Architecture is entering a moment where the boundaries between design, technology, and material production are dissolving. As cities demand faster construction, customized spaces, and environmentally intelligent solutions, traditional methods alone no longer match the pace or precision required. Digital fabrication has emerged not just as a complementary tool, but as a transformative force reshaping how buildings are conceived and constructed.

//image

Within this evolving landscape, architects increasingly rely on tools like 3D printing, laser cutting, CNC milling, and robotic systems to test ideas, explore new geometries, and prototype structural logics that were once impossible through conventional means. These technologies offer an alternative to linear construction workflows—introducing iteration, adaptability, and material optimization into the heart of architectural design. As prototypes evolve, they begin to reveal how future buildings might be produced: with fewer constraints, more automation, and a closer dialogue between computation and craftsmanship.

3-D Printing

3D printing allows ideas to take physical form through layered construction, often encouraging designers to lean into complex geometries, organic surfaces, and intricate internal structures. Working with this technology naturally draws attention to aspects such as orientation, support logic, material thickness, and detailing. Each print guides the next iteration, as slight adjustments in mesh optimization, slicing parameters, or material choice can transform the performance and finish of the prototype. Over time, a more intuitive understanding forms around what types of geometries respond best to additive manufacturing.

Tribolic

Modular Hexagonal 3D façade

A Modular hexagonal design comprises of all the major components which comprises of the Major tribolic design and the connectors which connected everything together which are the 2 mm x 2 mm 3D printed tube and the central connector and, to the components to attach everything on the wooden frame was also 3D printed.

Render to protype the design by putting them on a office building façade

Laser Cutting

Laser cutting offers speed and precision, making it ideal for testing modular systems, planar assemblies, and pattern-based explorations. Its workflow often leads designers to think in layers, joints, and interlocking mechanisms. Small adjustments—compensating for kerf, refining joint tightness, selecting material density—start to shape the clarity and stability of each prototype. As more iterations are produced, the relationship between digital drawings and physical fit becomes increasingly fluid, allowing complex ideas to be expressed through simple, clean cuts.

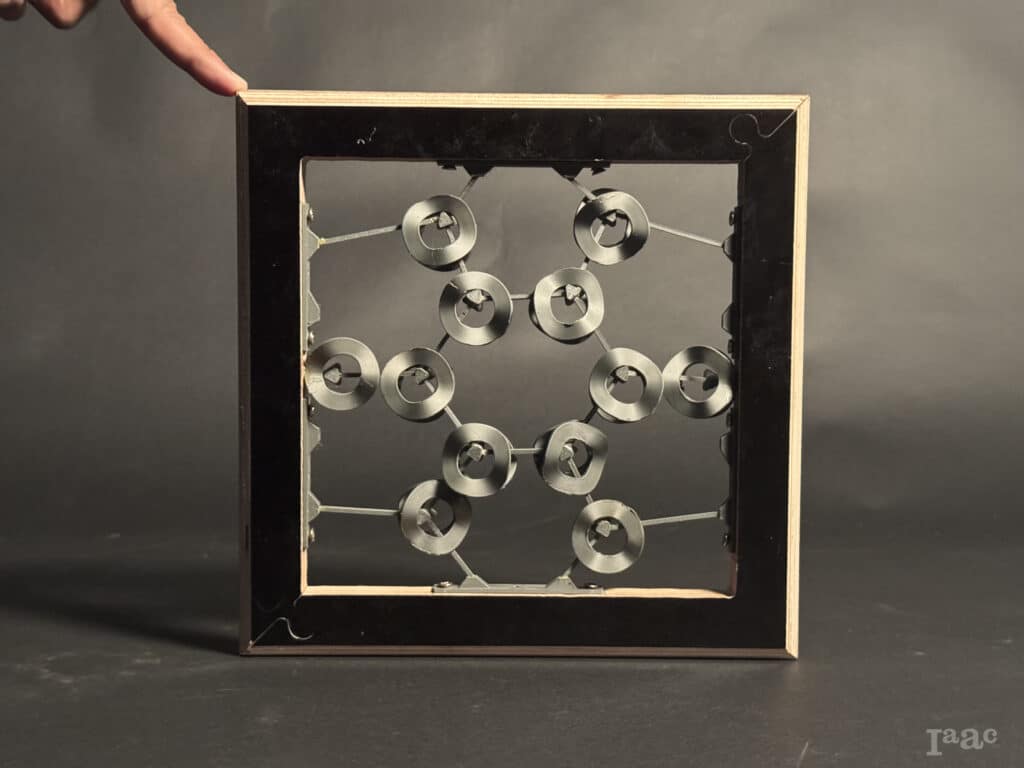

Spunaxis

Rotating interactive façade system

The design was crafted keeping in mind the interactive feature of rotating the individual disks on the axis. and the design when put together is joined between the gap of the biggest and smallest disk.

Render to protype the design by putting them on a office building façade

CNC Milling

CNC milling opens the door to robust, three-dimensional components where material depth and surface quality play a central role. As designers work with this method, they begin to recognize how tool paths influence the character of the geometry—contours, grooves, and textures are not just technical outputs but expressive qualities. Choosing the right bit, refining step-down values, or rethinking how a form should be oriented on the bed subtly influences the prototype’s accuracy and finish. Over time, the machine encourages a deeper appreciation for material behavior, structural logic, and the craftsmanship embedded in subtractive fabrication.

Mandala

Nine segmental design façade

Robotics

Robotic fabrication introduces a unique sense of spatial freedom. With multiple axes and customizable end effectors, ideas can evolve into dynamic toolpaths and experimental material processes. Working with robotics often invites a closer relationship with movement—how the arm approaches a surface, how it transitions between points, and how the end effector responds to the material. Through each prototype, designers gradually fine-tune their strategies, exploring calibration, adaptive toolpath design, and new opportunities that emerge from multi-directional fabrication. The robot becomes not just a tool but a collaborator in shaping form.

Clay-Pot

Digital fabrication does not replace architecture’s traditions; instead, it expands them. It opens pathways where form is informed by performance, where materials are used with greater efficiency, and where experimentation becomes a fundamental part of shaping the built environment. This shift signals a future where architecture is not merely drawn or modeled, but digitally crafted, layer by layer, cut by cut, path by path.