It seems we can’t find what you’re looking for. Perhaps searching can help.

The Master in Robotics and Advanced Construction (MRAC) seeks to train a new generation of interdisciplinary professionals who are capable of facing our growing need for a more sustainable and optimised construction ecosystem. The Master is focused on the emerging design and market opportunities arising from novel robotic and advanced manufacturing systems.

Through a mixture of seminars, workshops, and studio projects, the master programme challenges the traditional processes in the Construction Sector. It investigates how advances in robotics and digital fabrication tools change the way we build and develop processes and design tools for such new production methods.

Course: MAA02 MAEBB02 MRAC02 25/26 Advanced Manufacturing in Architecture

Credits: Aridditive

Intro Description & Structure

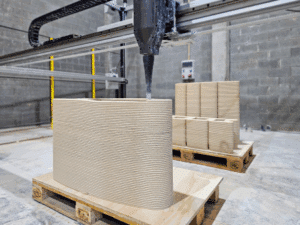

Advanced manufacturing in architecture, engineering, and construction explores how digital design and fabrication technologies reshape the way buildings and components are conceived, produced, and assembled. By integrating robotic fabrication, additive and subtractive manufacturing, computer-aided design and production (CAD/CAM), and data-driven control systems, it enables more efficient, precise, and sustainable workflows.

The Advanced Manufacturing Thesis Cluster focuses on applied research linking design, materials, and fabrication. Students investigate new processes and products through iterative experimentation, material testing, and digital prototyping, aiming to demonstrate manufacturability, scalability, and environmental responsibility.

Combining computational design with hands-on fabrication, the cluster fosters interdisciplinary collaboration and critical thinking. Its goal is to bridge the gap between digital innovation and construction reality, preparing a new generation of architects and designers capable of leading sustainable transformation in the built environment.

Learning Objectives

The second year of the Master represents a shift from guided studio work to self-directed research. Students in the Advanced Manufacturing Thesis Cluster are expected to define their own research agendas while developing expertise in the following key areas.

- Research Framework: Understand the principles and methodologies of advanced manufacturing and their relevance to contemporary architectural practice. Formulate a clear research question and situate it within current state-of-the-art knowledge.

- Digital and Fabrication Proficiency: Strengthen design-to-production workflows through the use of computer-aided design (CAD), computer-aided manufacturing (CAM), and robotic or additive fabrication tools, integrating simulation and data feedback.

- Material Exploration: Investigate the physical and mechanical behaviour of chosen materials to inform the design of components and systems.

- Design for Manufacturability: Develop design strategies that consider fabrication constraints, assembly logistics, and scalability from the earliest design stages.

- Sustainability and Circularity: Apply advanced manufacturing as a tool for sustainable practice, focusing on waste reduction, material efficiency, and reuse or recycling strategies.

- Prototyping and Validation: Translate research hypotheses into tangible prototypes, testing performance, accuracy, and feasibility.

- Future Trends and Industry Relevance: Anticipate how emerging technologies and materials can influence architectural production, envisioning paths for industrial application and real-world impact.

Structure

First Term - Framing & Direction

During the first term, students will define the framework of their research: state of the art, research question, scope, and early material or technological focus. The goal is to build a clear research hypothesis and validate its feasibility through initial mockups or exploratory prototypes.

Session 1 - Introduction to the Thesis Cluster

Students introduce their background, interests, and thesis abstracts. Group discussion focuses on shared themes, fabrication technologies, and research direction.

Session 2 - State of the Art & Research Framing

Students present their analysis of the state of the art, identifying research gaps, challenges, and potential opportunities. The aim is to formulate clear research questions and early experiment plans.

Session 3 - Methodology & Early Prototyping

One-on-one and group discussions focused on refining research methodology, CAD/CAM strategies, and the first physical tests or simulations.

Session 4 - Prototype Feedback & Iteration

Students present early prototypes or material mockups. Discussion focuses on design feasibility, material behaviour, and manufacturability.

Session 5 - First Term Final Presentation

Students present a coherent research framing, validated design direction, and preliminary prototypes establishing the foundation for the next term.

Second Term - Prototyping & Validation

This term focuses on prototyping and testing the proposed design system or components. Students are expected to iterate through several design-fabrication-evaluation loops, refining their MVP (minimum viable product) and documenting findings through data and performance analysis.

Session 1 - Prototype Plan & Initial Experiments

Discussion on the immediate next steps for prototyping, definition of testing protocols, and refinement of fabrication strategies.

Session 2 - MVP Development I

Students work in progress review: toolpath strategies, material calibration, and early performance data.

Session 3 - MVP Development II

Ongoing evaluation of experimental data and design iterations. Feedback on process efficiency, precision, and repeatability.

Session 4 - MVP Validation

Presentation of refined prototypes and validation results. Discussion of scalability and improvements for the next development cycle.

Session 5 - Second Term Final Presentation

Presentation of the consolidated MVP and testing outcomes, defining the roadmap for scaling, integration, and industry relevance in the final term.

Third Term - Scale, Transfer & Impact

The third term concentrates on scaling the prototype or process, testing its real-world feasibility, and positioning it within relevant architectural or industrial contexts. The focus is on transferability, environmental impact, and design implications at full scale.

Session 1 - Scaling Plan & Industry Alignment

Students present the proposed strategy for scaling up their prototypes and initial identification of potential industrial or architectural applications.

Session 2 - Development & Technical Integration

In-depth discussion on technical details, assembly systems, and performance testing at scale.

Session 3 - Pre-Final Review

Progress presentation of near-final prototypes and industry alignment. Feedback focuses on readiness for final delivery.

Session 4 - Final Preparations

Final adjustments, refinement of documentation, and consolidation of the final presentation.

Session 5 - Final Thesis Presentation

Comprehensive presentation of research outcomes, scaled prototypes, and potential industrial or architectural applications. Students conclude with a reflection on future research directions and impact.

view Syllabus & Faculty