Introduction

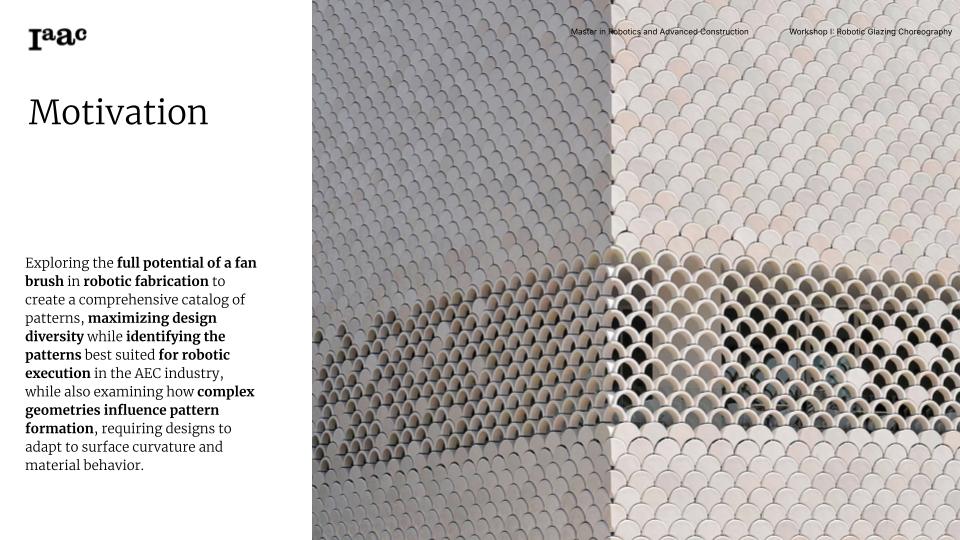

The exploration of robotic fabrication with traditional techniques has become increasingly important in the ceramic industry, opening up new possibilities for innovation, efficiency and mass production.

This research, in collaboration with Heatherwick Studio, bridges traditional artistry and robotic innovation, using only a fan brush to explore creative possibilities in ceramic glazing.

Design Methodology

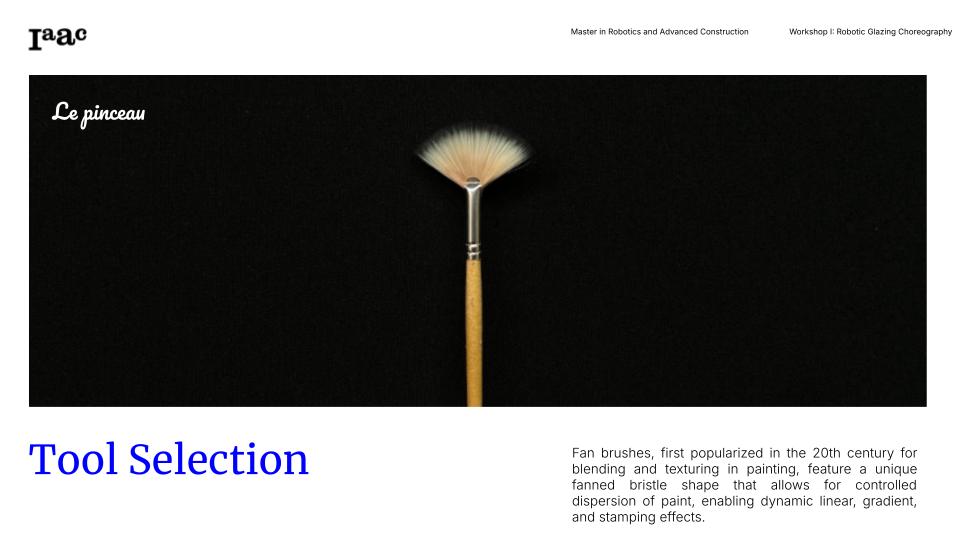

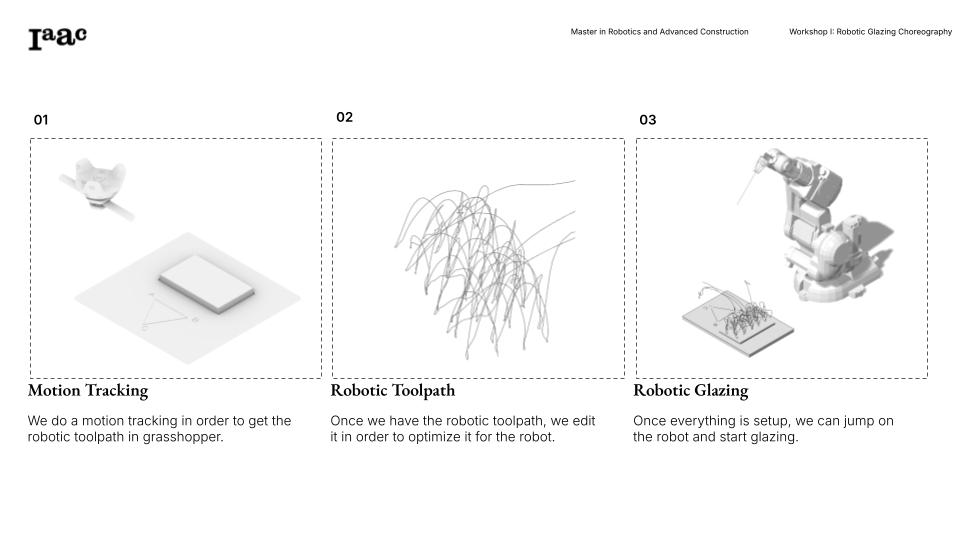

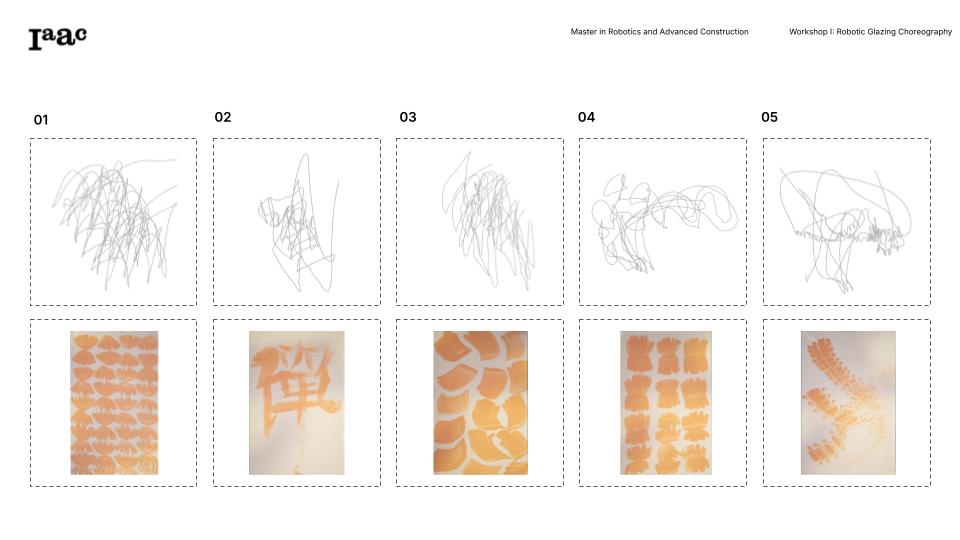

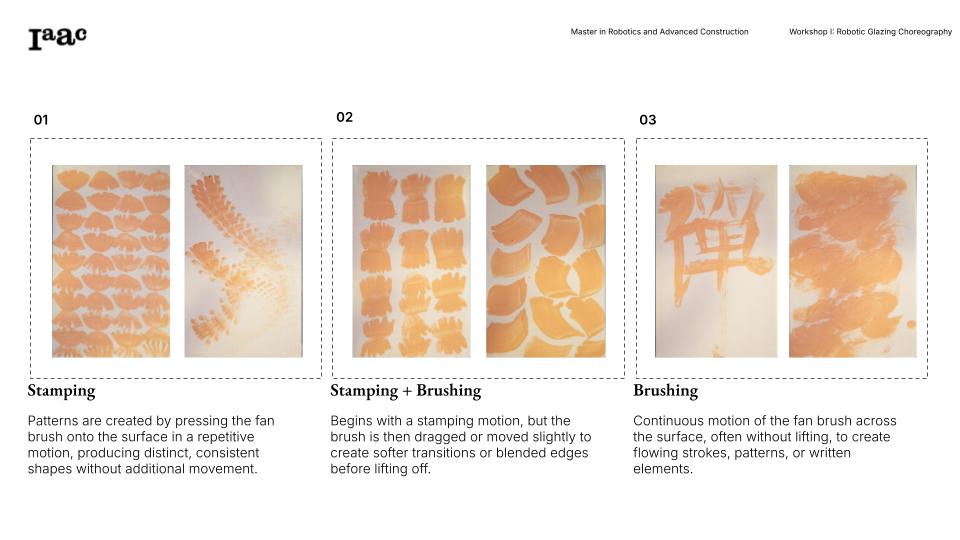

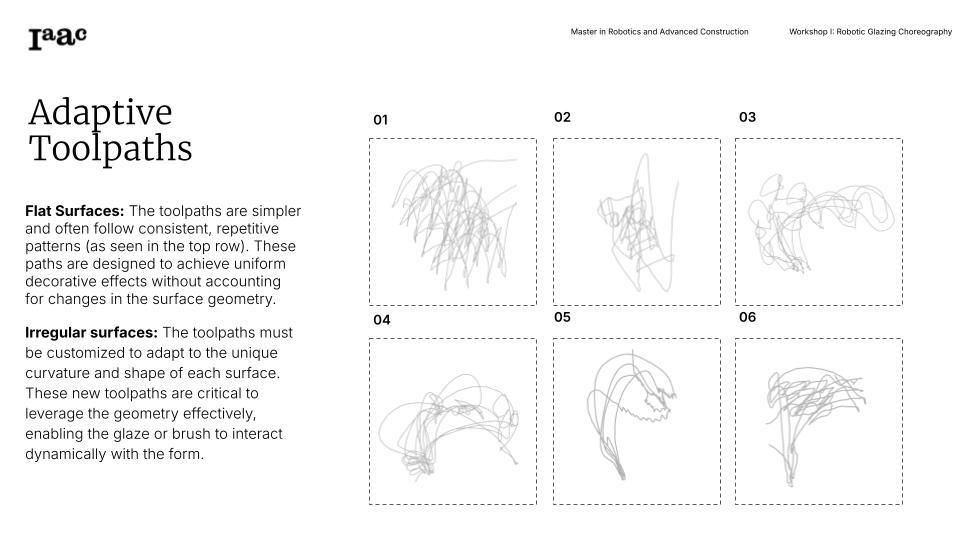

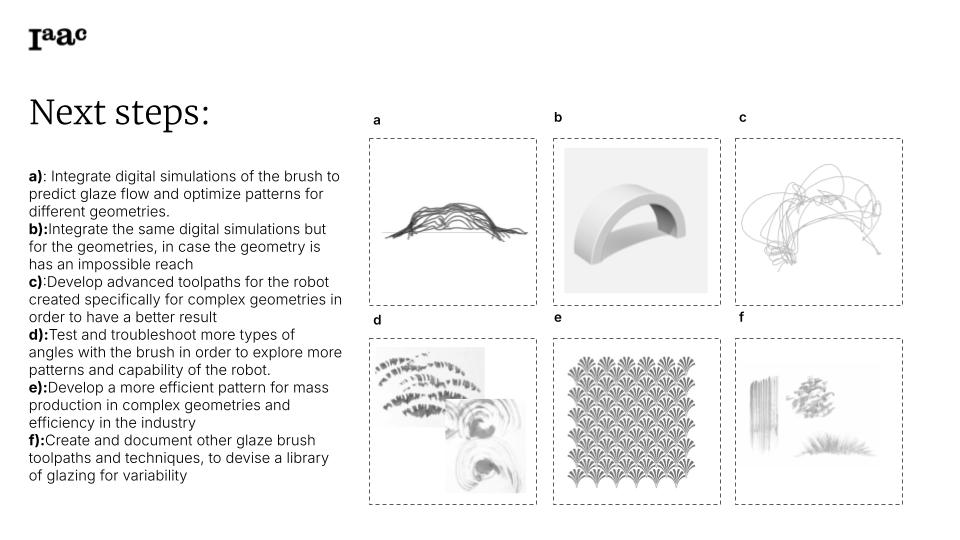

The design methodology follows a structured approach to exploring fan brush patterns in robotic fabrication. We begin with tool selection, defining the workflow to develop a comprehensive catalog of patterns. The process is divided into two main phases: flat surface testing, where patterns are generated and analyzed using photo scanning (OpenCV) to quantify brushstroke characteristics, followed by complex surface experiments, which examine how curvature and material behavior influence pattern formation.

Finally, the results are evaluated and compared, identifying the most effective patterns for robotic execution and optimizing their application across diverse geometries.

Process I: Flat Surfaces

How many unique patterns can be created with a single fan brush by exploring variations and overlaps on flat ceramic surfaces to build a comprehensive catalog?

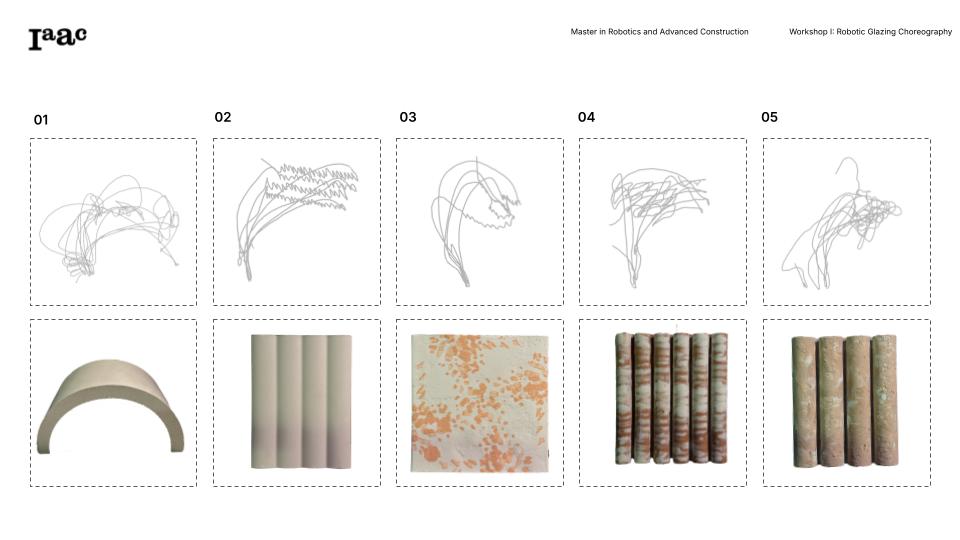

The image above explains the generated toolpath with motion tracking and the result on a ceramic tile.

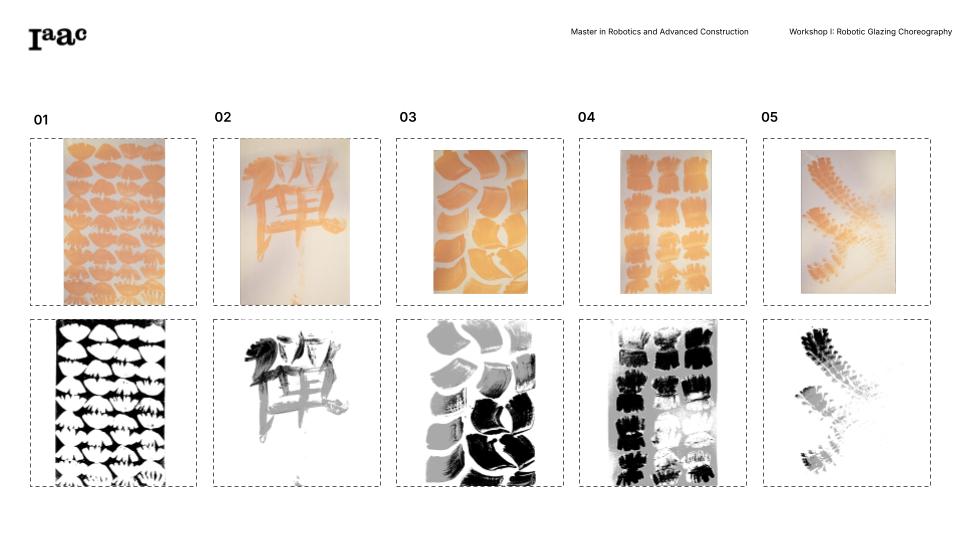

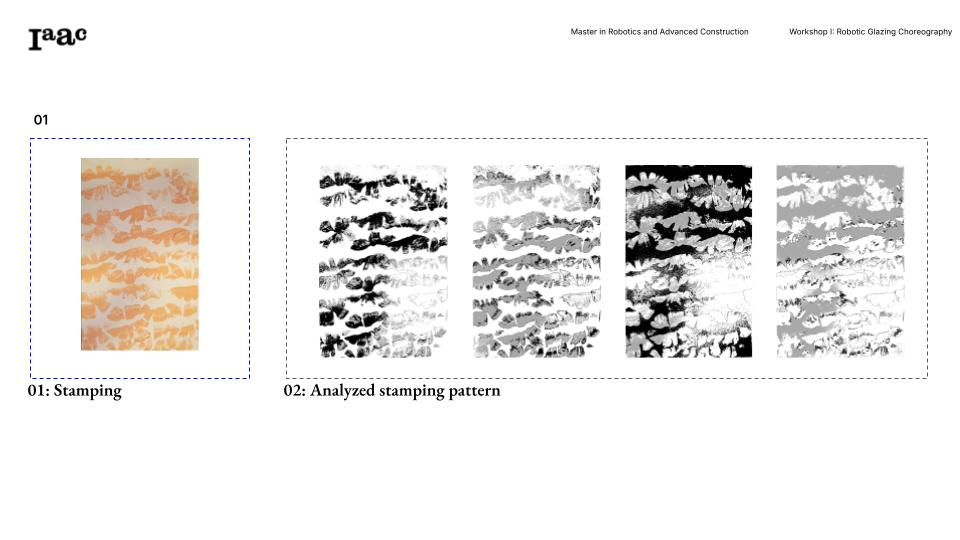

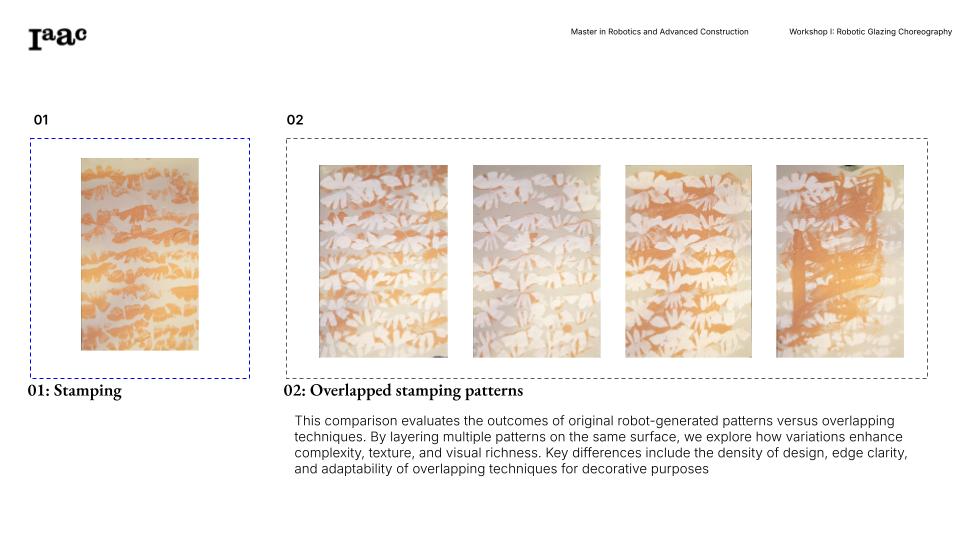

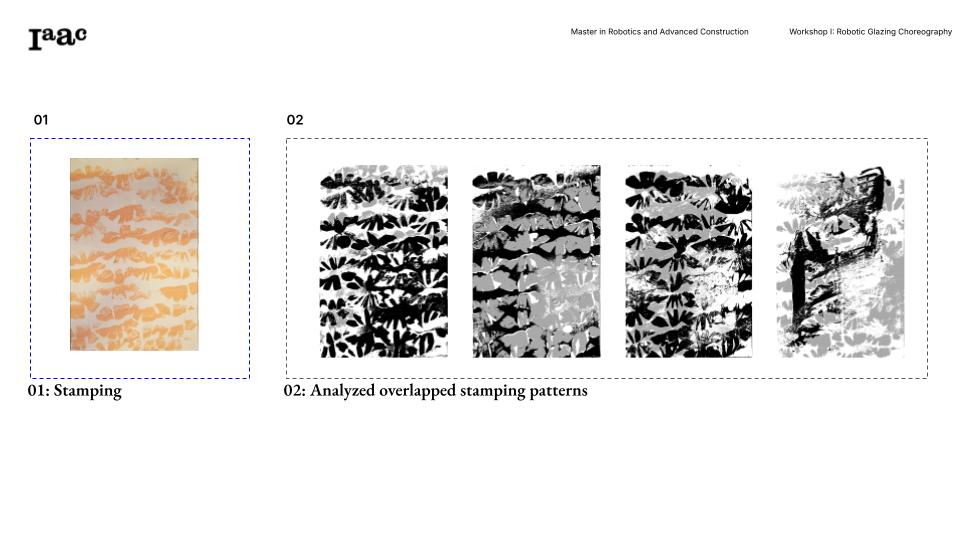

We then start comparing our generated robotic tiles with the help of open CV.

We also start analyzing our overlaped stamping patterns

Process II: Curved Surfaces

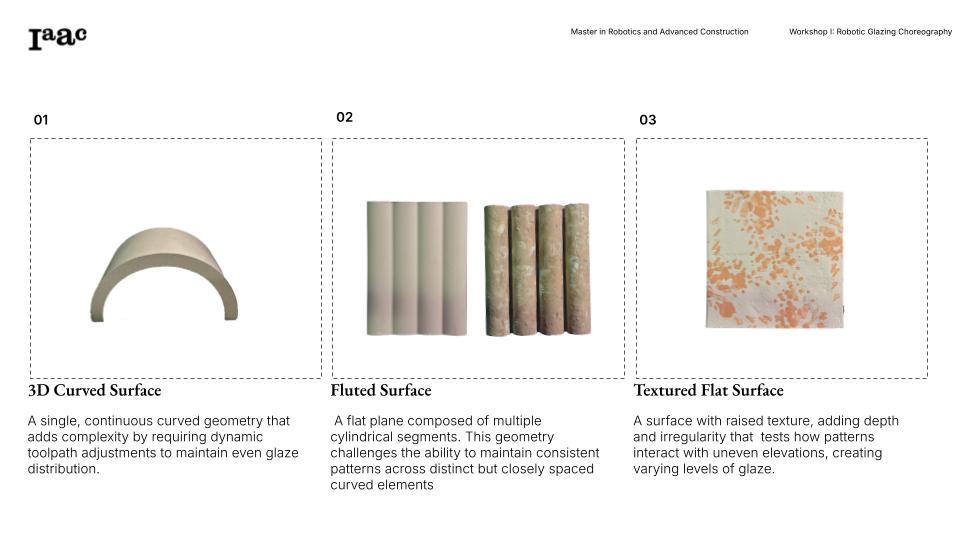

How can we create unique patterns with a single fan brush on complex ceramic geometries? This process explores how variations in shape and curvature influence pattern formation, requiring designs to adapt to each geometry while maximizing decorative possibilities

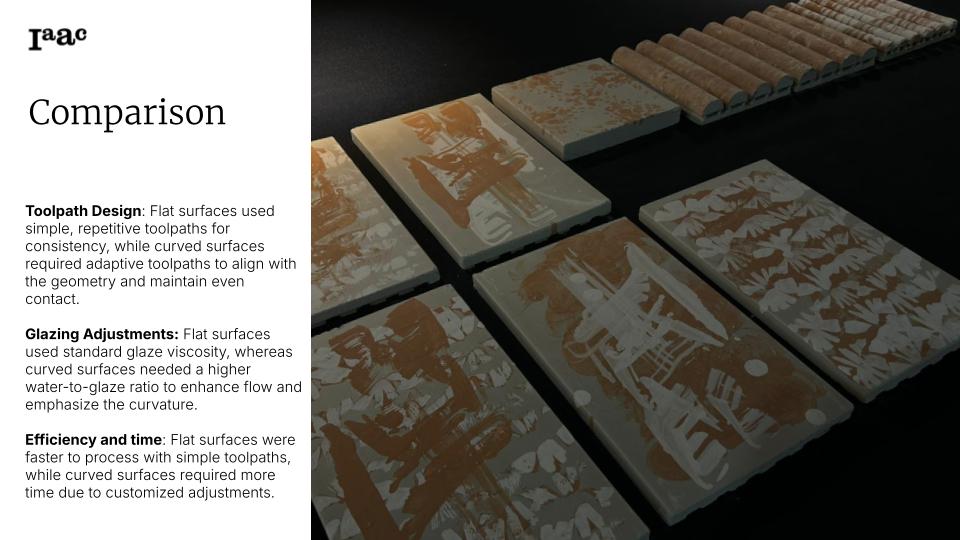

Comparison

How may we analyse our experiments on flat and complex surfaces, to enable seamless execution on tiles and experiments to come?

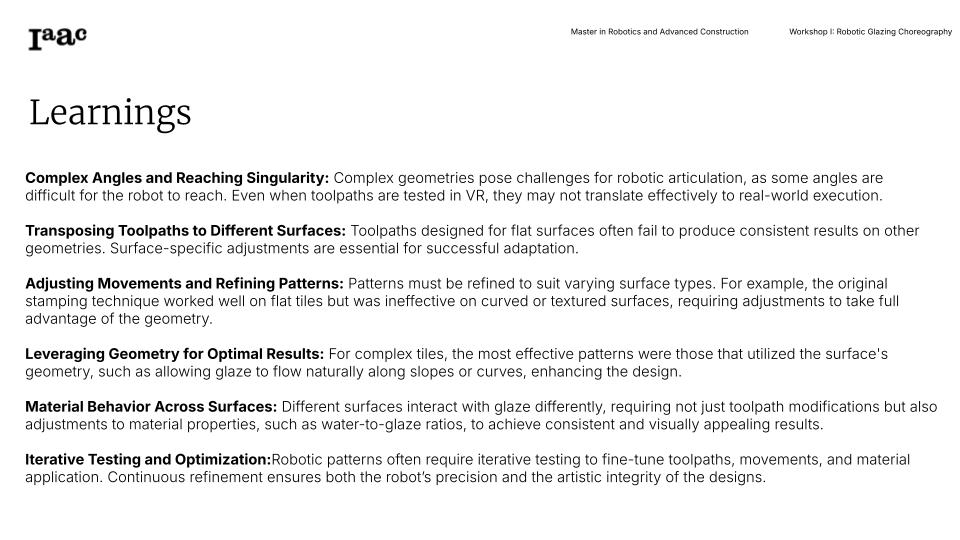

Learnings and Next Steps

Based on the insights gained from the analysis and comparison of flat surfaces to curved surfaces—such as how flat surfaces prioritize consistency and speed, producing precise, uniform patterns, while curved surfaces require customized toolpaths and glaze adjustments to create dynamic, shape-enhanced designs that embrace the complexity of the geometry—these are our conclusions:

Final Exhibition