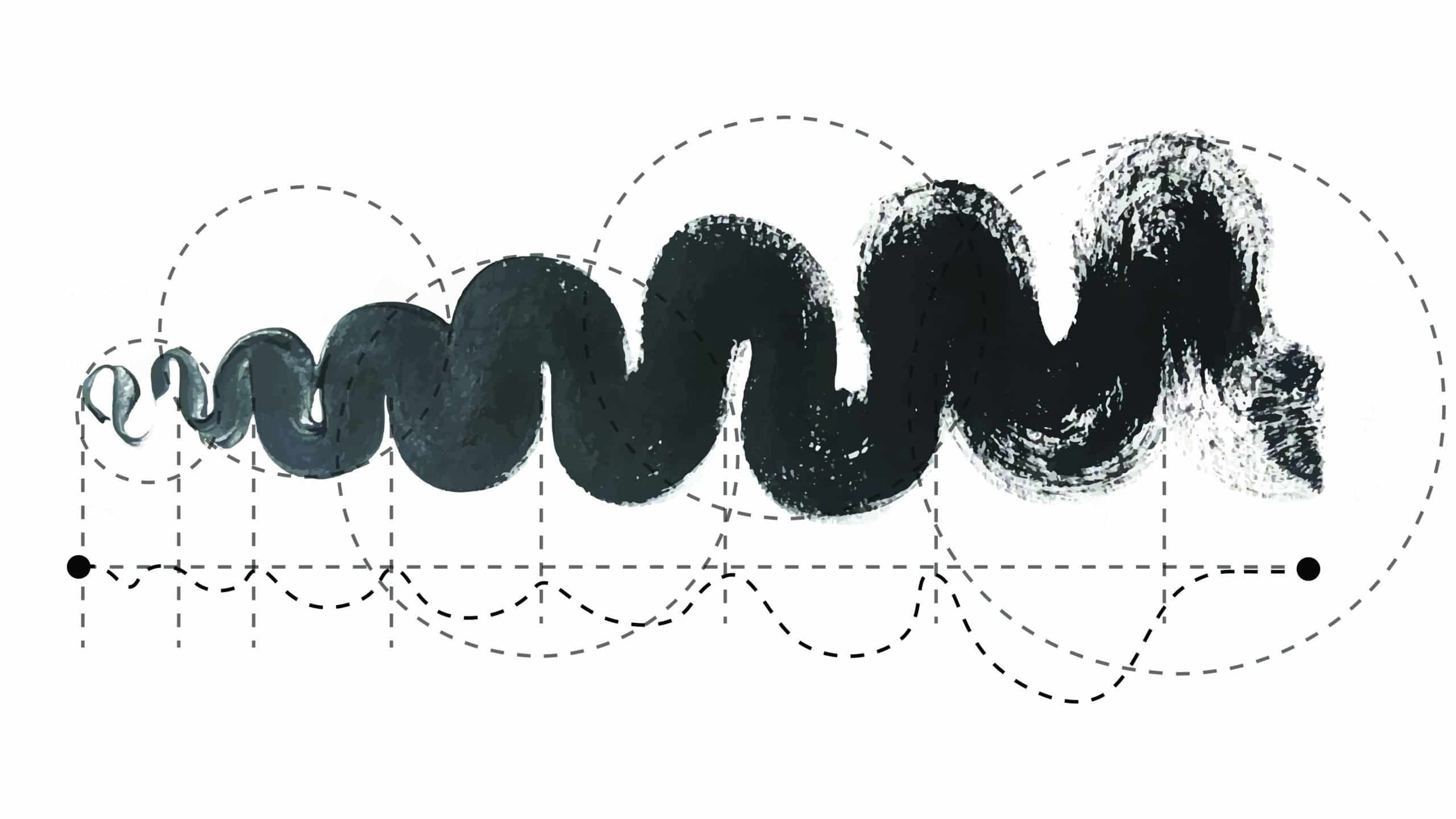

Workshop 1.2 Data to Motion – TSUNAMI

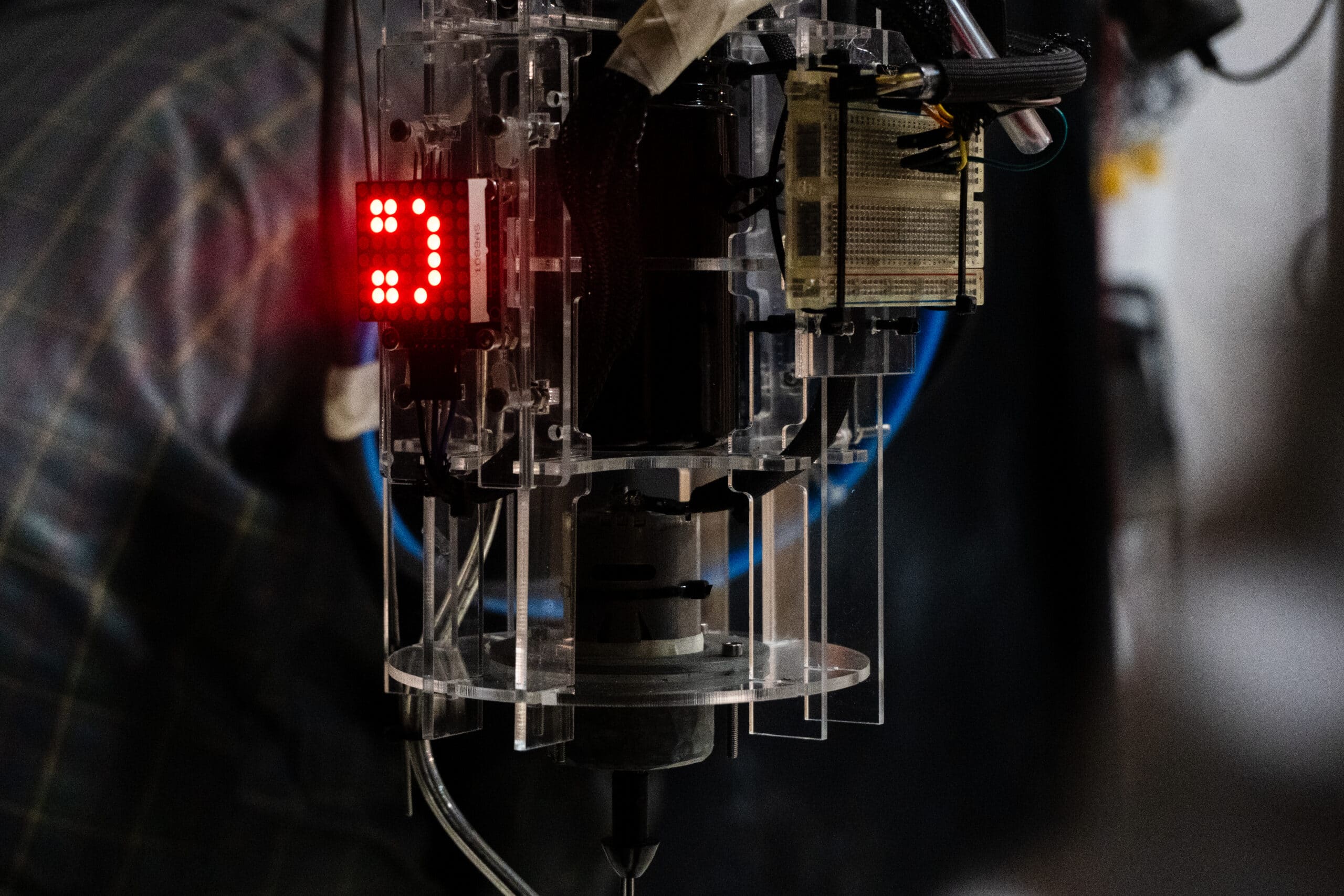

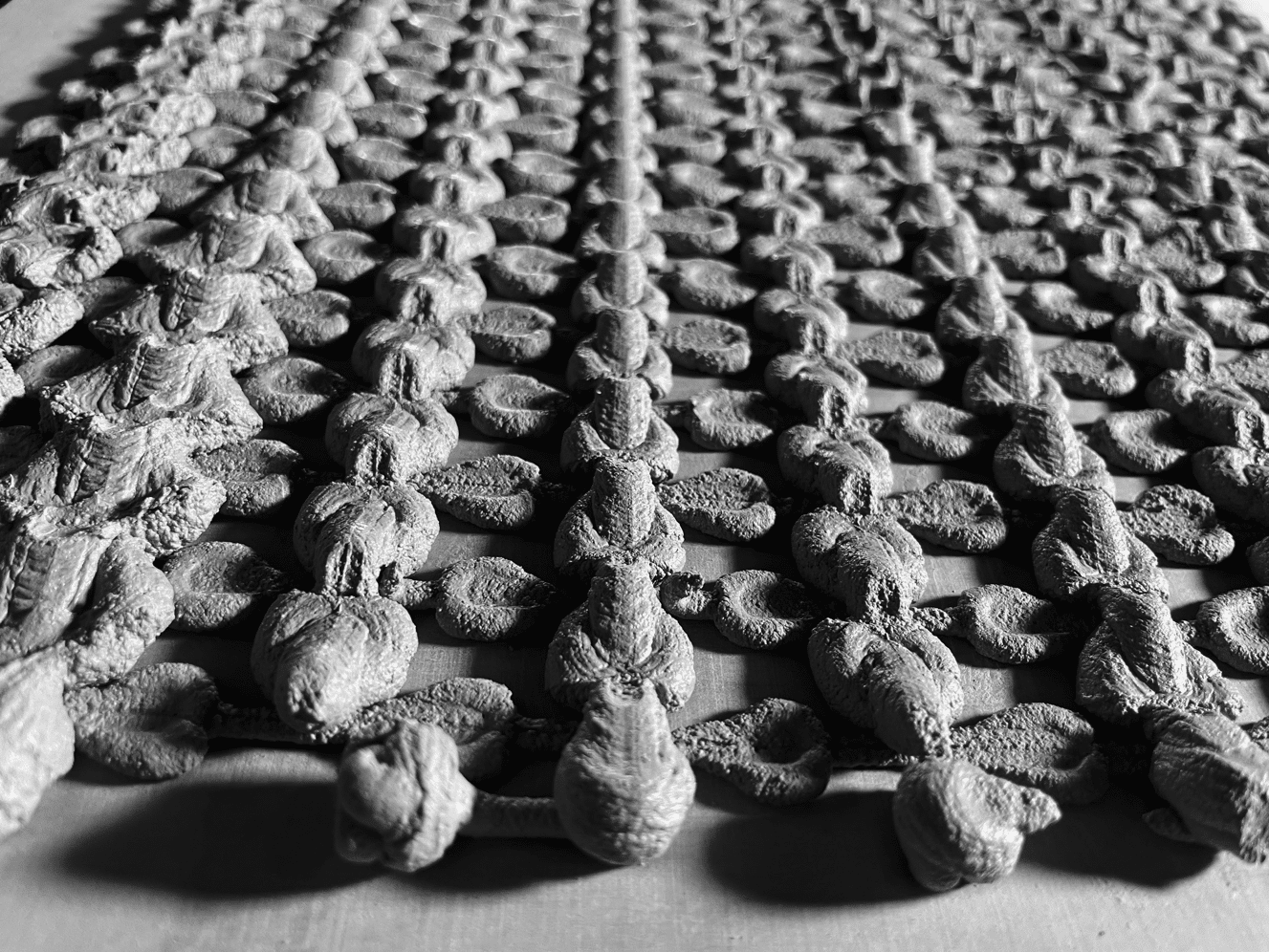

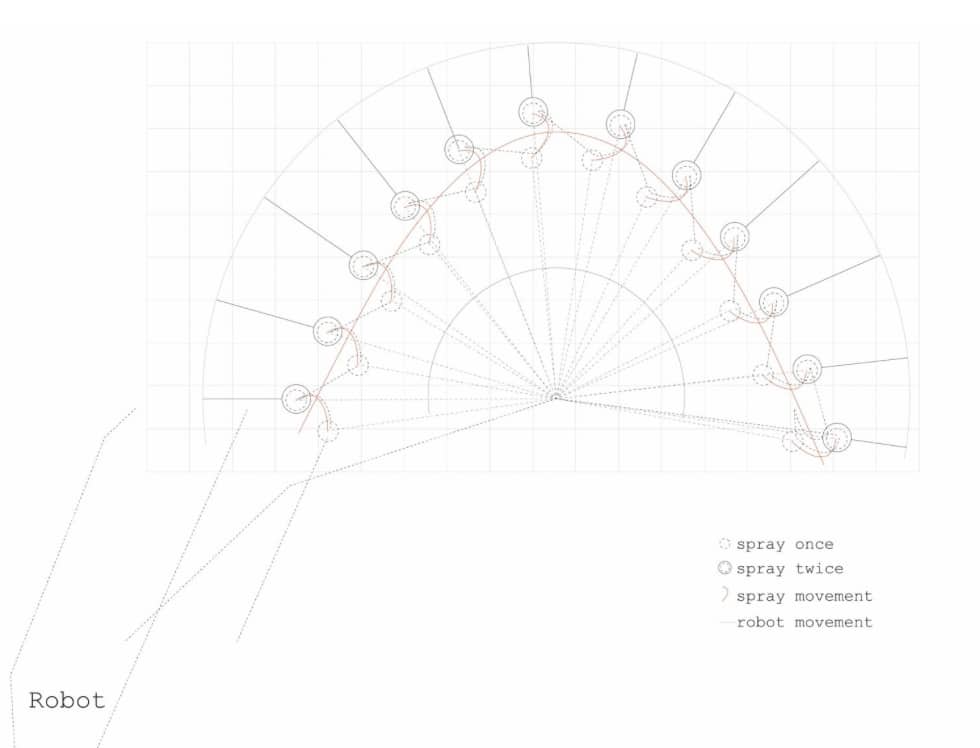

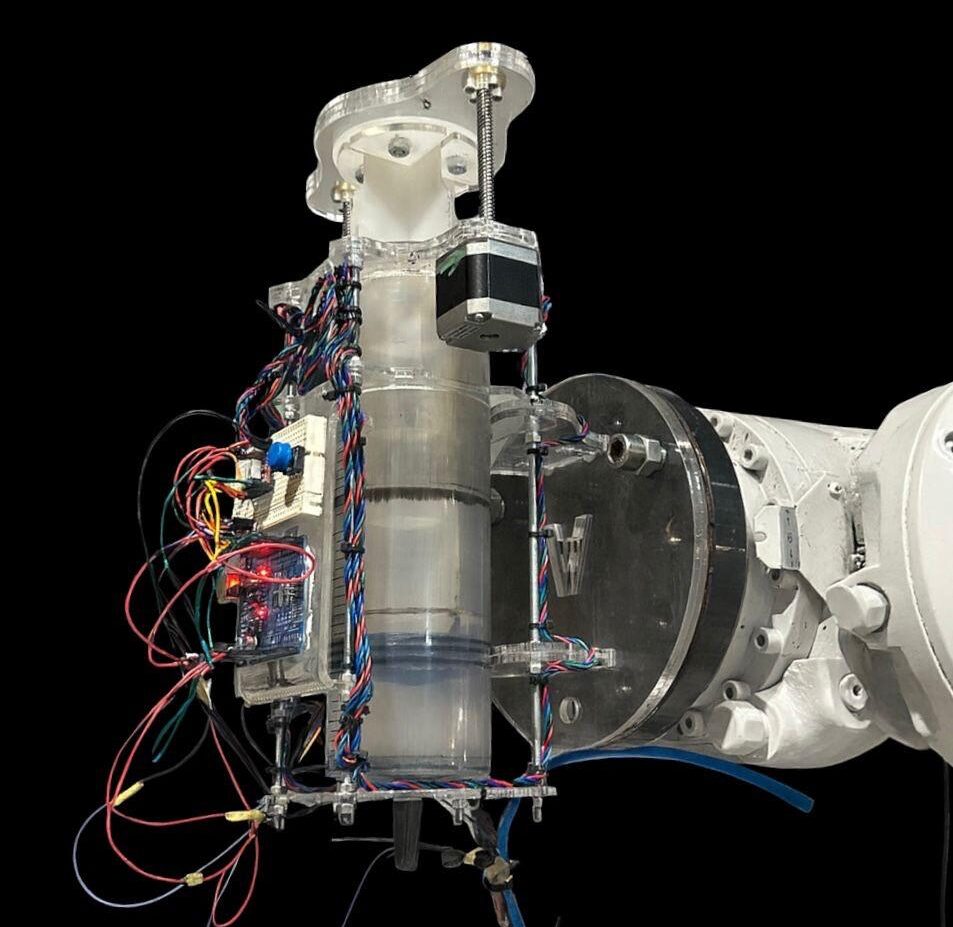

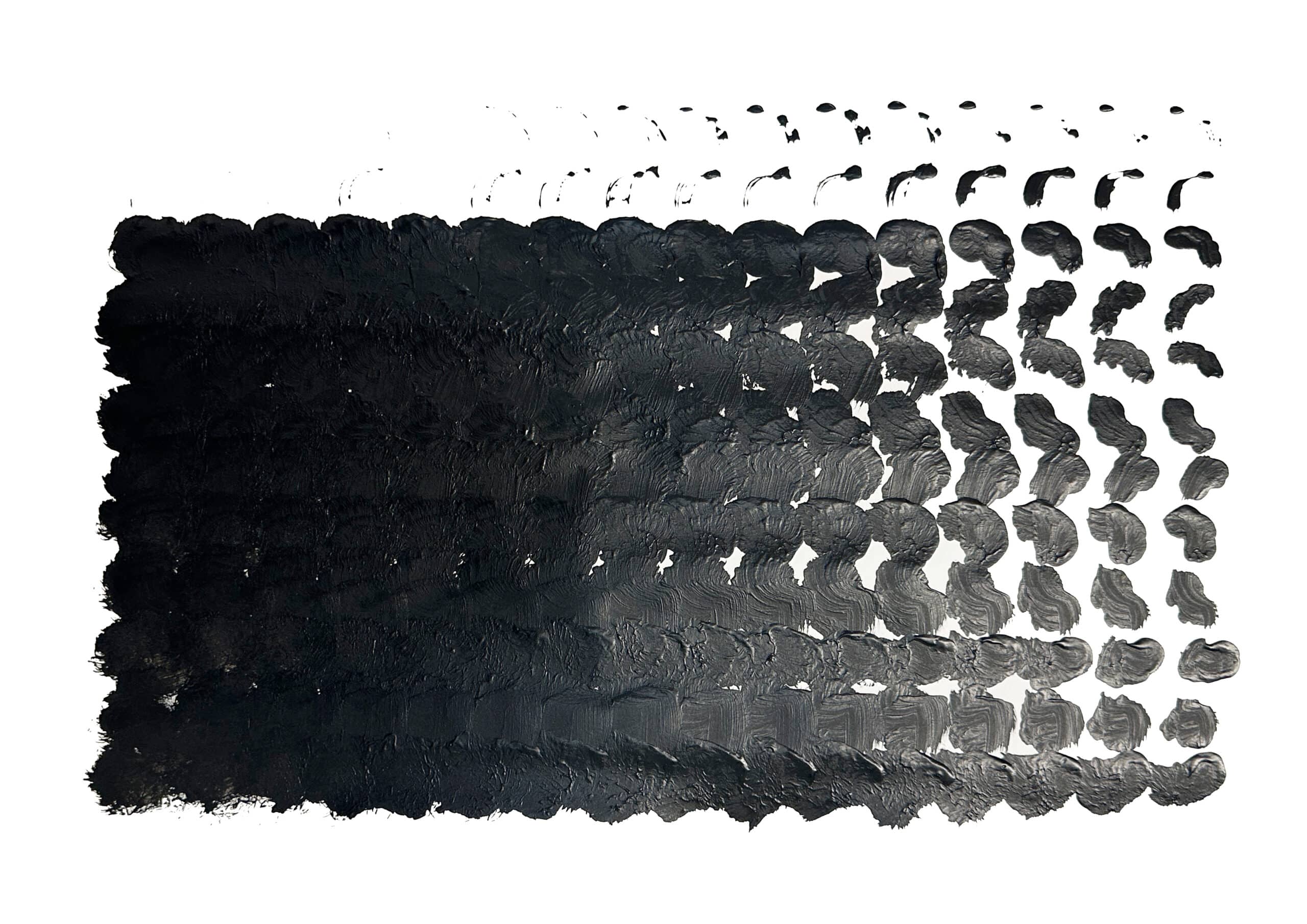

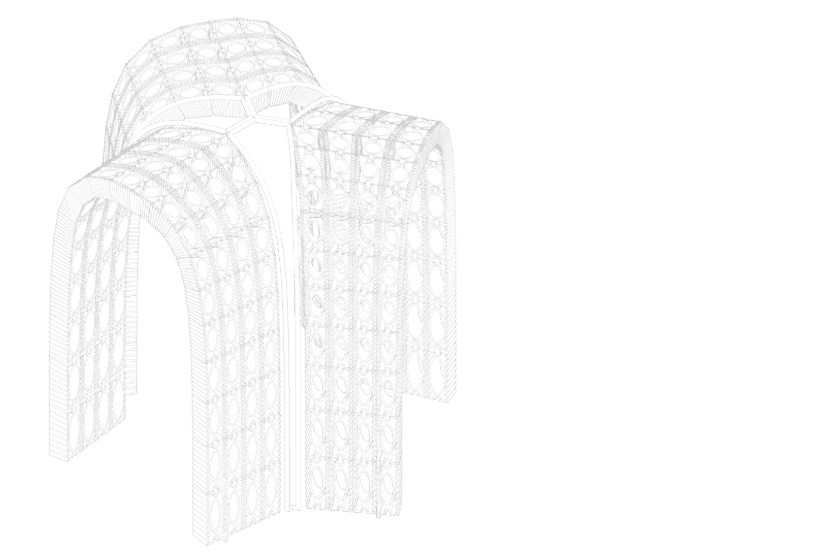

This article presents our Workshop 1.2 project, which focuses on analyzing data and translating it into robotic movements to control an ABB IRB 6700-150/3.20 industrial robot equipped with a plastic pellet extruder for additive manufacturing. The core concept of the project involved studying the tsunami-related terrain and displacement data, extracting spatial and intensity-based information to … Read more