping architectural filters or cladding systems.

Final model :

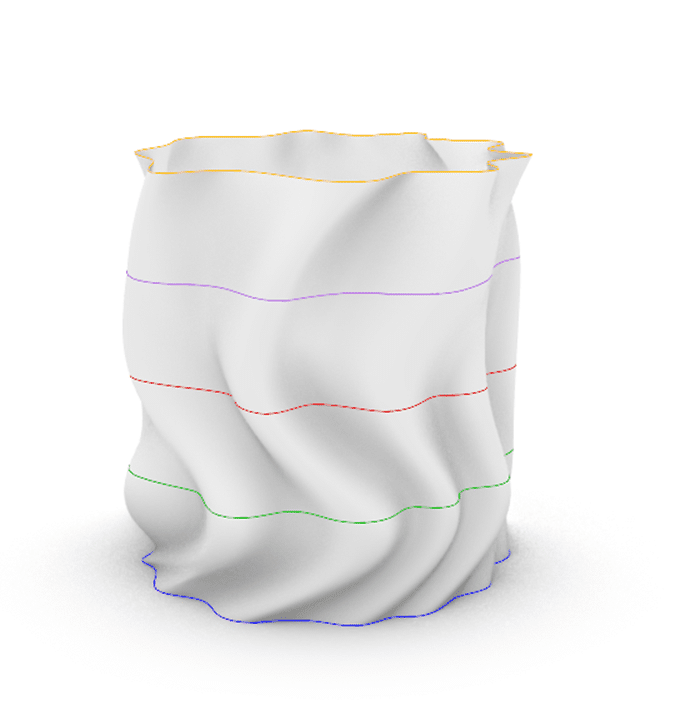

Robotic Fabrication

Lofted Vessel

This project explores robotic clay extrusion through the design and fabrication of a 90×90×90 mm vessel generated from lofted contour curves. By defining a series of wavy, the form introduces controlled geometric variation along the height of the cup. The robot translates this digital geometry layer by layer, producing a striated ceramic texture characteristic of additive clay deposition. The final result demonstrates how simple curve-based modeling can yield a complex, expressive ceramic object when combined with robotic precision and material behavior.

Final design :

Final Model :