Additive Manufacturing is the technology that builds 3D objects by adding layers of material on top of each other, whether the is clay, plastic, concrete etc. through various types of robotic technologies.

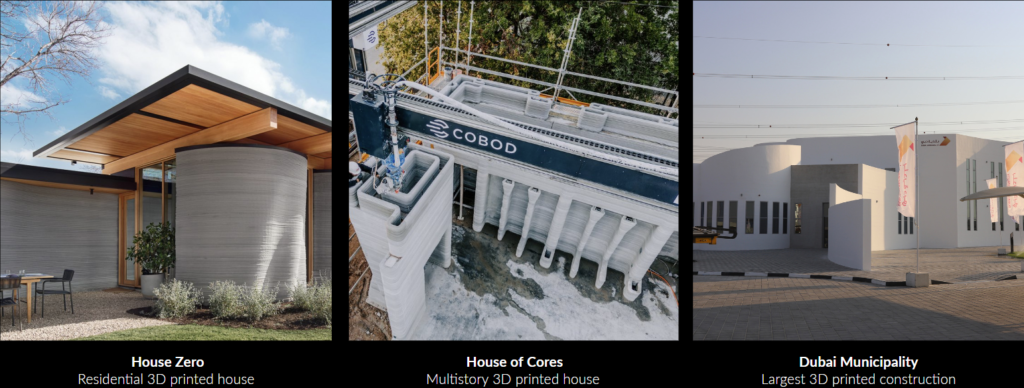

In recent years, there has been a growing interest in the additive manufacturing with concrete as it has shown potential advantages in comparison to traditional construction methods, such as better precision, faster construction times, and reduction in material waste, plus it allows to quickly create complex patterns and design possibilities with a high degree of accuracy and without the need of formwork.

Concrete has been used with this technology because of its great properties

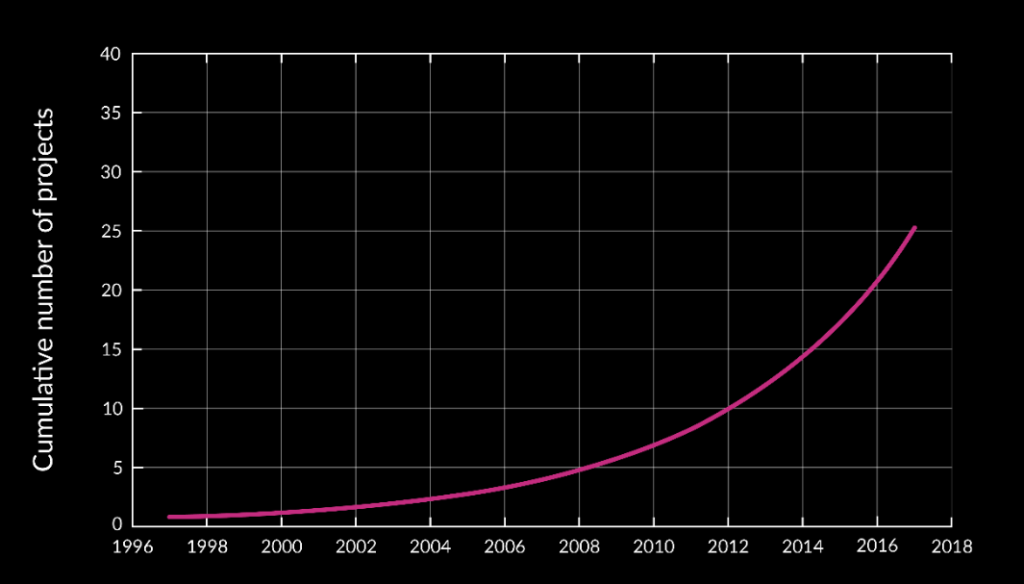

It is still a relatively new technology, but as it continues to develop, it is becoming becoming an important part of the construction industry.

As shown in this chart, the number of projects printed with concrete has been increasing exponentially over the past years.

Now a days, there are several large commercial 3D printed buildings with concrete, but most of them lack of aesthetics. They have flat walls, some of them are even plastered, hiding in a way the fact that is 3D printed.

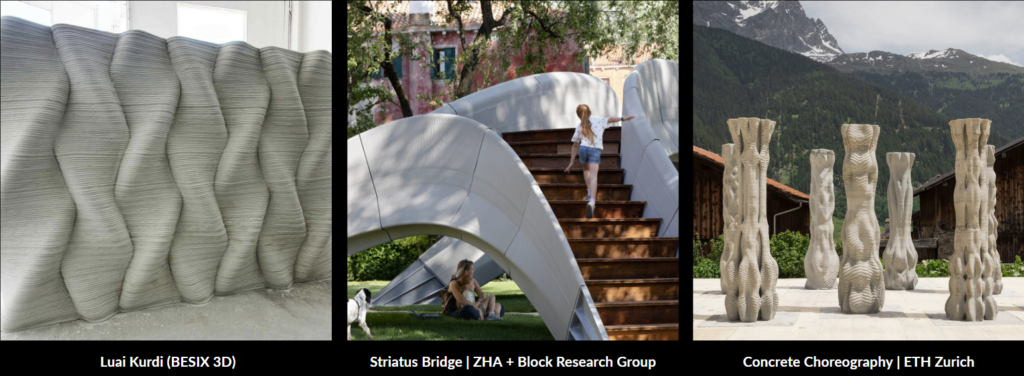

There are a lot of examples in small scale where we can see the degree of complexity 3DCP can achieve. But they are not connected to an identity or context.

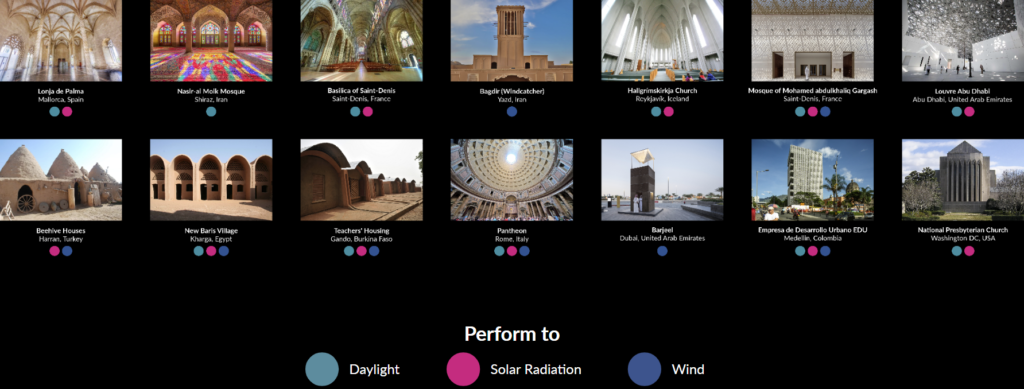

Heritage architecture is important for preserving cultural identity and architectural legacy. It represents a physical link to the past and provides an opportunity for future generations to learn from and appreciate the architecture of their ancestors.

There is an opportunity on using 3D concrete printing to achieve context specific aesthetics. Additive manufacturing in combination with digital design tools can be used to create customized ornamentation that is inspired by ancient architectural designs that reflect the cultural characteristics local communities.

STATE OF THE ART (Environment + Culture)

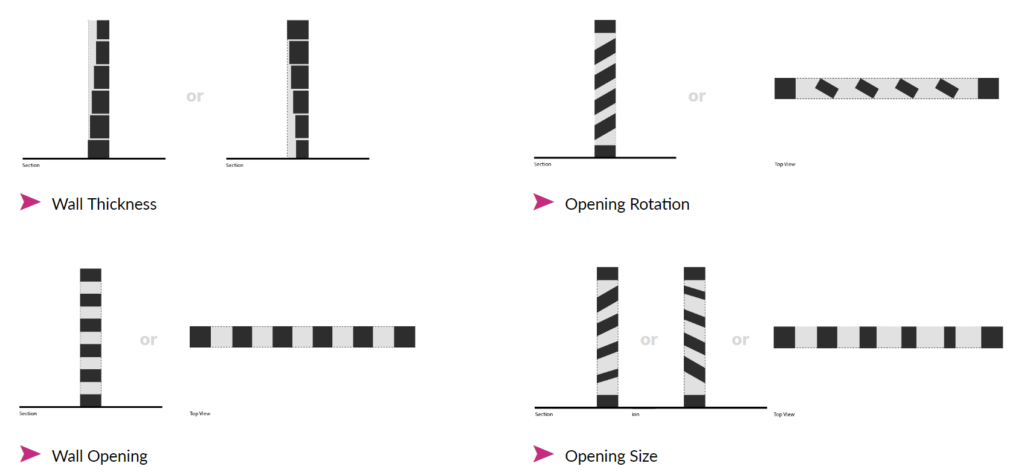

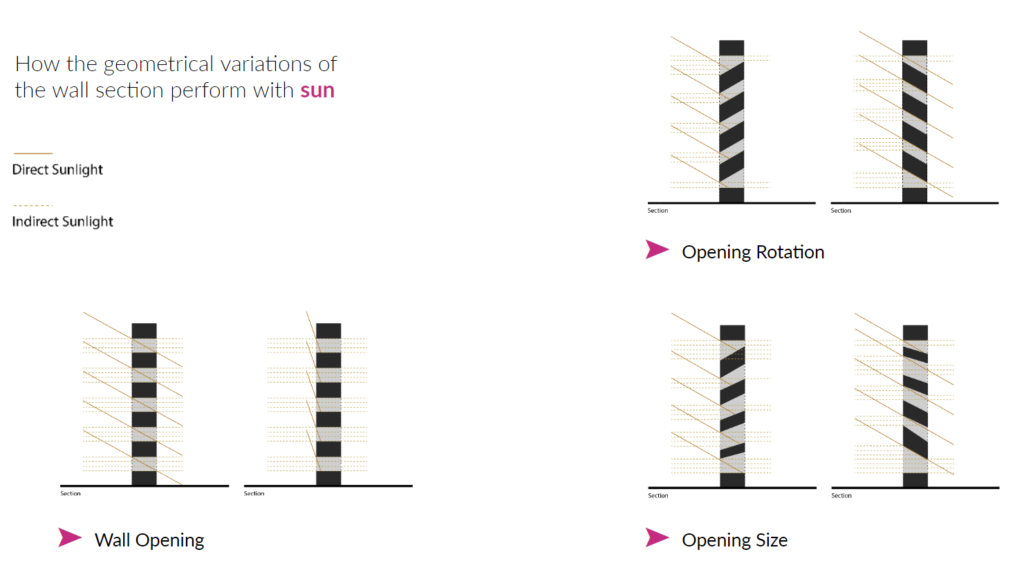

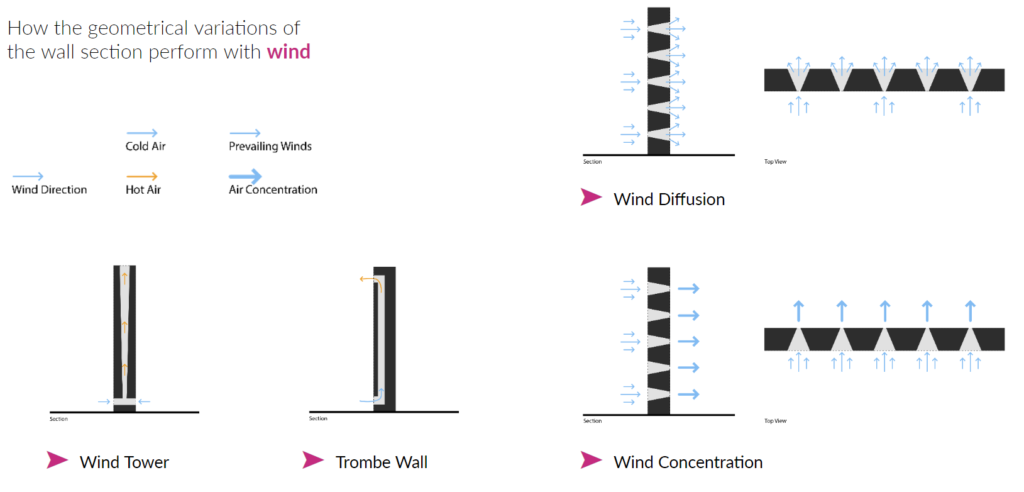

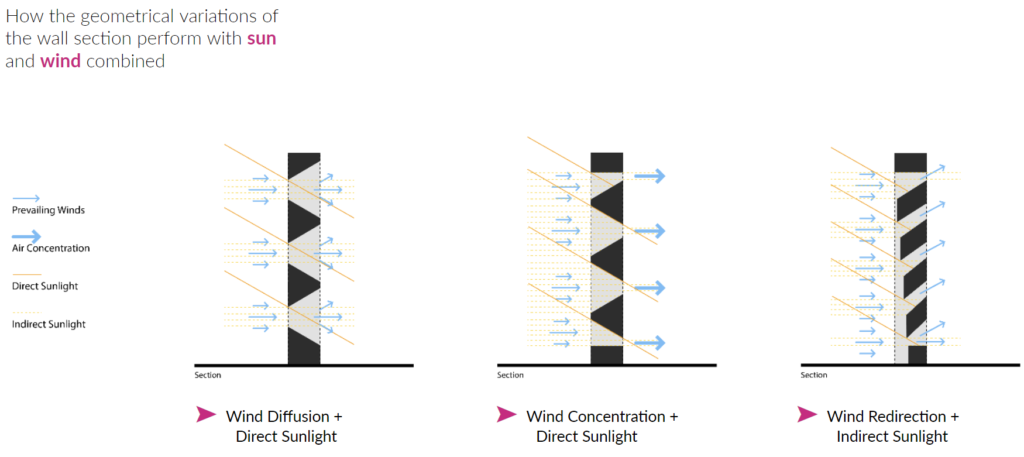

GEOMETRICAL VARIATIONS

PERFORMANCES

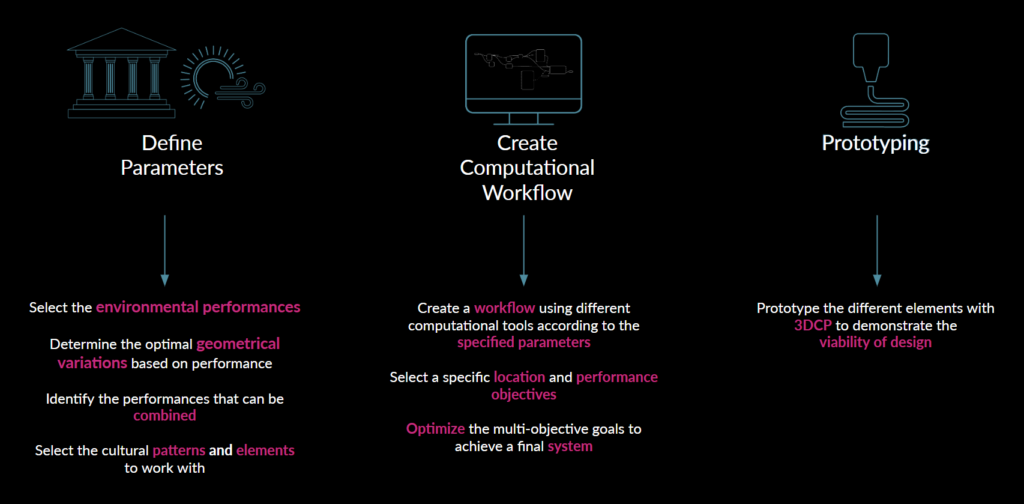

AIM

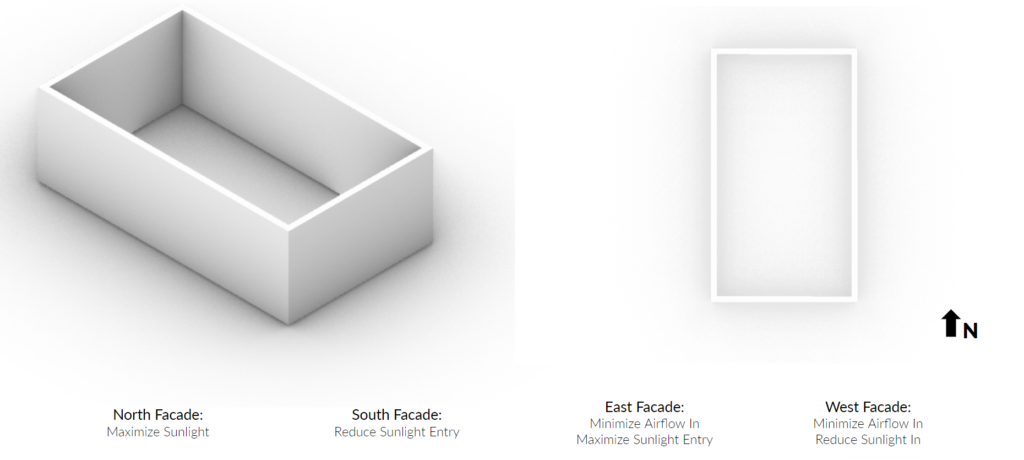

- Create a workflow using computational design processes for performative buildings using geometrical variations for wall openings using environmental data from solar radiation, daylight and wind analysis and combine them with tradition/culture patterns for aesthetics.

- Build a catalogue of complex pattern possibilities for different environmental conditions that can be applied into a specific location, using additive manufacturing with concrete to print prototypes.

OBJECTIVES

RESEARCH QUESTION

How can additive manufacturing applied in architectural construction produce aesthetically rich, culture driven complex geometries that are informed by environmental data to reduce operational carbon and that allow customization?

EXISTING BUILDING TO DIGITAL

NEW BUILDING USING CULTURAL CHARACTERISTICS

APPLIED INTO AN ENVELOPE

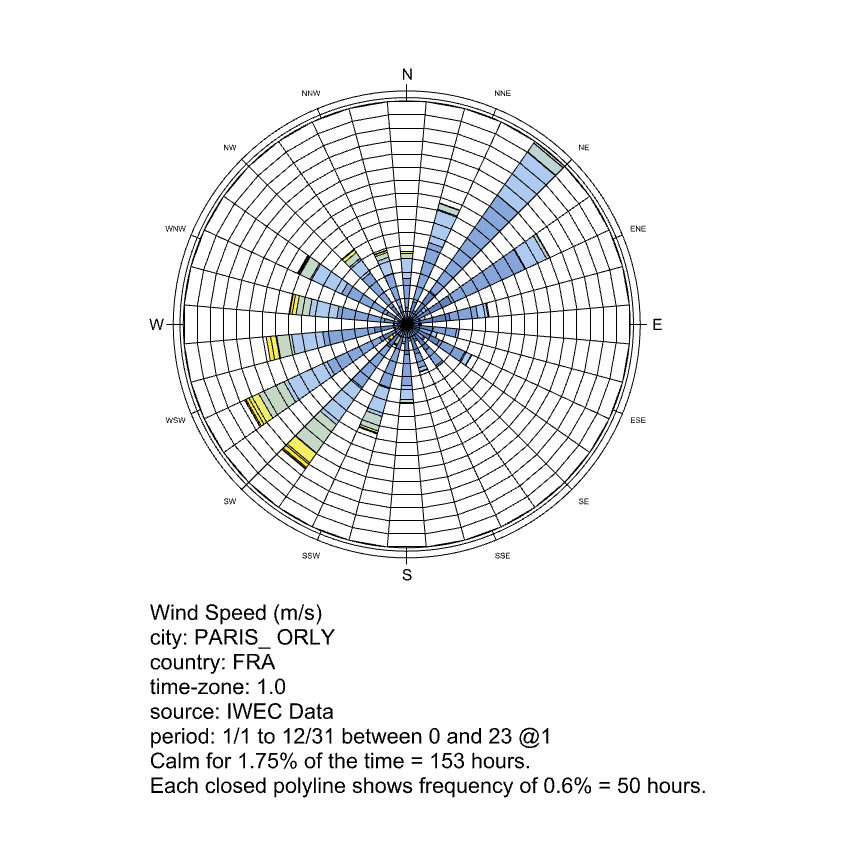

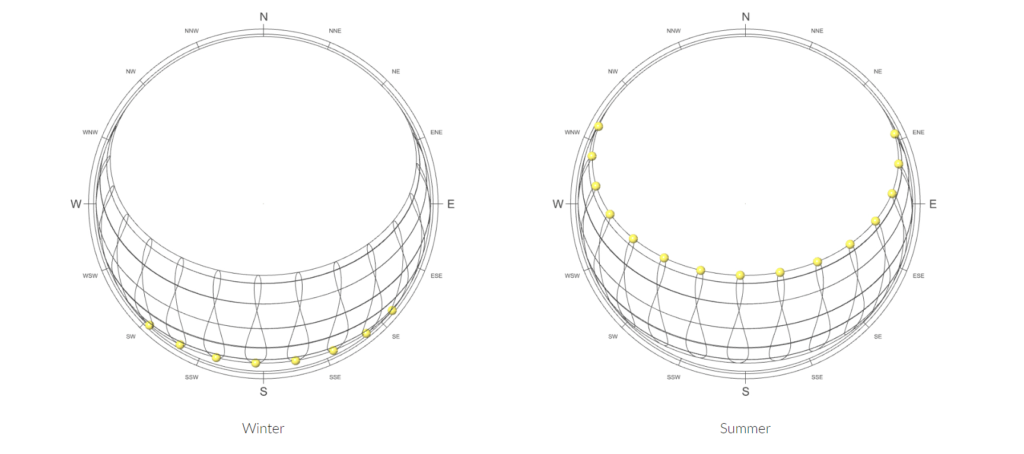

ENVIRONMENTAL ANALYSIS (Paris, France)