Our collaborative design project kicked off for Máquina Climática Exhibition based on farming and harvesting local varieties of fruits and vegetables which will be held at the greenhouse in Parque de la Ciutadella, Catalonia. The exhibition focused on urban food production, requiring tables and chairs for hosting various activities like workshops and dining. Our goal was to use wood as a natural building material, and its unique aspect was that all the wood we used came from trees we personally harvested during the course ‘Forest Management’ in Vallduara, from the Collserola Natural Park, north of Barcelona.

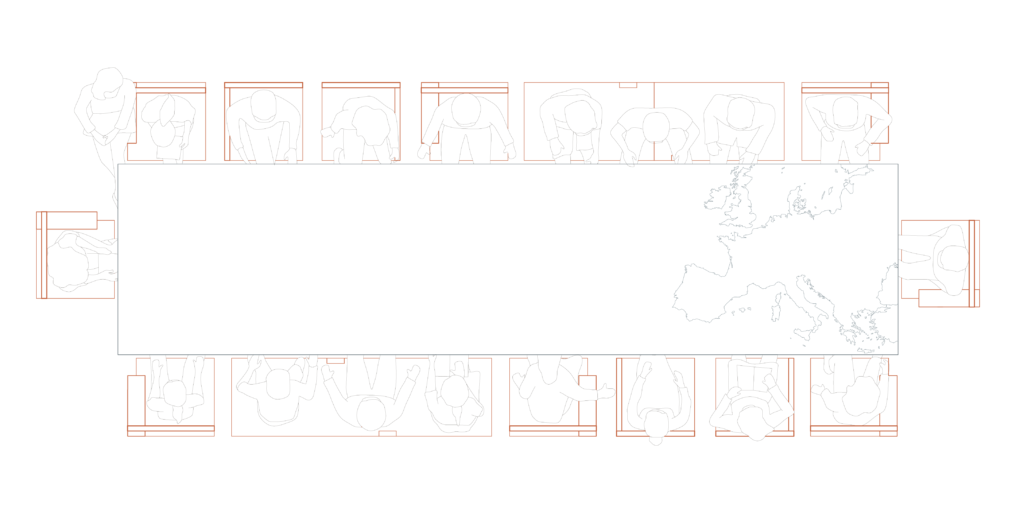

Our team consisted of four individuals from different parts of the world- India, Brazil, Ethiopia, and Iran. We also collaborated with other groups/ teams working on furniture such as shelve, table, armchair, and farming for the exhibition in the greenhouse. Our primary focus was on creating a cohesive design for tables and chairs, as these elements would be used together most of the time.

Research and Inspiration

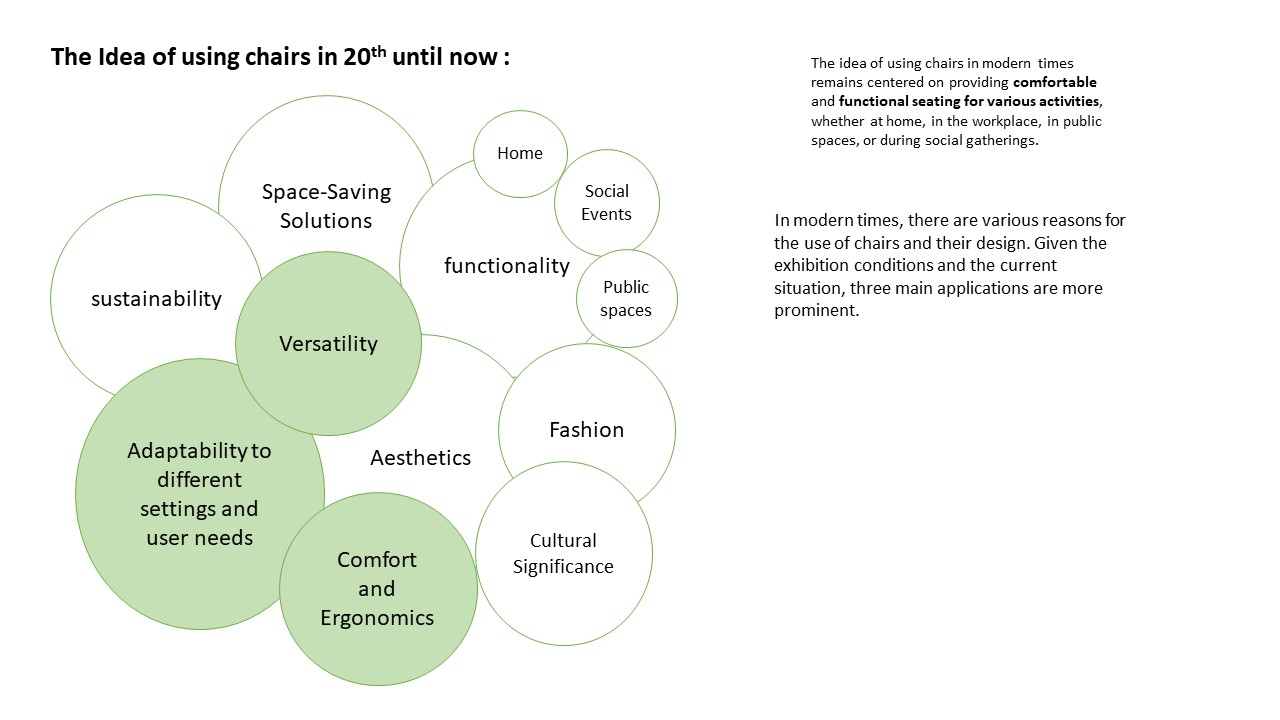

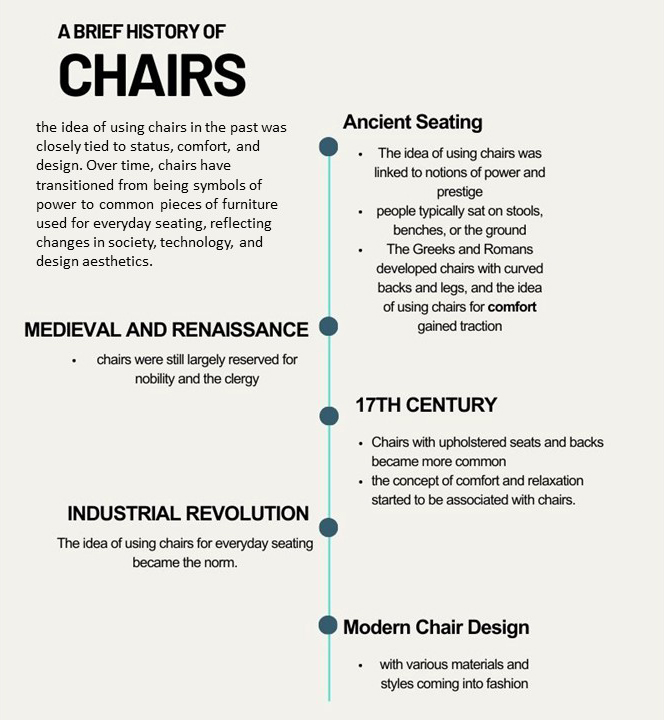

To start off, we started our research by exploring trough different books like “1000 Chairs” to gather ideas and get inspired. Our focus was to understand the basic needs, functionalities and priorities of chairs. We then looked into the use and evolution of chairs though out history. To streamline our design process, we collaborated with the table team in order to understand the activities that will take place at the table, to further study how our chairs may be useful at the exhibition. Our key design drivers were then established: social contact, flexibility, mobility, and the bold use of natural materials. The ability of the chairs to adapt to various activities during the exhibition, and showcasing natural materials became a crucial aspect of our vision.

This research laid the foundation for our design decisions, ensuring that the final product would not only meet our functional requirements but also convey the aesthetics of natural wood harvested from the region, in the exhibition space.

Conceptualization

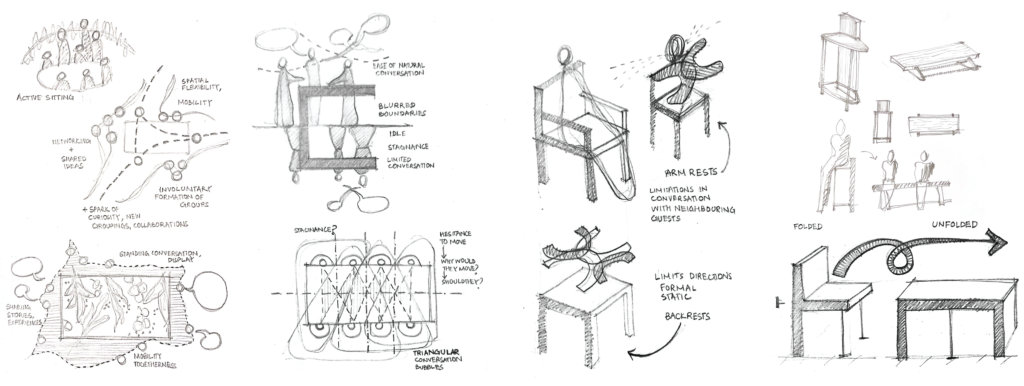

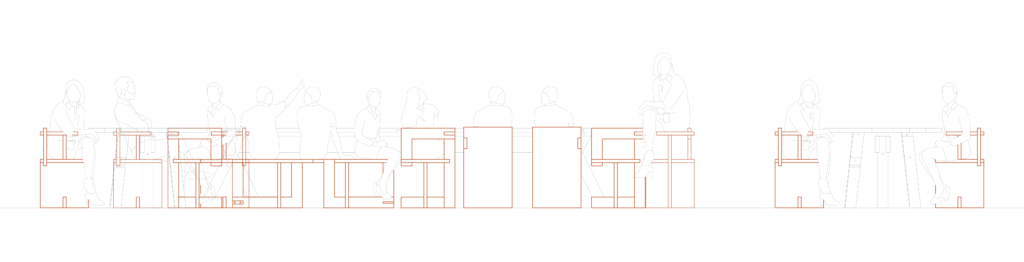

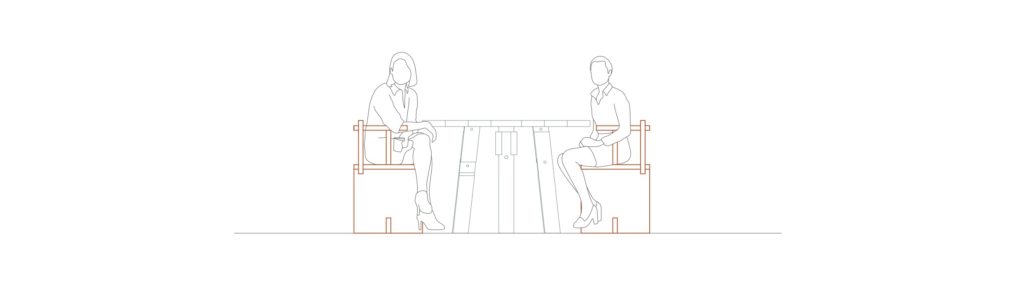

Moving into the conceptualization phase, our central idea revolved around flexibility and mobility. We envisioned chairs that could adapt to different needs seamlessly. “Furniture for situation” was another guide that we coined over this 3 month research and fabrication process. Our furniture aims to be adaptive to multiple situations. It is dynamic and multifunctional when compared to the traditional chair. Our design process involved creating several sketches. The core concept was to have two types of chairs—one with a single arm, encouraging others to join and engage in activities together. In a setting of strangers meeting for the first time in a workshop scenario, it is this type of candid conversation that leaves lasting memories. At the last moment as the conversation is almost coming to an end, and the guests are ready to leave, they lean against the chair to give the conversation another few minutes.

Additionally, we designed reversible chairs to maximize space and offer extra capacity as needed. This concept aimed to not only provide functional solutions but also to create an inviting and dynamic environment within the exhibition space. These chairs transform themselves from being able to seat 2 people in chair position, to having a capacity of 3-4 people in bench position.

Turn over chair transformation

Design Development

In the design phase, we transitioned to using solid woods and focused on creating robust joints to enhance the strength of the chairs. The joint system we employed was intricate—each piece securely interlocked with others, preventing movement in different axes. This ensured the stability and durability of our chairs.

For the foldable chairs transforming into benches, we implemented a joint on top of each chair, allowing them to connect seamlessly when needed. However, the design posed challenges as we were unsure of potential weaknesses. To address this, we embarked on fabricating a series of prototypes. We created scaled-down versions of the entire design and individual chairs to thoroughly understand and test the strength of the joint system. This iterative process allowed us to refine and perfect the design, ensuring its structural integrity for various activities during the exhibition.

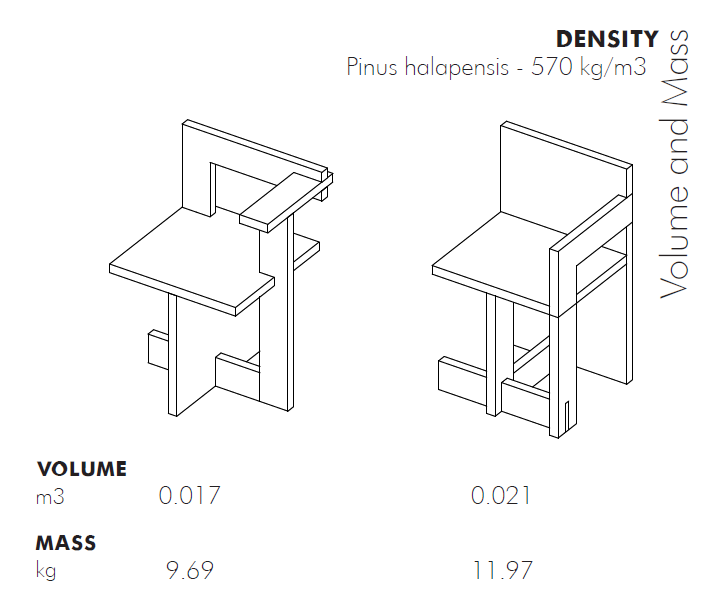

Having chairs that would be moved around to adapt to its function in alternate scenarios, it was imperative that we tested its ease of being handled by visitors. To acknowledge this, we performed some mass and density calculations digitally to ensure easy handling and mobility. We then weighed our prototypes manually and compared it with the calculated mass to find out that it weighed within the range of 9-11kgs. Since the average human can handle 16-25kgs effortlessly, we concluded that our chairs can be easily maneuvered by visitors.

Production

During the production phase, we faced a time crunch of 10 days after receiving the raw materials from the kiln, where our wood underwent drying. With a tight schedule, we swiftly moved into action.

The initial steps involved cutting the edges, segmenting the materials into smaller pieces, and meticulously planning the cuts. Due to the absence of large widths in the harvested timber bark, we had to carefully craft smaller parts for the seat and backrest. Surface planning was essential to ensure a smooth and uniform finish.

With the clock ticking, we had 5 days to produce and assemble the chair components. This posed a significant challenge, but we optimized our process using the CNC, table saws and bend saws. While the assembly involved the use of dowels and creating stable connections between the parts.

To maintain consistency, each chair’s parts were produced in series. This method ensured that every chair had identical dimensions and maintained a cohesive design. In total, we aimed to fabricate 16 chairs—8 armchairs and 8 benches, further divided into 4 left-arm and 4 right-arm variations for each group. This demanding production schedule required precision, teamwork, and efficient use of technology to bring our design to life within the limited timeframe.

Reflection and Lessons Learned

Our collaborative design project for the Máquina Climática Exhibition in Barcelona was a dynamic journey filled with lessons:

- Diversity Sparks Creativity: Our international team’s diverse backgrounds enriched the creative process, infusing global perspectives into our design.

- Research Guides Success: Thorough research, inspired by sources like “1000 Chairs,” laid the foundation for a design that not only met functional needs but also aligned with the exhibition theme.

- Conceptualization Drives Coherence: Focusing on flexibility and mobility during conceptualization ensured our chairs seamlessly adapted to various exhibition activities, enhancing both function and aesthetics.

- Prototyping Strengthens Design: Facing challenges during design development, iterative prototyping proved crucial. Scaling down and testing prototypes improved the robustness of our design, especially for foldable chairs.

- Efficient Production Requires Precision: In the time-sensitive production phase, leveraging technology and teamwork streamlined processes. Precision, especially with CNC table saws, ensured consistent and cohesive chair production.

In summary, our collaborative effort not only delivered functional furniture for the exhibition but also provided a platform for personal and professional growth, showcasing the power of diverse perspectives and effective collaboration in design success.