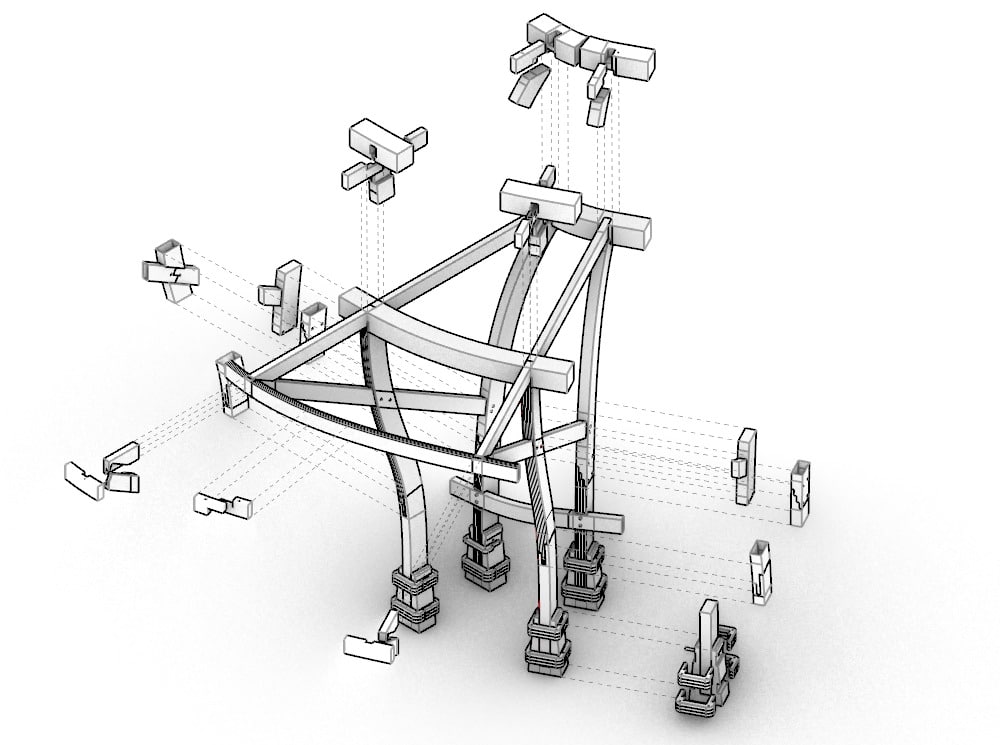

After spending some time learning about timber joinery last term, this term was all about implementing these logics onto a larger and more complex system: a small chunk of a bird observatory. We designed and made all of the beams that comprised the chunk, which were all unique to one another. Some were straight, others curved, segmented and bent. Additionally, in order to experiment even further we made complex joints that differed from each other as well.

BRIEF

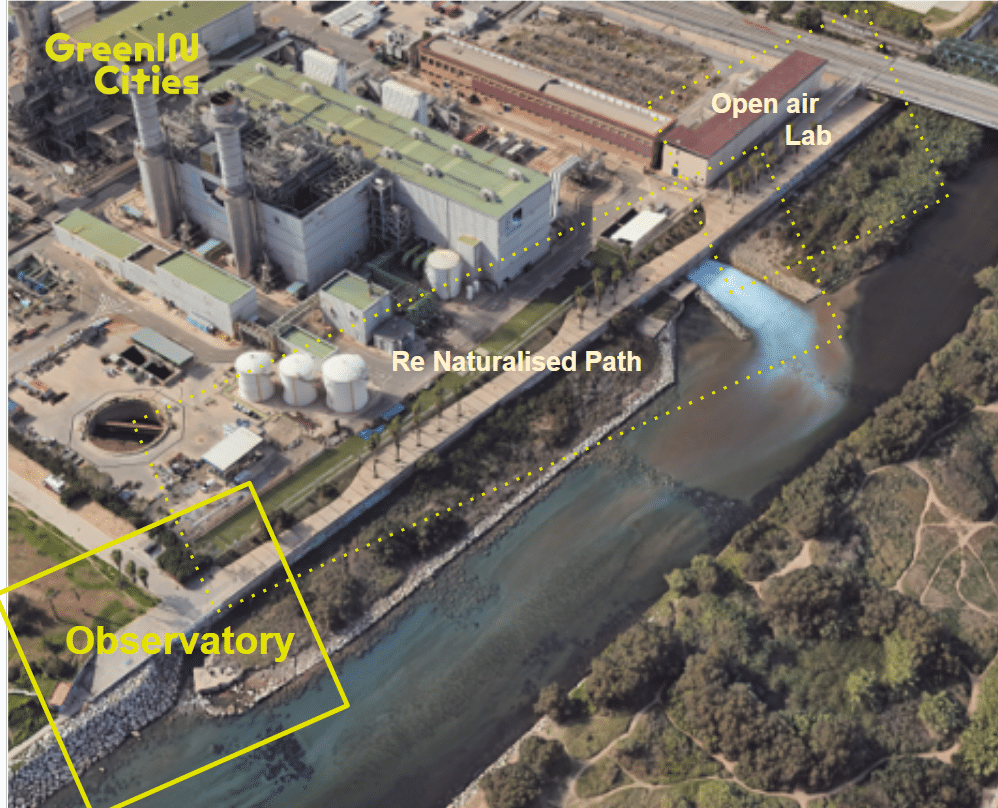

after studying digital fabrication methods in the first term, through group work. The challenge in the third term was to combine all of our knowledge on wood joinery, fabrication methods and design an observatory for birds, in the Besos area.

SITE

PROPOSALS

proposal 1. Cedar Group

proposal 2. Teak Group

proposal 3. Rose Group

proposal 4. Oak Group

proposal 5. Cork Group

FINAL PROPOSAL

The final proposal selected was a conglomeration of multiple designs and methods. At it’s final iteration, the bird observatory is viewed as an elevated platform, with an elegant curved staircase rising up to a 4m high viewing deck, overlooking the sea.

For our one week seminar, we decided to construct a small chunk of the observatory.

DIGITAL CRAFT METHODS

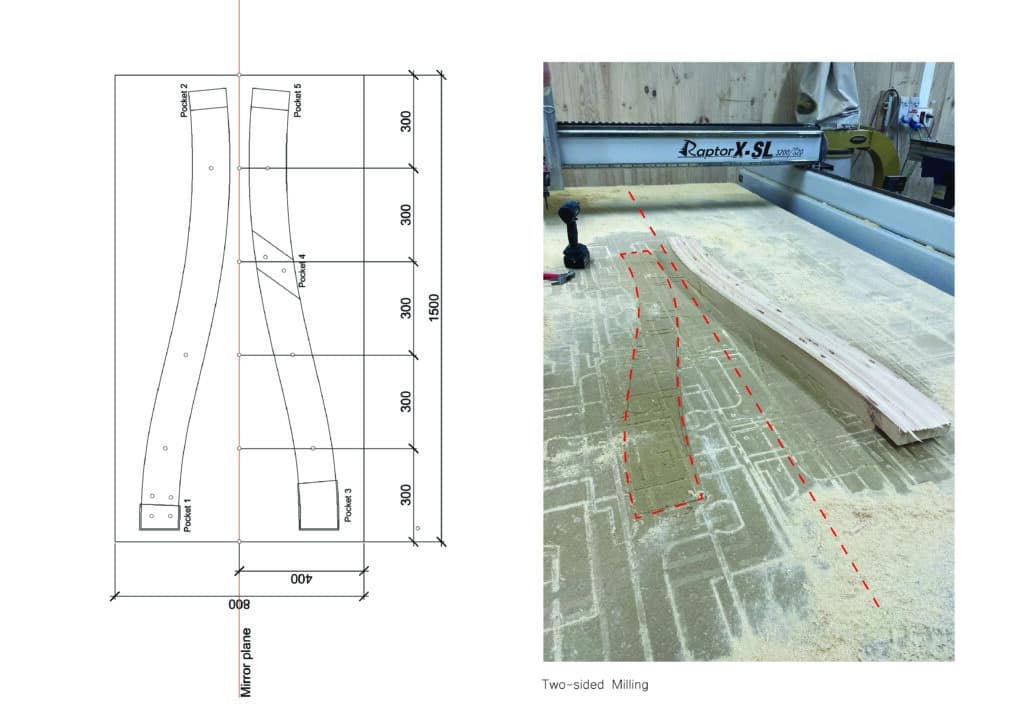

One of the biggest challenges was having beams that required double-sided milling, especially with curved beams. We came up with a simple system that allowed us the most precision when mirroring the beam along the CNC bed.

WOOD CRAFT