The old builds the new

Manifest

Can we transform construction waste? Can brick waste be a potential upcycled material in an structurally optimized system?

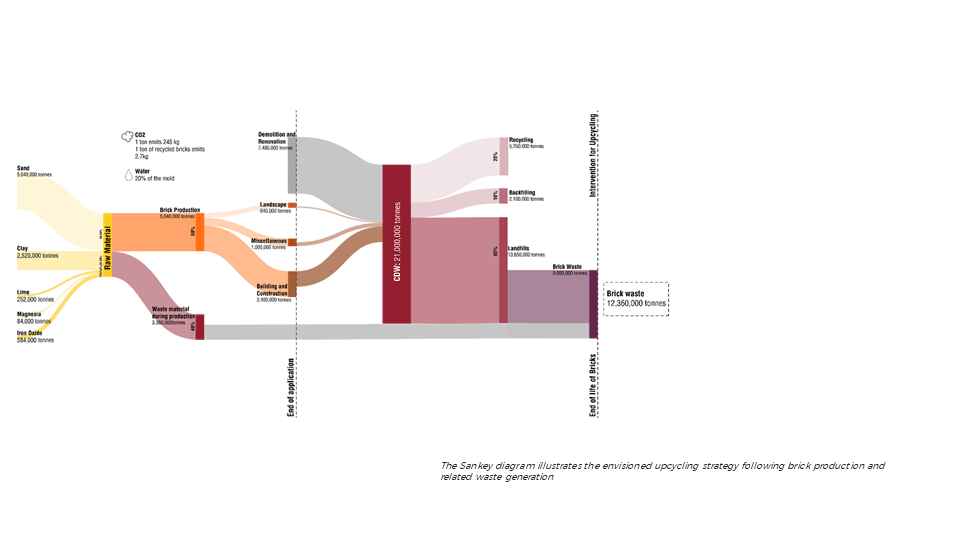

Two main factors, the huge amount of CDW and the importance of brick production in Spain, gives us the decision to select our material, the brick waste.

We attempt to propose optimized solutions for the usage of disintegrated Brick Powder and Brick aggregates for a structural purposes.

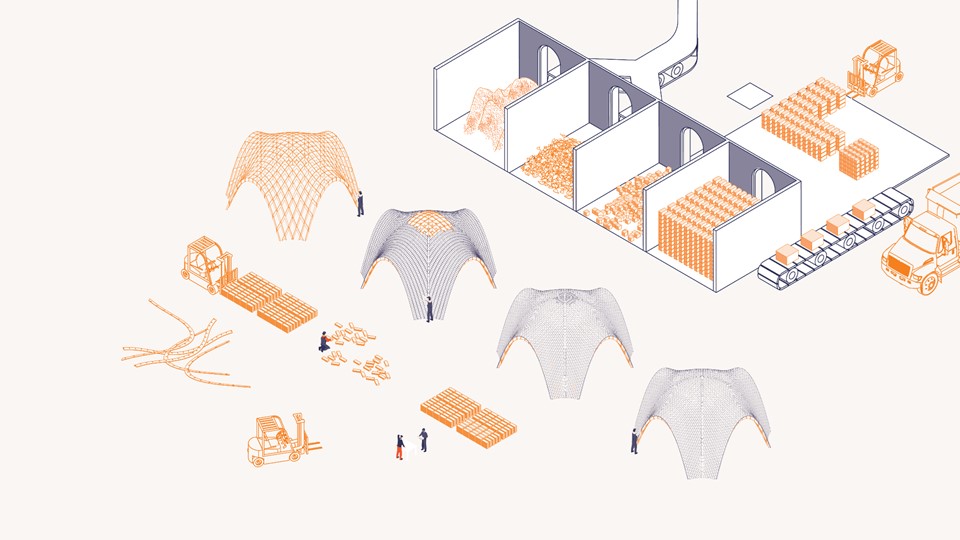

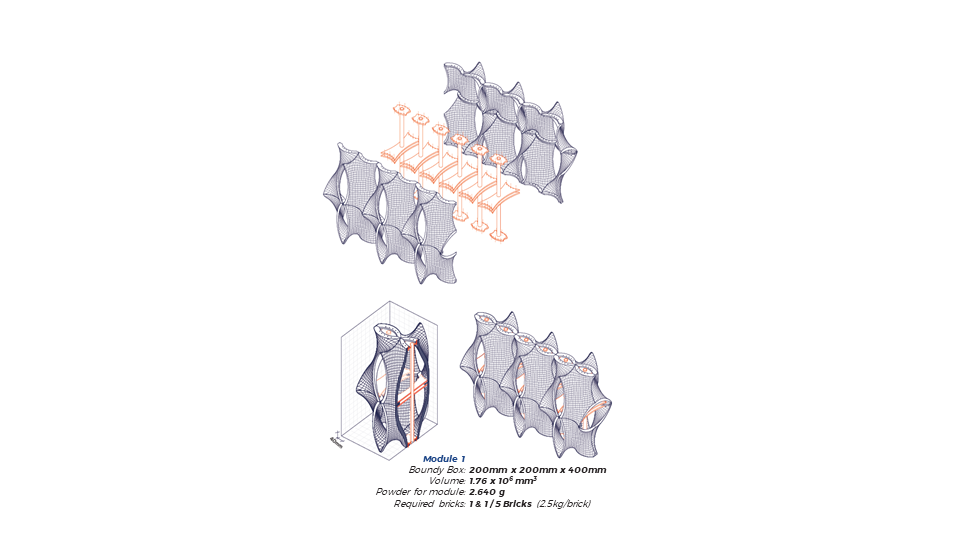

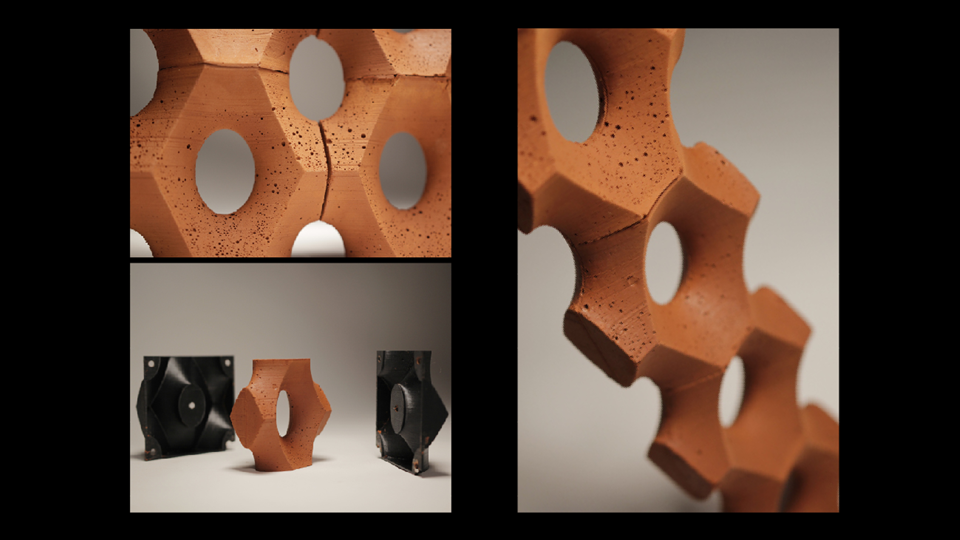

By performing experiments to understand the mechanical properties of this material. Furthermore, by creating brick powder geopolymers and brick aggregate composite modules assorted for strength, size, and geometry to fulfill desired structural requirements which can be translated into a funicular structure that correspond to the traditional method of brick construction.

Material system

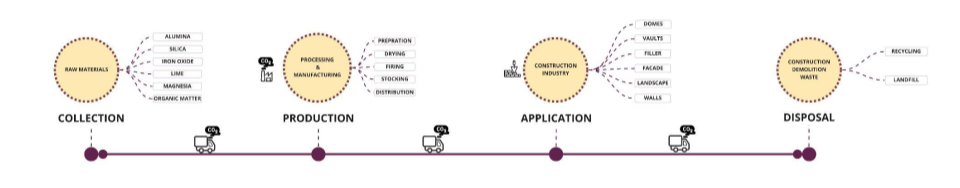

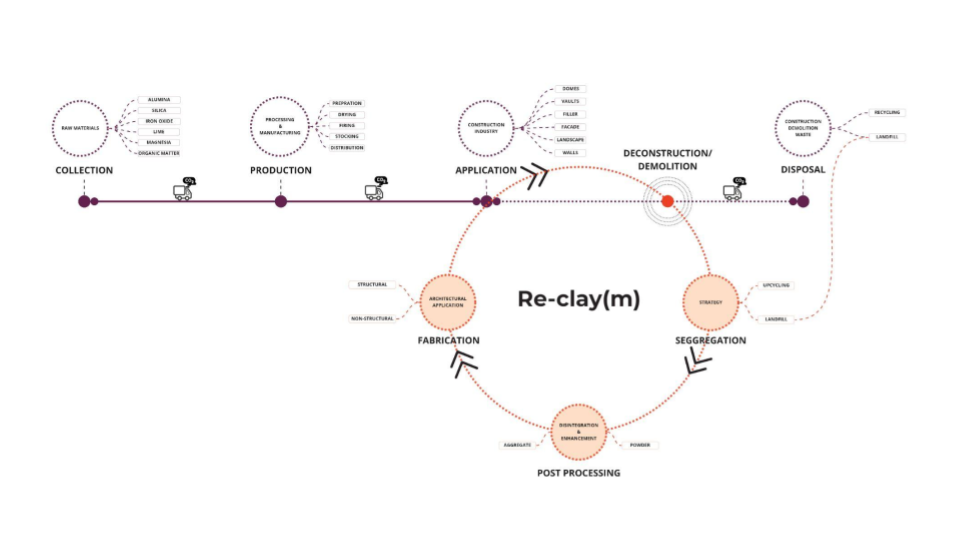

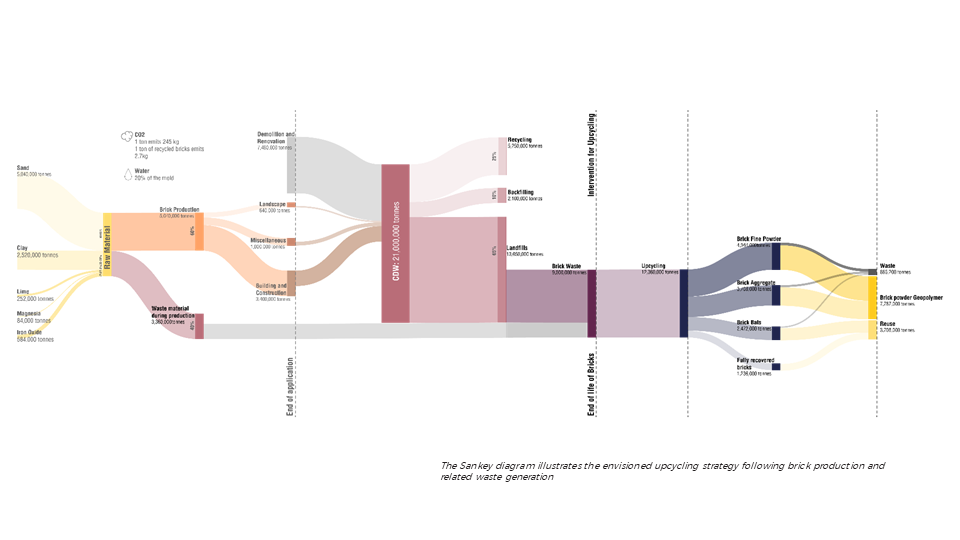

We start by understanding the existing linear production channel of the brick industry

which showcases the collection, production application, and disposal of brick.

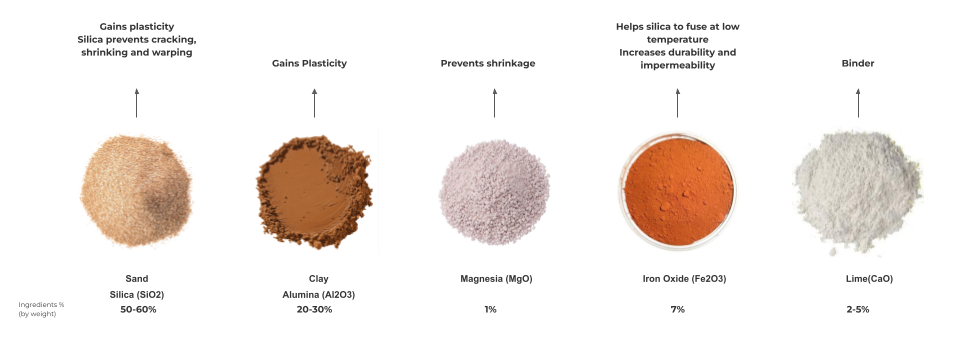

Raw materials that are extracted to make the bricks are Sand, Clay, Magnesia, iron oxide, and lime.

Sand and clay consist of silica and alumina respectively.

From raw material extraction to manufacturing the bricks it takes

a total of 22.046 GJ/ 1000 bricks and is highly energy intensive.

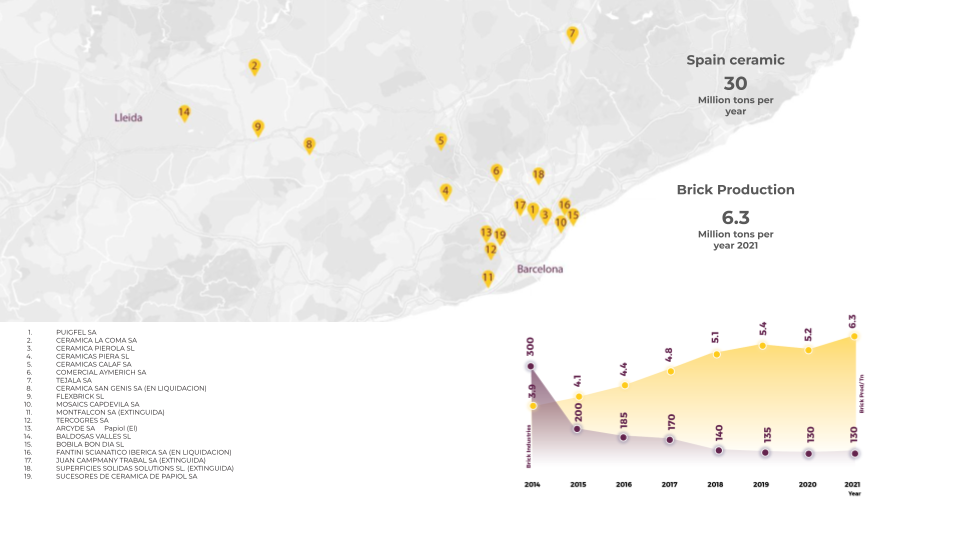

Yearly brick production of brick in Spain is 6.3 Million tons per year.

Even if the no. of brick industries has reduced over time production has only increased.

The map shows the existing brick production factories in Catalunya.

“Brick kilns are recognised as one of the largest stationary sources of black carbon

which along with iron and steel production, contribute 20% of total black carbon emissions.”– CCAC

Health Hazard

High rates of respiratory disease

Agricultural impacts – damaging soil, crop production and food security

Unconventional fuels burned in brick kilns: Coal, wood, local biomass,

waste oil, used tires sawdust, plastics, battery cases, dung

“CDW: Any type of waste that is generated from construction and demolition works… which consists of activities

within the context of construction, demolition, and renovation of any:

building, road, port, airport, railroad, canal, dam, sports zone, leisure area, or any other type of engineered structure”

Construction demolition waste consists of waste generated by activities

within the context of construction, demolition, and renovation

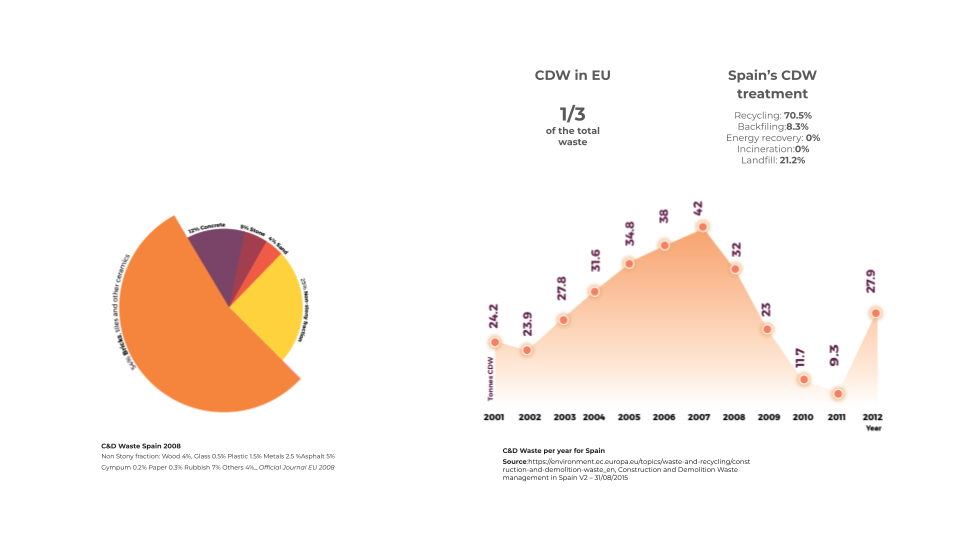

Construction demolition waste in the EU is almost one-third of the total waste generated globally.

Brick/ ceramic waste accounts for more than 50% of CDW generated in Spain.

The graph shows yearly waste generation in Spain.

Taking into consideration the quantities of brick production and waste generation in Spain.

It showcases that 40% of brick waste is generated during production and from the 28 million tonnes of waste generated after application

21.8% end up in landfills. Accounting for approximately 10 million tonnes of Brick Demolition waste per year.

The question is how we can intervene in this channel.

What are the upcycling strategies?

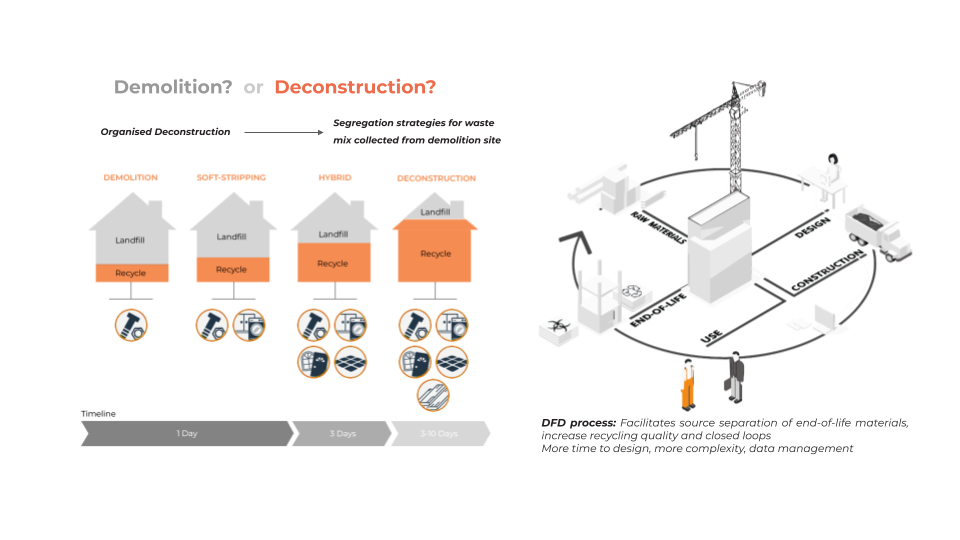

Demolition or deconstruction?

This diagram shows the comparison of waste generated through demolition and deconstruction.

Organized deconstruction will increase the possibility of recycling and upcycling process

of this waste by eventually designing strategies for segregation of the waste mix collected.

Transformation of the existing linear economy of brick production to disposal into a circular economic cycle.

Upcycling through introducing reclaym.

How can Re(clay)m change the linear economy to a circular economy?

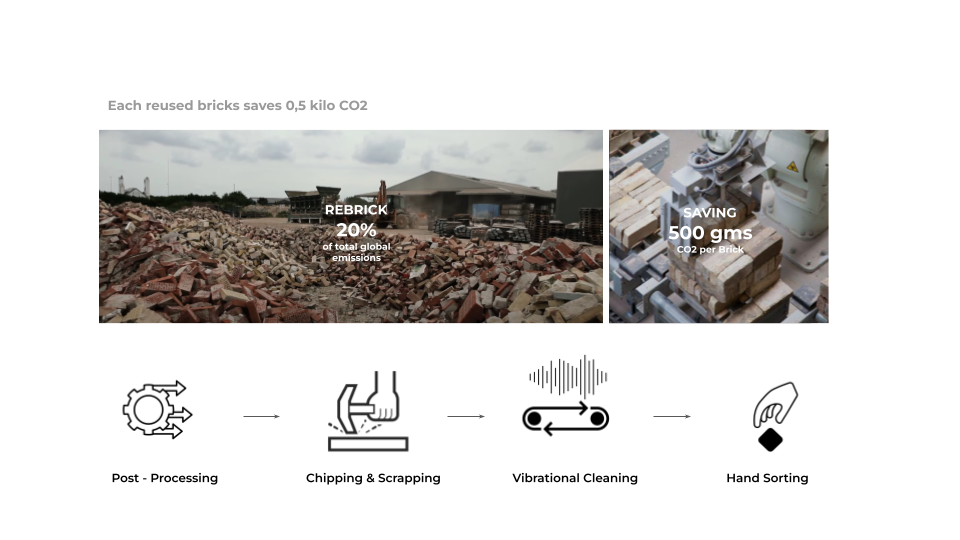

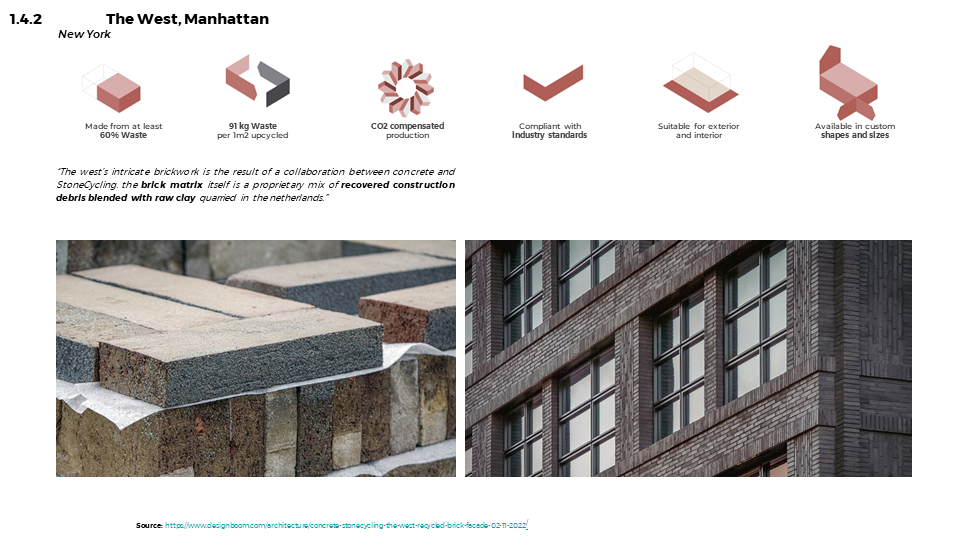

This is one of the case studies of an established BRICK upcycling organization

that is working on demolition waste handling and recycling in Europe.

They upcycle bricks through the automated sorting of demolition wastes,

the Old bricks are separated and cleaned using vibrational rasping and then further hand sorted for use.

Recycling bricks is a tedious, time-consuming process that involves pulling the old bricks apart individually from the strong mortar holding them in place. A new system that “harvests” bricks — mortar and all — from old buildings is on display at the Resource Rows in Copenhagen.

- The brick modules resulted in “saving as much as 29% CO2 by upcycling only 10% of all building materials

- Life-cycle assessments indicate a savings of 463 tonnes of waste

- By cutting the facades of abandoned houses and other buildings and then installing the recycled brickwork in steel frames, the masonry can be used as prefab facade modules in new buildings.

Material exploration

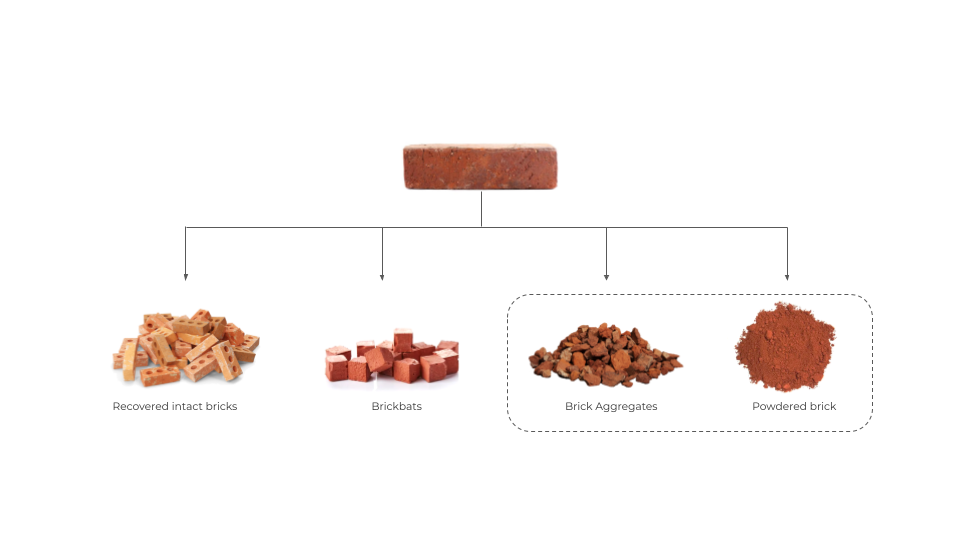

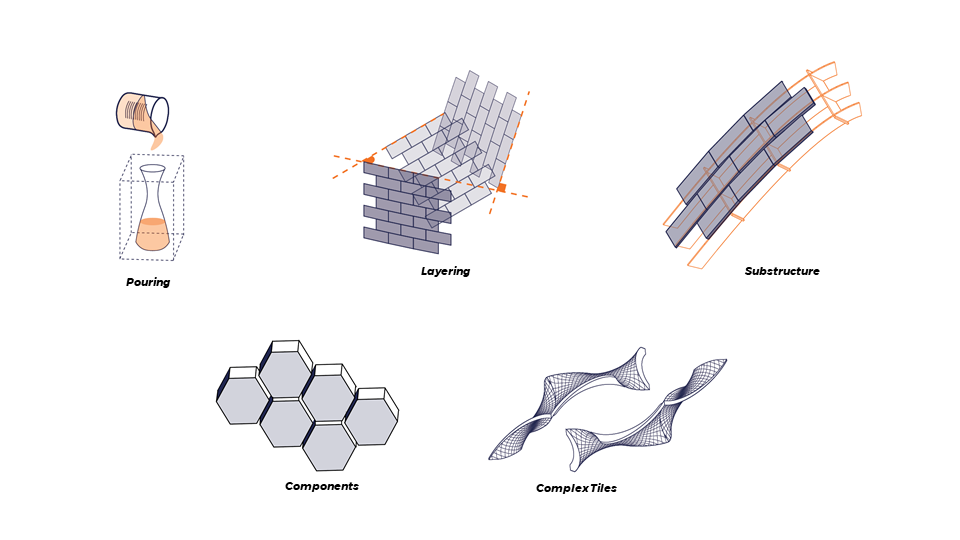

There are four key disintegrations that are possible and hold potential in many ways for building construction.

Here we introduce our focus on the finer particle grade which is brick aggregates

and brick powder and possible geopolymer combinations with them.

Geopolymers are made by activating cementitious materials which are Aluminate and silicate-bearing materials with alkaline activators such as Sodium hydroxide and sodium silicate.

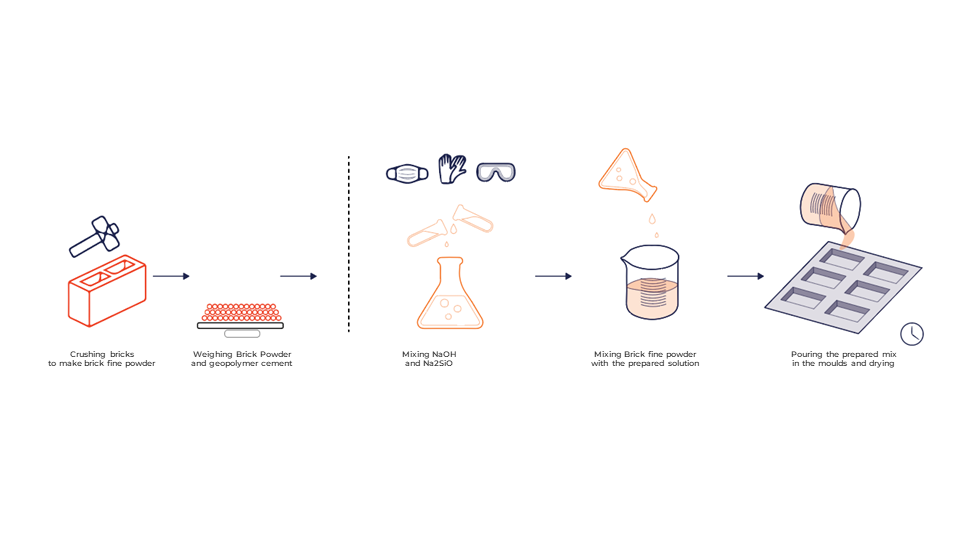

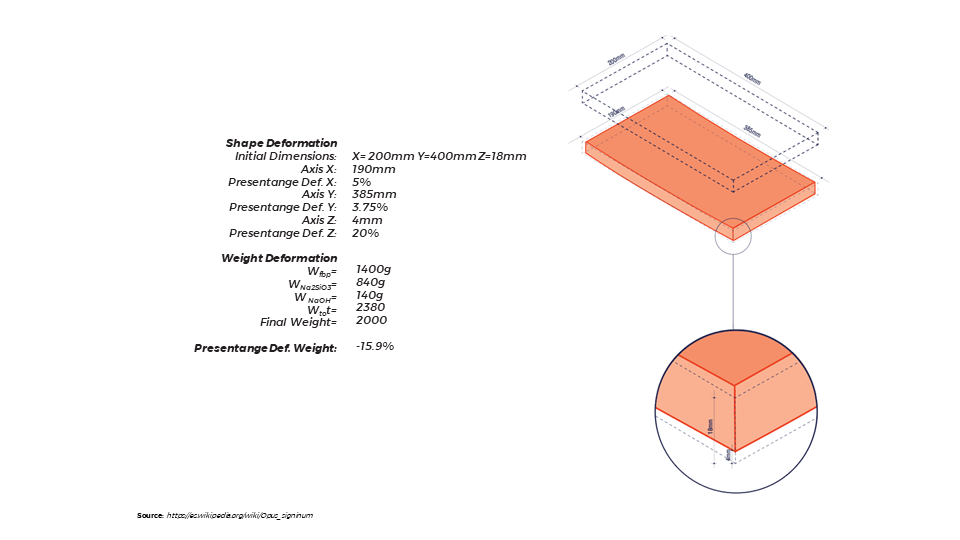

The diagram shows the experimental procedure for making Brick powder geopolymer with alkaline activators as well as geopolymer cement.

As bricks are exposed to high temperatures during manufacturing this leads to the transformation of the clay’s crystalline network to a disordered, unstable amorphous state and as a result increases the pozzolanic properties of the material.

This makes the material potential to be used as a binder and geopolymer composites with aggregates.

The experiment highlights the cementitious properties of the brick powder potential for it to become a binder and further enhances the compressions properties of the material when turned into brick powder and brick aggregate geopolymers.

References

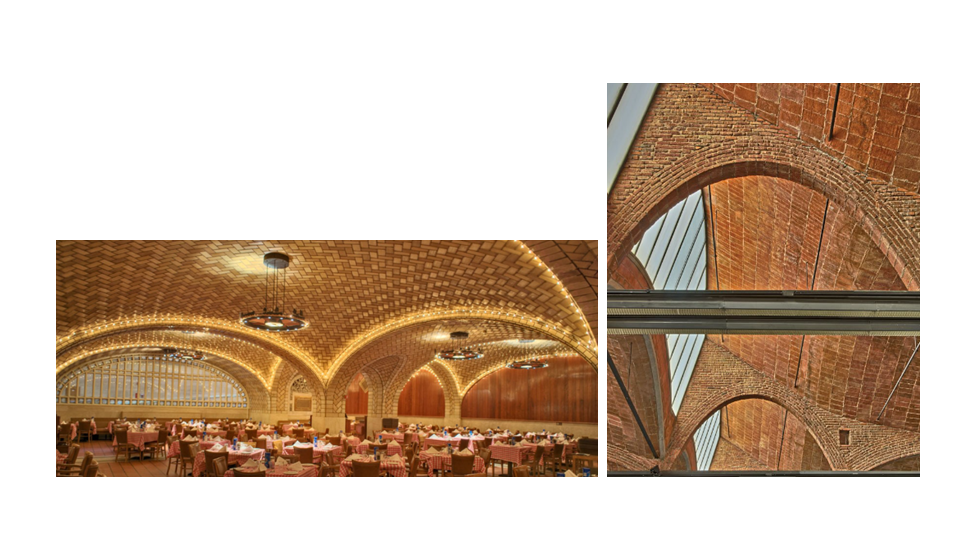

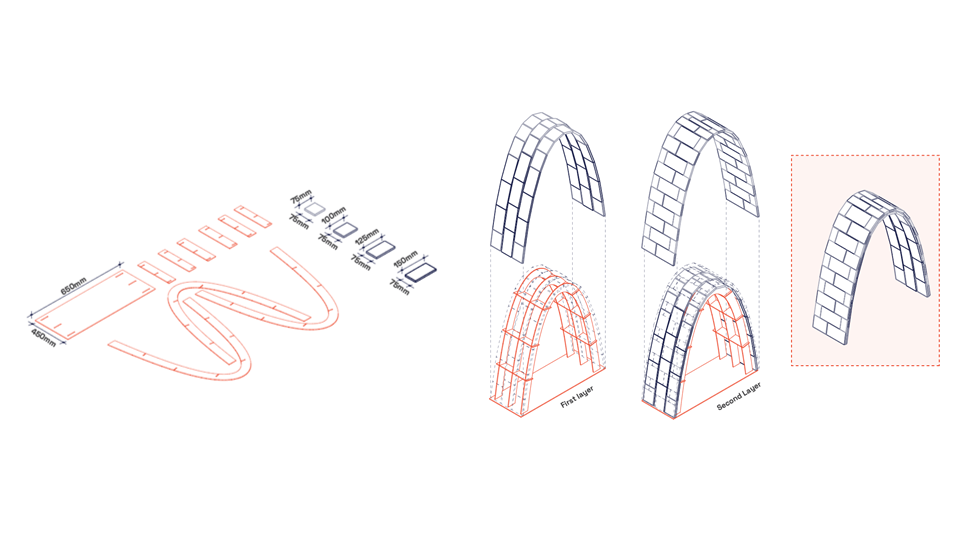

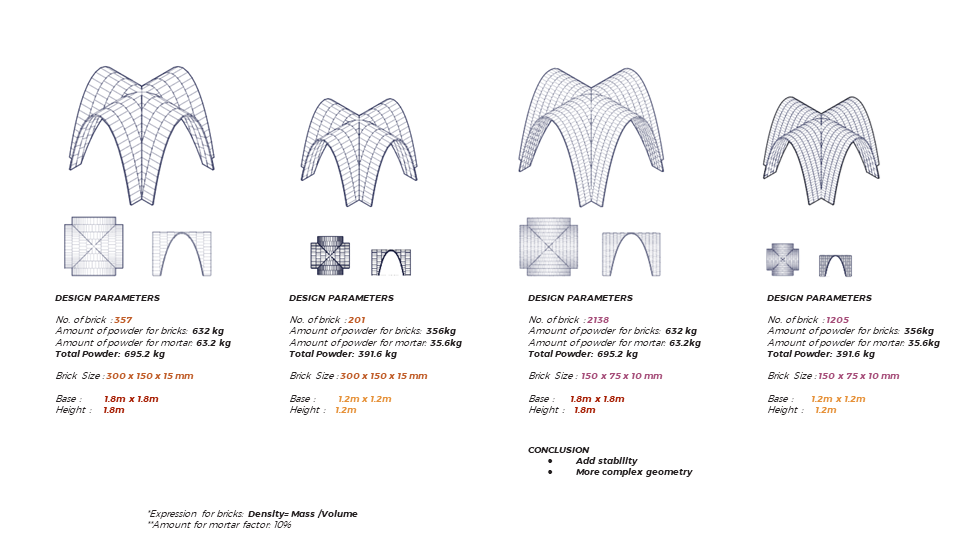

“The Guastavino method of masonry construction uses thin ceramic tiles, roughly 15 x 30 x 2.5 cm, which are laid flat in multiple layers. This method was considered to be revolutionary in the 14th century, when it was first described as being a lightweight and inexpensive method of construction compared to traditional stone vaulting. The tile vault appears to have been developed by Moorish builders near Valencia, Spain, though it quickly spread to become common throughout the Mediterranean region. The method is known as timbrel vault (so-named by Guastavino Sr.) or the Catalan vault (so-named by 20th century Catalan architects).”

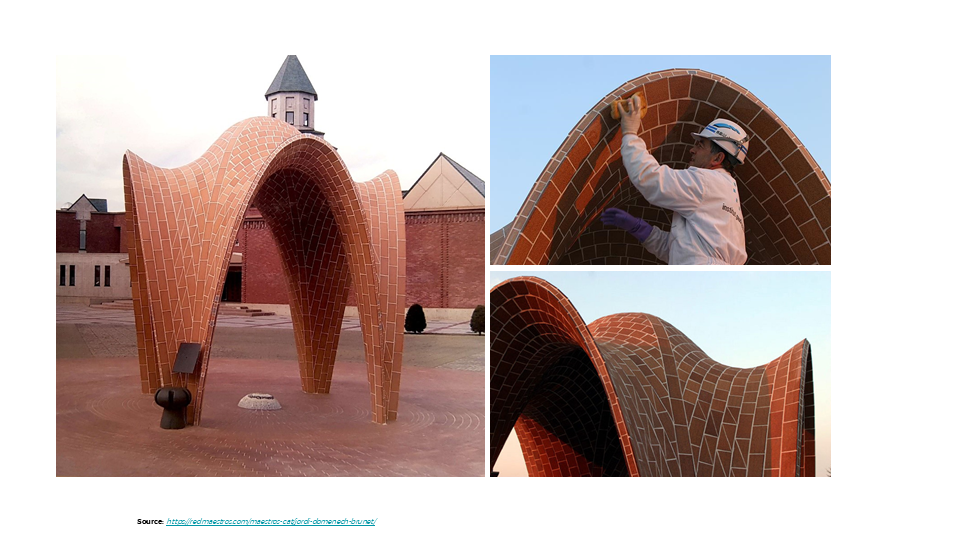

“Catalan vaults” are masonry structures made with bricks and binder. The bricks are placed flat setting up two, three or more layers. Traditionally thin bricks -or thin tiles- are used because of their lightness, which is a necessary condition to build the first layer on space using gypsum or fast setting cement. Brick-topia collects the material tradition and the constructive knowledge of tile vaulting and combines them with contemporary computational tools.

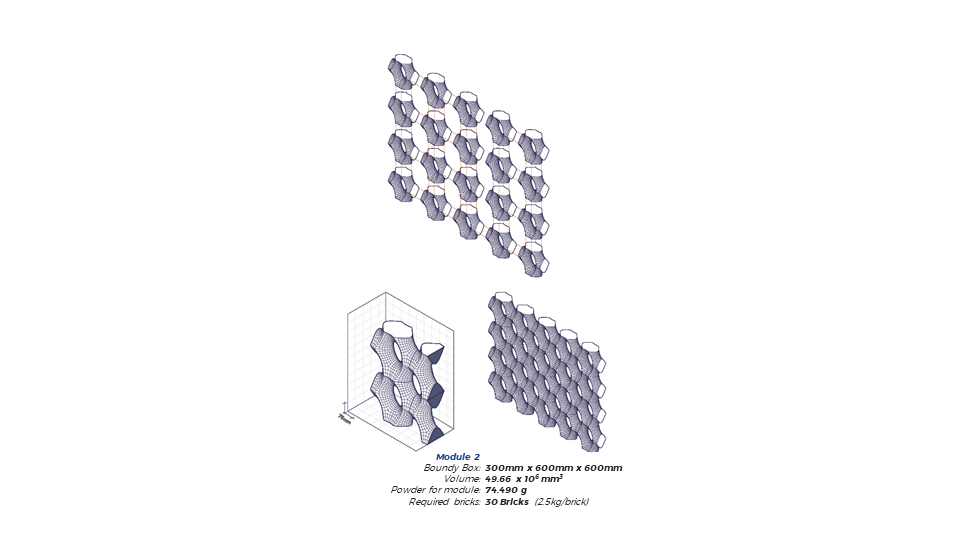

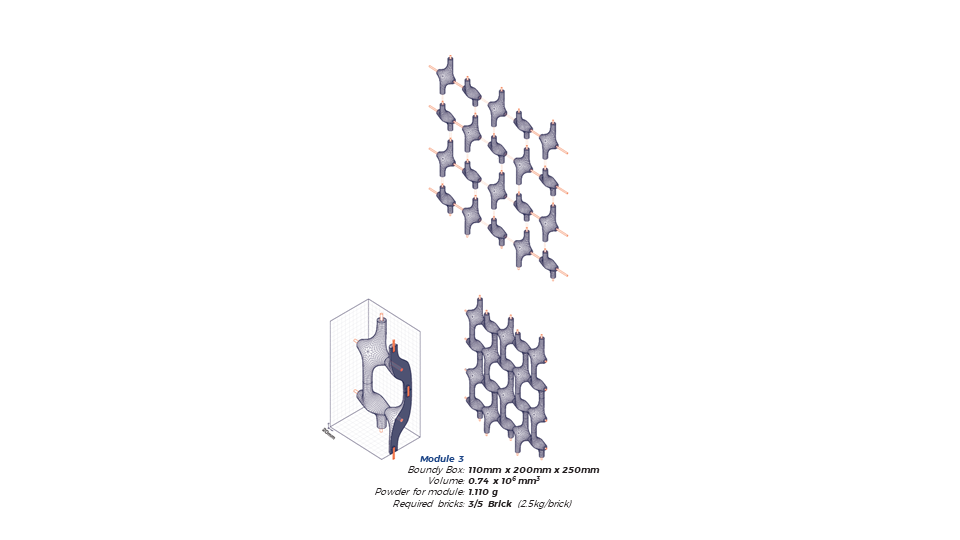

Fabrication

Urban Design Intervention

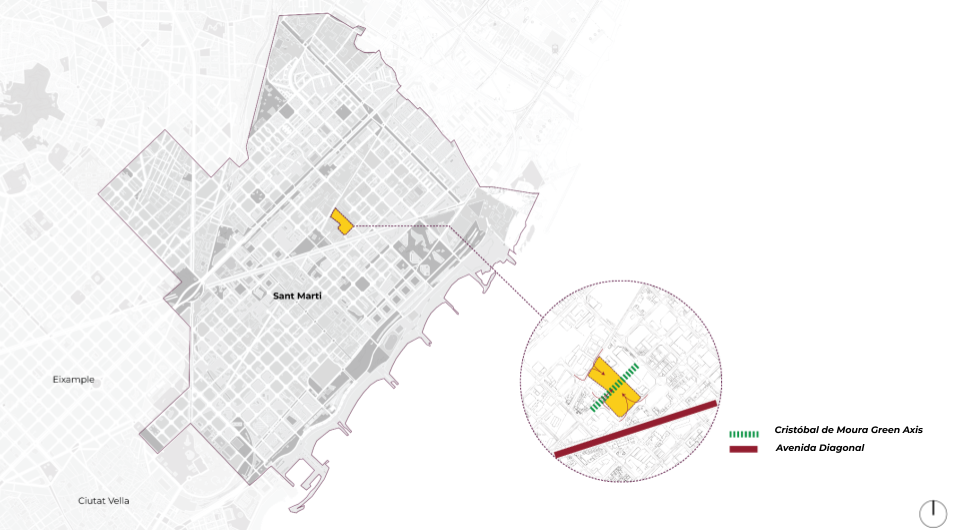

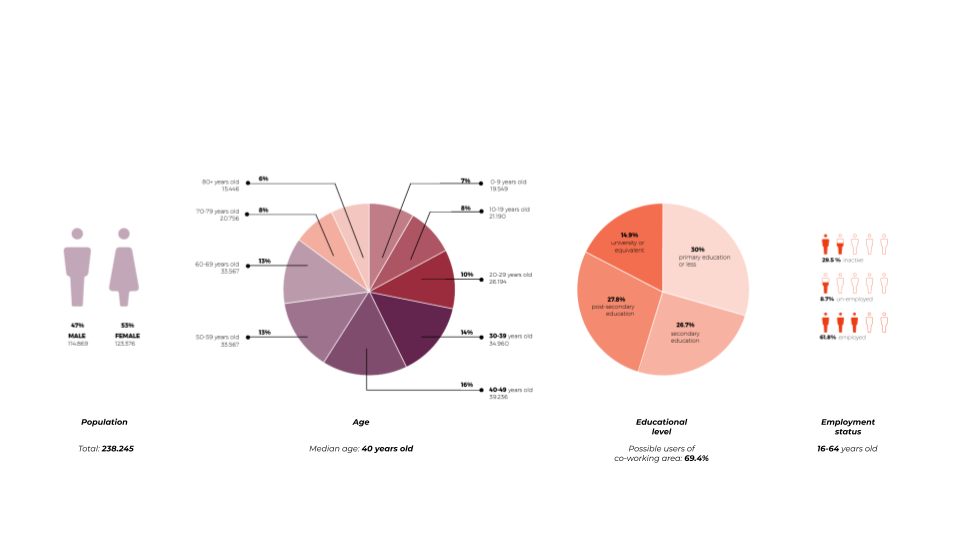

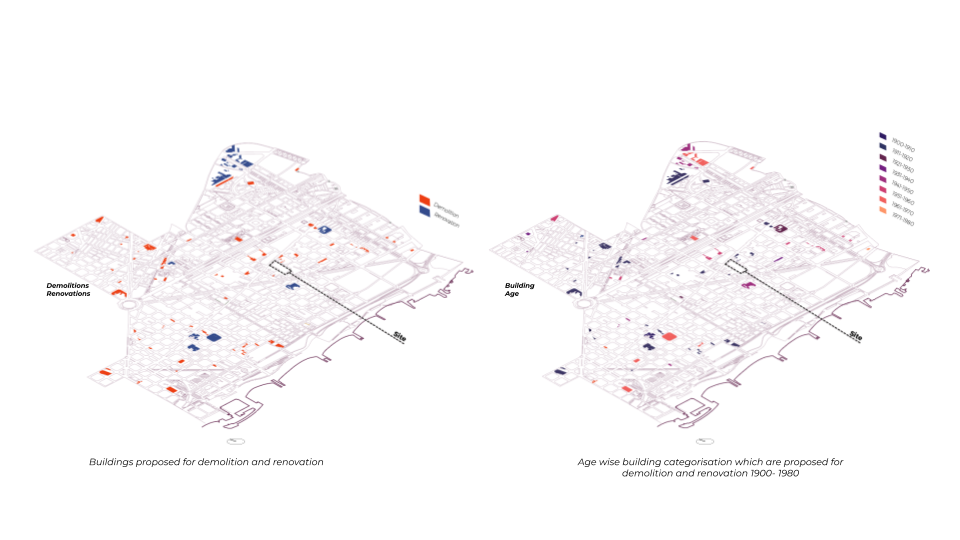

Sant Martí has a population of 22 hundred thousand people,

which makes it the second most populated district in Barcelona and the fourth largest district in Barcelona. (10,8 km2)

It is also undergoing an infrastructure development stage and has many buildings which are proposed for demolition and renovation.

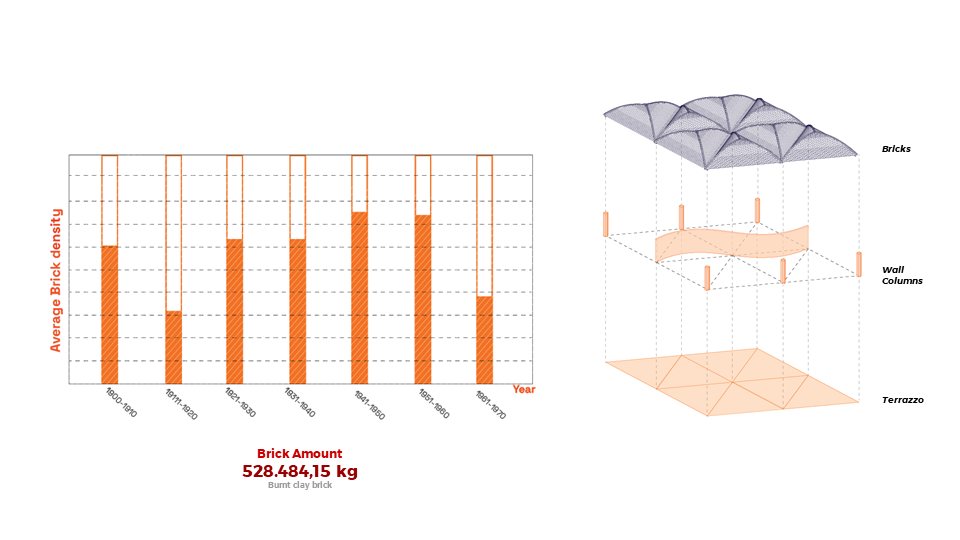

The graph shows the varying brick densities by the age of building, this method of mapping allows us to extract information of material availability. In this case, the available bricks for upcycling is 528.484,15 kg. Of the buildings that are going to be demolished the majority are built in 1900- 1920, however, the building with the bigger brick density are those that built-in 1950-1970.

Site analysis shows

- The main green spaces are within a radius of 1 km from the case study. The plot is a in center of industry land.

- Corresponding land use map showcasing residential, service, and industrial areas.

- There is low mobility and social cohesion around our plot. The area needs a hub, a pole of attraction.

The mid-young media age in combination with the education comparison and employment status give us an image of an area with people with skills and abilities. A place with possibilities for the creation of collaborations and possible new job positions.

Strategy

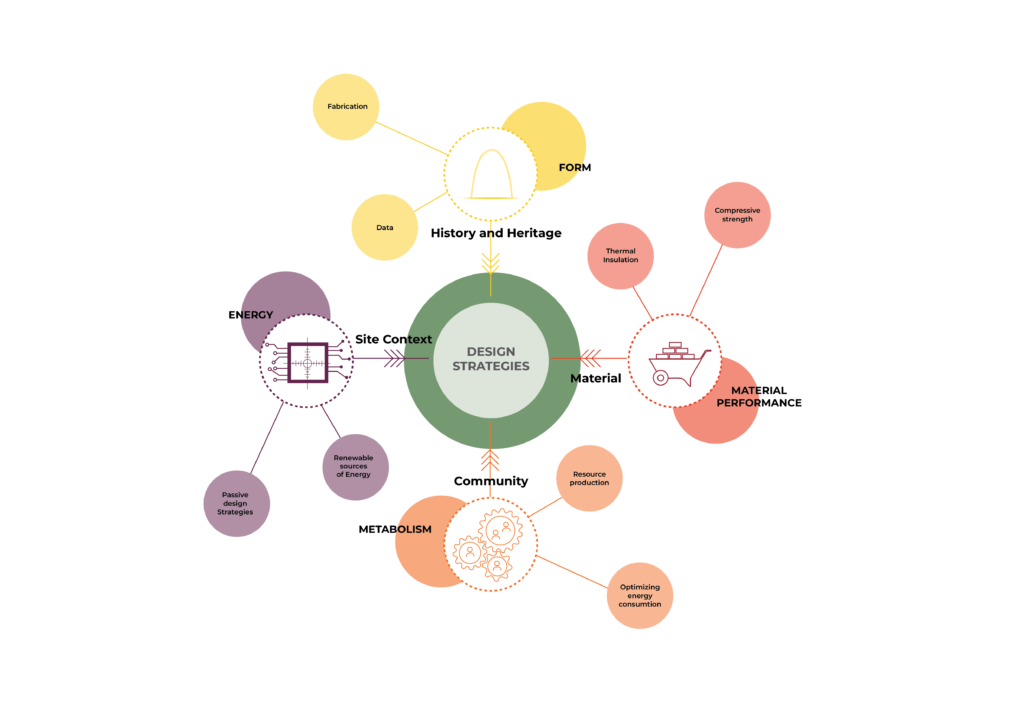

The project intervention is driven by four main design drivers which are

- Site context: Site selection based upon the expansion of green and social gathering spaces.

- History and heritage: Reviving the construction method used by Rafael Gustavino of using thin layered tiles for timbrel vaults.

- Material: The amount of available brick waste will be utilized to determine the scale of the project which will lead to improving the circular economic cycle.

- Community: Strategically situated in an area with low social interaction and activity. The space attempts to enhance the social experience and participation of the neighborhood.

Design strategies

- Energy: Using passive design strategies and renewable energy.

- Form: designing the fabrication strategies and design based on availability.

- Material: Material performance enhances its thermal property and compressive strength.

- Metabolism: Resource production through introducing urban farms and optimizing energy consumption.

Brief

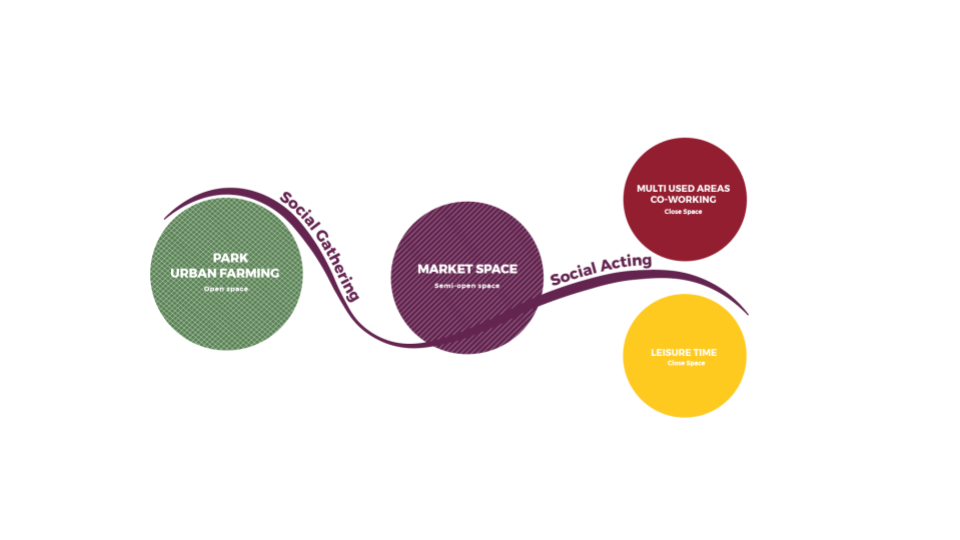

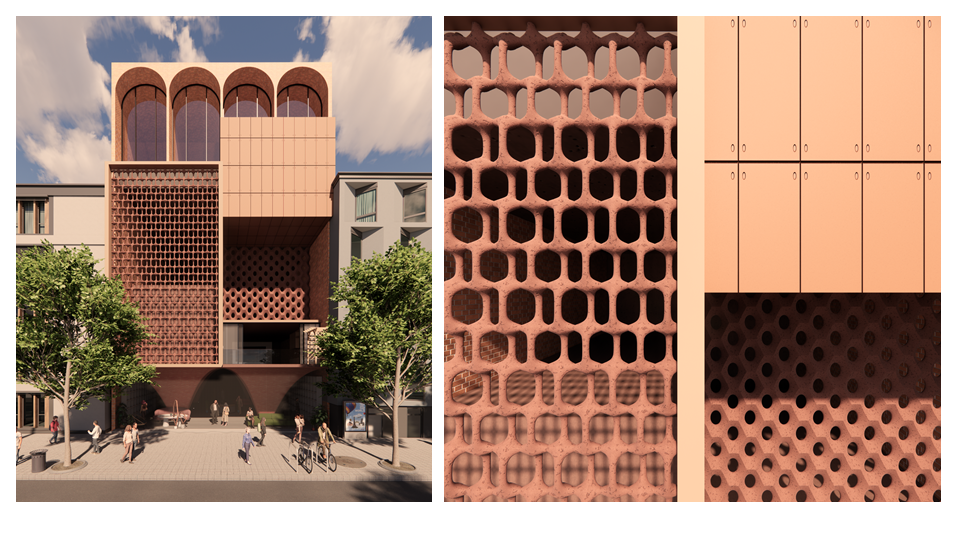

This project aims is to built an urban oasis in the district of Sant Marti. Strategically situated in the area with low social interaction and activity. The space attempts to enhance social experience and participation of the neighborhood infusing vitality to the site.

Demolition and renovation waste in the neighbourhood of Sant Marti give us the raw material to design a funicular structure. A community centre, a co-living space hub with multi-use spaces for the public that increase the sense of local community.

The aim is the social gathering and the social acting. Through a urban farming, a open market space and gathering spaces for education and leisure time.

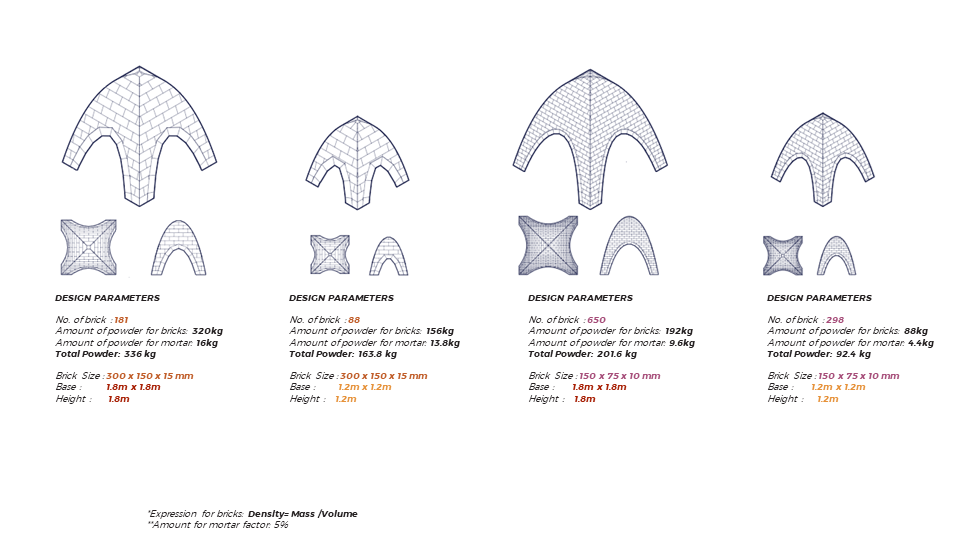

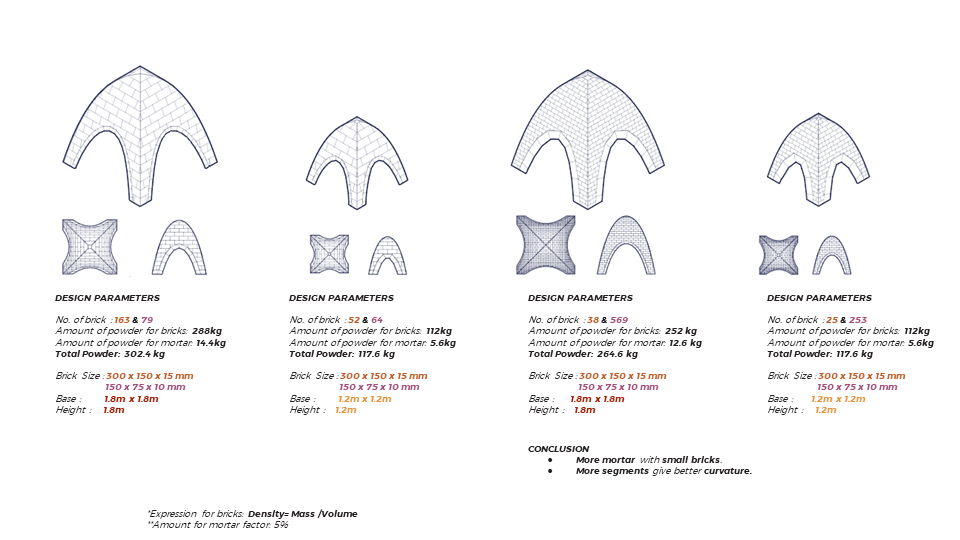

Design Catalogue

Re-clay(m) is a local solution to the global problem of construction and demolition waste.

In this context, the raw material utilized is disintegrated form of brick,

a widely available resource all around the world, obtained from the construction demolition waste.

The primary objective is to promote the upcycling process and facilitate the transition towards a circular economy

and reduction of carbon emission within the brick construction demolition waste industry.

By harnessing the abundance of brick waste, its favorable mechanical properties,

and its suitability for compression construction, we can design diverse structural systems.

These systems not only contribute to recycling efforts but also offer alternatives

in building construction that reduce reliance on energy-intensive materials.