In the dynamic field of structural design, efficiency has emerged as a central theme driving innovative solutions. Our recent venture in the structural design and optimization seminar delves into the intriguing concept of minimal surfaces applied to timber gridshell structures. But what exactly do we mean by minimal surfaces?

Defined as shapes that require the least amount of material to enclose within a specific boundary, minimal surfaces became the focal point of our project. The canvas for this exploration was the Mass Timber Innovation Center—a visionary initiative inspired by the Detroit Future City Strategic Framework. This center is not merely a construction project; it is a deliberate effort to exhibit sustainable practices, support local employment, and instill community pride.

This blog post unfolds the intricacies of developing a timber structure that not only showcases engineering finesse but also sets new standards for resource-conscious design. Read on as we dissect the synergy between minimal surfaces and timber structures in the context of the Mass Timber Innovation Center.

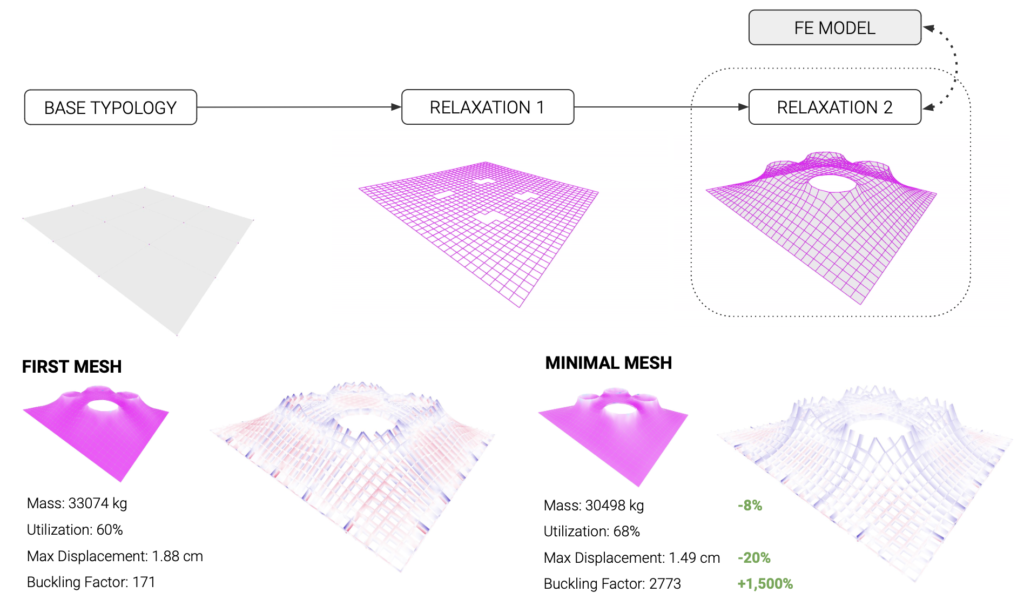

Mesh Relaxation in Timber Structure Parametrization:

Within the intricate world of structural design, our journey into crafting a timber structure based on minimal surfaces unveils a critical chapter—mesh relaxation. This essential process, central to our parametrization methodology, transforms a humble planar mesh into a structurally optimized roof structure.

Commencing with a foundational planar mesh, our design undergoes a meticulous evolution through mesh relaxation. This technique, involving the reduction of edge lengths to zero and the strategic introduction of curvature, serves as the cornerstone of our approach. The result is a refined, minimal mesh that not only decreases mass but also maintains high structural utilization—a delicate equilibrium that significantly enhances the overall system’s buckling factor.

In the following sections, we will delve into the intricacies of our parametrization process, shining a spotlight on the indispensable role of mesh relaxation. Join us as we explore how this method becomes the silent conductor, orchestrating the harmonious balance between structural efficiency and resource consciousness in our timber design. Step into the heart of innovation, where mesh relaxation emerges as the key player in reshaping the landscape of sustainable timber structures.

Once the parametric system is deployed, we utilize Karamba3D to validate, design, and optimize the structural performance of the FE model and global system.

Loads:

The diagram below illustrates the load conditions utilized for the structural design. Meshes are used to distribute superimposed, live, and wind loads. Prevailing winds come from the West, therefore, we apply both pressure and suction along this cardinal direction.

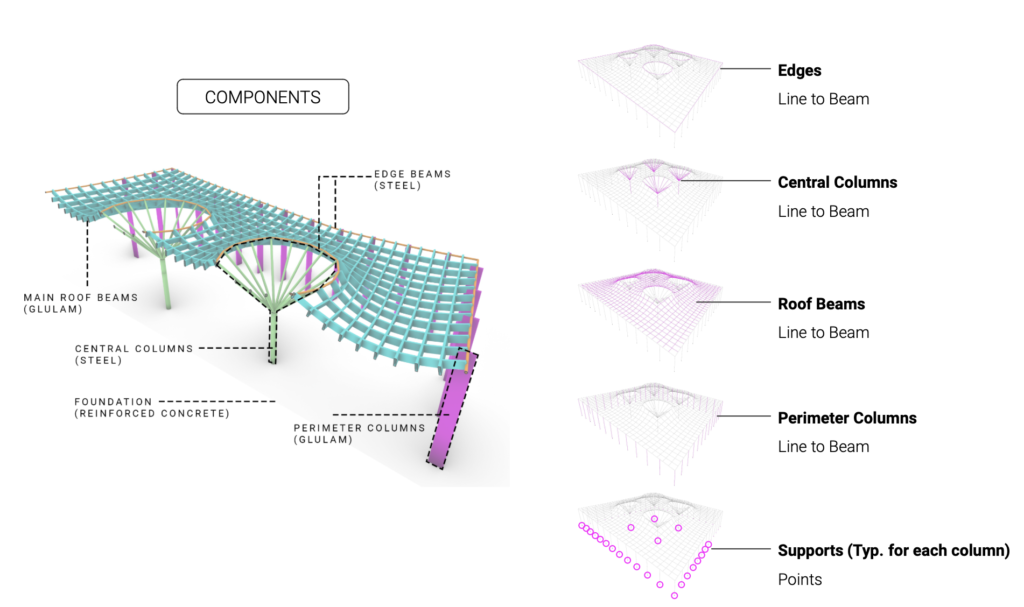

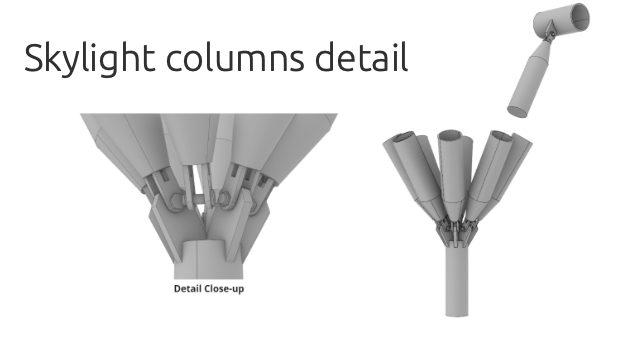

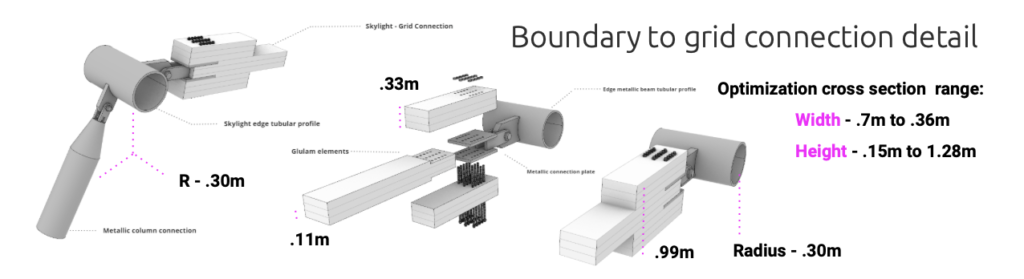

Construction:

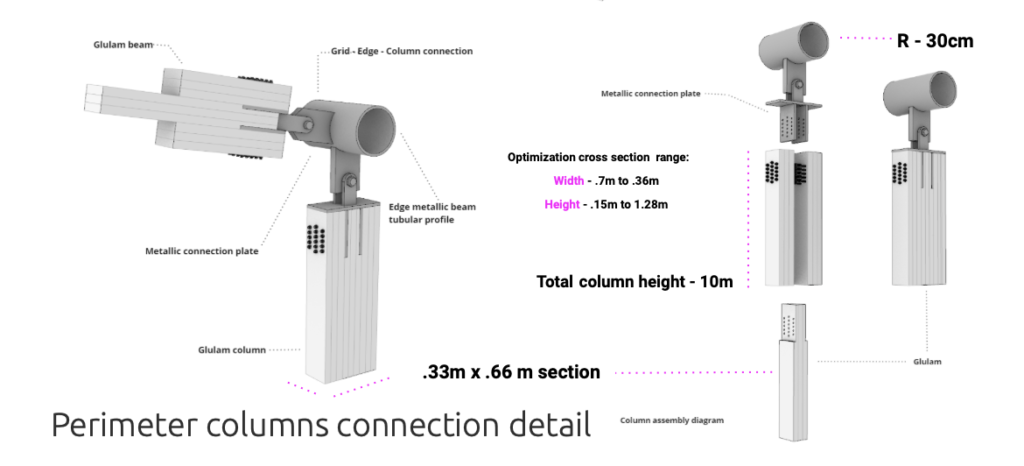

Derived from our structural analyses, the diagrams below detail the functionality of our system. Central to our design is the integration of a glulam gridshell, contributing to enhanced strength and efficiency.

Optimization Process:

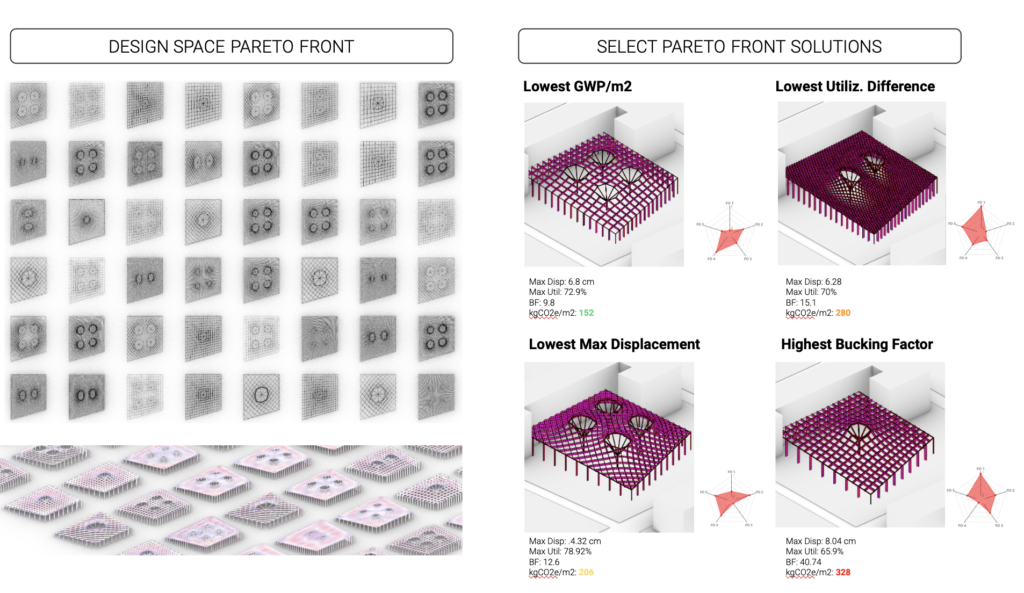

In the optimization process, we conducted an exhaustive exploration of over 1 billion potential combinations using Wallacei X to attain what we deemed the best result. Design parameters are illustrated below; our design goals are to minimize Max Displacement, Max Utilization, kgCO2e/m2, Buckling Factor (with an emphasis on maximization), and roof Mean Curvature. Importantly, calculations for Global Warming Potential of our different structural elements is built directly into our script so that we can automatically calculate and optimize for CO2 performance as the structure changes.

Iterations and selection:

Here, we showcase our final selections from the pareto front for our multi-objective optimization (MOO) procedure. Additionally, we provide a glimpse into the diverse explorations undertaken during this process. Ultimately, as designers we selected an option that performed relatively well in all aspects and still met the architectural and aesthetic goals of the project.

In conclusion, our observations underscore the superior utilization efficiency of the diagrid configuration within the structural context. However, it is important to note that while the quad grid demonstrates better CO2 performance (less GWP/m2), it does so at the expense of aesthetic quality. The presence of uneven skylights adversely impacts overall performance, resulting in a CO2 SCOR exceeding 300. Furthermore, a grid spacing exceeding 3m tends to lead to failure, with utilization exceeding the 70% limit.

Upon evaluating these outcomes, it is evident that the CO2 SCORS, despite its commendable score of 232 in a grade system, contributes to an overall system grade of ‘C’. This underscores the significance of prioritizing carbon footprint considerations in the design process. Noteworthy structural parameters include a Max Displacement of 6.14 cm, Max Utilization reaching 69%, and a Buckling Factor of 17.61. These collective findings provide valuable insights for optimizing both structural and environmental performance in future design iterations, with the ‘C’ grade serving as a constructive guide for further enhancements.