Balances Structures uses the ABB robot to develop a column through a pick-and-place strategy. Pushing robotic precision to its limits and minimizing human error, this project showcases how a structure in a state of delicate balance can be produced. The balance of the column was showcased not only through the placement of the structure on very small surface areas, but also through protruding and twisting elements.

Goal:

- To achieve Balance

- To push limitations through Precision

Overview:

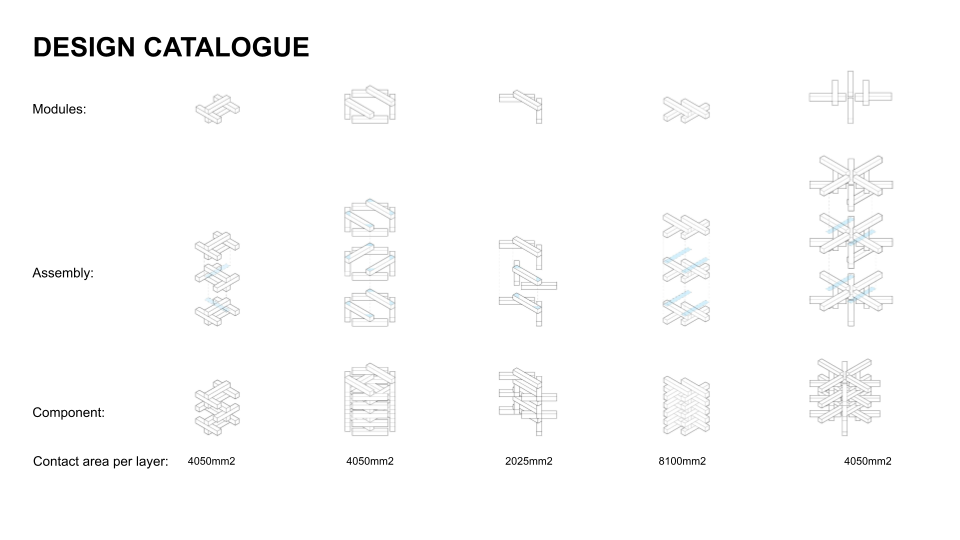

This project aimed to usher architectural design and construction into the automation era via robotic timber assembly;

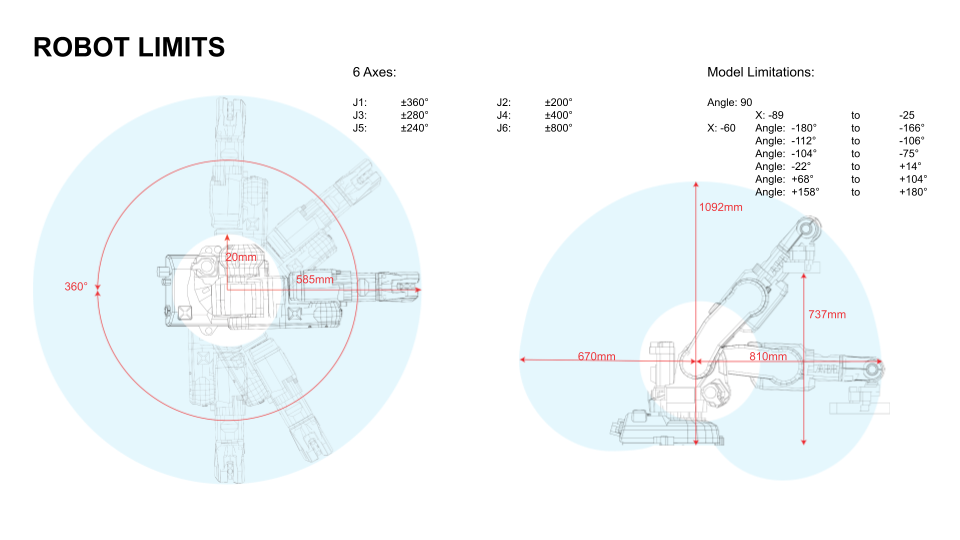

- Using ‘pick and place’ method with ABB IRB 140 – 6 Axes Arm.

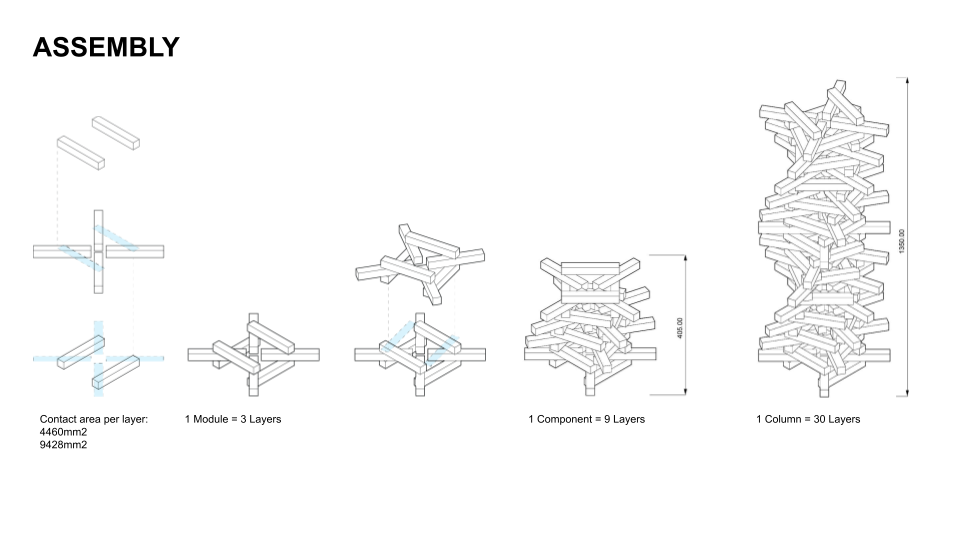

- Stacking timbers with a rotation in order to create columns.

Process

Construction Statistics

Robot settings:

- Picking Speed 40%

- Placing Speed 20 %

- Model Placement X -40mm

- Model Placement Y 100 mm

- Model Rotation 80 Degrees

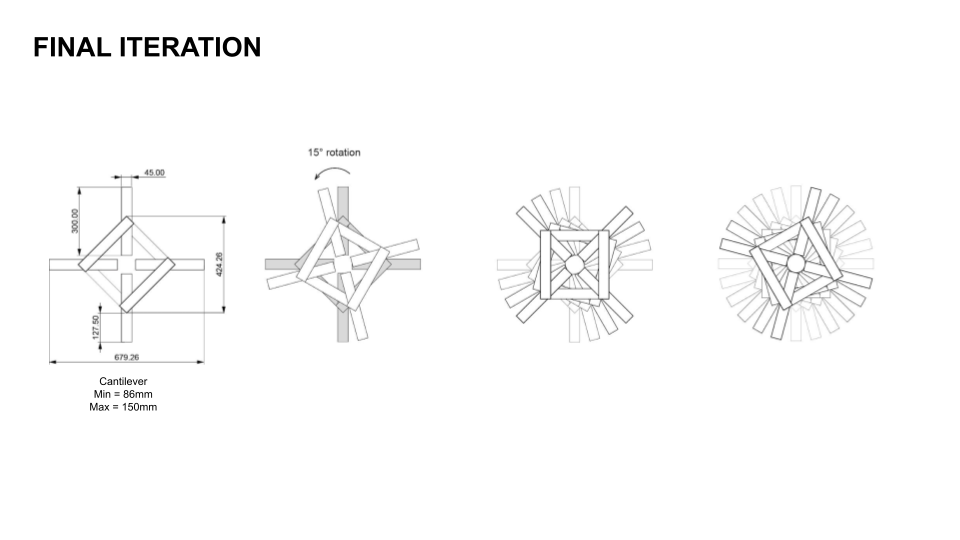

- Layer Rotation 15 Degrees

Construction Material Status:

- Stick Size 45mm x 45mm x 300mm

- Stick Numbers in each Module 24

- Height of each Module H: 405mm W: 680mm x 680mm

- Gluing time 5 minutes

General Statistics:

- Construction Time (for each module) 48 minutes

- Total height of the Model H: 1350mm W: 680mm x 680mm

- Total Construction Time 2hours and 40 minutes