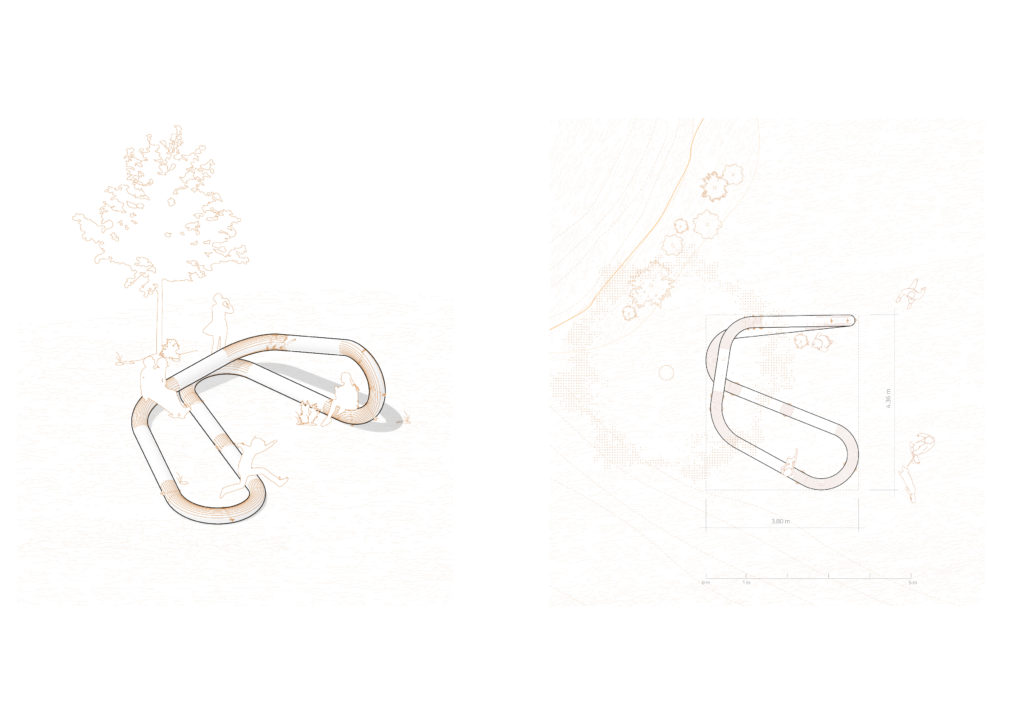

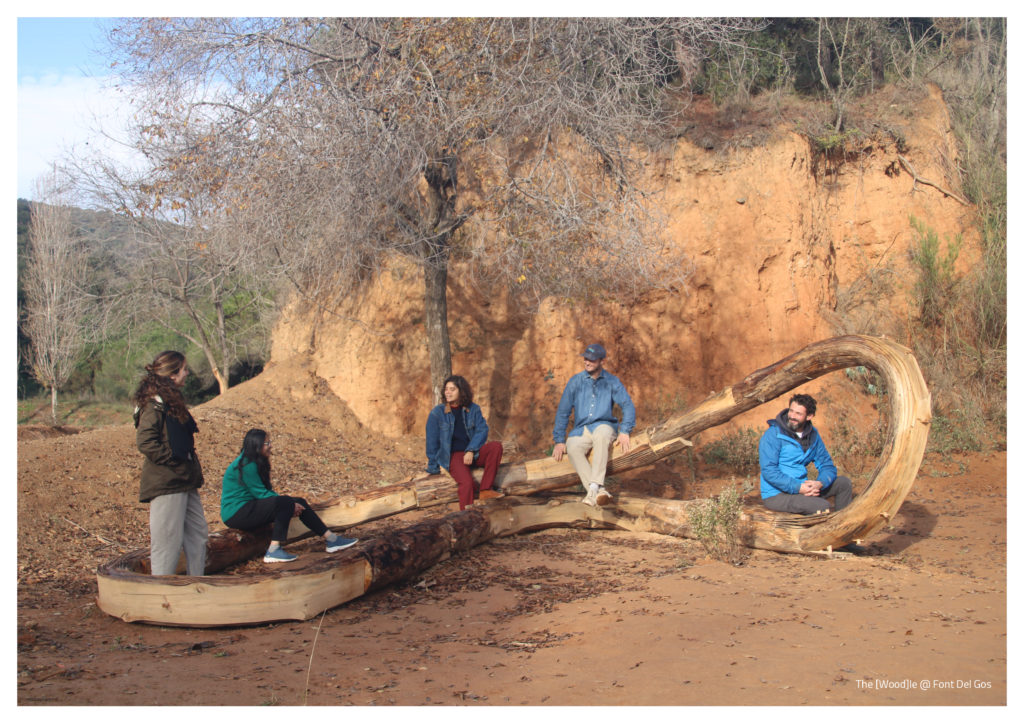

The project ‘[Wood]le’ – a ‘Wooden Noodle’ explores the idea of steam-bending tree logs to create a self stable structure. The [Wood]le assumes the function of a seating area as it rests on the ground at one end and folds up to become an element that frames the valley of Font Del Gos on the other.

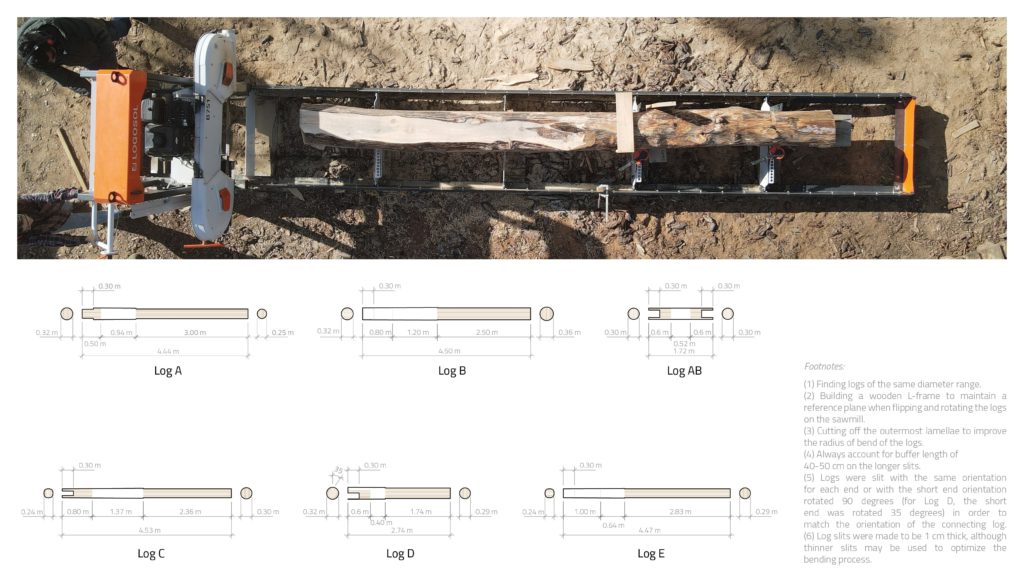

The project was developed over a period of a month through iterative cycles of material prototyping and digital modeling & scripting to define and re-define workflow. The infinite loop consists of 6 members; 5 bent and 1 straight. All the logs were pine wood sourced from the Wood Yard at Valldaura.

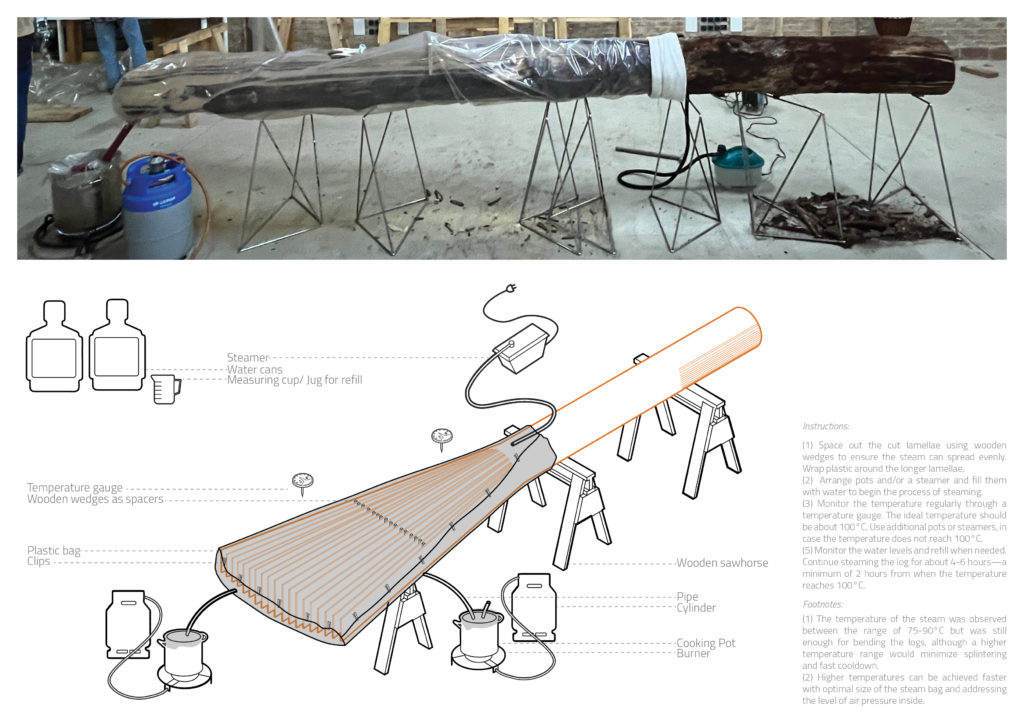

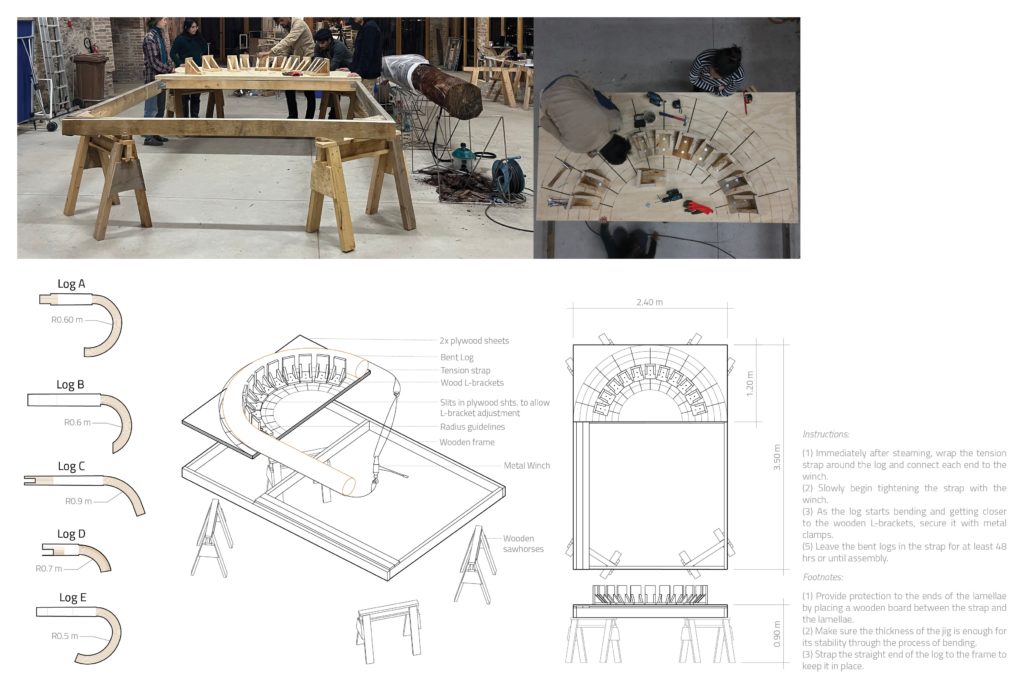

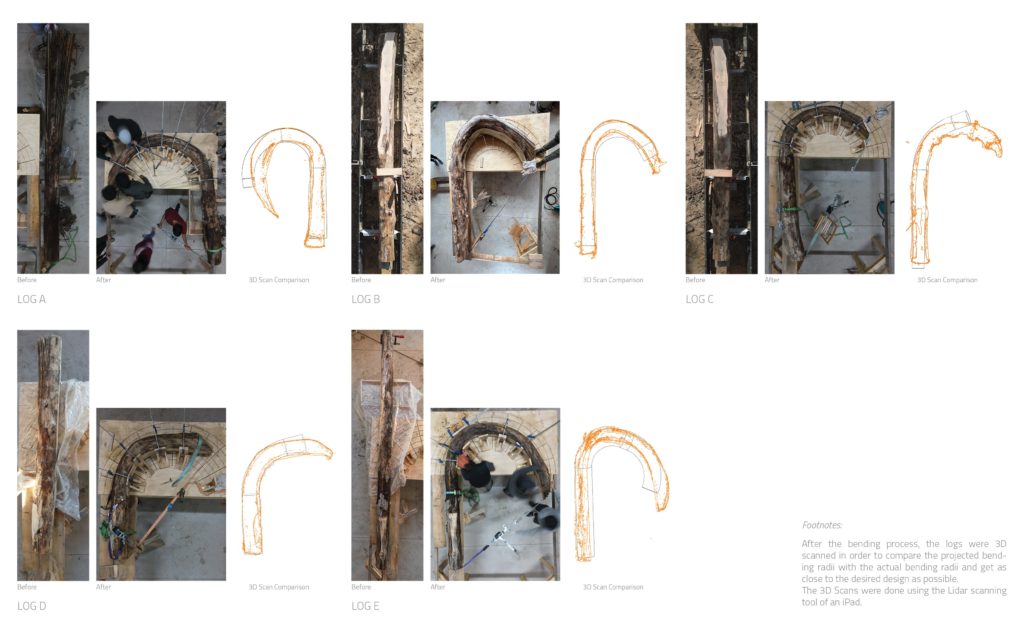

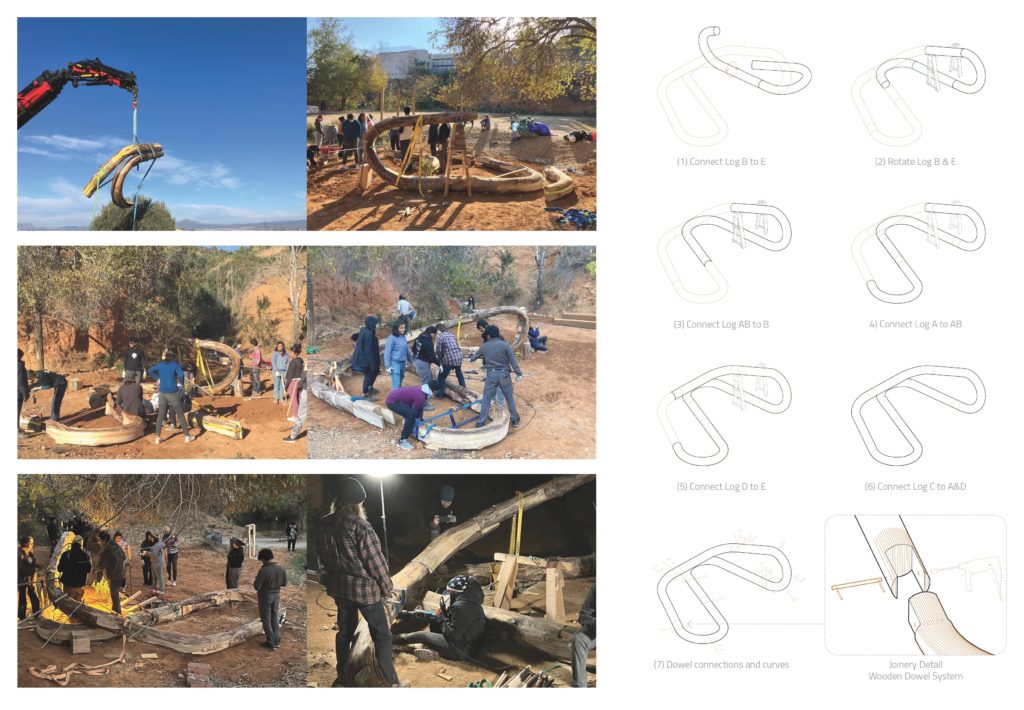

The logs were sliced into ‘lamellae’ of different lengths on both ends, steamed and bent on an adjustable jig with a radius range of 50 – 120 cm. After the bending process, the logs were 3D scanned in order to compare the projected bending radii with the actual bending radii and get as close to the desired design as possible. Knowing that the bent logs always have a spring-back angle, the project’s salient feature is to connect the logs as an infinite loop which stabilizes and maintains the tension in the bends. The biggest challenge was to manage the forces at the connections. Due to an unforeseen degree of friction between the lamellae at the shorter ends, the intended finger joint tested at 1:10 scale had to be replaced by a pocket joint at 1:1 scale. In lieu of the tight timeline and limited tools, this project was concluded with the future scope of testing and devising a way to make the finger joint of the lamellae work.

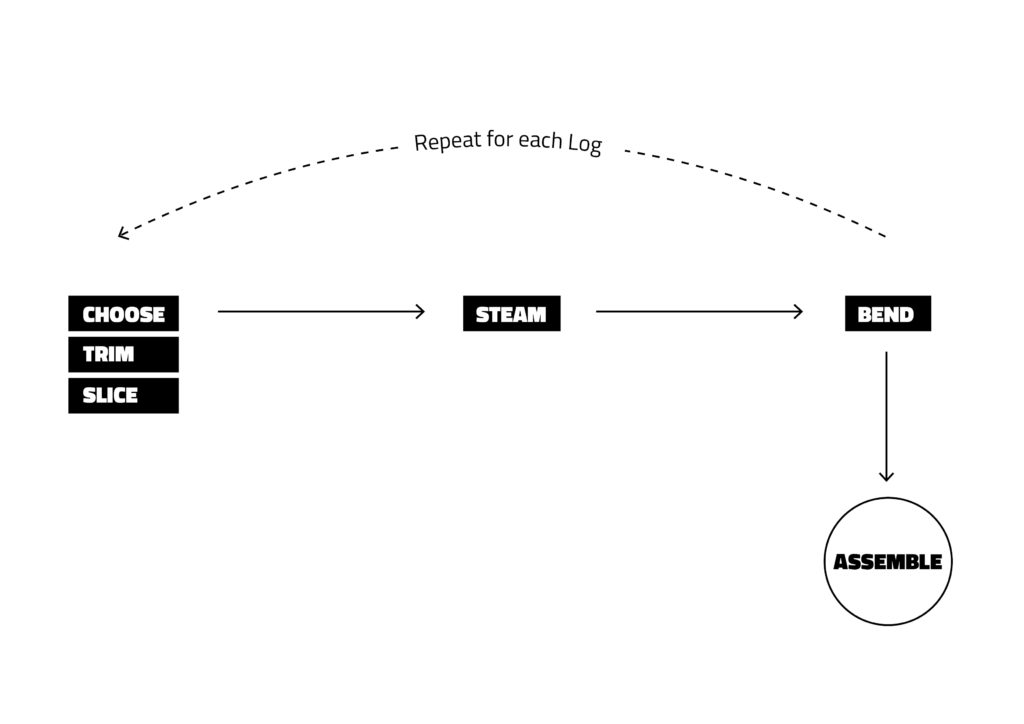

Choose | trim | slice

Steam

Bend

Assemble

Design Team