The excitement was immense after nearly two weeks of living in Valldaura, as we were finally about to use the Fablab and all its machines. However, the excitement dimmed slightly when we learned that the CNC machine wouldn’t be operational for at least a month. This meant we wouldn’t be able to produce our stool assignment (if it required CNC work) during the first term.

Seeing this as an opportunity, I decided to explore the materials available around Valldaura and experiment with techniques to creatively utilize the other machines in a more “advanced” way.

For the stool, I chose to work exclusively with branches and offcuts from the trees we harvested—and I’m still pursuing this approach. I collect the best branches, scrape off their bark, 3D scan them for digital manipulation in Rhino, and then use the CNC (when available) to shape an offcut plank from the sawmill. This process allows the individual branches to become the stool’s legs.

This project might become an all year thing, since the time here is very limited and most of our “Design and Fabrication” time whent into CDS prototypes.

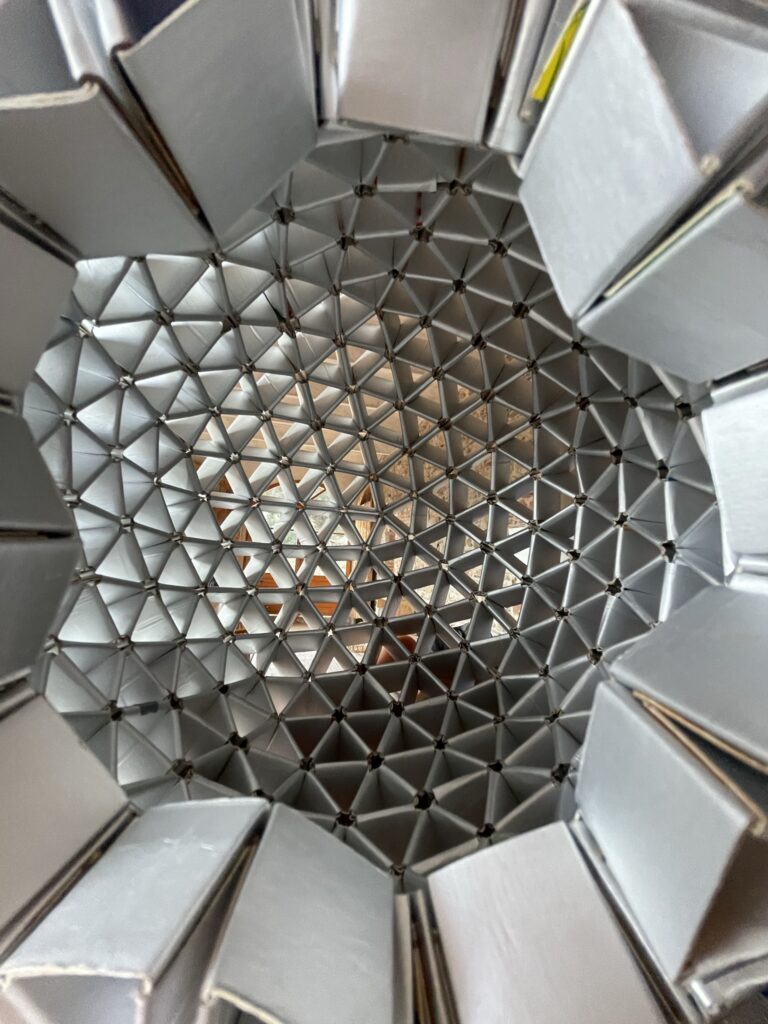

A side project that emerged was creating a lampshade from recycled Tetra Paks, inspired by a DIY tutorial I found on YouTube. The laser cutting process turned out to be a significant upgrade to the original method.

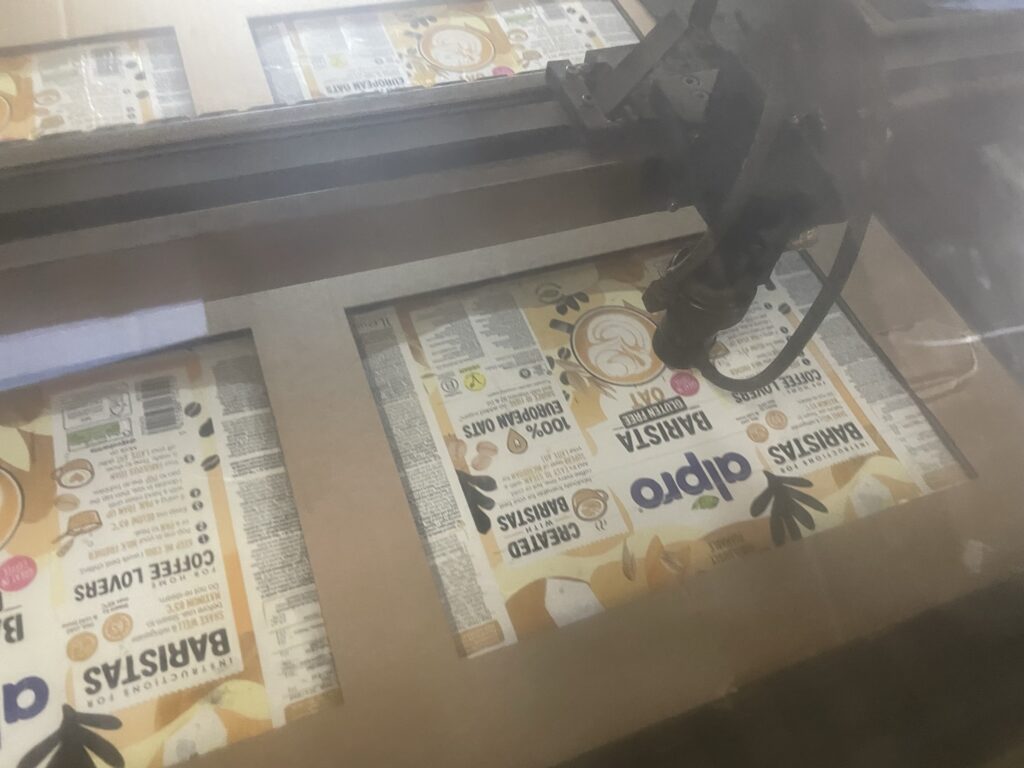

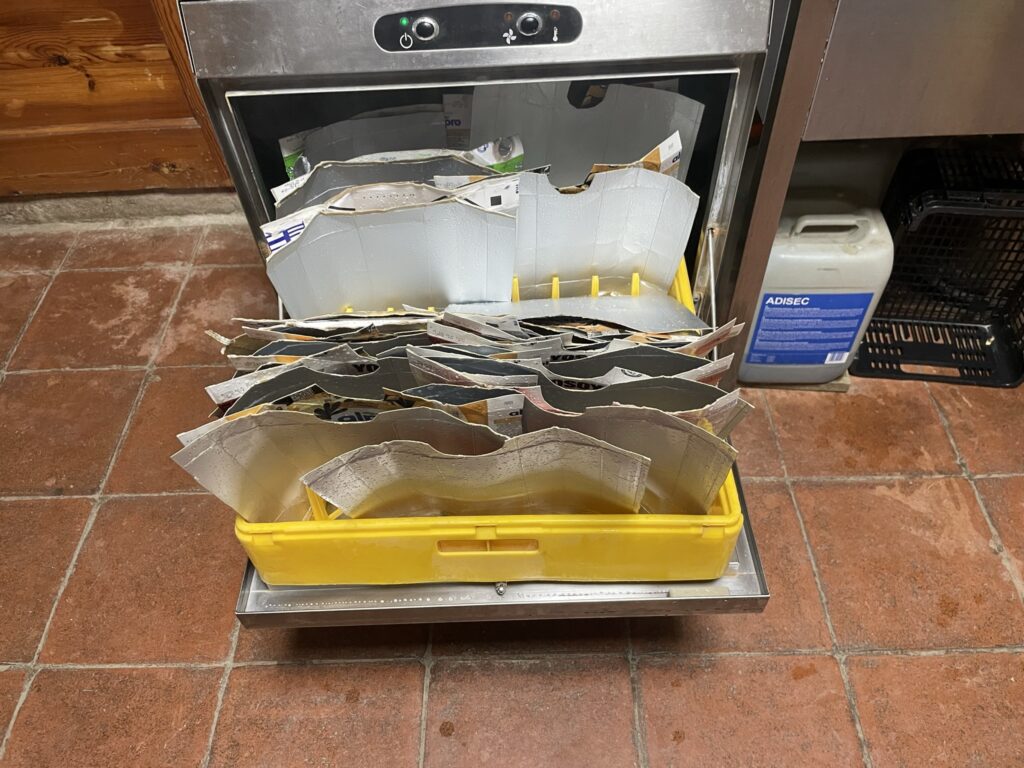

I collected empty milk cartons from Valldaura and Barcelona, washed and pressed them, and then used the laser cutter to engrave cutting guides and fold lines.

109 Tetra Paks ended up beeing 725 pieces that made a robust Hexagon Sphere which serves now as a lampsade in our common toilets.

To be continued