00- ABSTRACT

Digital fabrication is a design and manufacturing workflow where digital data directly drives manufacturing equipment to form various part geometries. This data comes from CAD (computer-aided design), which is then transferred to CAM (computer-aided manufacturing) software. This data directs a specific additive and subtractive manufacturing tool, such as a 3D printer, CNC milling machine and Laser Printing. The aim of this exercise is to learn these digital fabrication production techniques and design strategies within the capabilities and limitation of material and machine.

01- 3D PRINTING

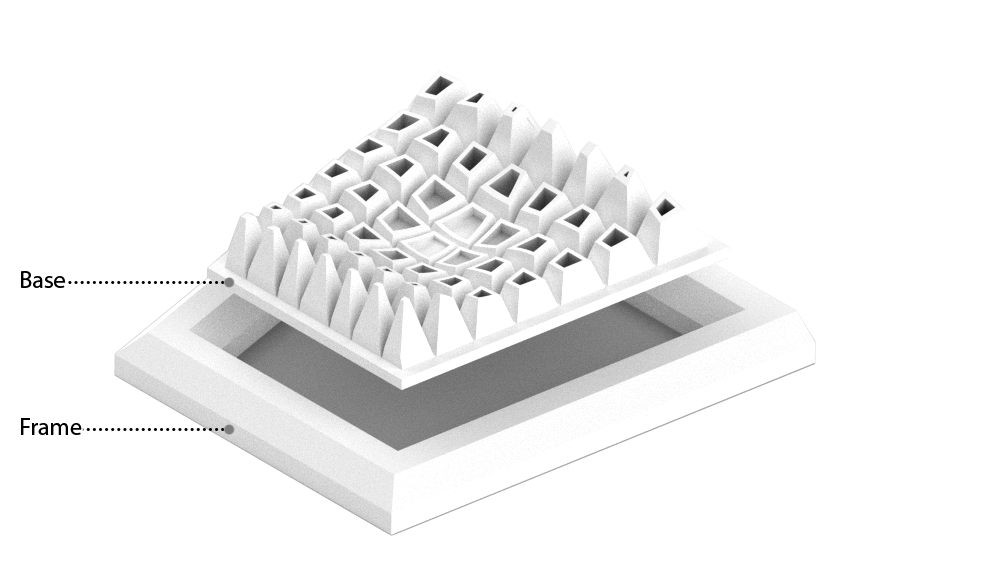

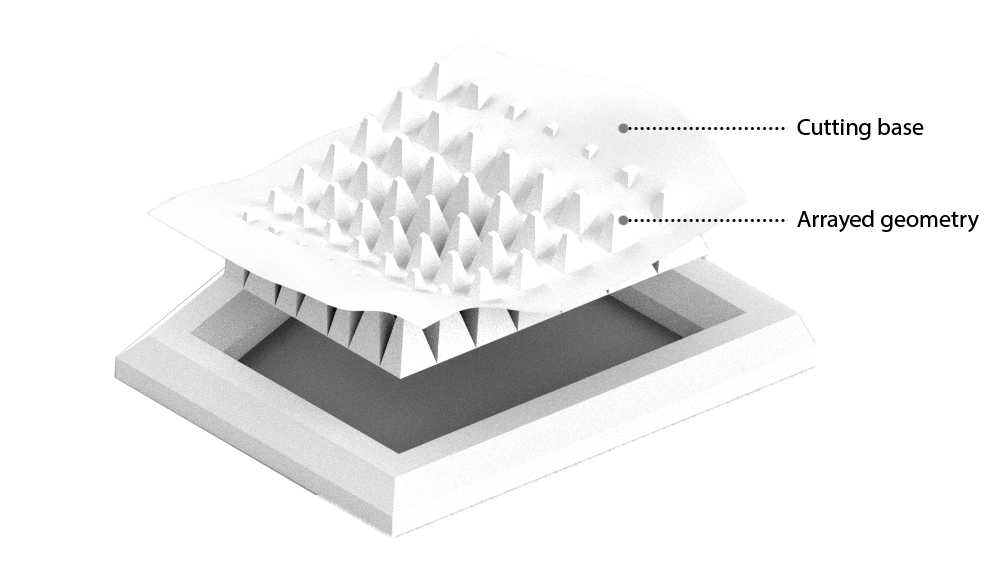

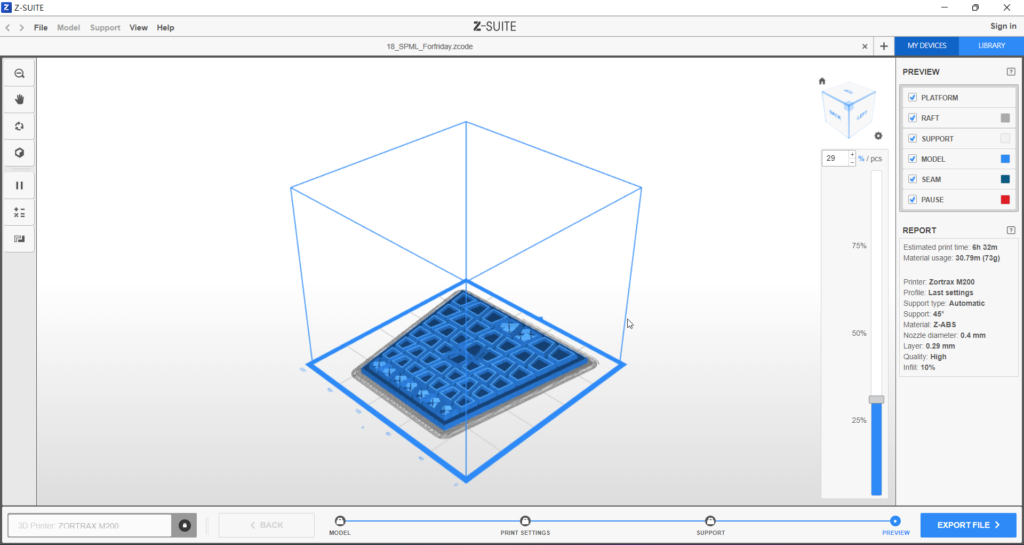

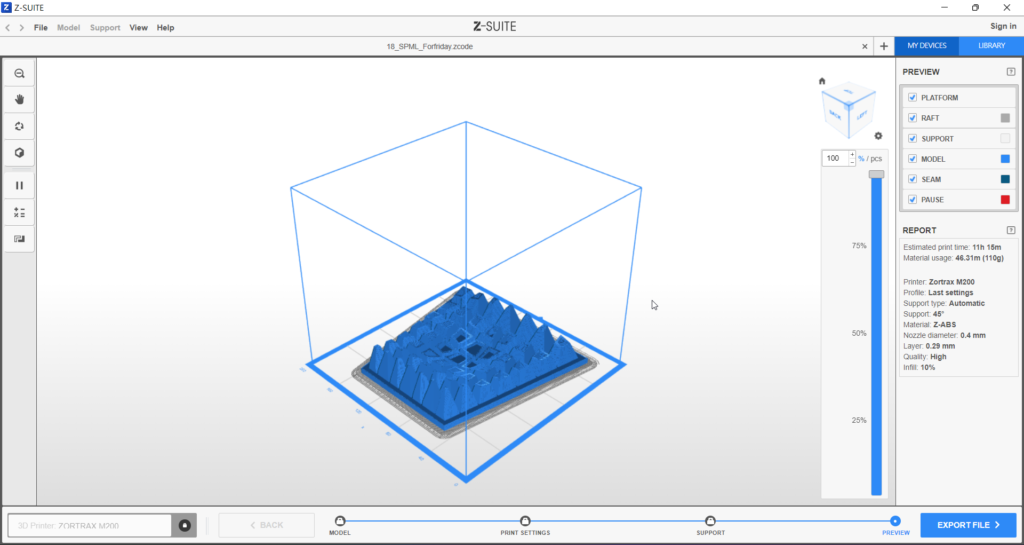

The aim of this exercise was to develop complex 3D printing components that will proliferate, and adjust CAM settings (in Z-Suite software) to optimise printing time, material usage and print quality.

The design is limited by a 1:1 Modul (155 x 165 mm) for a facade with Zortrax M200, 3D printer. Therefore, a total printing time of 10 hours was required.

For final Module, facade shading had to be taken into consideration.

Prospective Geometry

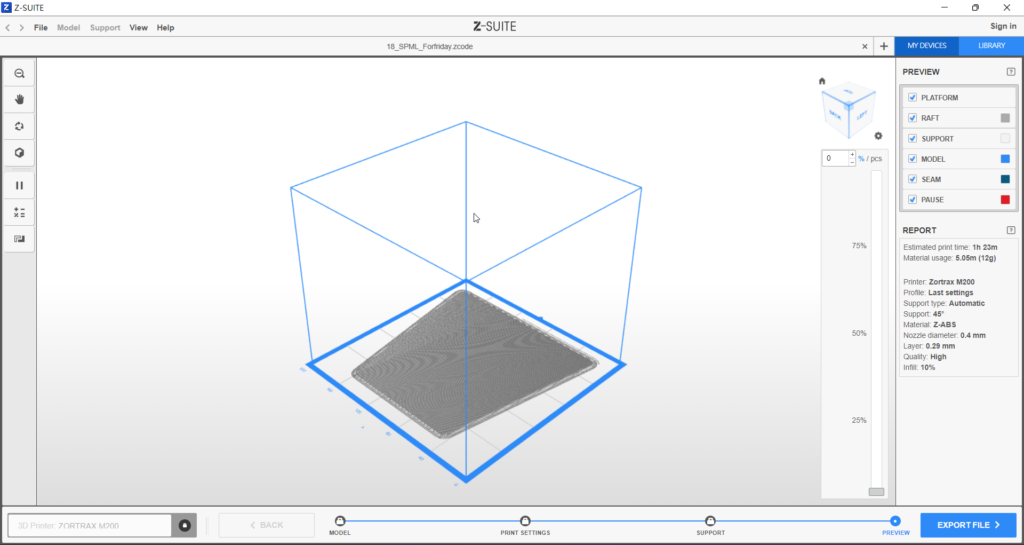

Z- Suite settings:

The base was given to connect to the wooden frame.

Give a base to prevent model move while printing.

Change the density to reduce time.

Printer: Zortex M200

Profile: Last settings

Support type: Automatic

Support: 45

Material: Z- ABS

Nozzle Diameter: 0.4mm

Layer: 0.29mm

Quality: High

In model we make each pyramid to become a shell to have a aesthetic final outcome.

An overall dynamic shape to create shading.

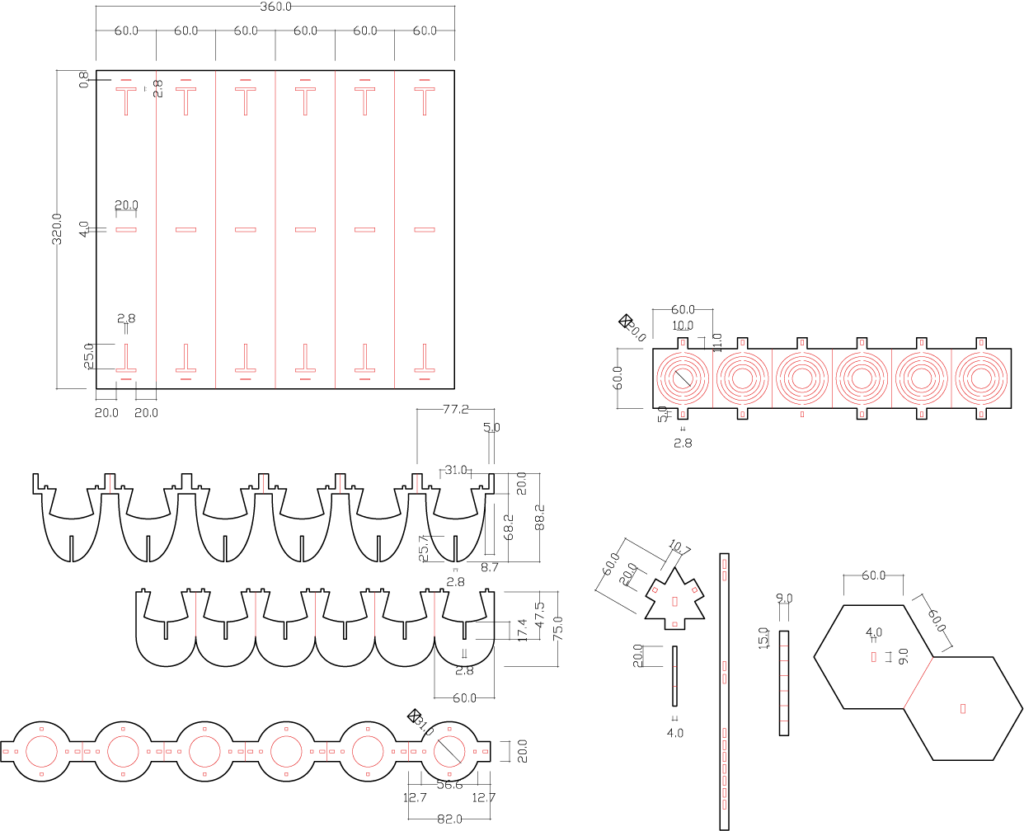

02- CNC MILLING

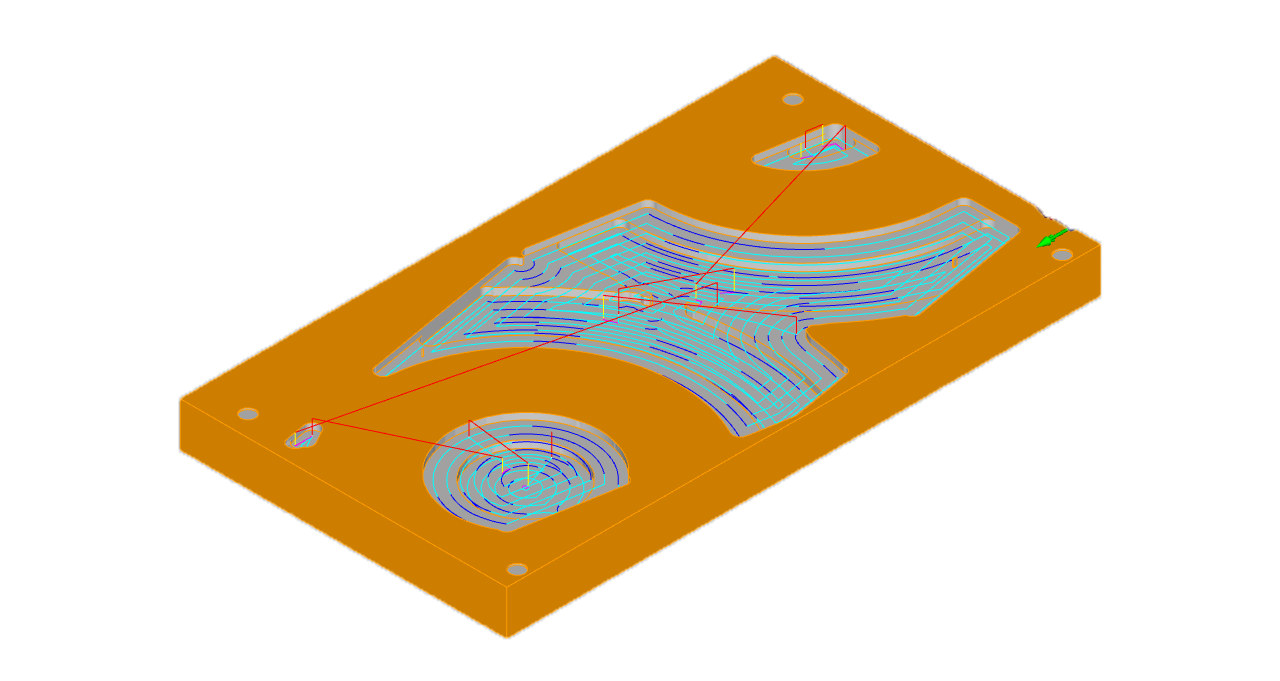

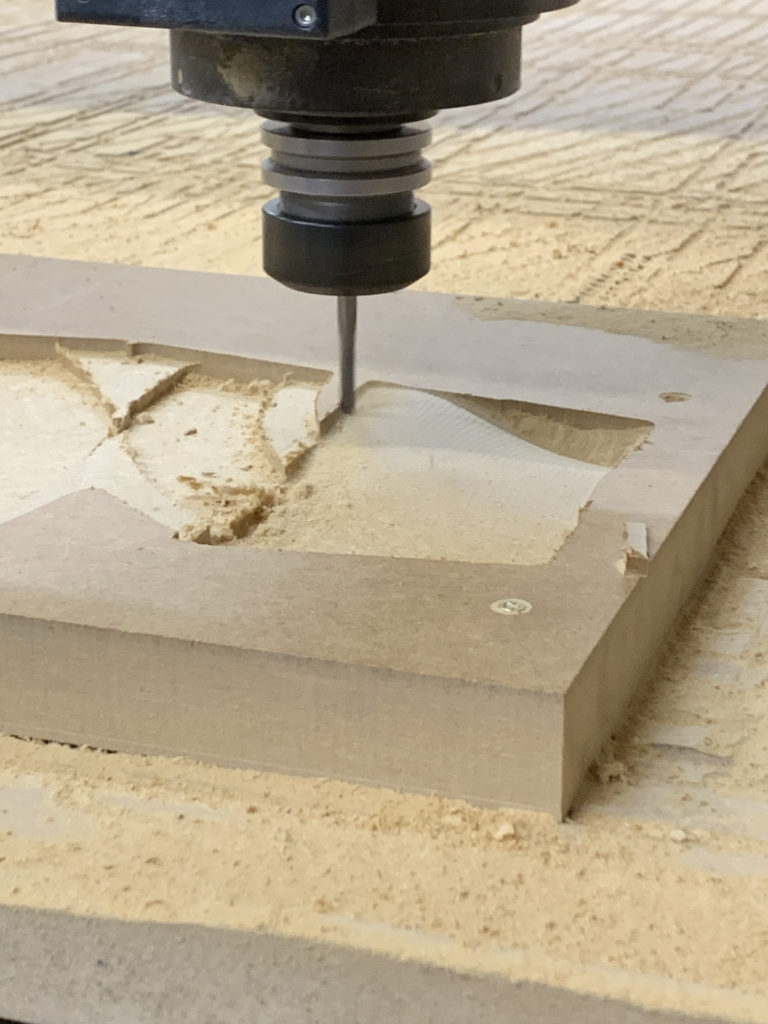

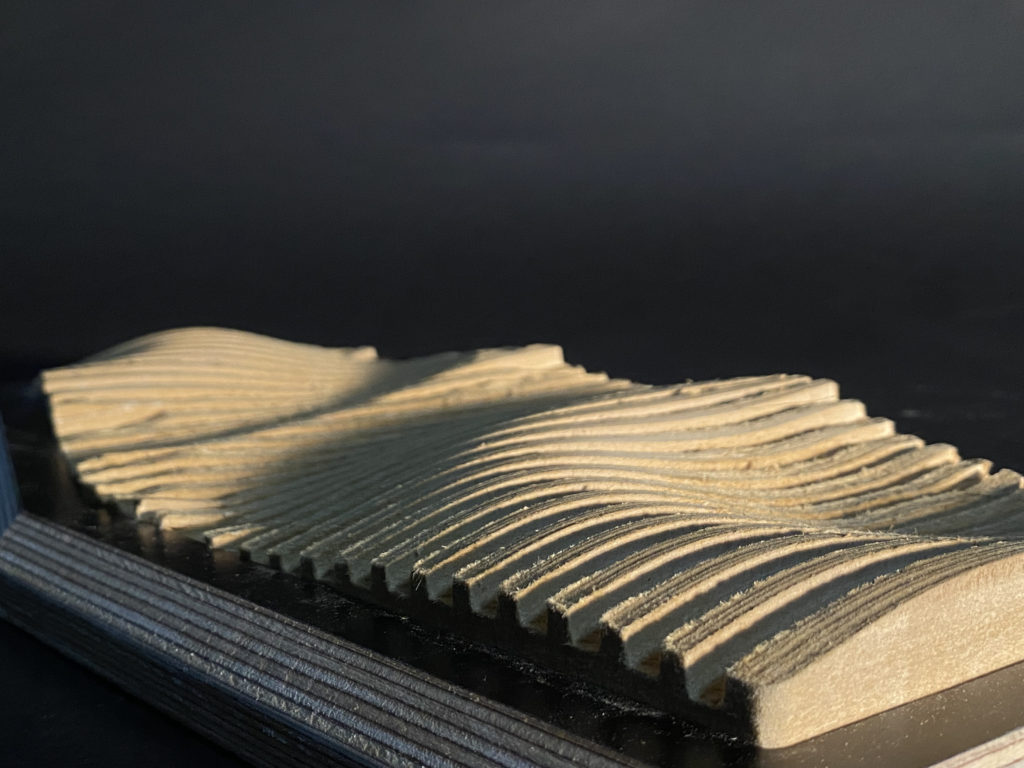

CNC machining is a subtractive manufacturing technology: parts are created by removing material from a solid block using a variety of cutting tools. It produces high-accuracy parts with excellent physical properties directly from a CAD file with a high level of automation.

2022/ 10/ 10- 10/ 17

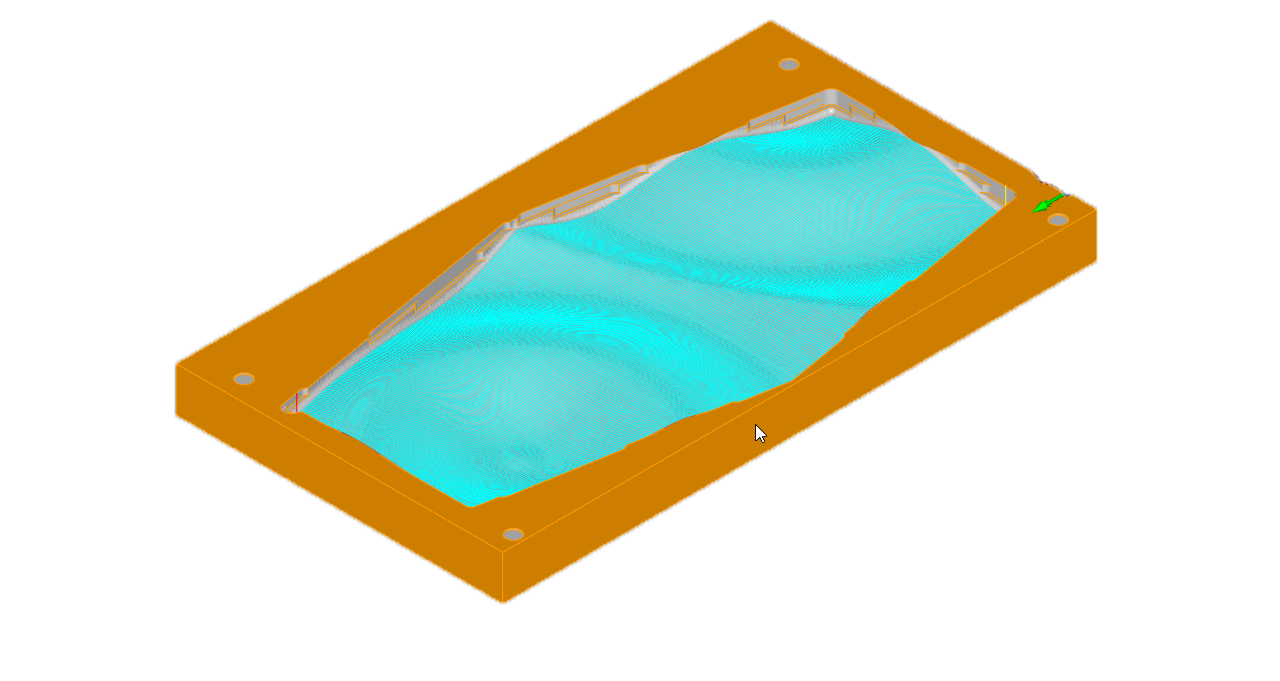

Prospective Geometry

Positioning and fixing the MDF slab by positioning screw.

Flat Mill

Flute: 30mm

Diameter: 10mm

Spindle Speed: 12000 rpm

Cut Direction: Downcut

Step Down Control (dZ): 60%

Stepover Distance: 70%

Total mill time: 4.13 min

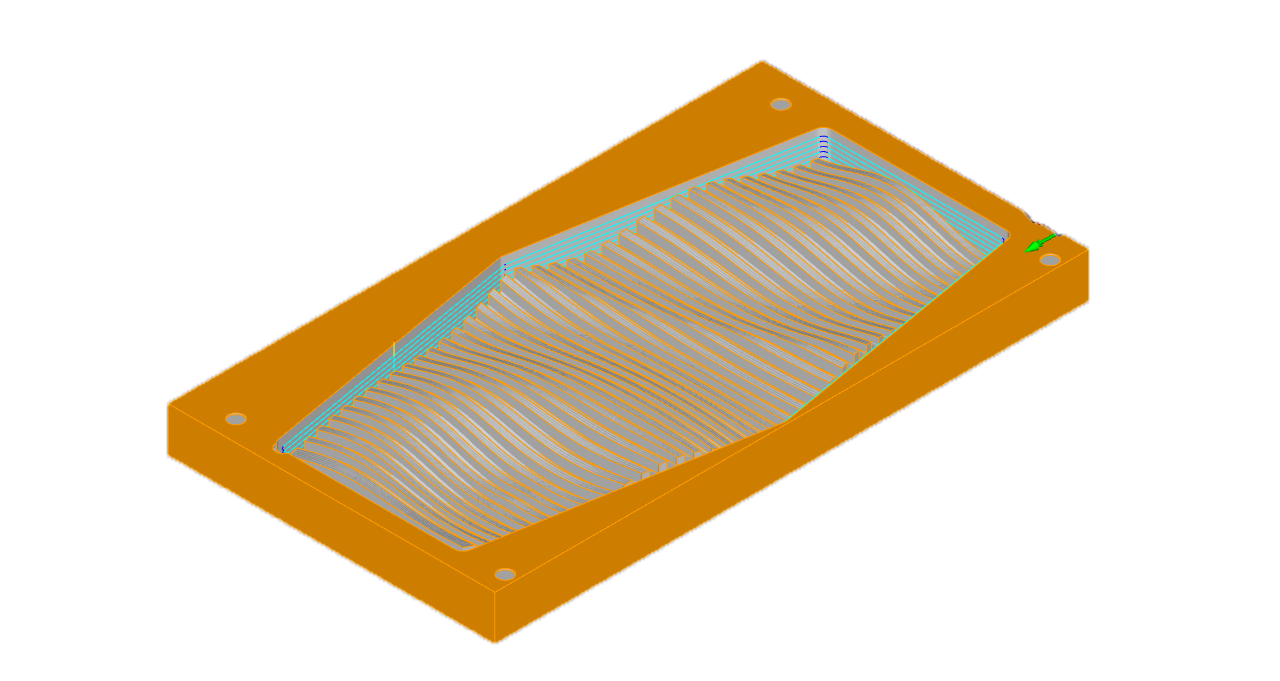

Ball Mill

Diameter: 6mm

Spindle Speed: 12000 rpm

Cut Direction: Mixed

Stepover Control: 20%

Total mill time: 22.81 minutes

Flat Mill

Diameter: 6mm

Spindle Speed: 12000 rpm

Cut Direction: Upcut

Total mill time: 4.97 minutes

Flat Mill

Diameter: 6mm

Spindle Speed: 12000 rpm

Cut Direction: Upcut

Depth Control :Total cut depth 5mm

Rough cut: 1mm

Finish depth 4mm

Total mill time: 10.31 minutes

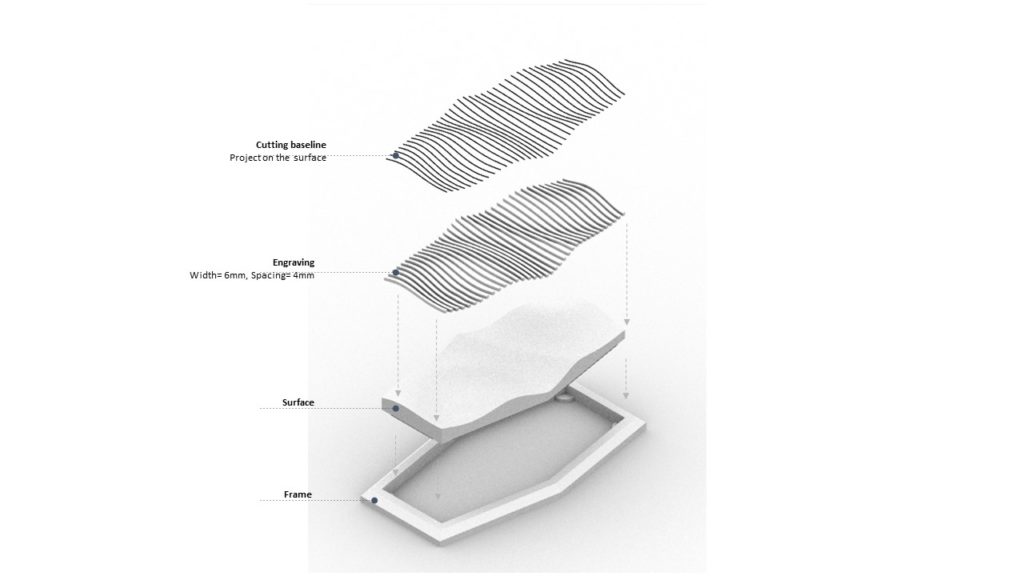

02- CNC MILLING

LASER CUTTING

2022/ 10/ 17- 10/ 24

Final structure render