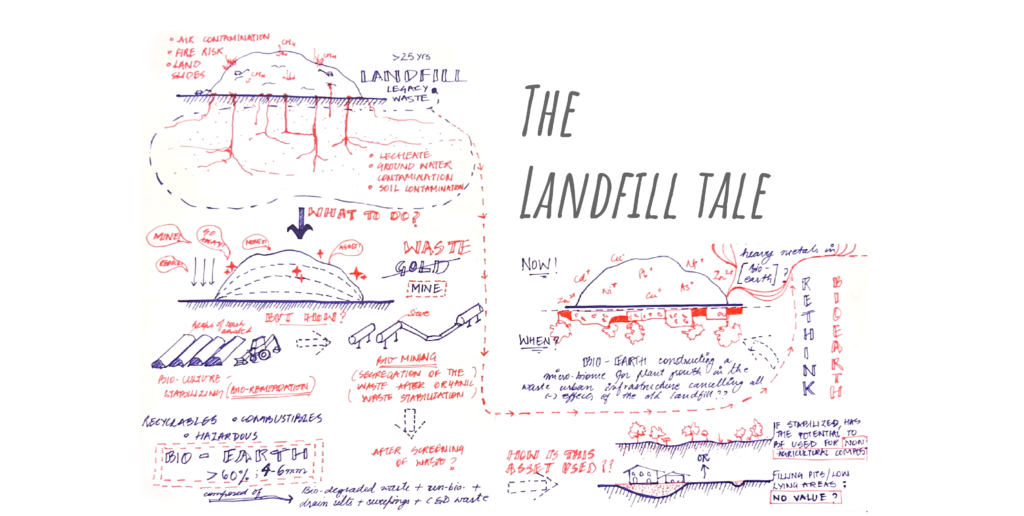

The excessive waste produced in countries worldwide is a grave and unignorable concern. Urbanization contributes to enhanced municipal solid waste generation, harming health and the environment. Landfills, globally emit thousands of tons of methane gas into the air, 30 times more harmful than CO2. Waste is not waste but a resource if managed judiciously. The thesis aims to reduce the load on landfills by diverting the legacy waste, giving it a new life, and forming it into materials that mitigate the harmful effects to the ecology and result in regenerative design.

Problem Statement

Less than half of people know that municipal solid waste is dumped in landfills and those landfills in turn rank 3rd in the global methane production, accounting for 18% of the total methane produced. LFM is a less well-known method of handling solid waste in old landfills/ waste dumps and is increasingly utilized as time goes on. LFM is the extraction and processing of legacy waste from an active or closed landfill for extracting secondary resources to mitigate the effects of rising raw material costs and other environmental reasons.

Info: People’s unawareness about waste management, Source: Making Delhi Swachh; Participatory Solid Waste Management Policy for Delhi (2015)

Info: Waste/Landfill is 3rd highest global methane producer, Source: Estimates from end-uses are for 2019 (IEA, Greenhouse gas emissions from energy, 2021

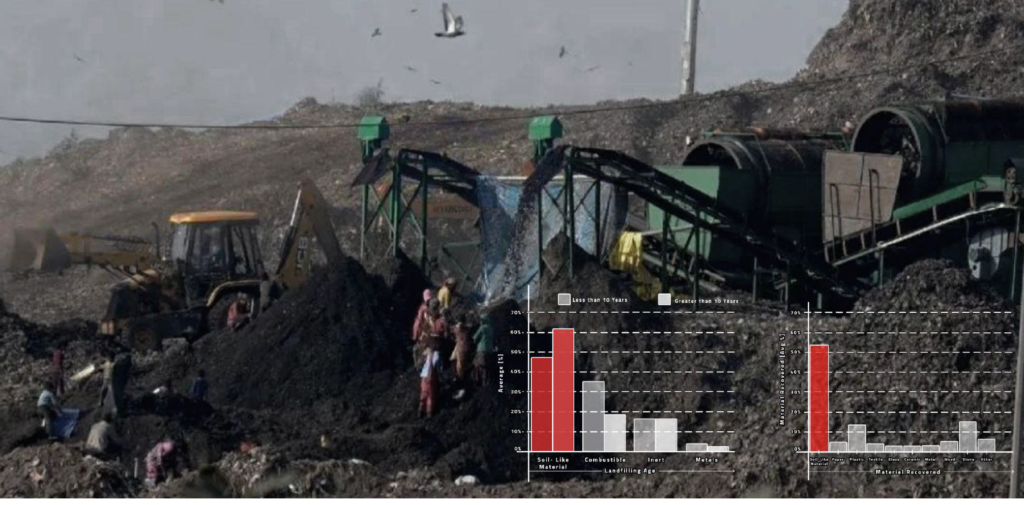

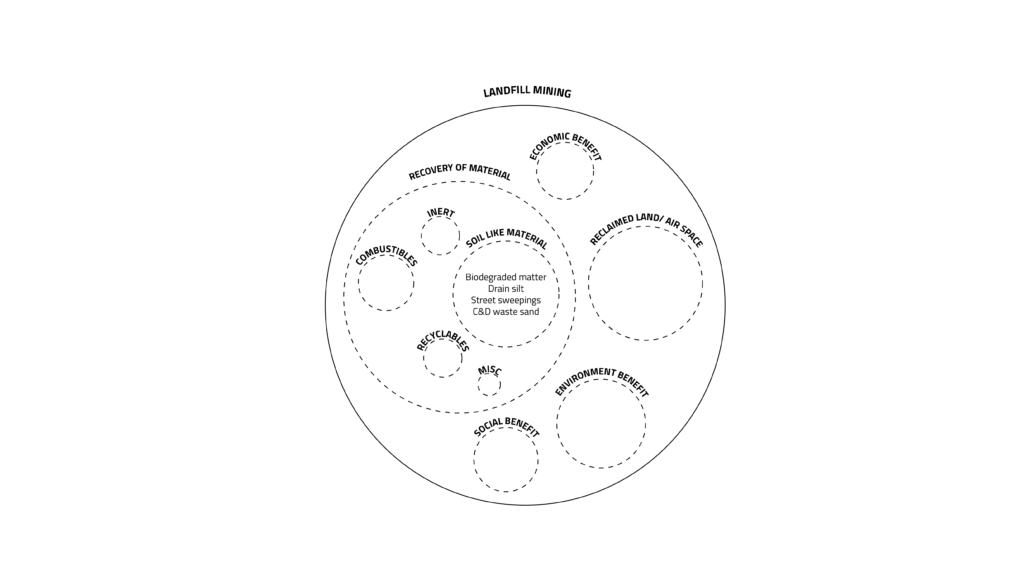

The process of landfill mining is carried out around the world but for different reasons. Some of the important factors are urbanization, material recovery, environmental protection, closure/post-closure, etc. Landfill mining first requires the extraction of chunks of landfill waste from the landfill. The extraction is followed by, not a universal step, of bio-remediation, in which parallel windrows are set to air and bi-innoculate the legacy waste, to biodegrade the organic matter quicker. This step gives a dried, shrunken volume of waste which is further sent for bio-mining, a step where sieving of the waste is done. The sieving is done in different sizes ( <4mm->150mm) and can be followed by magnetic separation etc., to extract various kinds of materials, ranging from combustibles (plastics, etc.), debris waste, recyclables, soil-like material(SLM, the finest of all) and miscellaneous. Material extraction is a part of the bigger pool of landfill mining which has various other benefits as reclaimed land benefit and social, environmental, and economic benefits.

Info: Why different countries adopt landfill mining, Source: https://www.iea.org/data-and-statistics/data-tools/methane-tracker-data-explorer

Info: Average extracted material composition in Landfill mines, Source: Calderón Márquez, A. J., Cassettari Filho, P. C., Rutkowski, E. W., & De Lima Isaac, R. (2019). Landfill mining as a strategic tool towards global sustainable development

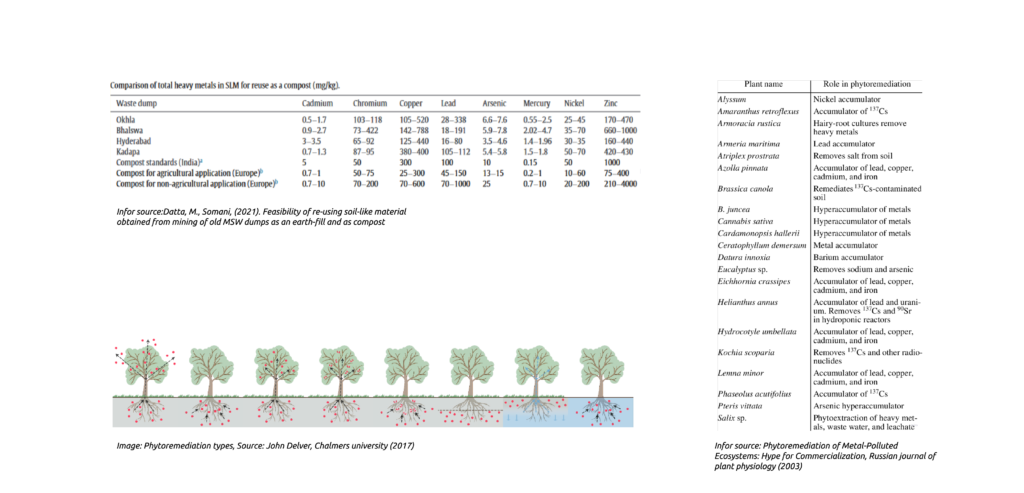

More than 50% of the recovered materials from mined landfills around the world are identified as inert soil or Soil-like material or fines. It comprises mostly biodegraded matter but differs from regular compost or soil because it has been retrieved from the landfill’s legacy waste and has particles <4mm, including drain silt, street sweeping, C&D waste sand, and many other contaminants. These huge quantities of soil are met with a common practice of using it as an earthfill material which is a questionable end-of-life scenario for this mined ‘waste’ or material since it is being disused and can contaminate groundwater and nearby soil.

Scientific Interest

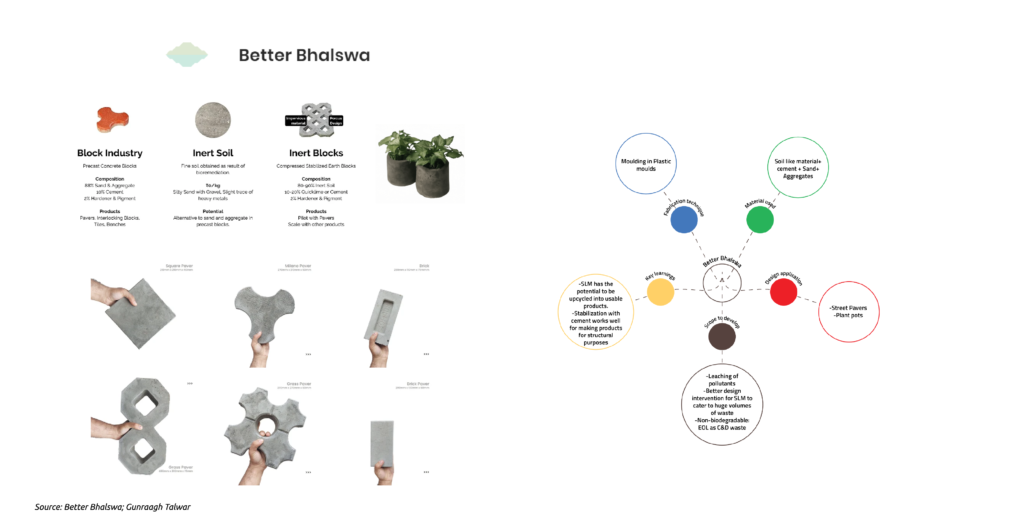

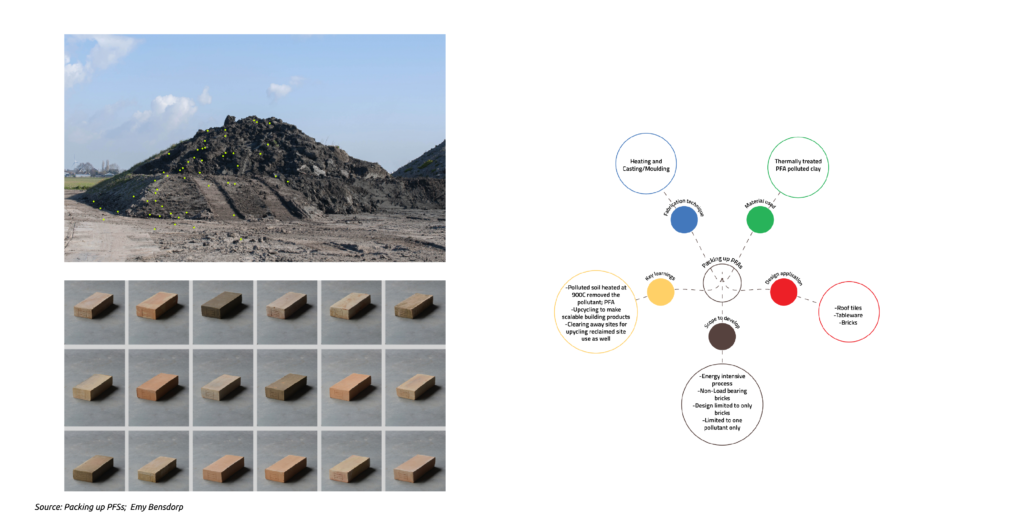

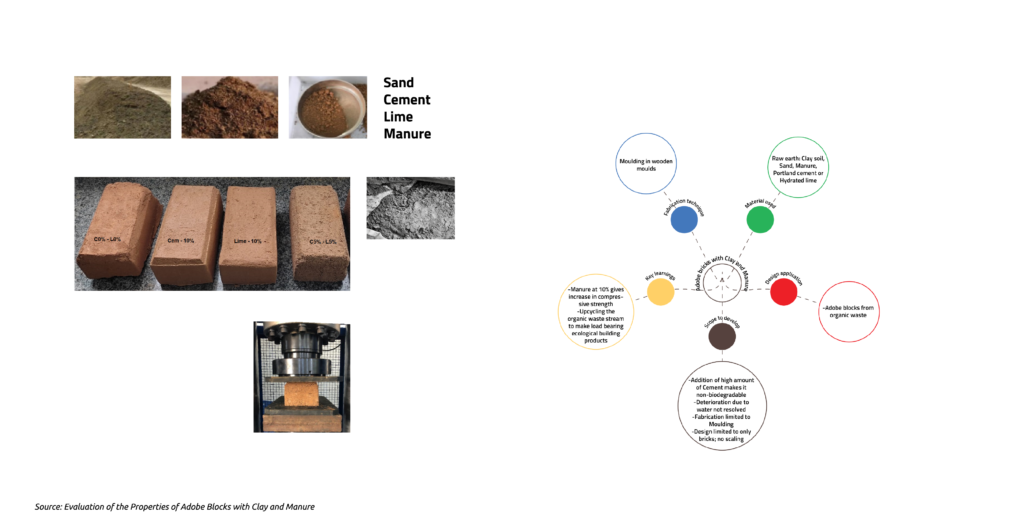

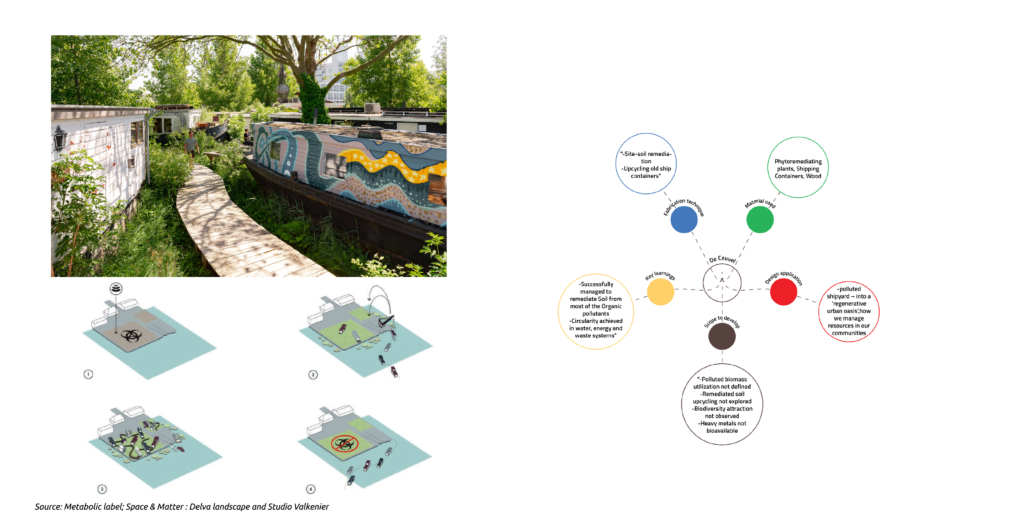

State of the art

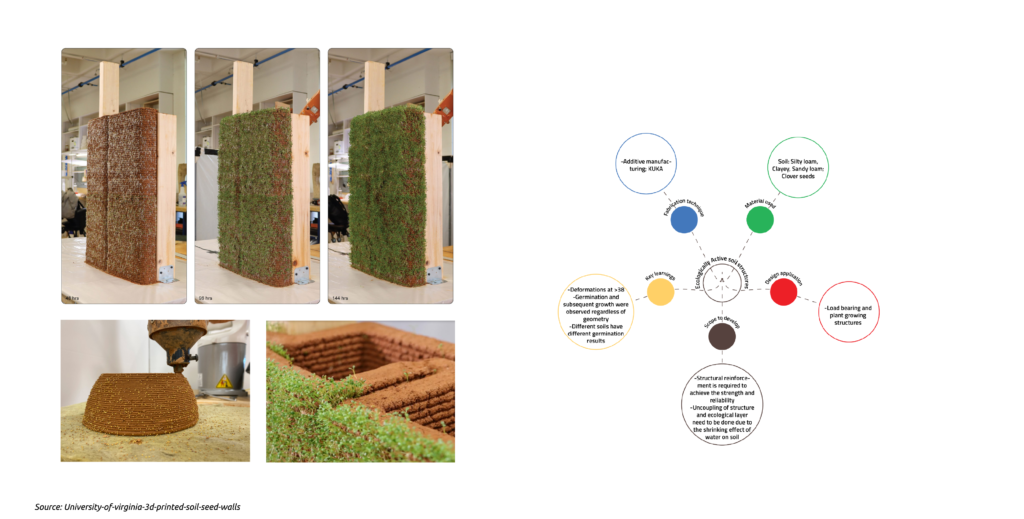

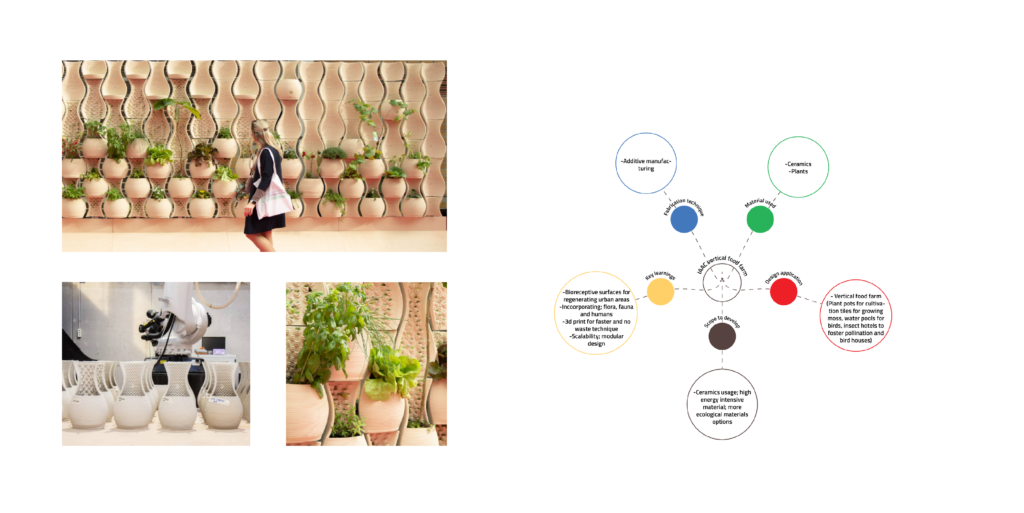

The state of the art is found in three major categories. Firstly, Identifying and studying architectural interventions for contaminated or landfill soil. Then, an analysis of organic matter-derived clay building blocks is done. Lastly, examples of nature-based solutions in earth/soil-based composites are studied.

1. Contaminated soil

2. Organic matter with clay

3. Nature-based solutions with clay/soil

Research Question

Can the soil-like-material (SLM) be continuously decontaminated/purified in its built form through bioremediation

techniques of phytoremediation and stabilization additives, using suitable digital fabrication techniques for SLM,

by formulating decarbonizing and regenerative design iterations?

Material Exploration

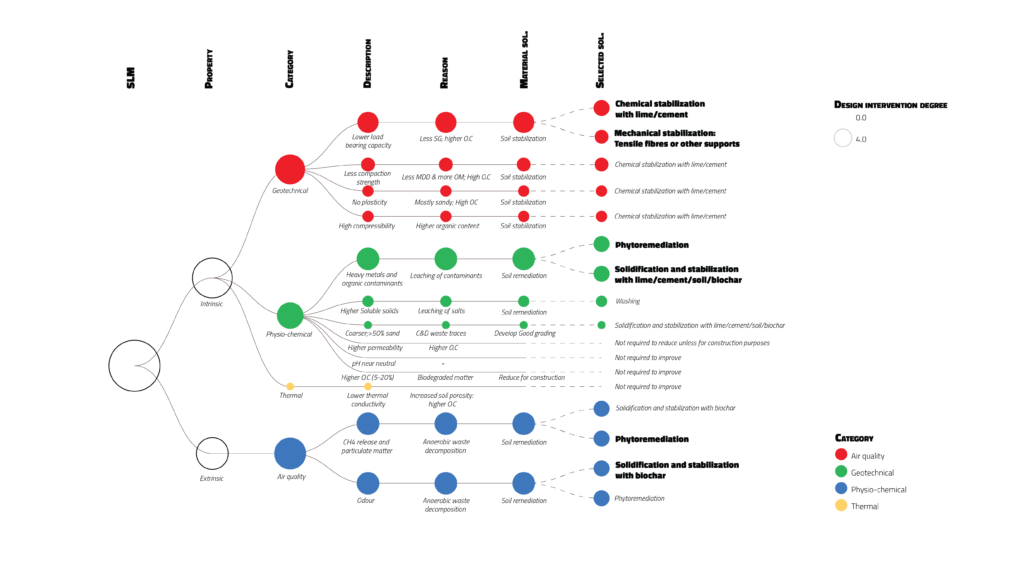

The soil-like material(SLM) is studied on three main intrinsic parameters; geotechnical, physicochemical, and thermal, and an extrinsic parameter of air quality. The observations are done in comparison with the background soil. Higher organic content and the presence of heavy metal/organic contaminants in SLM is observed to be the reason for compromising its geotechnical and physicochemical properties respectively. Through literature studies, analyzing various soil stabilizing methods for improving SLM’s geotechnical properties, two major methods are selected; chemical stabilization with lime/cement, and mechanical stabilization with tensile elements (fibers, etc.)

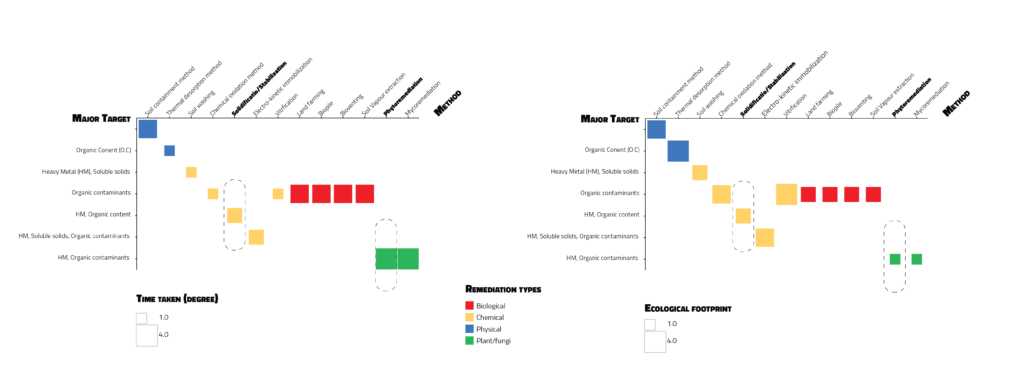

Various soil remediation methods are identified and analyzed based on the time taken by the method to remediate different problems in the soil and also analyzing its ecological impact in the process. Two major techniques are chosen, namely Phytoremediation and solidification (clay, biochar, etc)

Phytoremediation is a soil remediation method in which certain plants act as hyper-accumulators of contaminants. Based on the contaminants that need to be stabilized/degraded by the plants, particular plant species are identified and planted in the soil. This process is a long-term process but with the least ecological footprint and has the potential to bring green areas and attract biodiversity in an otherwise toxic space of soil.

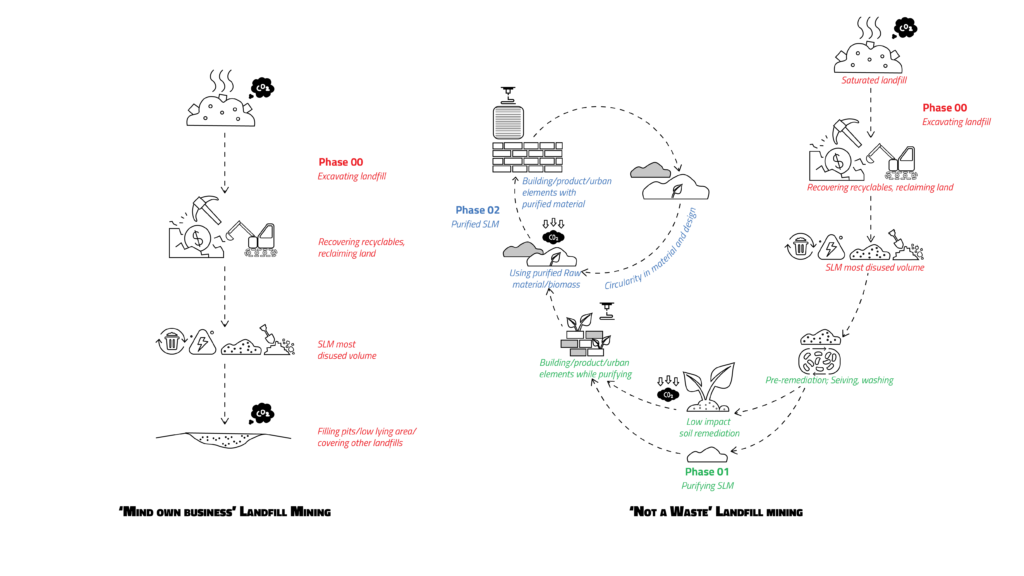

The chosen remediation techniques offer opportunities to remediate the soil for upcycling for its built use over a long period. The design with SLM is proposed in two phases of design, where the first phase is the ‘purified’ phase for SLM and the second phase, which is the EOL of the first phase, is the purified phase of SLM. The linear system of mining disused SLM from landfills is converted into a circular system where SLM is given life to regenerate and become a circular and pure material. The chosen stabilization and remediation techniques are employed in these phases to achieve the desired design results from SLM.

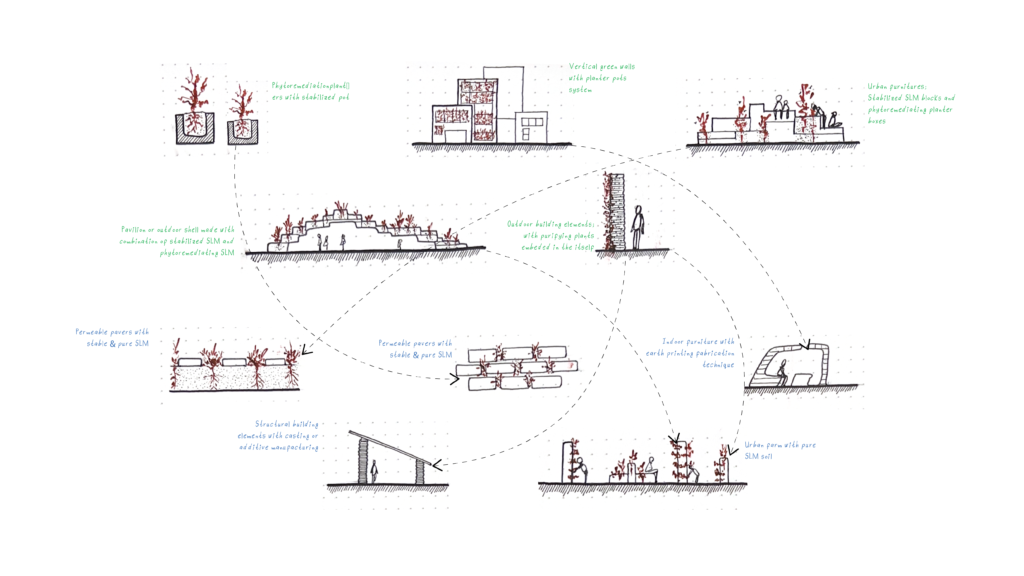

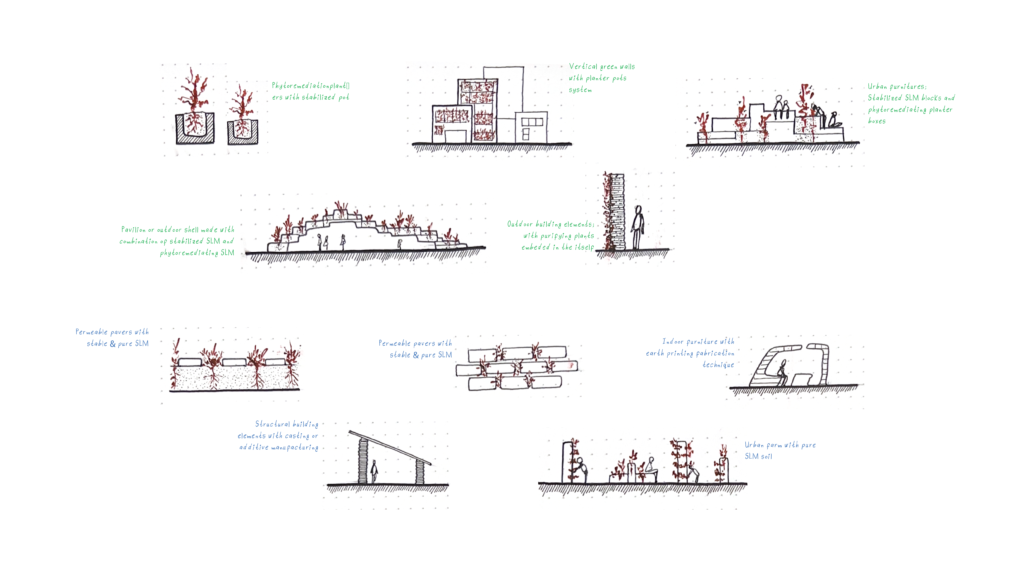

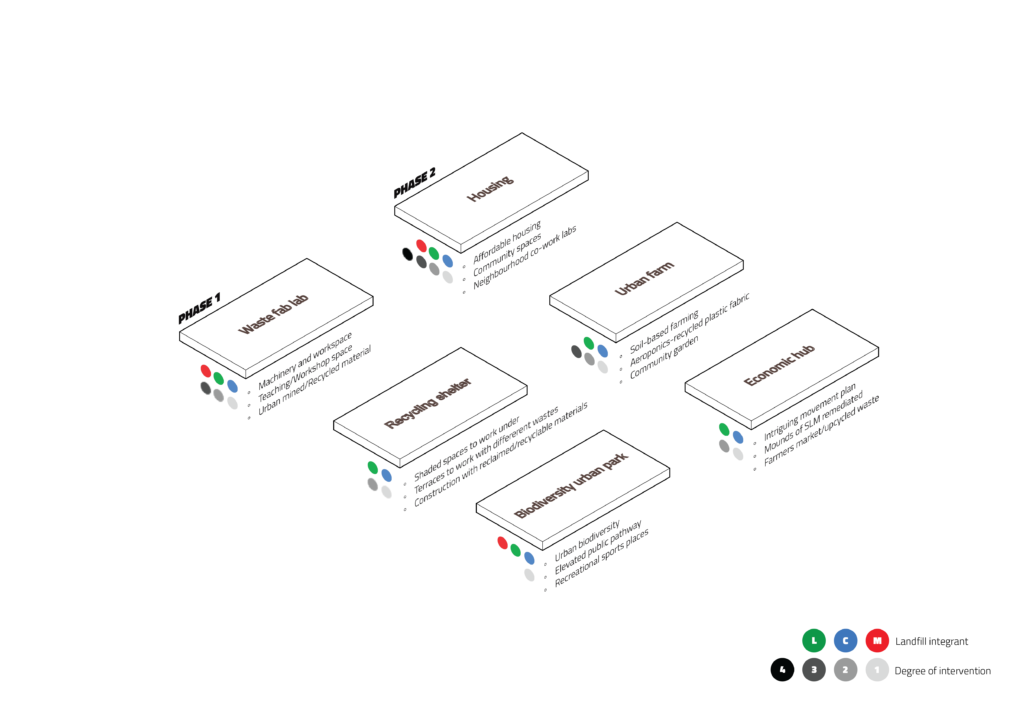

The main parameters of Phase 1 are temporality, long-term usage, purifying state, and Phase 2 as EOL. In contrast, Phase 2 has the following parameters: Permanence, Long-term usage, purified state, and low-impact EOL. Based on these parameters, different design uses are produced with SLM at three design scales,i.e., product, architecture, and urban.

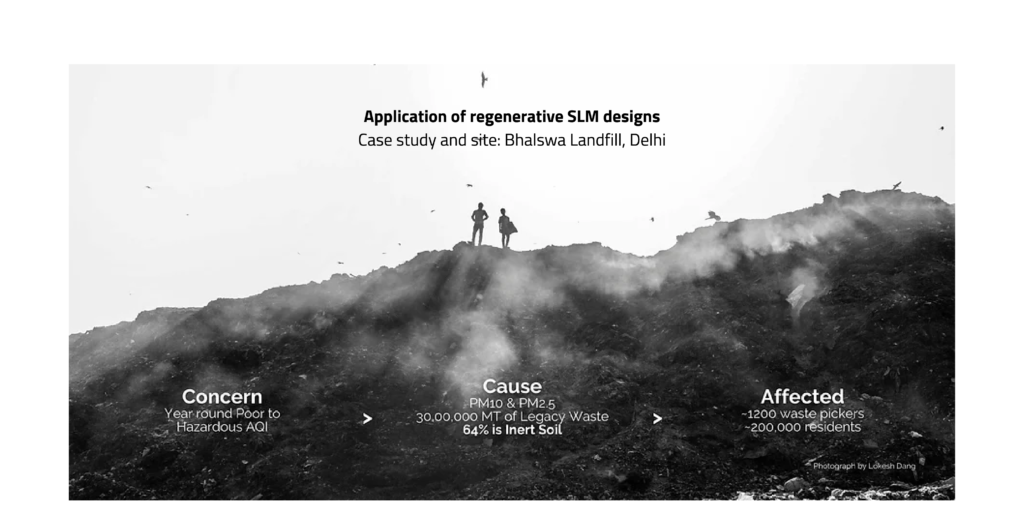

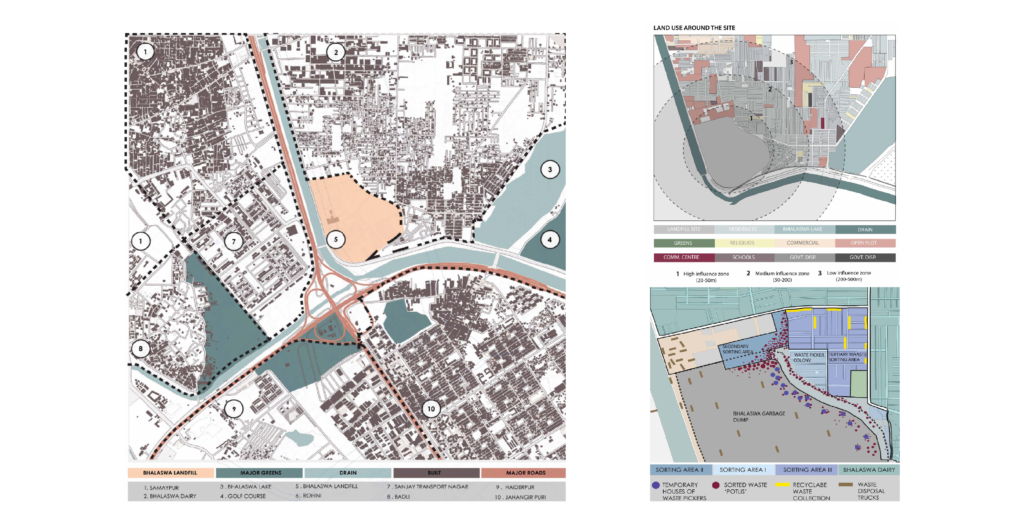

About the site

The proposed design with SLM in phases can not be done in isolation, since they have to respond to its place of origin, landfill. For this reason, a landfill site is chosen based on the complexity of the legacy waste which is getting mined, and some extrinsic factors affecting the landfill. Bhalswa Landfill, in Delhi, is one of its three major dumpsites, spread over 40 acres of land, which started its operation in 1991. The landfill, technically a dumpsite, was saturated in 2001 but is still in operation in 2023. The landfill has reached a mammoth height of more than 60 metres which surpasses the heights of the major landmarks of Delhi, being a prominent and infamous element in the city’s skyline.

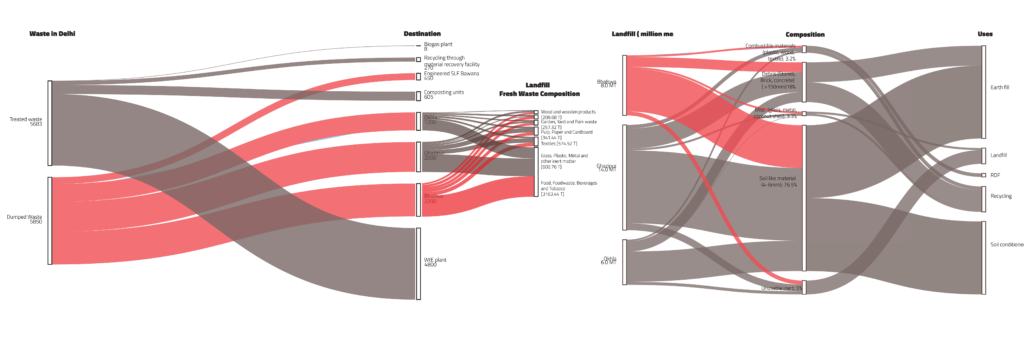

Around 2200 tonnes of fresh waste reach this site by more than 400 trucks daily, even during the biomining process being carried out for 4 years. The major waste component is wet waste/biodegradable waste, mostly kitchen waste from residences. This is followed by plastics, glass, metals, C&D waste, inerts, etc.

The burden of the legacy waste in this landfill is estimated to be around 8 million mega tonnes, of which, after processing more than 60% is SLM. This is partly because of the informal waste pickers communities living adjacent to the landfill edge, contributing around 18% of scavenging and segregating all waste, to send recyclables to recycling companies. These communities have poor living conditions, even though they are an essential part of the waste management system. They are living in extremely close proximity to the landfill, which is a boon and bane at the same time as it is toxic for them yet is a means of livelihood for them.

Design for SLM and landfill

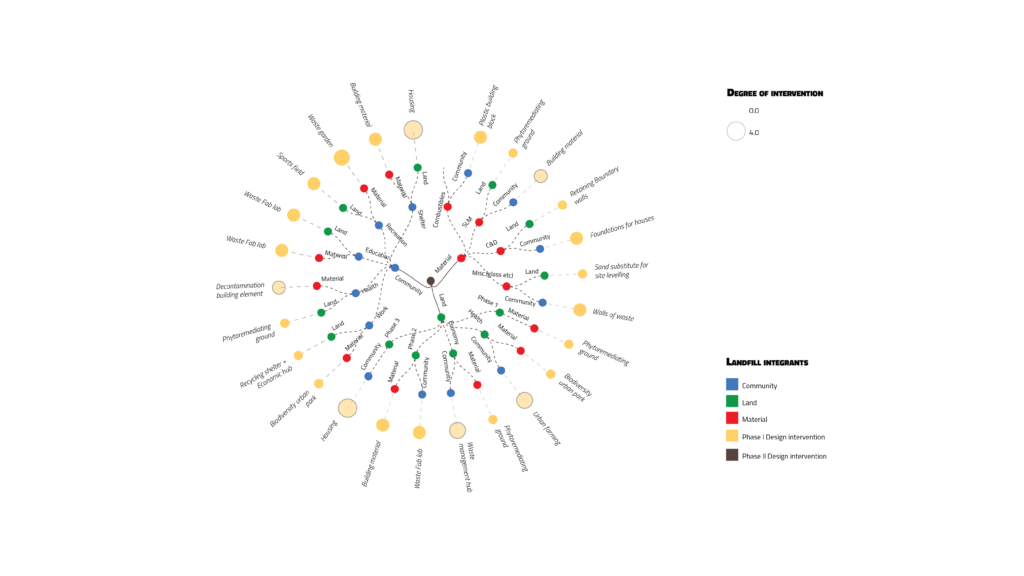

There are three major integrants for landfill mining; the land, the community, and the material. These three integrants affect and are affected by the landfill the most. There is an inherent relationship among these three integrants which brings out the necessity to design for all to keep this ecology of landfill in balance. Additionally, various components, that make up the integrant of what it is, are identified for the three integrants individually. Interconnecting these components with the other two integrants, for each integrant, a design matrix is developed to give results for designs suited best for LCM.

Since the design is proposed in two phases, for this particular case, three design options, per phase, are chosen from the matrix which can regenerate the reclaimed landfill site, and uplift the community while using the material (SLM). The information about each design chosen and their degree of intervention can be seen in the diagram below.

The different designs with SLM are employed on the site according to these chosen landfill design options. SLM design phases define the phases of the landfill regeneration and vice-versa. Phase 1 of SLM design ideally transforms to phase 2 of SLM design which gives a system of complex design system for both SLM and landfill.