This term, we explored three fabrication techniques: CNC Milling, Laser Cutting, and 3D Printing. Our objective was to create complex geometries while investigating the unique properties of each method. Through this investigation, we aimed to demonstrate how different shapes can be produced using various machines and techniques, thereby enhancing our understanding of advanced fabrication processes.

Concept

The design of the cabin draws inspiration from Slavic fairytales, presenting a modern take on Baba Yaga’s house, a well-known figure in Slavic folklore. Its light glass structure reflects the forest surroundings, creating an effect that makes the cabin appear to float on three “legs.” The wooden elements on the second floor reinforce the natural theme and harmonize with the intended environment.

Inspiration

Reference

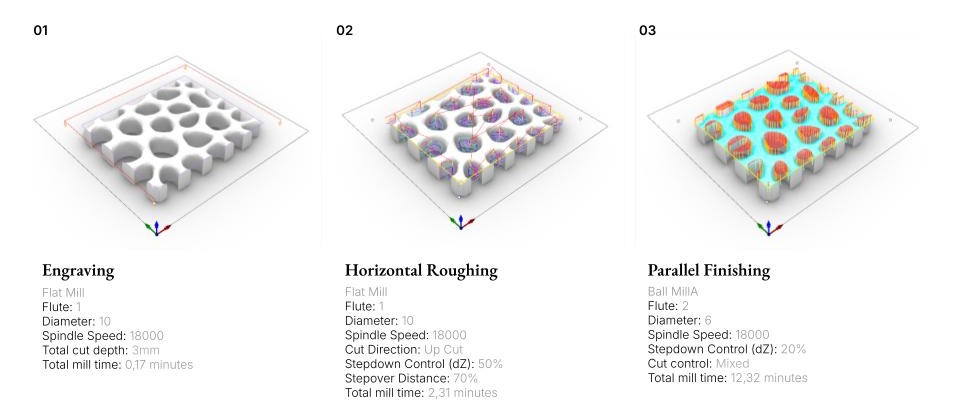

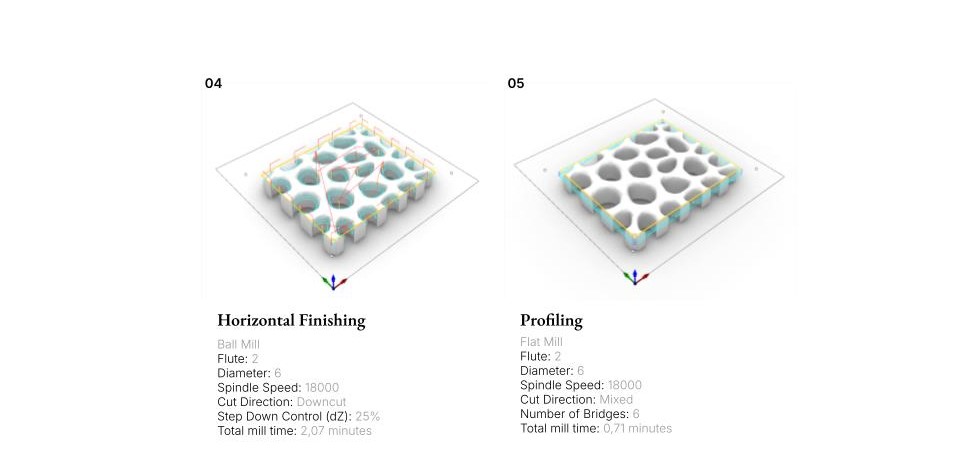

CNC Milling

The design intention was to create an architectural element featuring a Voronoi pattern using CNC milling, as we aimed for this element to be integrated into the overall design.

Parameters:

Material : 19mm ply

Machine : Raptor CNC

Post Processor : CNC_STEP_BCN RAPTOR

Workpiece volume : 180x150x9mm

Fabrication Strategy

Fabrication Process

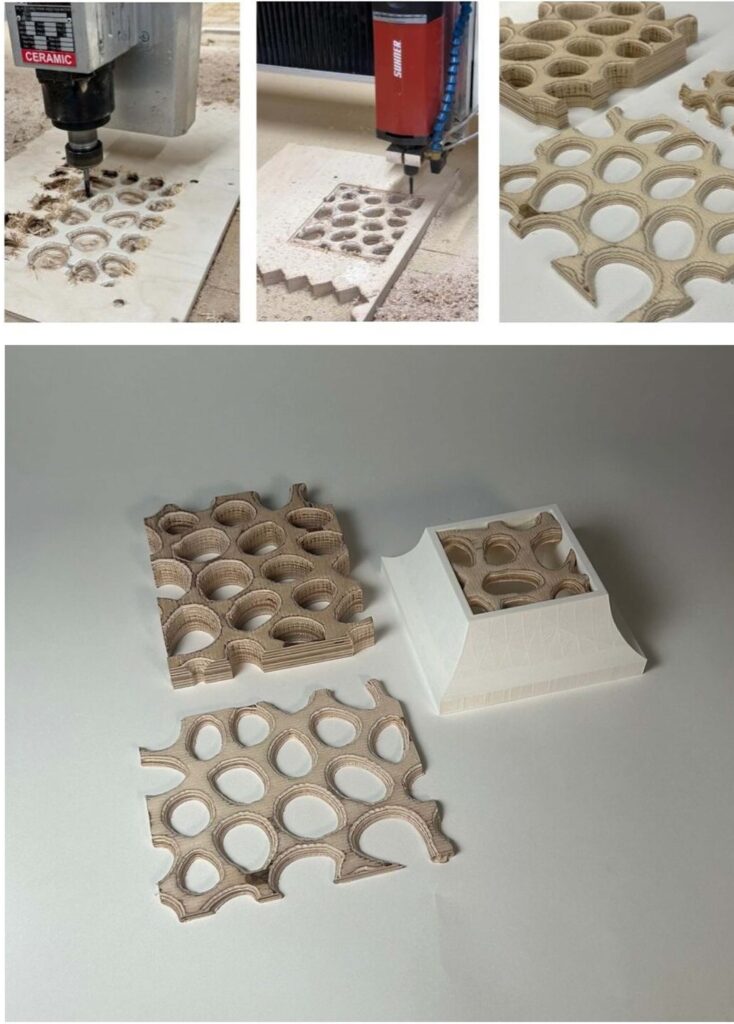

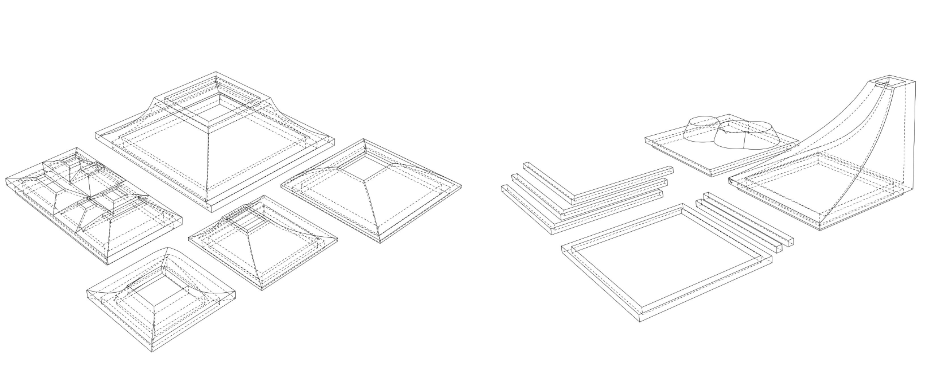

Laser Cutting

Laser cutting technology was employed in the design of architectural elements crafted from Medium Density Fiberboard, incorporating stacking techniques. This approach enhances both aesthetic and structural efficiency.

Parameters:

Material : Medium Density Fiberboard

Technique : Laser cutting

Joint type : Staking

Machine : Rayjet 500; bed size 1300x900mm (CO2)

Fabrication Strategy

Fabrication process

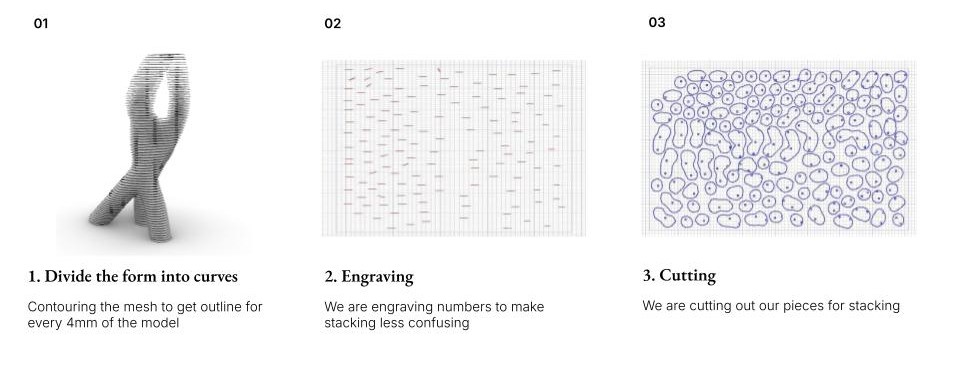

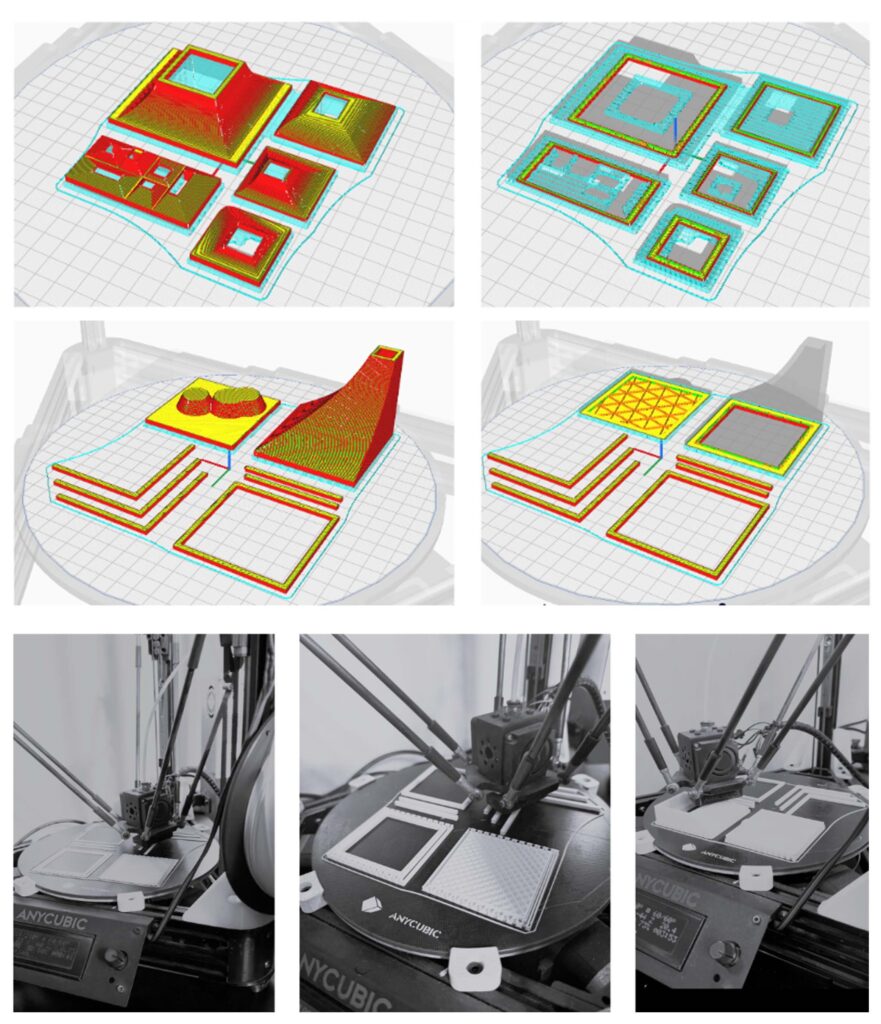

3d printing

3D printing technology was employed to fabricate the components of the structure. Each element was designed to facilitate both assembly and disassembly, resulting in a modular construction system.

Parameters:

Printer : Anycubic Kossel Linear Plus

Layer height : 0.3 mm

Wall Thickness : 0.8mm

Support Structure : Normal

Technical drawings

Fabrication process

Final Render