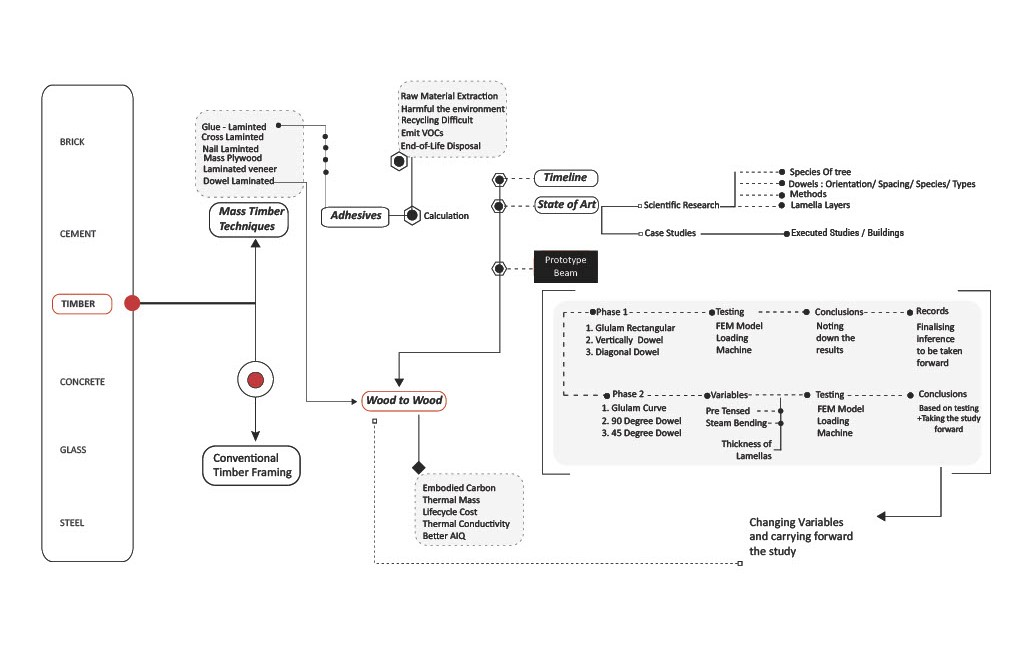

Starting with my master’s thesis, my primary objective was to delve into the realm of sustainable materials. Throughout my first year, I immersed myself in the study of timber assemblies, intrigued by their potential contribution to environmentally conscious construction practices. Researching concepts such as the circular economy and cradle-to-grave analysis, I gained a deeper appreciation for the pivotal role of building materials in architecture and their broader environmental impact.

As I continued my exploration, my fascination with timber steadily grew. It was during the culmination of our final project that I encountered Dowel Laminated Timber (DLT) through a conversation with my roommate, Jackie. The notion of wood attached to wood without the use of traditional adhesives was initially met with scepticism. However, upon further investigation, I became captivated by its potential and its implications for sustainable construction practices.

Driven by a desire to understand the intricacies of DLT, I embarked on a journey of research and exploration. I sought to uncover the underlying principles behind its assembly techniques, its applications in construction, and its environmental benefits. Through this process, I gained a deeper understanding of the environmental richness inherent in this innovative timber assembly method.

Despite having studied various timber assemblies, DLT stood out to me for its simplicity, efficiency, and sustainability. Its capacity to minimize environmental impact while providing structural integrity made it a compelling subject of study. As I delved deeper into its intricacies, I became increasingly convinced of its potential to revolutionize construction practices and contribute to the advancement of sustainable architecture.

Now, armed with knowledge and passion, I am eager to further explore the potential of DLT and its implications for sustainable construction. I am committed to contributing to the ongoing dialogue surrounding environmentally conscious building practices and am excited to play a role in shaping a more sustainable future for the construction industry.

Research Topic

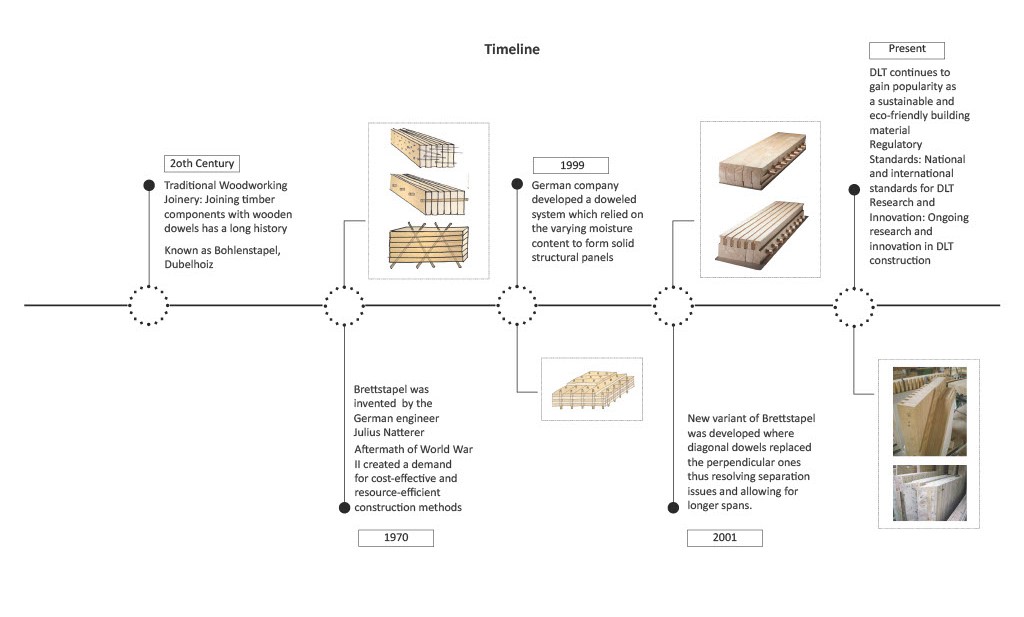

In the vast landscape of timber craftsmanship, there exists a treasure trove of ancient woodworking techniques, often overshadowed by modern innovations. Among these, one particular method stands out—a time-honoured tradition passed down through generations, yet largely overlooked in today’s fast-paced world.

My thesis embarks on a journey to resurrect this forgotten craft, delving deep into its historical roots and evolution over time. Through rigorous research and hands-on exploration, I aim to uncover the intricacies of this traditional woodworking technique, elucidating its principles and applications in contemporary timber assembling.

Join me as I traverse the annals of woodworking history, unravelling the stories of master craftsmen and the techniques they meticulously perfected. Through empirical study and analysis, I seek to revive this ancient art form, breathing new life into age-old practices and shedding light on their relevance in today’s woodworking landscape.

Together, let us embark on a scholarly pursuit of rediscovery, as we bridge the gap between past and present, honouring the rich heritage of traditional woodworking while paving the way for its resurgence in the modern era.

Historical Perspective: Timber, with its enduring charm and unparalleled versatility, has left an indelible mark on the world we inhabit. From the homes we dwell into the majestic bridges connecting entire communities, wood has been an integral part of our societal fabric. Its rich history spans epochs, from the dawn of humanity to the present day and beyond, making it one of the few building materials that has stood the test of time.

Timber and its story :

Exploring the early days of timber construction reveals its foundational role in human civilization. Dating back to the Stone Age, timber was among the earliest materials wielded by our ancestors. It began as simple tools, such as handaxes, empowering early humans in their quest for survival and dominance over their environment. As civilizations flourished, so did their utilization of timber in construction. Ancient cultures like the Egyptians, Greeks, and Romans employed timber for diverse purposes, from crafting homes to erecting monumental structures. Remarkably, timber was often sourced from distant lands, as evidenced by the discovery of Roman villas built with oak planks transported from the mountains of France.

The medieval period ushered in a golden age of timber-framed architecture. With timber’s abundance and inherent strength, builders crafted intricate designs and spacious interiors, evident in the grand cathedrals of Europe and the graceful pagodas of Japan.

The Industrial Revolution heralded a new chapter in timber’s history, marked by technological advancements and mass production. Innovations like Glulam revolutionized construction, enabling the creation of complex structures on an unprecedented scale.

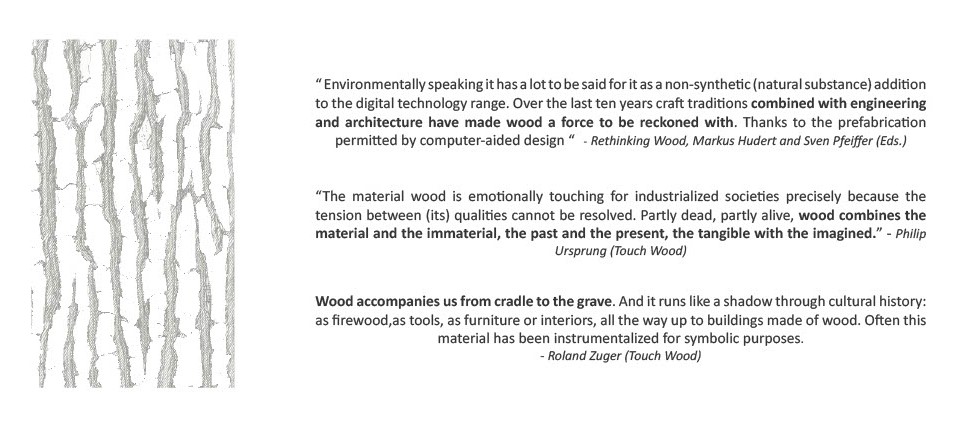

In the modern era, timber has experienced a resurgence fueled by sustainability and innovation. With growing awareness of eco-friendly building practices, timber’s renewable and carbon-sequestering properties have made it a preferred choice for environmentally conscious projects.

Is Timber the optimal material for today’s building industry?

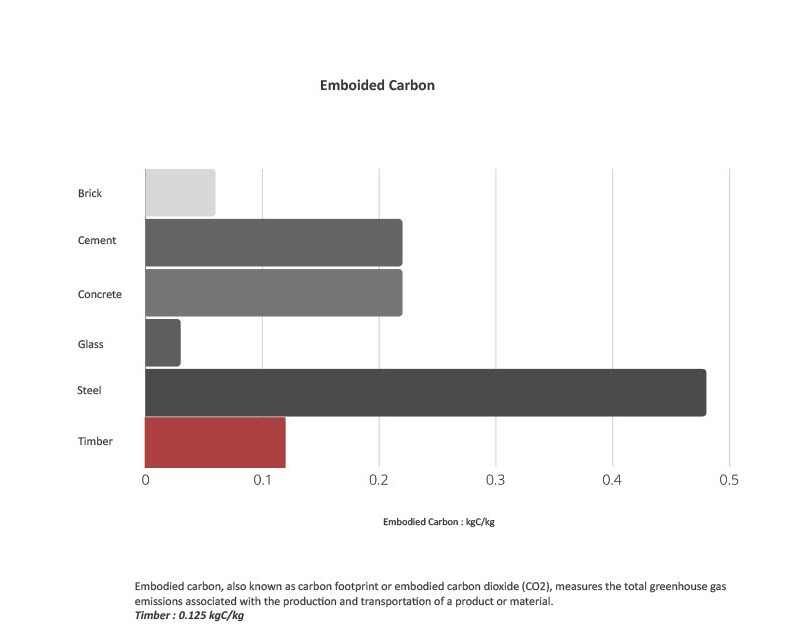

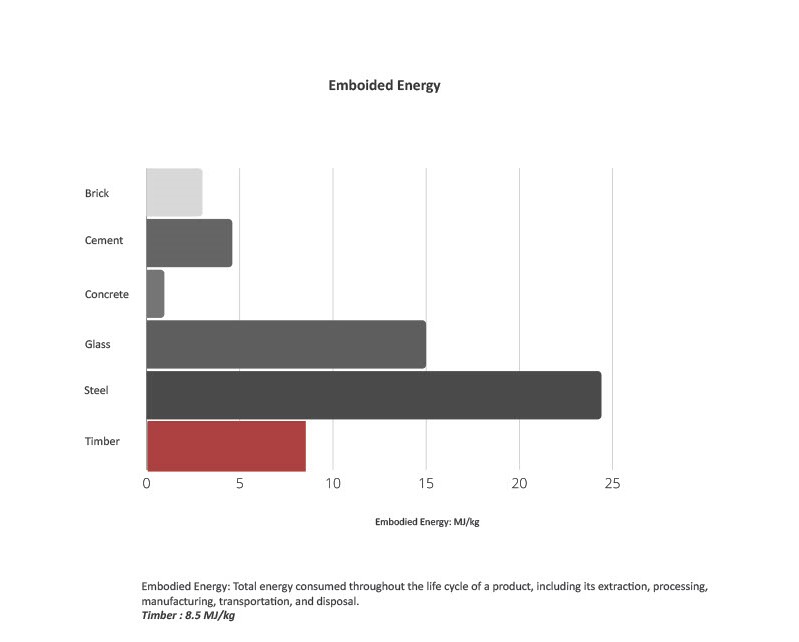

Timber is an environmentally friendly building material, sourced from sustainably managed forests. Unlike non-renewable materials like steel and concrete, timber is renewable, with trees being replanted to ensure a continuous supply. Additionally, timber is carbon-positive, meaning it stores carbon dioxide throughout its lifecycle, helping to reduce greenhouse gas emissions.

Another key benefit of timber is its recyclability. At the end of its life, timber can be recycled and repurposed, minimizing waste and contributing to a circular economy. Unlike some building materials that end up in landfills, timber remains a valuable resource that can be used in new construction projects or converted into other products. Using local timber species further enhances the sustainability of public projects by reducing transportation emissions and supporting local economies. Native timbers blend seamlessly with the surrounding environment, creating spaces that are deeply connected to their surroundings and celebrate local culture and heritage. In addition to its environmental benefits, timber also offers practical advantages. Timber structures provide excellent insulation, reducing heating and cooling costs and creating a comfortable indoor environment. With advances in preservative technology, modern timber products are highly durable and resistant to pests, decay, and fire. Furthermore, the natural beauty of timber adds warmth and character to public spaces, creating inviting and visually appealing environments. Whether used for decking, cladding, or interior finishes, timber enhances the aesthetic quality of buildings and fosters a greater sense of well-being among occupants.

In conclusion, timber’s resurgence in contemporary construction is driven by its sustainability, recyclability, practical advantages, and aesthetic appeal. As architects and designers continue to prioritize environmental responsibility and innovation, timber is poised to play an increasingly vital role in shaping the built environment of the future.

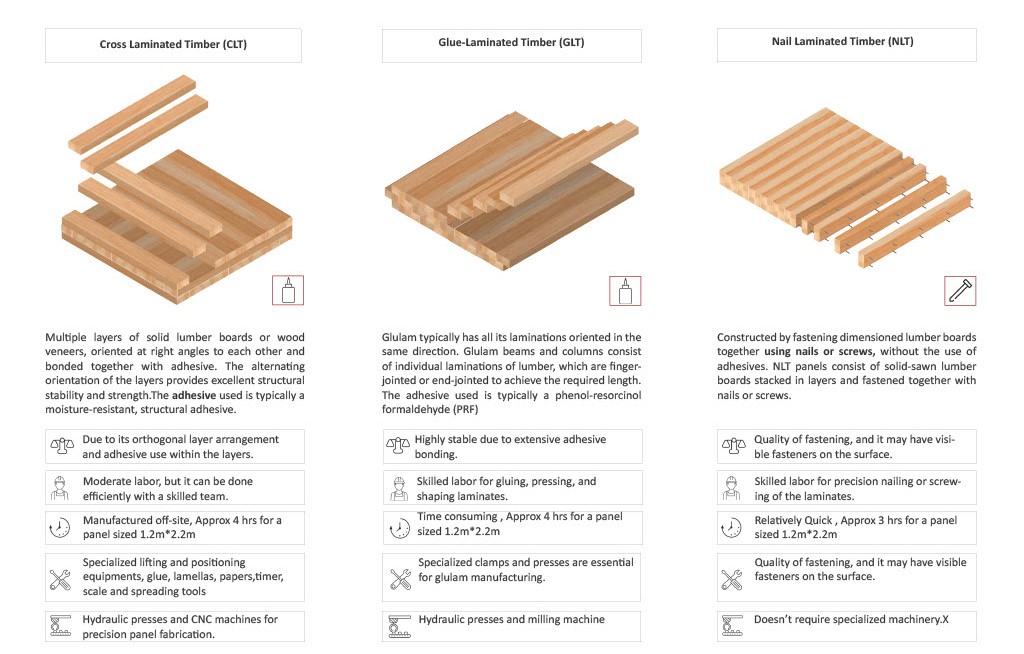

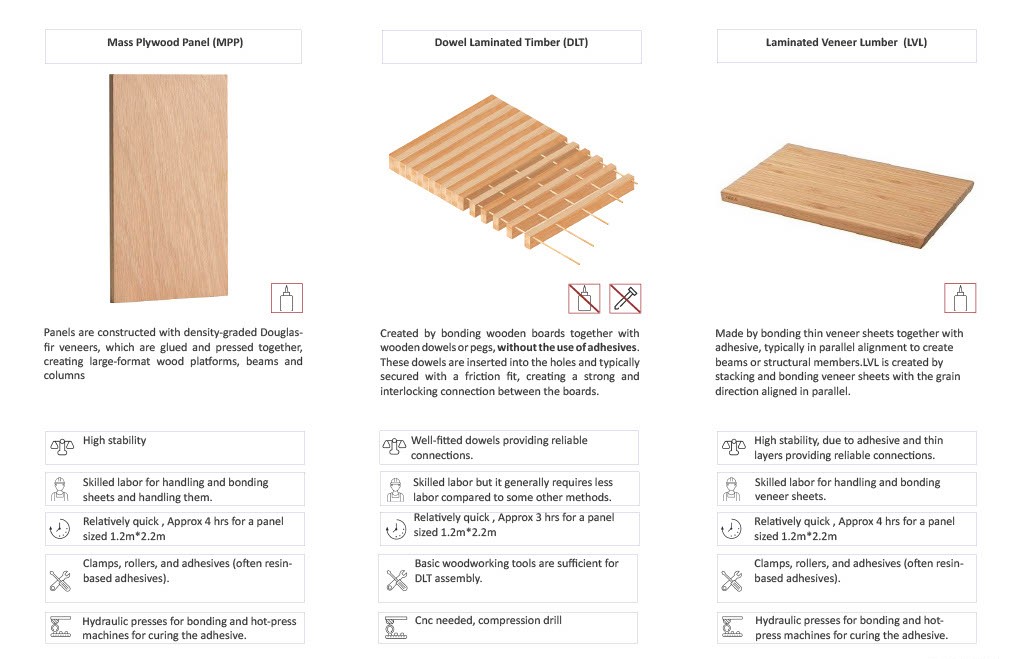

What are the advanced assembly methods for mass timber construction?

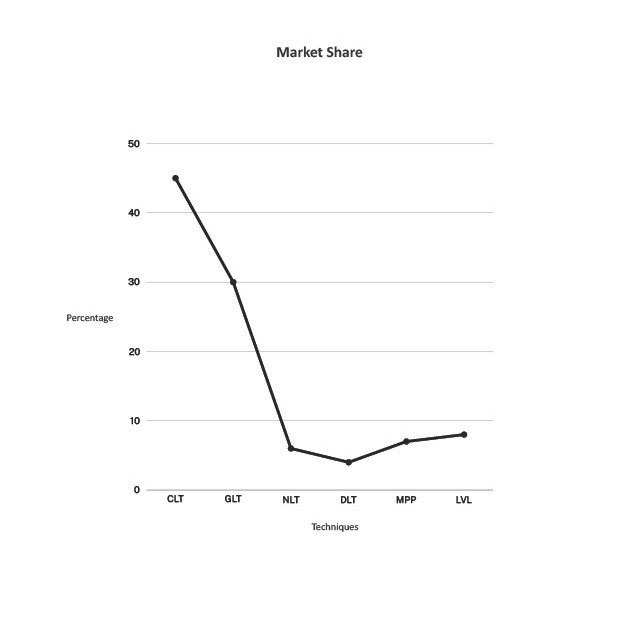

In today’s construction landscape, Cross-laminated timber (CLT) and Glue-laminated timber (GLT) reign supreme, commanding a significant market share compared to other assembly techniques. Their popularity stems from their exceptional structural stability, sustainability, and efficient construction processes. CLT’s strength and load-bearing capabilities make it ideal for tall buildings, while GLT offers versatility in design. Both materials are derived from sustainably managed forests and boast eco-friendly manufacturing processes. Prefabricated panels and beams contribute to cost savings and faster project timelines. As the demand for green building solutions grows, CLT and GLT are poised to maintain their dominance in the market.

RESEARCH QUESTION

Part 1: Is the utilization of adhesives in construction practices environmentally sustainable?

Adhesives are substances used to make things stick together better. However, they can release harmful chemicals called volatile organic compounds (VOCs), which are bad for both people and animals. These chemicals can cause serious health issues like cancer, headaches, and breathing problems. When adhesives are made, the wastewater produced contains a lot of pollutants, including toxic compounds like formaldehyde. Cleaning up this wastewater is difficult and requires special methods.Lot of reserach looks at how toxic adhesives are and how they affect the environment. It also discusses how much VOCs are released from adhesives and wooden construction materials, as well as ways to treat the wastewater from adhesive production. Additionally, it examines how to handle and dispose of leftover wooden materials that still have adhesive on them.

The Adhesive-Free Timber Buildings project, led by the University of Liverpool, aims to revolutionize construction practices by eliminating toxic adhesives in Engineered Wood Products (EWPs). By promoting the use of compressed wood, the project boosts confidence in adhesive-free EWPs, advancing from Technology Readiness Level (TRL) 4 to 7.

Collaborating with academia, industry, and the public sector, the project demonstrates the viability of new adhesive-free EWPs using innovative technology. It targets significant environmental benefits, including the production of 1 million m3 of adhesive-free products, the removal of 6000 tonnes of toxic adhesives, and the reduction of timber waste in landfills across Europe.

Additionally, the initiative supports ten businesses in adopting the new technology, fostering economic growth, sustainable jobs, and contributing to forest management and rural livelihoods in North West Europe. Advocacy and business support activities ensure the sustainability of positive impacts beyond the project’s duration.

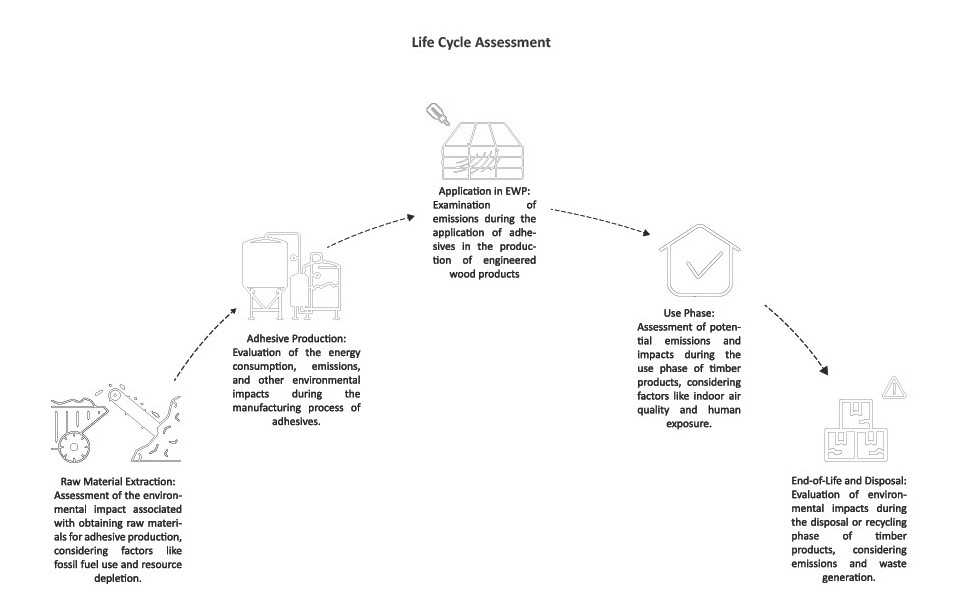

The life cycle assessment (LCA) of adhesives reveals that their environmental impact extends far beyond the endpoint stage of disposal. Instead, it begins at the very inception with the extraction of raw materials, progresses through manufacturing, application, and utilization, and culminates in the disposal phase. This comprehensive analysis emphasizes that the ecological consequences of adhesives permeate every stage of their lifecycle journey, underscoring the imperative for sustainable alternatives.

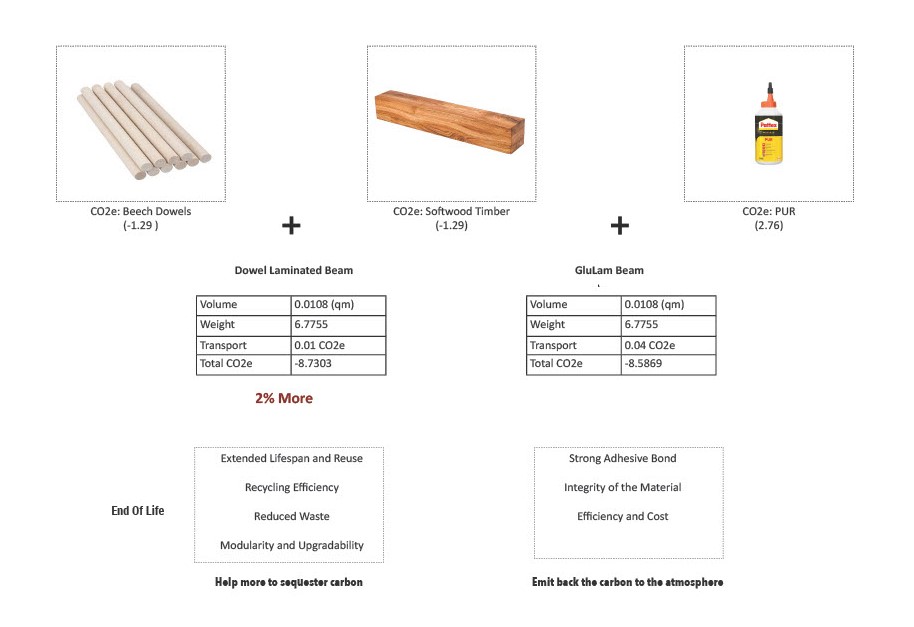

Estimating the potential impact of eliminating adhesive usage reveals a substantial opportunity for overall savings across various metrics. While the exact figures may vary depending on specific contexts and applications, preliminary assessments suggest significant reductions in environmental footprint, resource consumption, and health risks. By transitioning away from adhesives, we could potentially achieve noteworthy percentages of savings in terms of energy consumption, emissions, waste generation, and associated costs. This shift towards adhesive-free solutions not only aligns with sustainability objectives but also paves the way for a more resilient and environmentally responsible future.

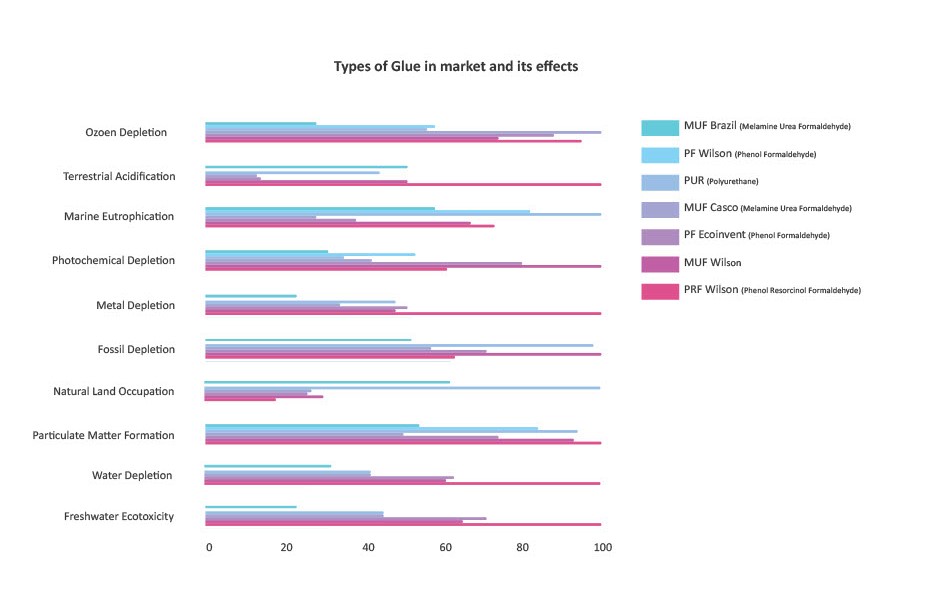

This study compares the environmental impact of traditional formaldehyde-based adhesives (MUF, PF, PRF) with formaldehyde-free polyurethane (PUR) adhesive using life-cycle assessment and ReCiPe methodology. Results show that PUR adhesive has the lowest environmental impact in CLT production due to requiring less adhesive and no additional hardener. However, endpoint results may be influenced by subjective weighing in the ReCiPe method, and uncertainties remain due to data aggregation and small differences between adhesives. During application, emissions are low and do not exceed workplace concentration thresholds, but human toxicity impacts are observed. Overall, focusing on substituting synthetic raw materials with renewable alternatives like lignin and tannin could reduce the environmental impact of adhesives in wood construction.

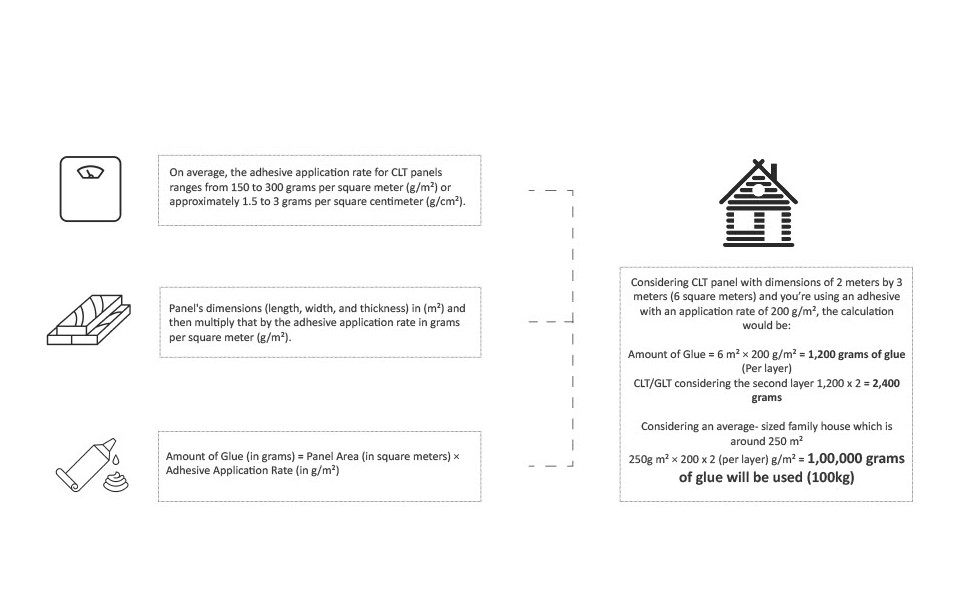

Let us calculate how much adhesive is used to produce timber panels?

Bio-Based Adhesives :

The potential of biopolymers like lignin, starch, and plant proteins as alternatives to petroleum-based wood adhesives. While native lignin has limited substitution capabilities, chemical modifications have shown promise, with some studies achieving up to 50% substitution. Starch- and plant protein-based adhesives can replace petroleum-based ones but often have lower water resistance and bonding strength. Research should focus on chemical modifications to enhance bio-adhesive performance and investigate adhesive bonding properties for optimal formulation. Despite challenges, bio-based adhesives offer a pathway to reducing environmental impact and meeting sustainability goals in wood composite construction. However, considering the structural loading it is still in process to understand the overall integrity.

Bio-based adhesives hold significant promise for the engineered wood products industry, offering environmentally friendly alternatives to fossil fuel-derived adhesives. While challenges remain in terms of mechanical properties and long-term durability compared to synthetic counterparts, ongoing research and advancements in modification techniques show potential for bridging this gap. By utilizing components such as cellulose, proteins, lignins, and tannins, bio-based adhesives can be tailored to meet the specific bonding requirements of engineered wood products. Improvements in strength and water resistance through modifications and blending techniques contribute to the development of sustainable products with clean synthesis and water-based processing. Addressing research gaps will be crucial for accelerating the adoption of bio-based adhesives on an industrial scale

Adhesives do not contribute to the cyclical nature of timber usage.

RESEARCH QUESTION

Part 1: Is the utilization of adhesives in construction practices environmentally sustainable?

Part 2 : How can we investigate timber construction methods that achieve structural strength without relying on adhesives?

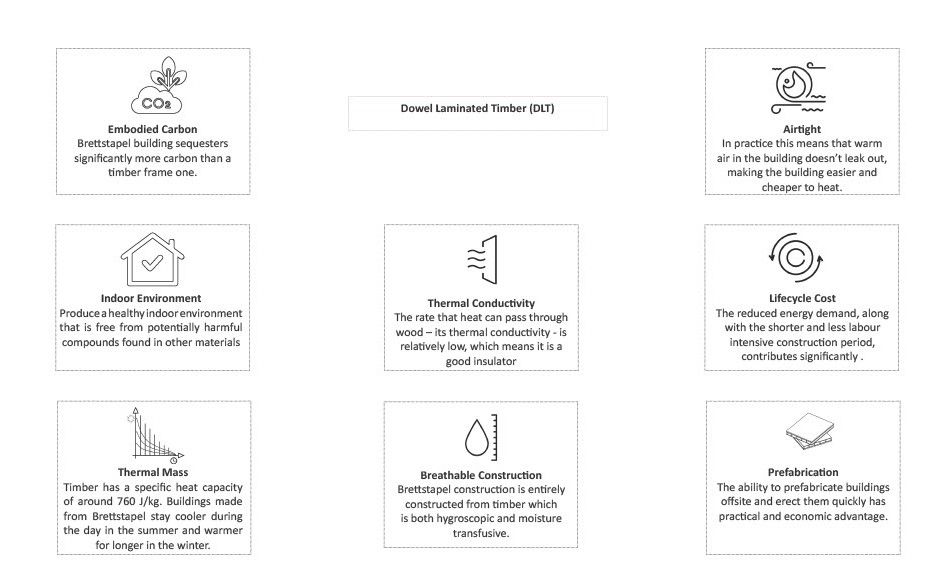

The System : Brettstapel construction offers a straightforward yet effective approach to solid timber building, bypassing the need for glues or nails. It involves assembling softwood timber posts with hardwood timber dowels, creating sturdy load-bearing panels for walls, floors, and roofs.The beauty of Brettstapel lies in its simplicity: the dowels, with a lower moisture content than the posts, expand gradually over time to reach moisture equilibrium. This natural process effectively “locks” the posts together, forming a robust structural system without the need for adhesives or metal fasteners. One of the key advantages of Brettstapel is its reliance solely on untreated timber. This means no glues are necessary, resulting in healthier indoor air quality. Additionally, the timber itself acts as a carbon sink, capturing and storing significant amounts of carbon dioxide from the atmosphere.In essence,

Brettstapel is a solid timber construction method originating in Central Europe. Initially, it involved sawn timber posts nailed together, evolving into the Dübelholz system in 1999, which replaced nails with hardwood dowels for enhanced structural integrity. Further innovations addressed issues of contraction and expansion, leading to a 100% timber product. Today, Brettstapel is widely manufactured, offering sustainable building solutions without the need for glue or nails

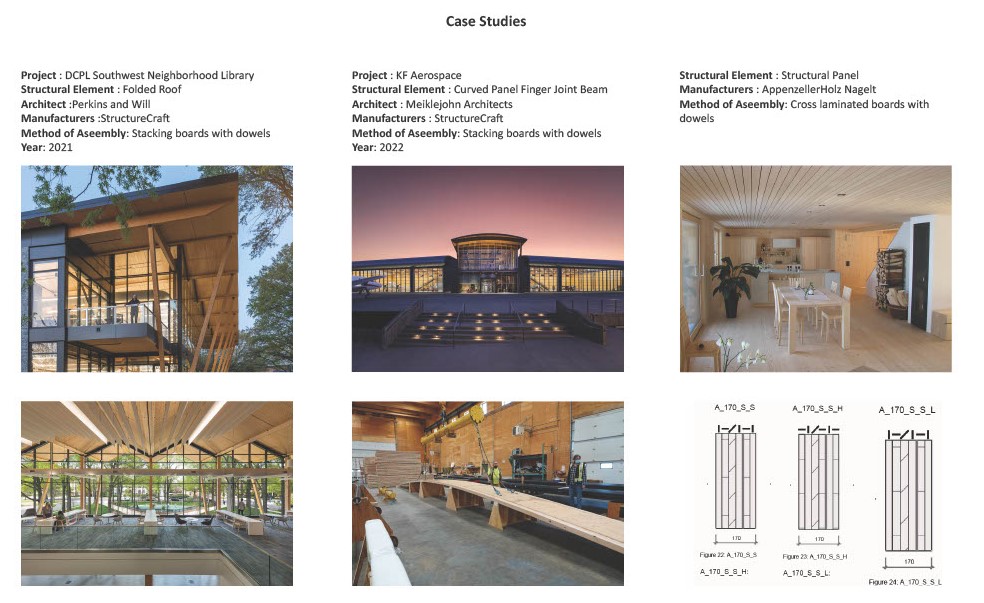

STATE OF ART

Scientific Paper Research

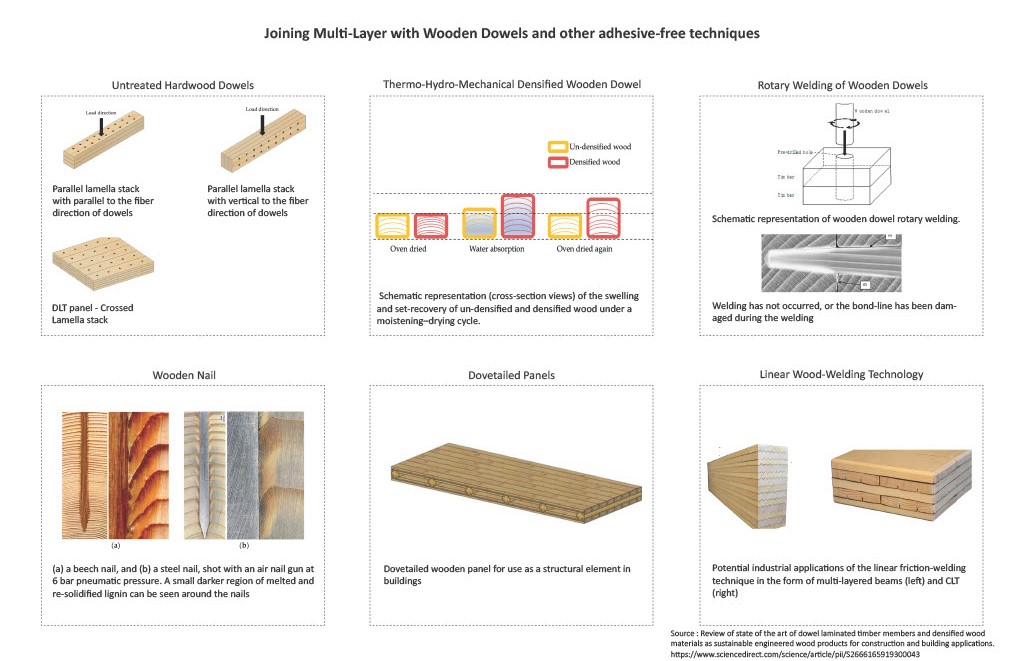

Untreated Hardwood Dowels

Hardwood dowels, conditioned for moisture content, provide a secure connection with timber lamellae, resisting sliding apart under force. Friction-induced locking and load transfer mechanisms ensure stability, but viscoelasticity and humidity fluctuations pose durability challenges. Densified wood dowels offer promise for long-term performance improvement, addressing concerns of connection stability

Wooden Nail

Metal nails have been widely used historically, but they have limitations in thermal performance and machinability. Wooden nails, especially when combined with wood-modification technologies, show promise as connectors in standard timber assemblies. LIGNOLOC® is a notable market implementation of wooden nail technology, offering bio-composite solutions for future-oriented timber construction.

Thermo-Hydro-Mechanical (THM) Densified Wooden Dowel

Techniques like post-steaming or resin impregnation mitigate set recovery, aiding in tight joining between densified wooden dowels and surrounding wood in multi-layered EWPs. Understanding set-recovery behaviour is crucial for optimizing densification parameters and ensuring long-term performance.

Dovetailed Panels

Dovetailed wooden panels, developed as part of the European DoMWoB project, offer a cost-effective alternative to adhesives and metal fasteners for modern structures. With the aid of digital fabrication technologies, these panels show promise for use in multi-story buildings, providing benefits like fire resistance and sound insulation. Further research is needed to optimize their design and performance for wider adoption in construction.

Rotary Welding of Wooden Dowels

Rotary welding of wooden dowels creates strong bonds through friction-generated heat, offering a fast and adhesive-free wood joining method. Process parameters and wood species influence bond strength, with denser woods and optimized dowel dimensions yield better results. Preheating and additives enhance performance, making rotary welding a promising, cost-effective, and eco-friendly

Linear Wood- Welding Technology

Linear wood-welding techniques, as demonstrated by Haha and Ganne-Chedeville, offer promising alternatives for joining EWPs, with mechanical properties comparable to conventional adhesives. However, their sensitivity to moisture content restricts their application to indoor use.

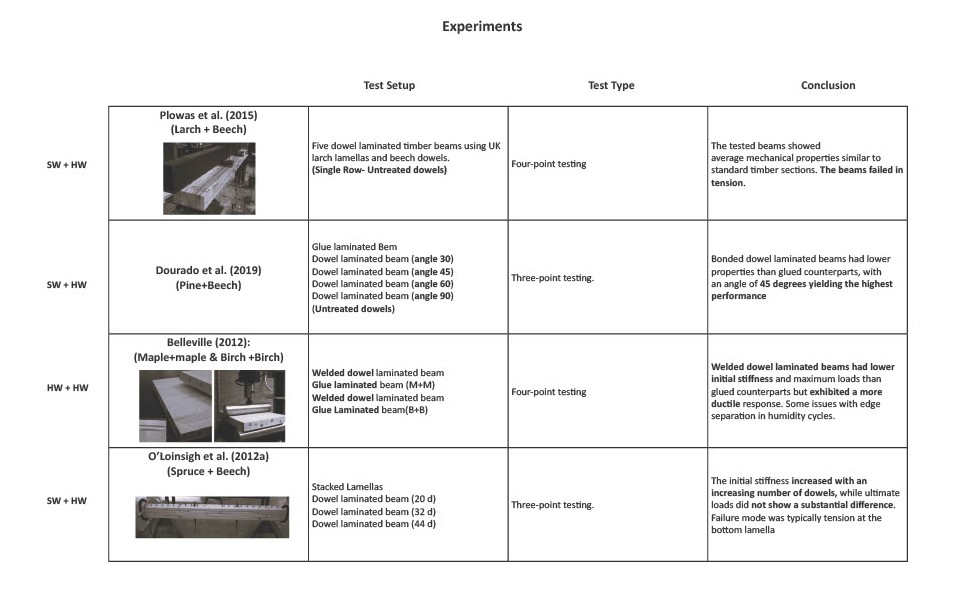

Introduction: The research investigates the viability of utilizing compressed wood (CW) dowels as a greener alternative to conventional hardwood dowels in dowel laminated timber (DLT) construction. By reducing reliance on adhesives, this approach aligns with the construction industry’s sustainability goals and efforts to minimize carbon footprints. Through comprehensive finite element modelling, we evaluate the structural integrity of DLT beams incorporating CW dowels, considering critical factors such as damage initiation within timber boards and dowels. Our findings provide valuable insights into advancing environmentally friendly building practices, contributing to the ongoing global initiatives aimed at mitigating climate change impacts in the built environment.

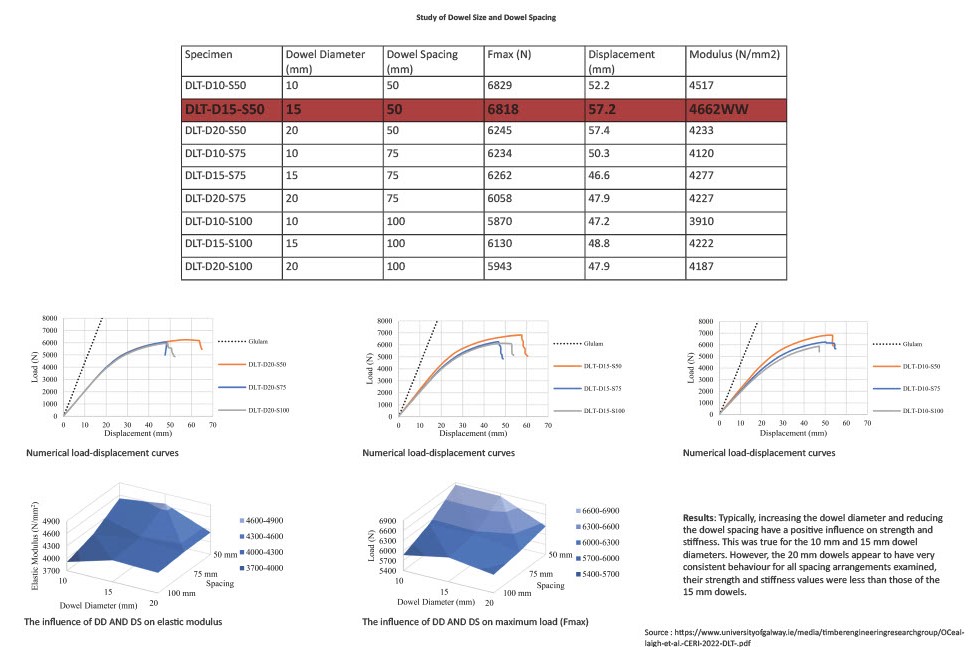

Results: Typically, increasing the dowel diameter and reducing the dowel spacing have a positive influence on strength and stiffness. This was true for the 10 mm and 15 mm dowel

diameters. However, the 20 mm dowels appear to have very consistent behaviour for all spacing arrangements examined, their strength and stiffness values were less than those of the 15 mm dowels.

Conclusions:

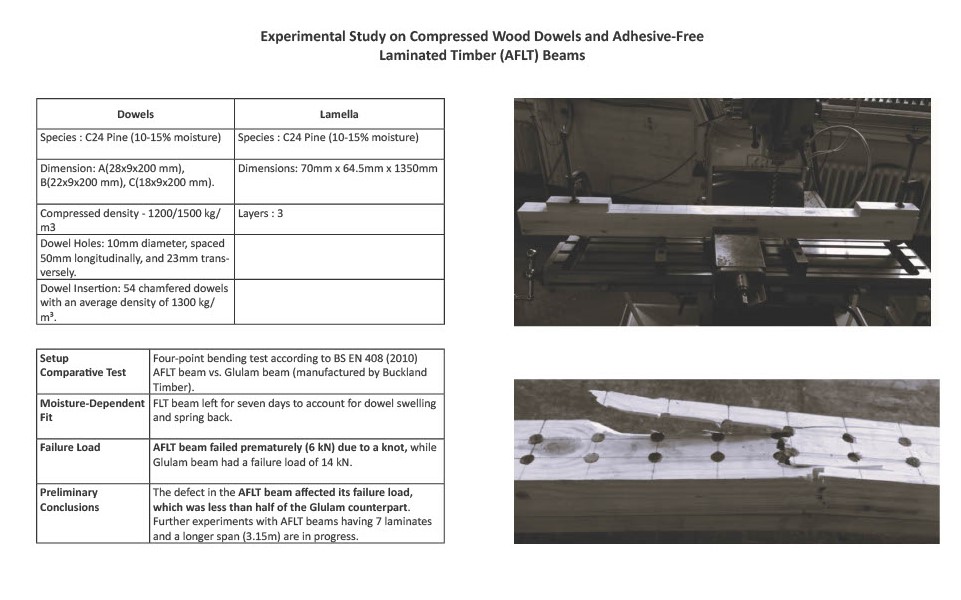

In this preliminary test, AFLT beams were subjected to four-point bending tests alongside glulam beams of similar dimensions. The AFLT beams, constructed with compressed wood dowels and timber laminae, exhibited premature failure due to a knot at the tension extreme fiber. Consequently, their failure load was significantly lower than that of the glulam counterpart. Further testing with AFLT beams of different configurations and spans is underway to assess their performance comprehensively.

HYPOTHESIS

Adhesive-free curved timber structural elements show promise for efficient load transfer under various conditions, warranting further investigation.

METHODOLOGY

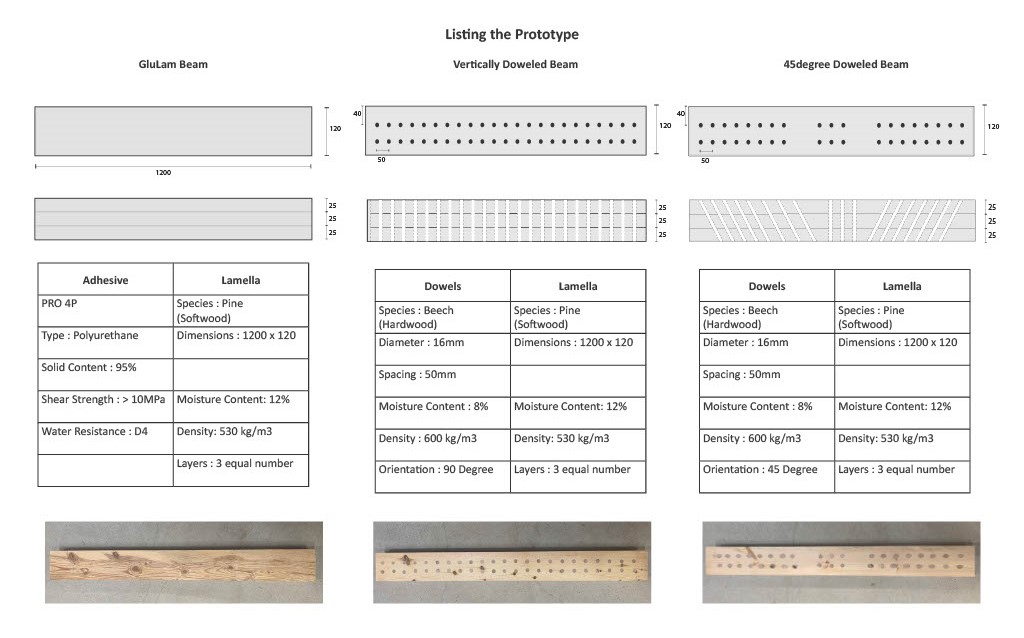

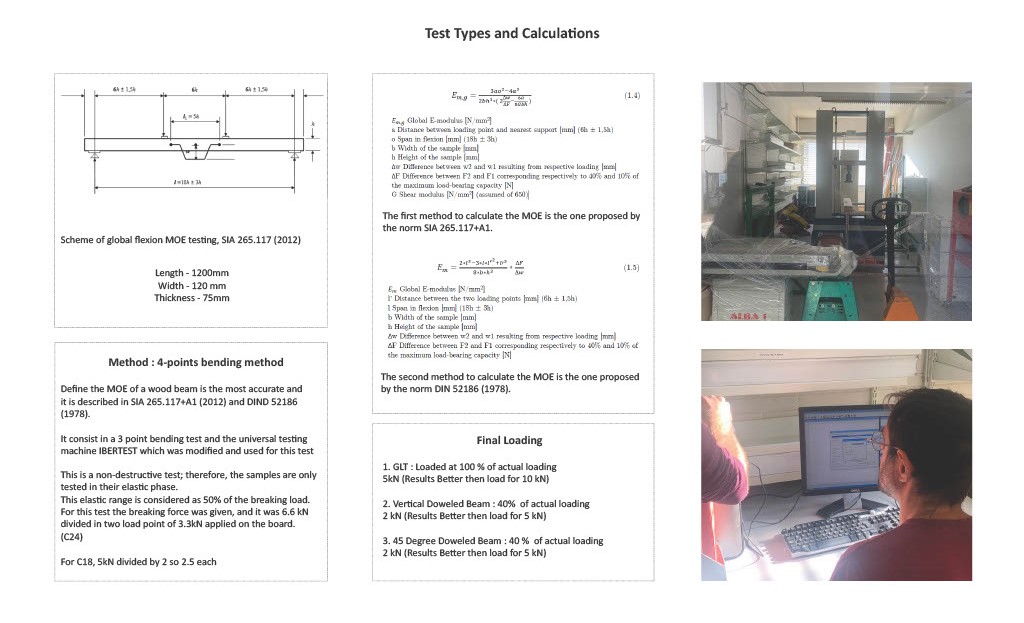

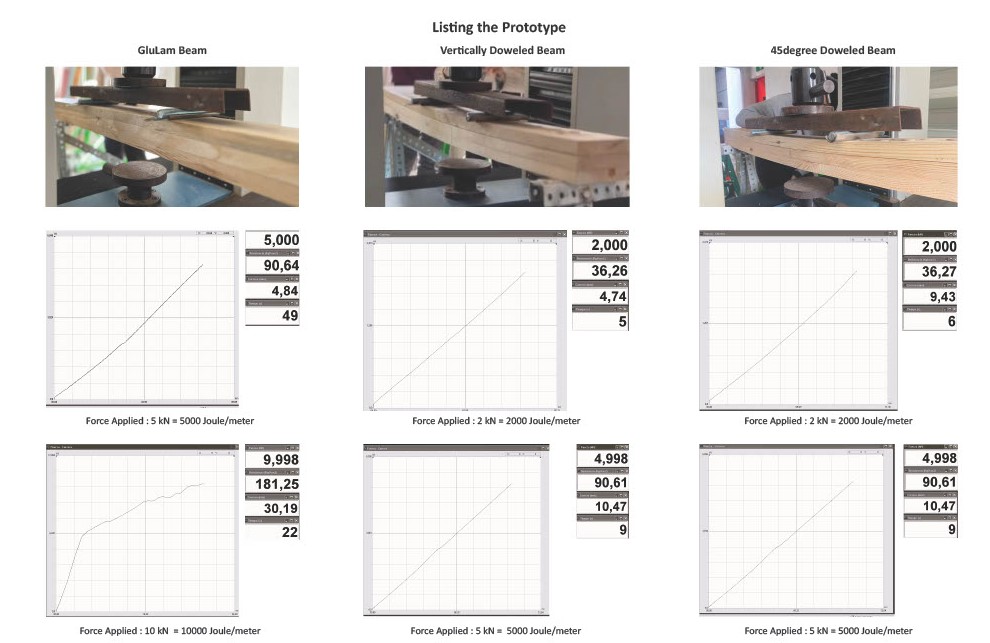

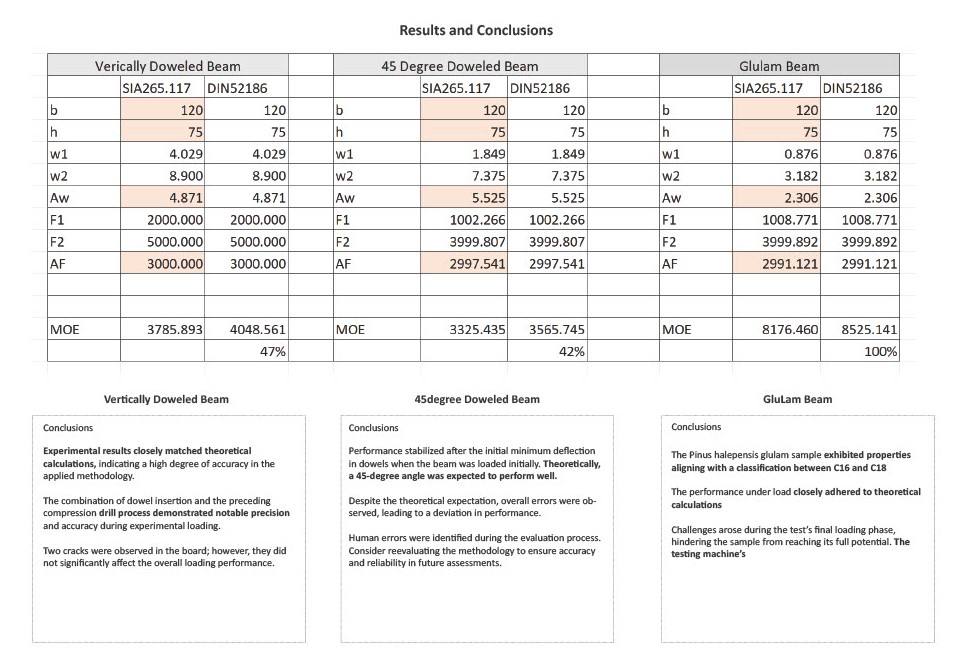

To understand how the dowel laminated beams work initial prototype study was carried out in the form of regular rectangular beams

Phase 1: Prototype

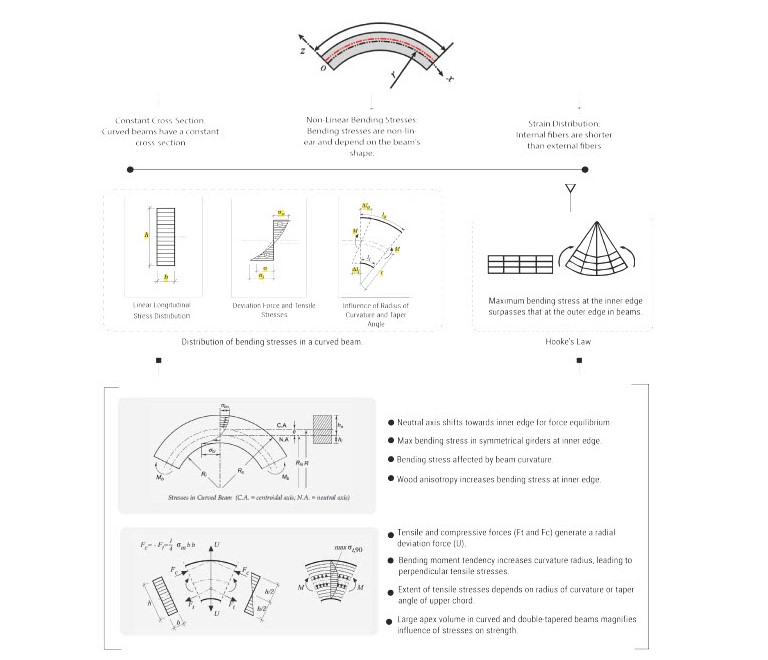

Phase 2: Understanding Curve Beams and their loading in bending

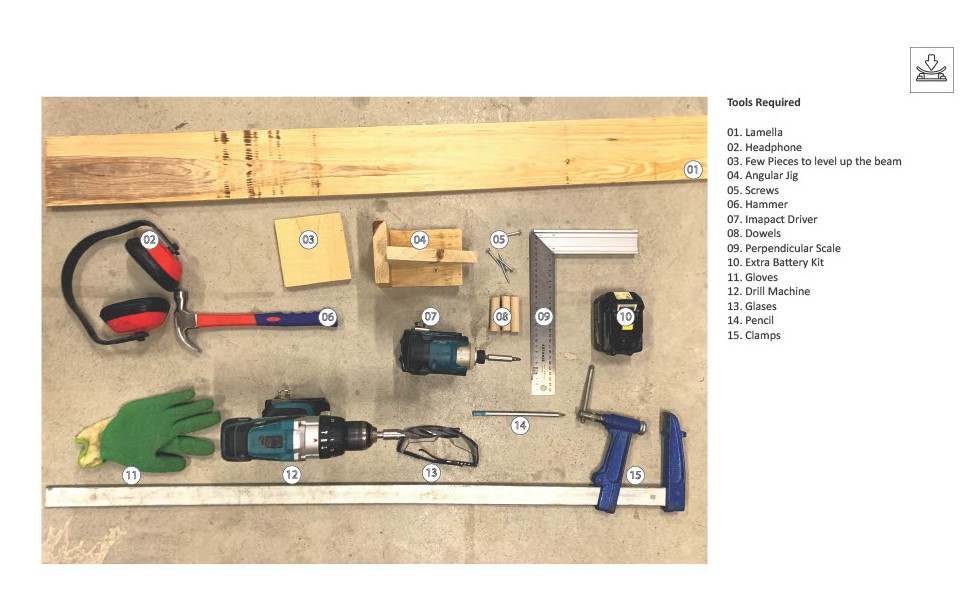

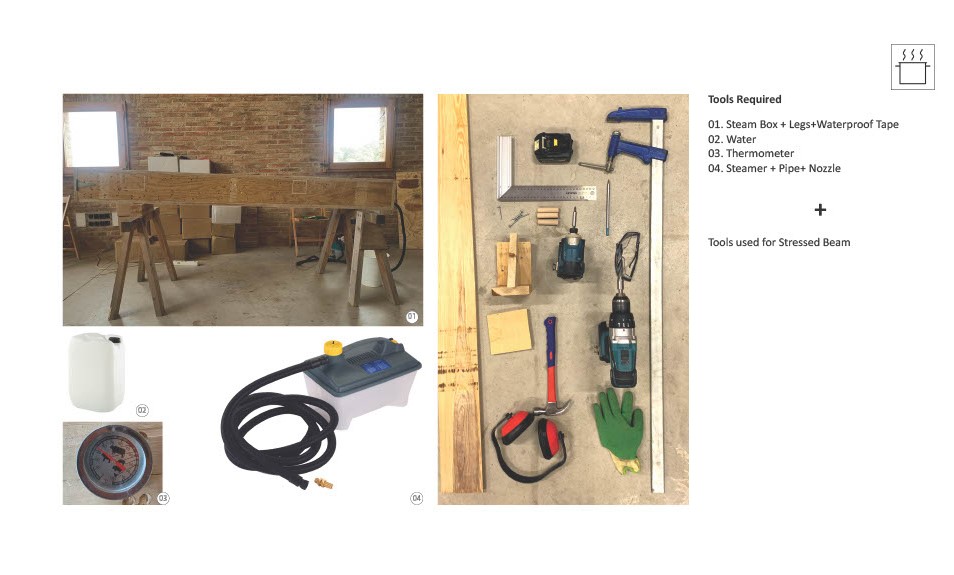

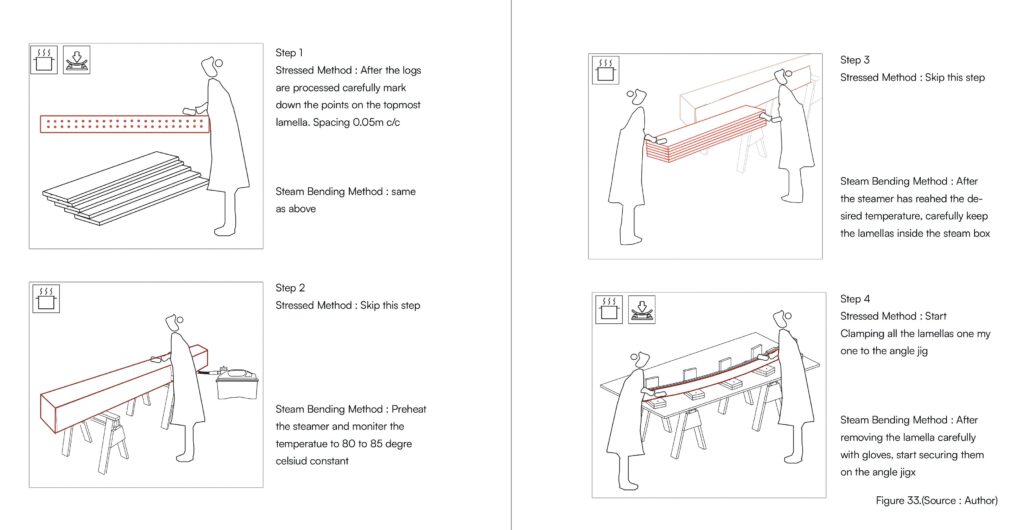

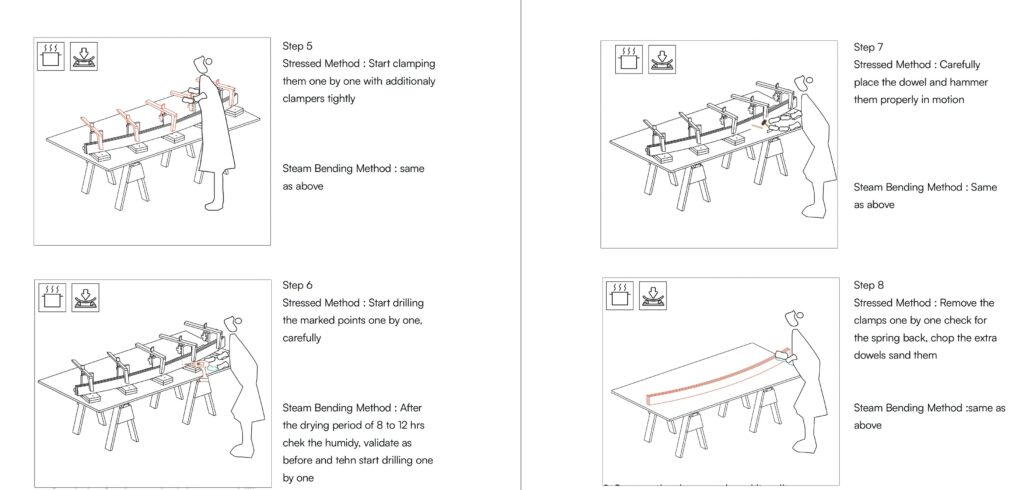

Fabrication Process: Steps / Methods and Tools

Methods/ Steps of Fabrication

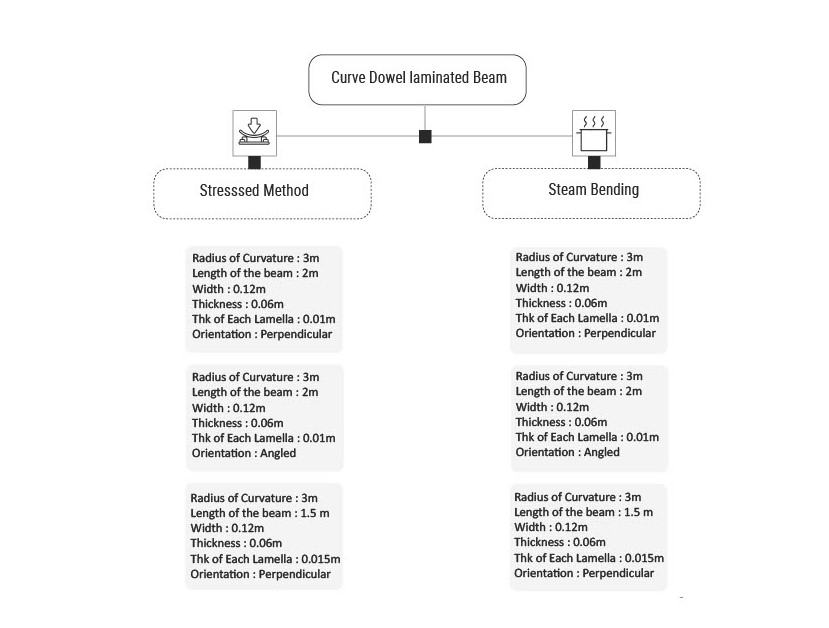

Types and Variations of Curve Dowel Laminated Beams

Phase 2 : Prototypes

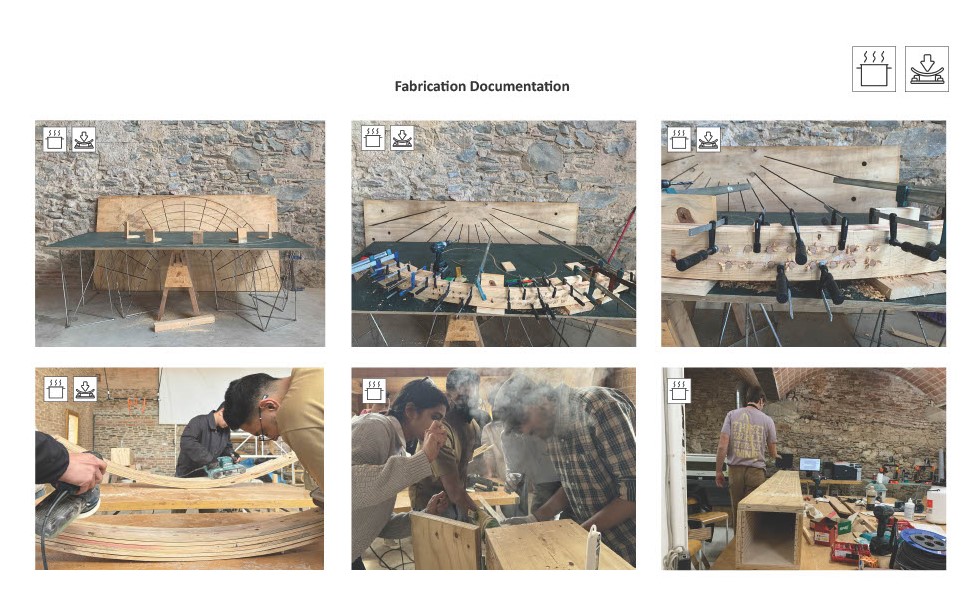

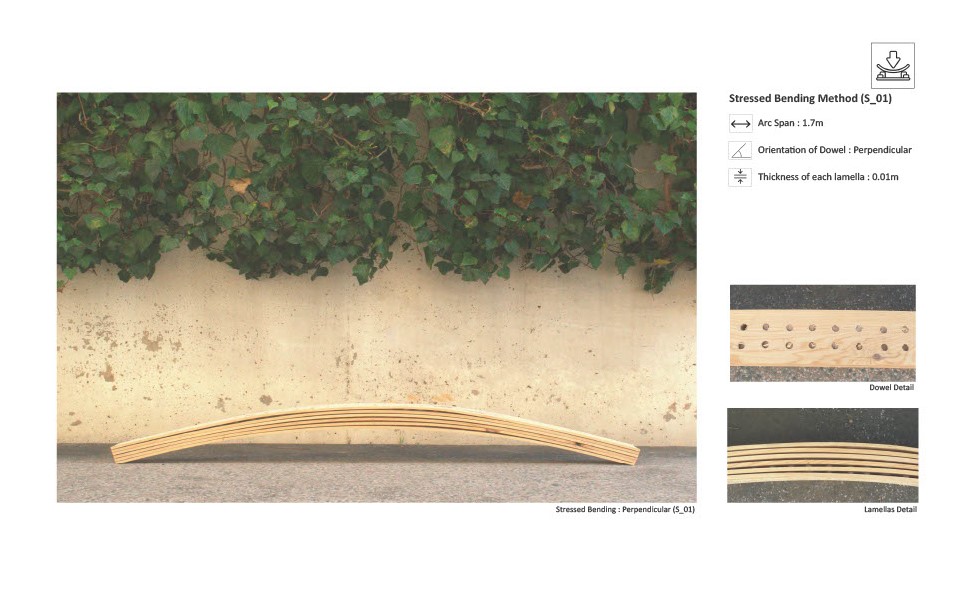

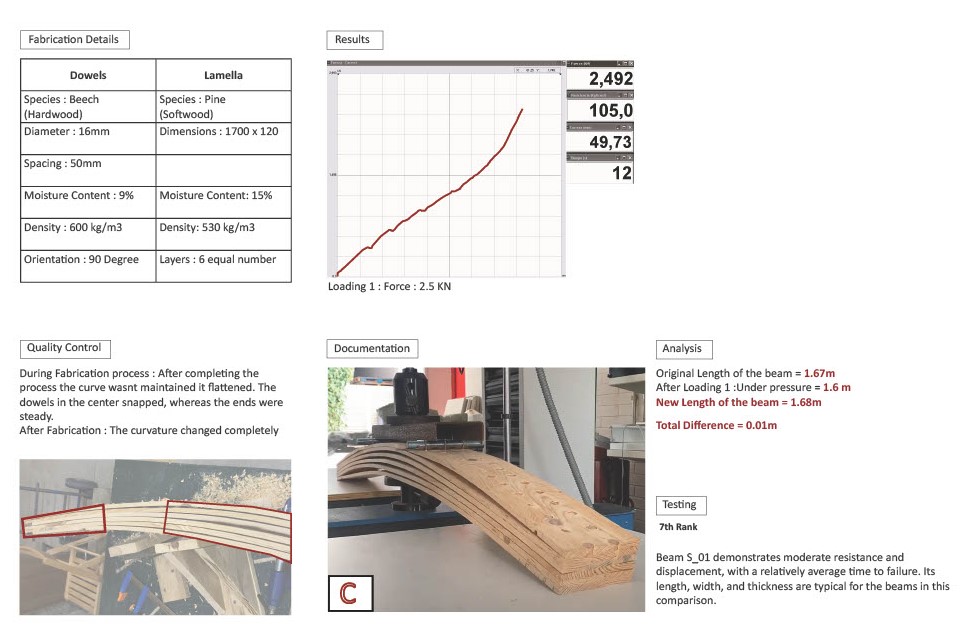

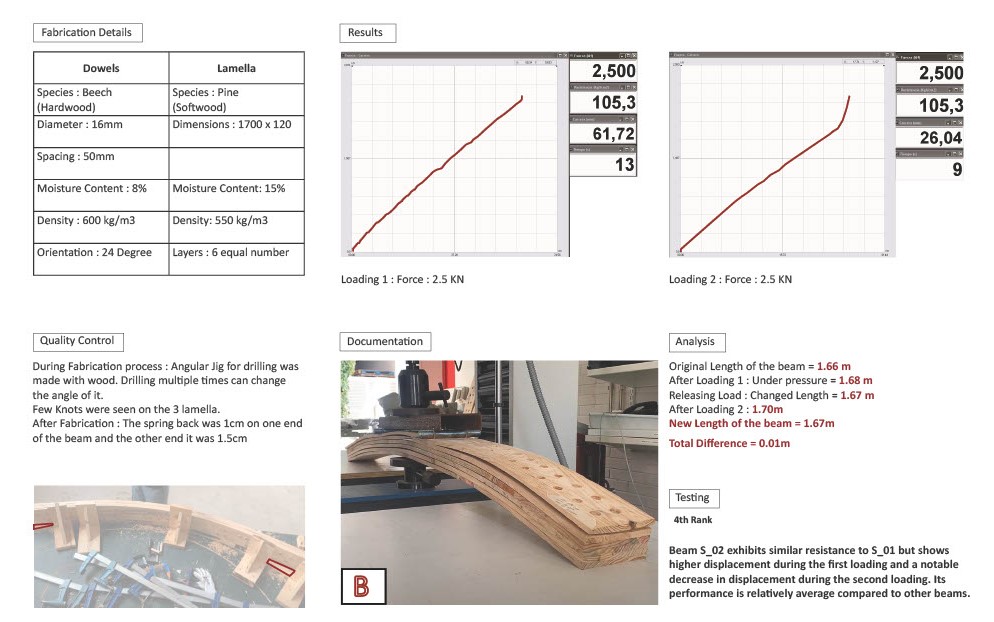

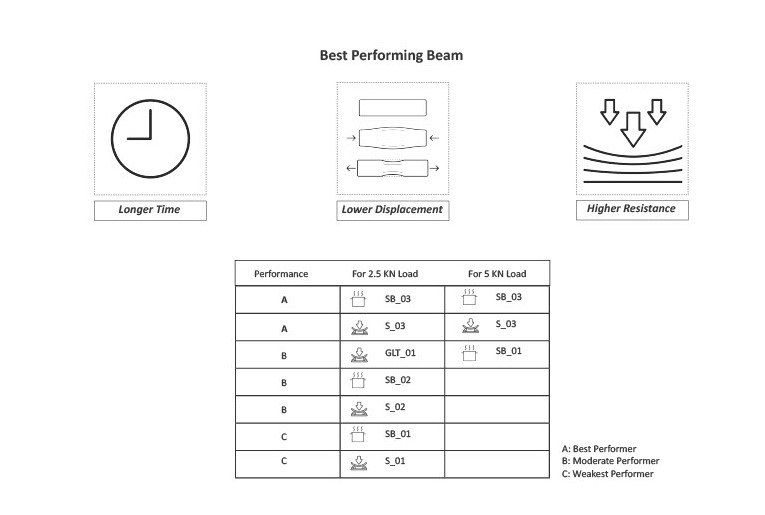

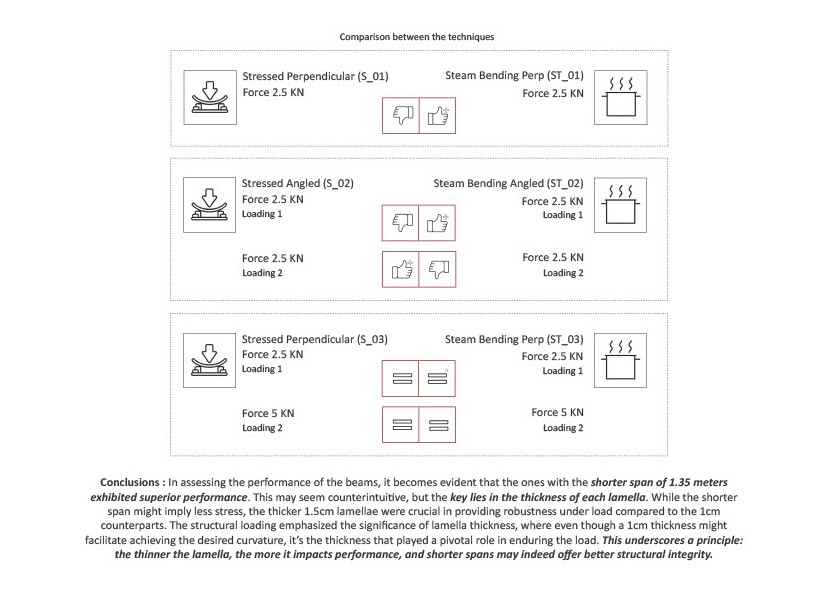

After the fabrication of the first beam, we meticulously recorded variations to discern the impact of methods, techniques, depth, and orientation on its load-bearing capacity.

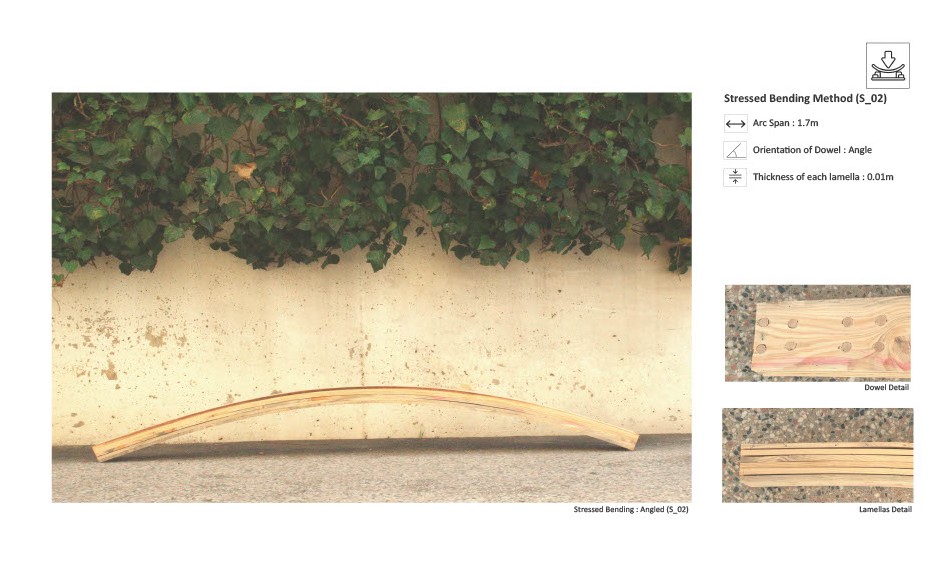

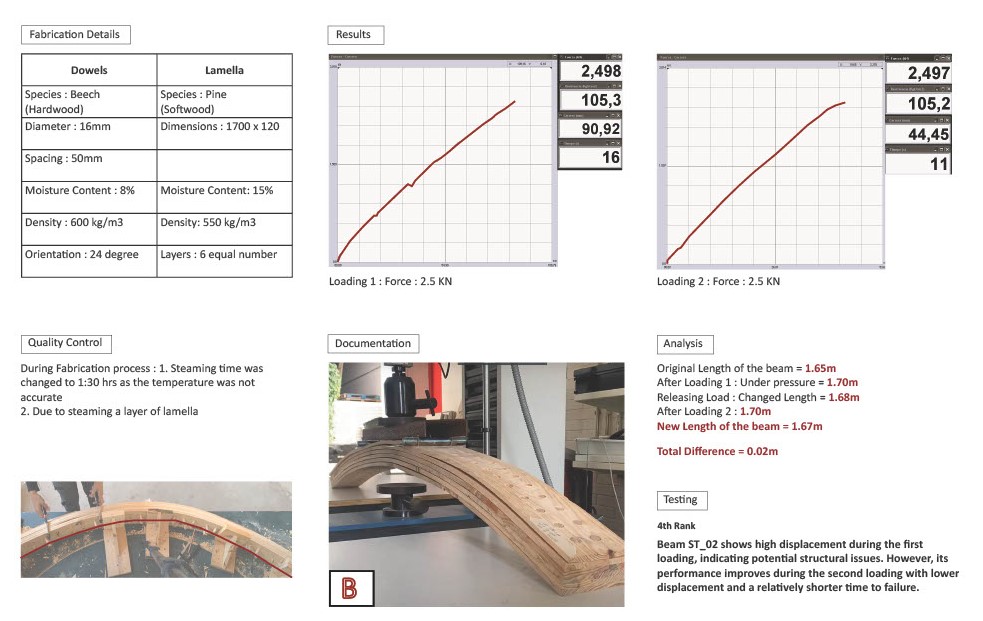

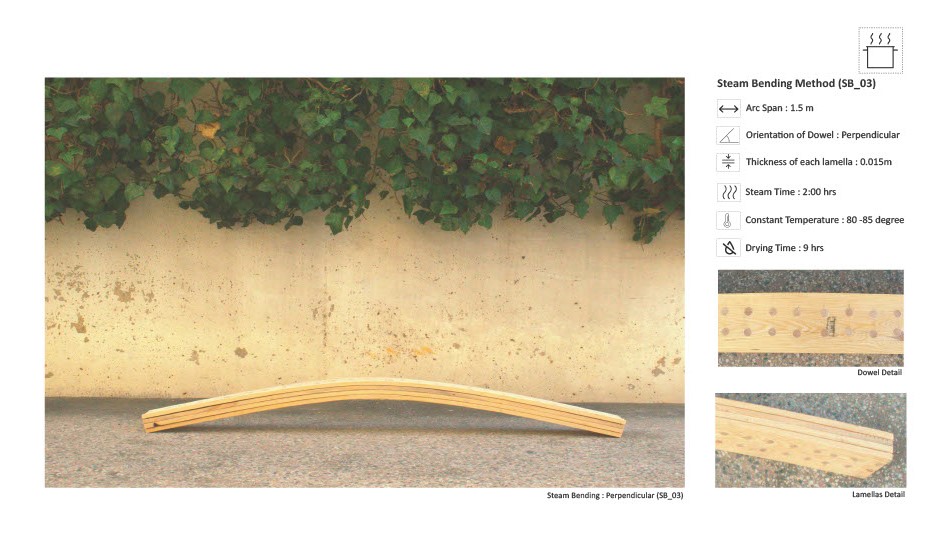

The exploration focused on the variable of dowel orientation. It was observed that an angled dowelled orientation could enhance beam stability and maintain its shape. However, following fabrication, the curvature altered, revealing that this orientation did not align effectively with the changing curvature of the beam.

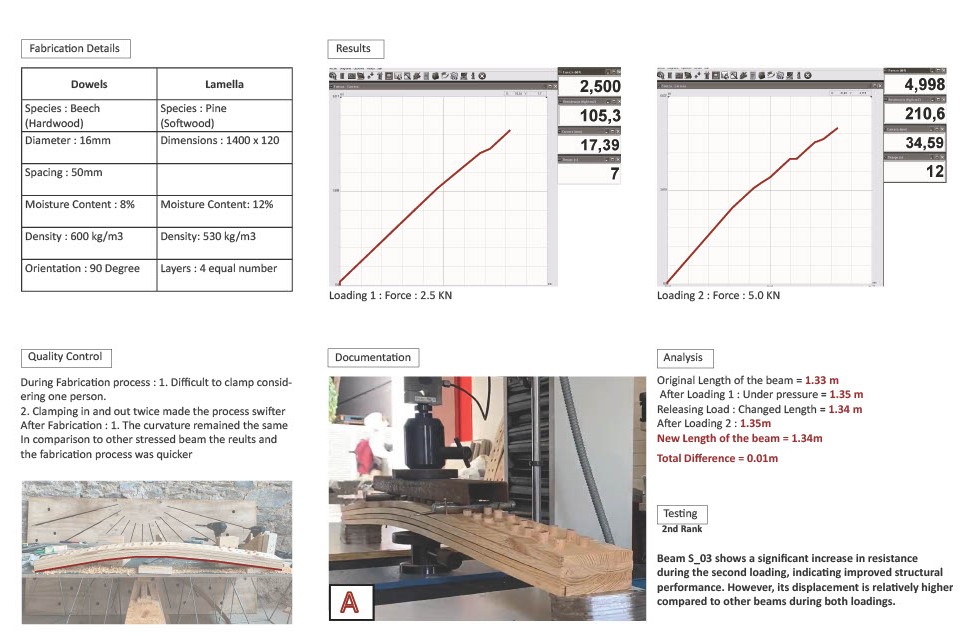

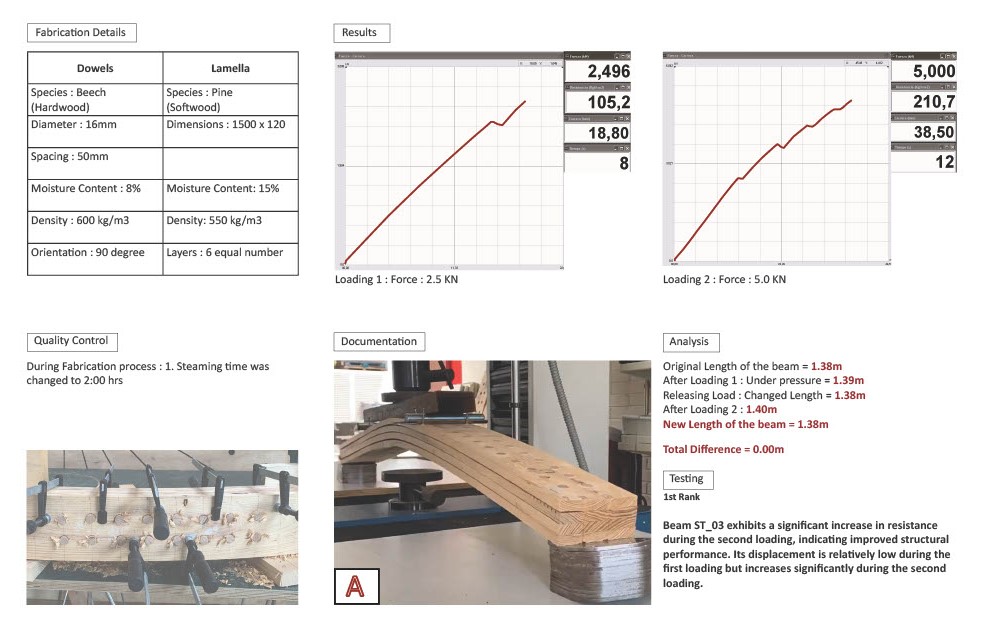

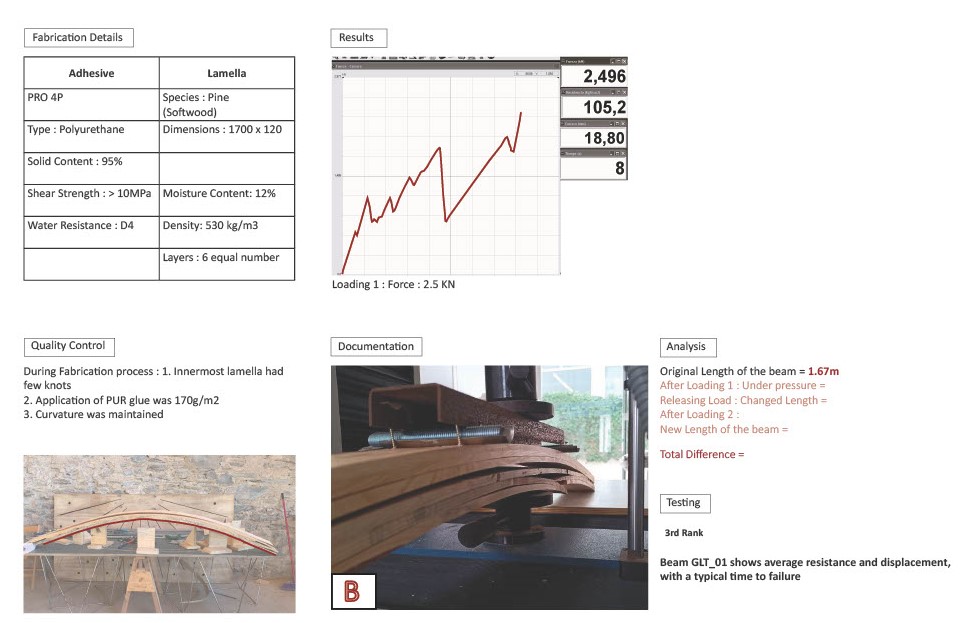

Stressed Bending Method: S_03 – Testing Results

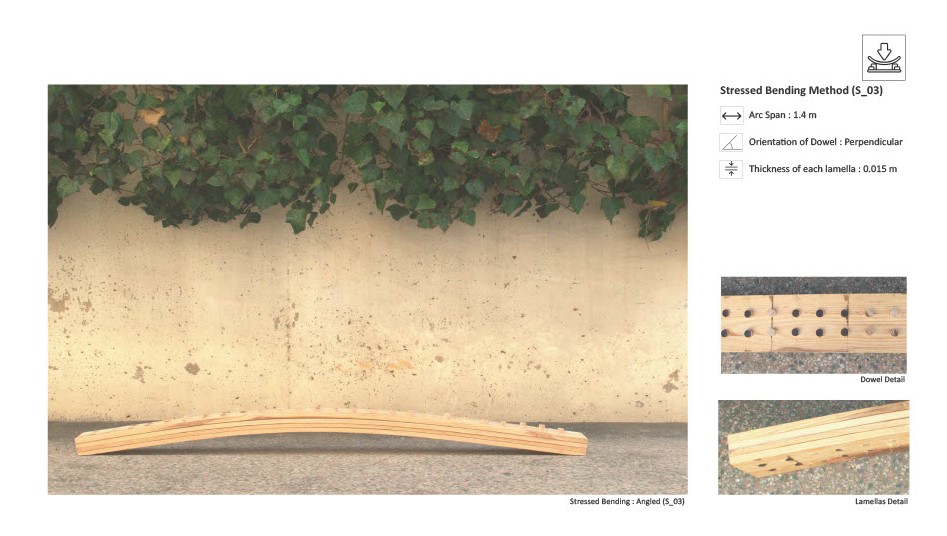

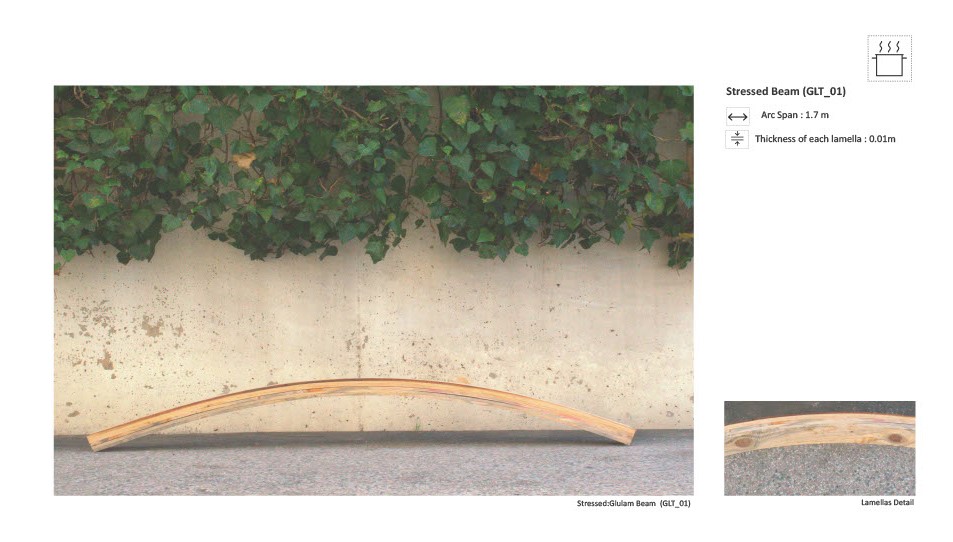

The exploration focused on the span of the beam and the thickness of each lamella. It was observed that a shorter span could enhance beam stability and maintain its shape. However, following fabrication, the curvature altered, revealing that this orientation did not align effectively with the changing curvature of the beam. After the testing was done the thickness of each lamella played a major role in stability.

Steam Bending Beams

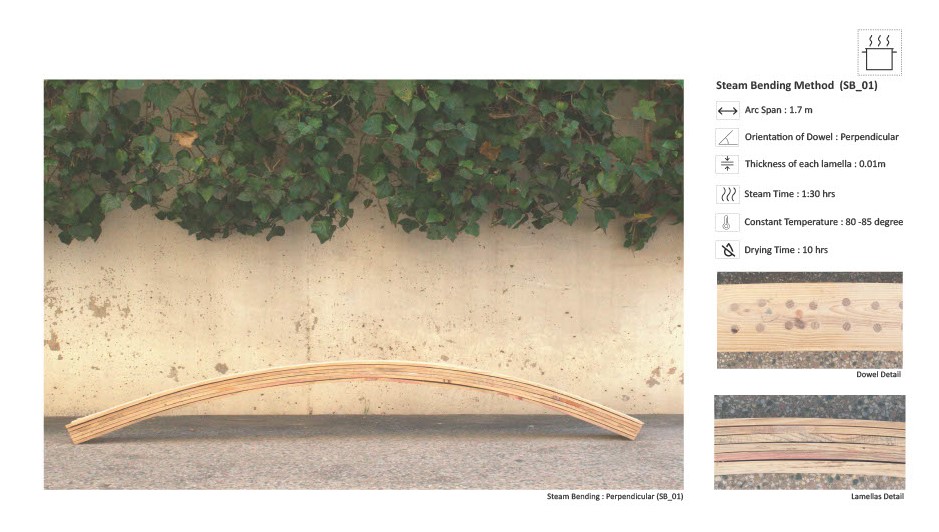

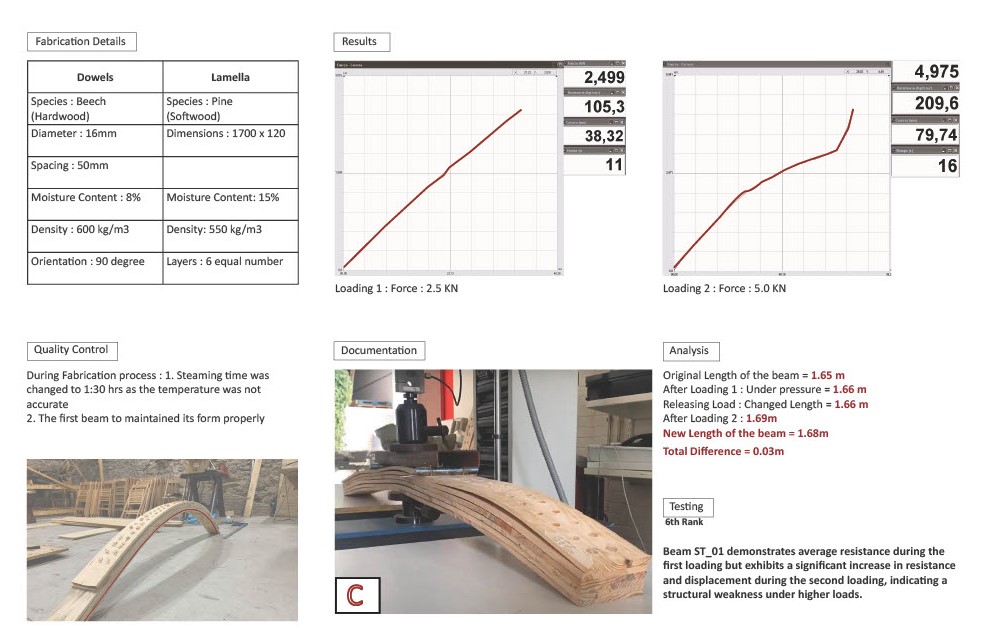

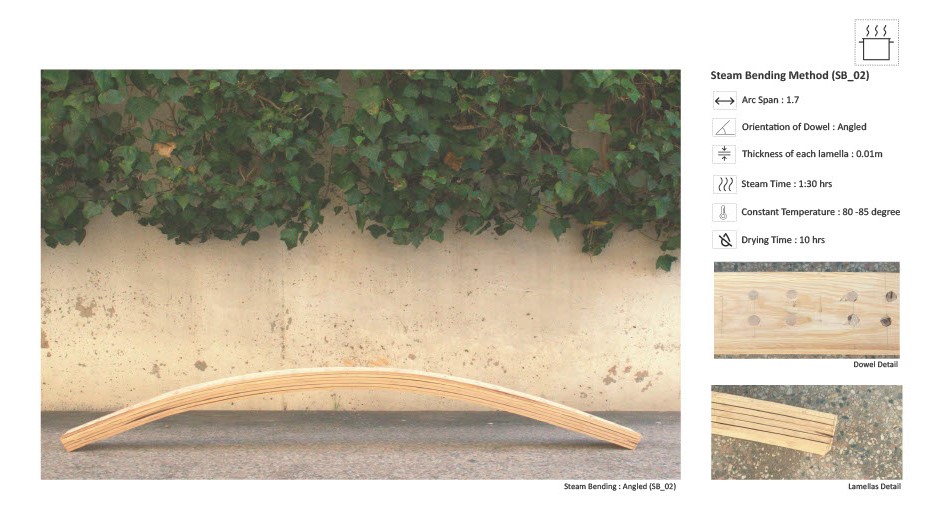

Steam Bending Method: SB_01

The exploration focused on changing the method of fabrication to obtain the curvature. The steam itself allows greater benefits to wood. The dowel orientation was vertical. It was observed that the curvature was maintained after the fabrication process due to the steaming of wood.

Final Conclusion for Phase 1

Further Studies: Moving forward, the immediate next step in advancing our research involves exploring the use of angled dowels and employing the stress method and steam bending technique to assess their effects on DLT assemblies. This approach aims to further enhance the quality and structural integrity of the beams by introducing innovative assembly methods.

Additionally, we propose incorporating robotic fabrication into the manufacturing process to evaluate its efficiency and feasibility in DLT assembly. By leveraging robotic technology, we can streamline the production process and potentially increase the scalability of DLT construction.

These proposed advancements not only seek to improve the performance of DLT structures but also aim to expand our understanding of the assembly methods and their applicability in real-world construction projects. By embracing innovative techniques and technologies, we can continue to push the boundaries of sustainable construction practices and contribute to the ongoing evolution of timber engineering.

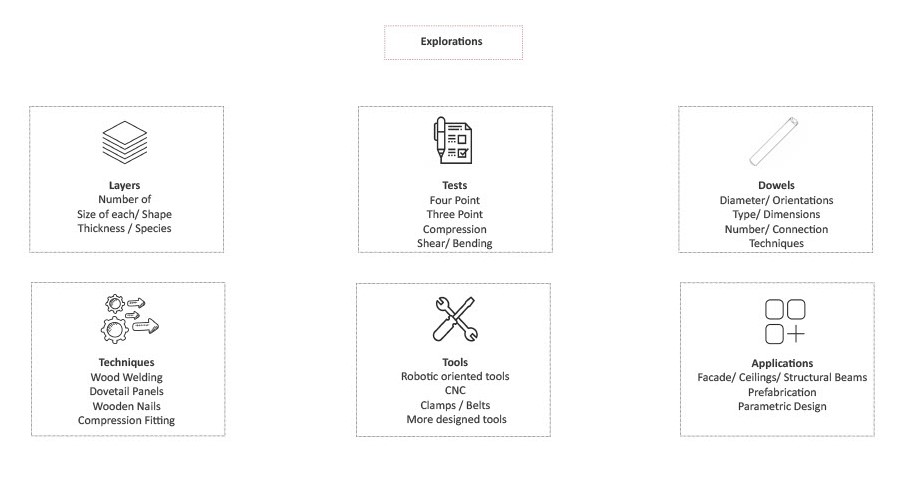

In the pursuit of maximizing the capabilities of dowel laminated timber (DLT) assemblies, we embark on a multifaceted exploration, delving into the intricate interplay of various parameters. By strategically adjusting layer configurations, integrating diverse tree species, and employing cutting-edge fabrication tools and techniques, we unravel a tapestry of innovation and possibility. This iterative process serves as a gateway to unlocking new dimensions of structural efficiency and versatility within DLT. By pushing the boundaries of conventional thinking, we not only optimize DLT for a myriad of applications but also usher in a new era of sustainable construction. As we navigate through these realms of exploration, we not only enhance the intrinsic qualities of timber but also propel it into the forefront of modern architecture and engineering.

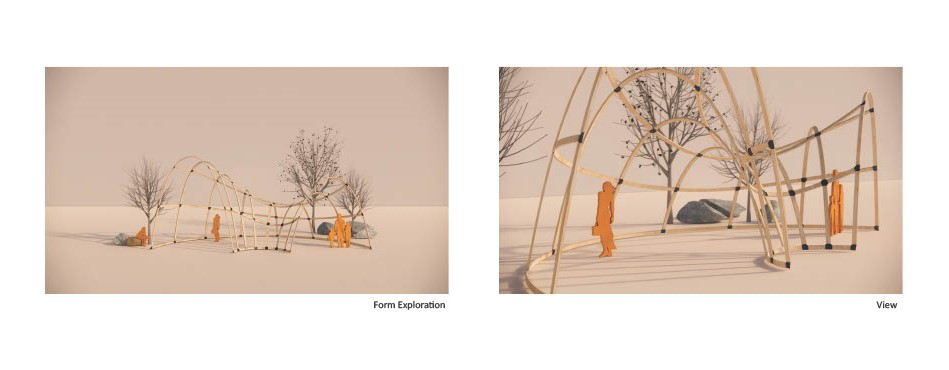

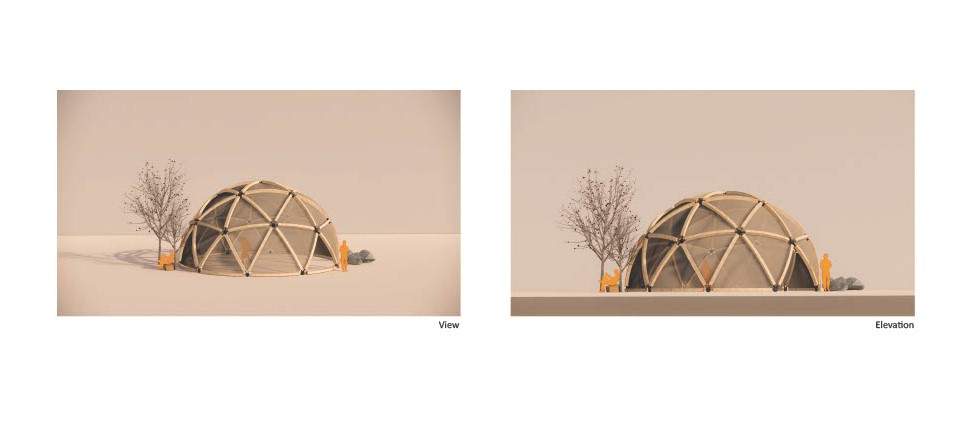

Proposals:

Two proposals were designed to explore the form and the potentials of these DLT beams in a Parametric Design.

Reflections:

In conclusion, this thesis has provided valuable insights into the structural capacity and potential of dowel laminated timber (DLT) assemblies. Within the scope of this study, I have delved into the mechanics of DLT structures, exploring their load-bearing capabilities and deformation characteristics under various conditions. The findings presented here shed light on the promising aspects of DLT as a viable alternative in the construction industry, particularly in the context of sustainability and environmental impact.

It is important to note that while this study has offered significant contributions to understanding DLT assemblies, there remain avenues for further exploration and research. As highlighted, even small variations in parameters can yield different conclusions, suggesting the need for more comprehensive studies. Additionally, while DLT shows promise, it is not intended to discredit other assembly techniques prevalent in the market. Rather, this research serves to elevate the discussion around DLT and its potential applications, paving the way for future advancements in timber assembly methods.

Furthermore, the integration of bio-based adhesives with DLT holds immense potential, not only in terms of structural performance but also in promoting environmental sustainability. My collaborative efforts in exploring and implementing such technologies will undoubtedly contribute to the evolution of timber assembly practices and their positive impact on both industry and the environment. In essence, while this thesis marks a significant step forward in understanding DLT assemblies, it is just the beginning of a broader journey towards realising their full potential. By raising awareness and fostering innovation in timber assembly techniques, I can unlock new possibilities for sustainable construction practices and contribute to a greener, more resilient built environment.

Special Thanks to Brian (Structure Craft) & Appenzeller Holz