MOVEMENTS

The ideation revolved around exploring the nature of movements, as they express themselves in environment, forms, dimensions and spaces. Humans perceive this notion as a bridge to liveliness & entropy. The studio, ‘Introduction to Digital Fabrication’, aimed at understanding fabrication dialogues through the technology of Laser Cutting, 3D Printing & CNC Milling, where these projects were developed.

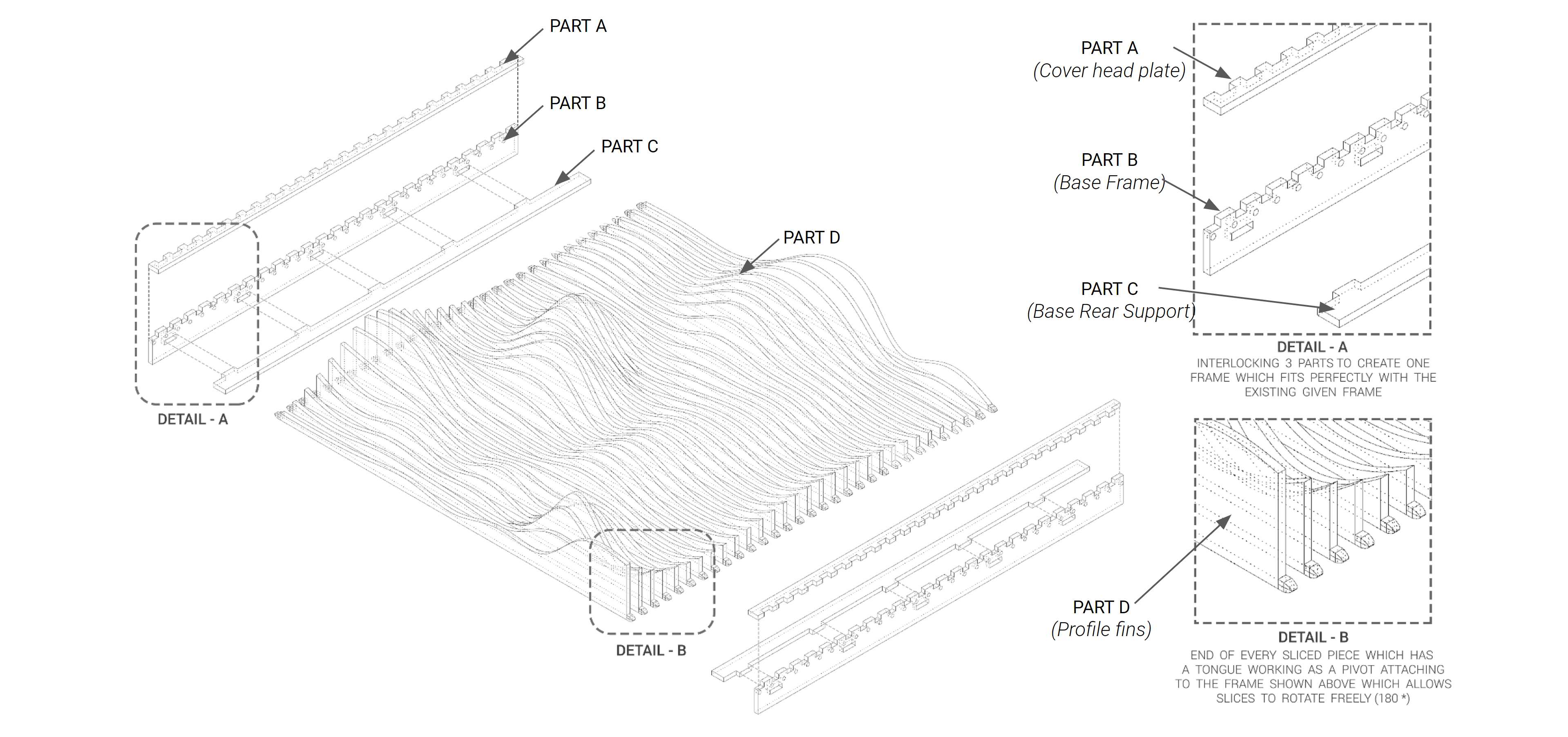

Laser Cutting

The Concept inspires itself with the dynamism of the waves in the ocean, understating their patterns and rhythm and how it correlates with the current architectural interpretations. The fins as shading devices and facade have the same idea, but lacked the freedom of moving. The vision aligned with having a wavy facade element which moves and interacts with the site pertaining to the expression of the theme.

The development required an idea of having pivots to add movement in the Z axis, as the XY plane delivered the profile for the sliced waves. This added the constraint of controlling the axial movement, where a head board frame with holes and nodes solved the problem.

The Assembly is a composed form where the fins move in the virtue of the locked head board.

3D printing

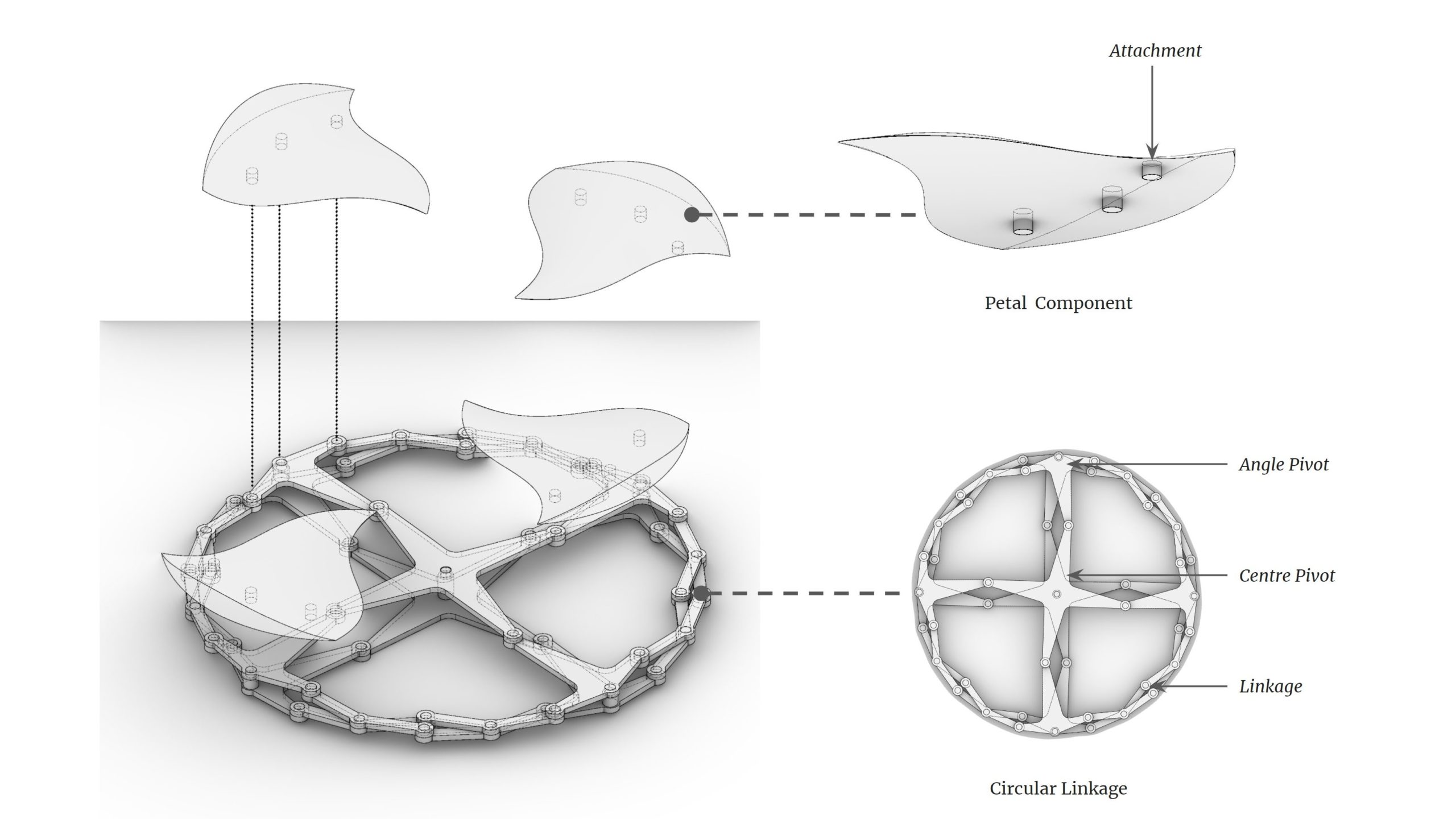

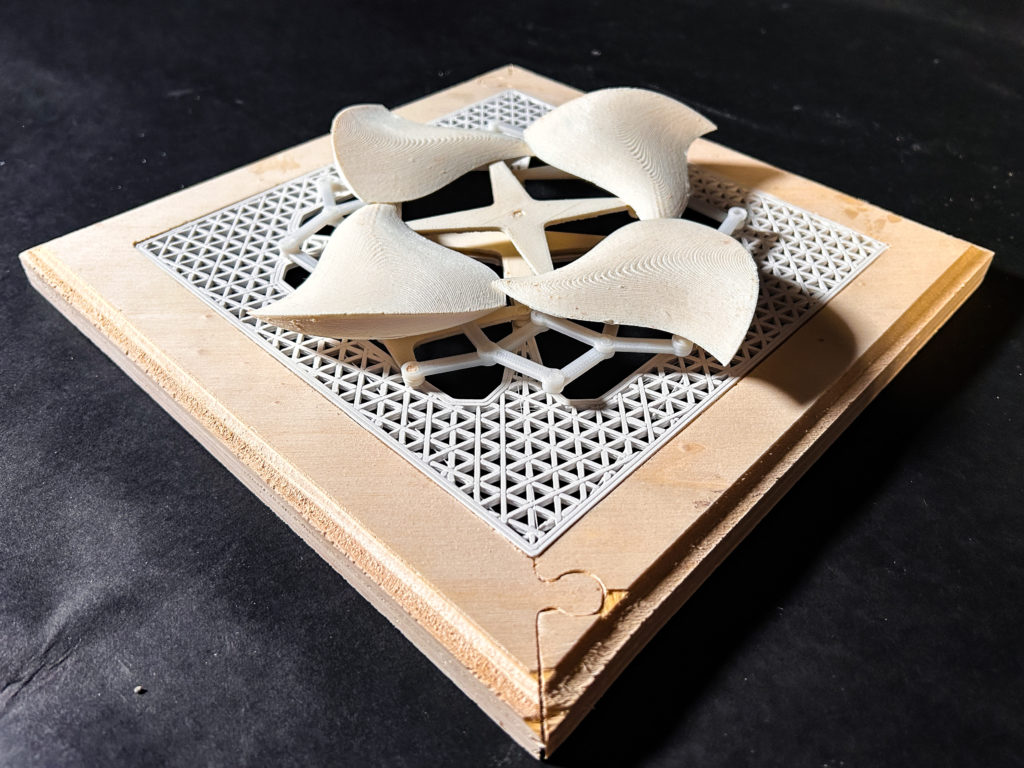

The objective of this project was to explore the circular linkage with a fixed center, primarily characterized by two predominant movements: rotation and sliding. The main idea of this project was to imitate the impressive movements seen in remarkable buildings like the Qi Zhong Forest Sports City Arena and the Mercedes Benz Stadium. We especially focused on capturing the dynamic mechanics found in convertible roof systems.

To achieve the circular linkage and multi-foci coagulation, several prototypes were created with varying thicknesses and dimensions, as illustrated below. Using only a single layer of linkages allowed for expansion and contraction, but rotation could not be attained along with it. Consequently, multiple layers were added to fulfill this rotational capability.

CNC Milling

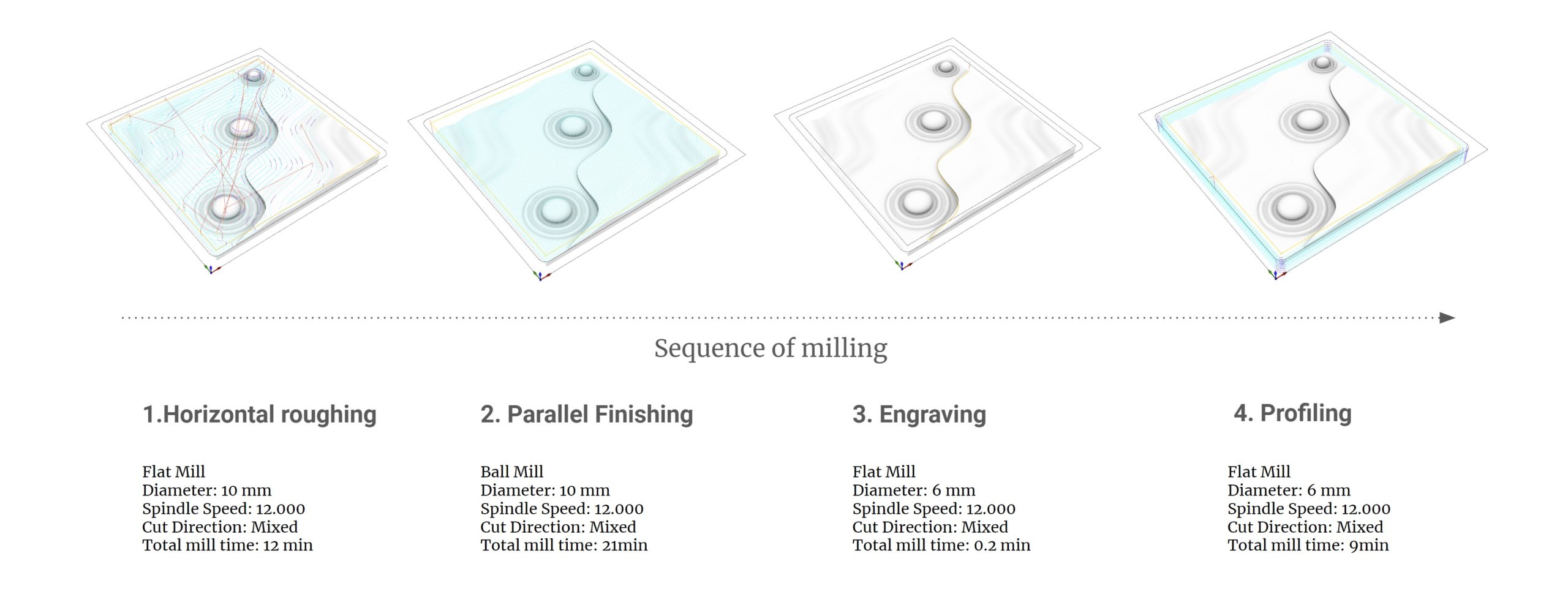

The project originated from the concept of arid landscapes, drawing inspiration from the intricate patterns and abstract geometry found in Zen gardens.

The underlying idea behind the execution was to evoke a sense of the landscape through the incorporation of contours and textures. For the milling process, plywood was chosen as the medium due to its layered structure, allowing for the creation of nuanced contours.

The production process initiated with horizontal roughing, followed by parallel roughing, engraving, and profiling to meticulously bring the envisioned landscape to life.