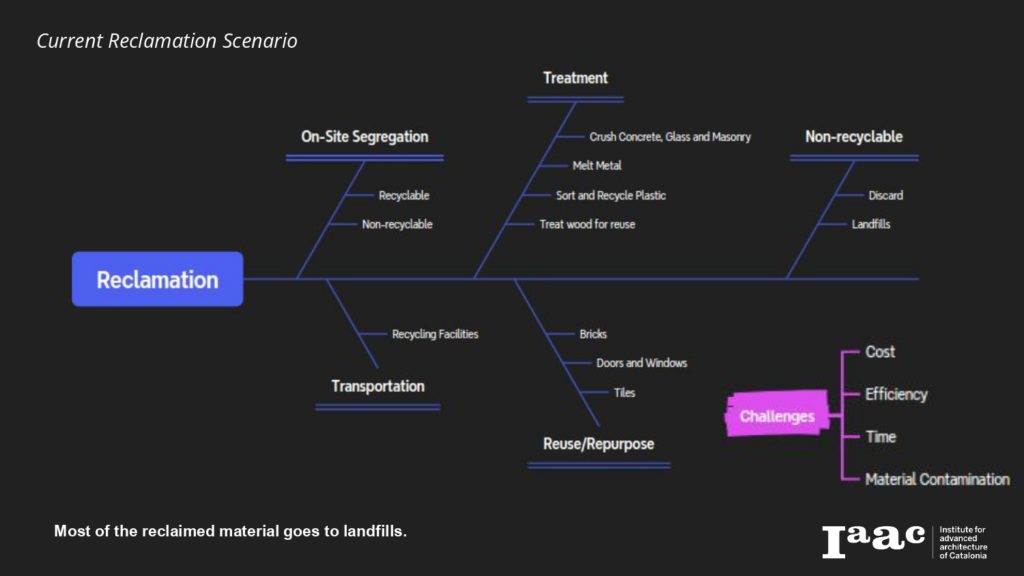

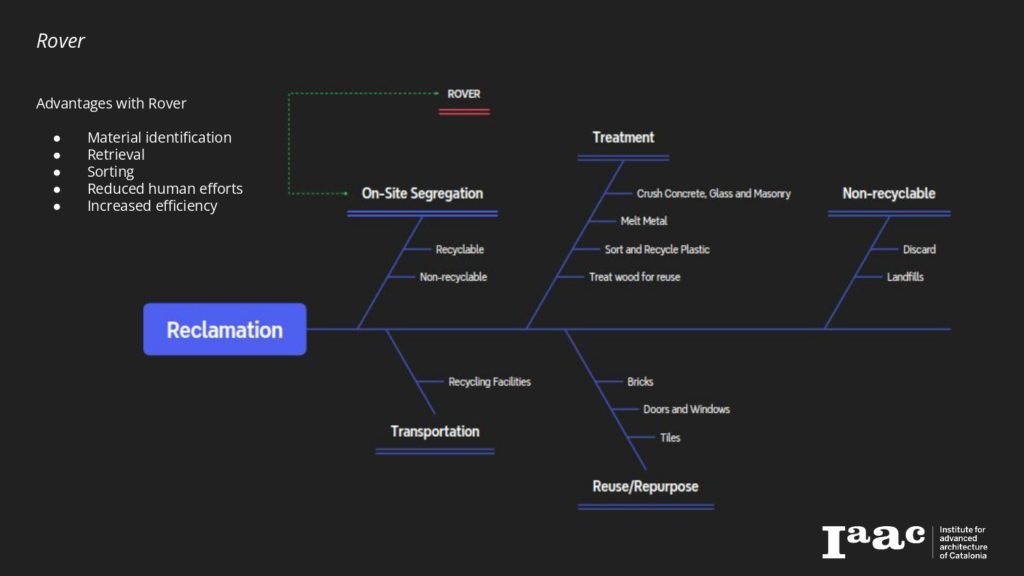

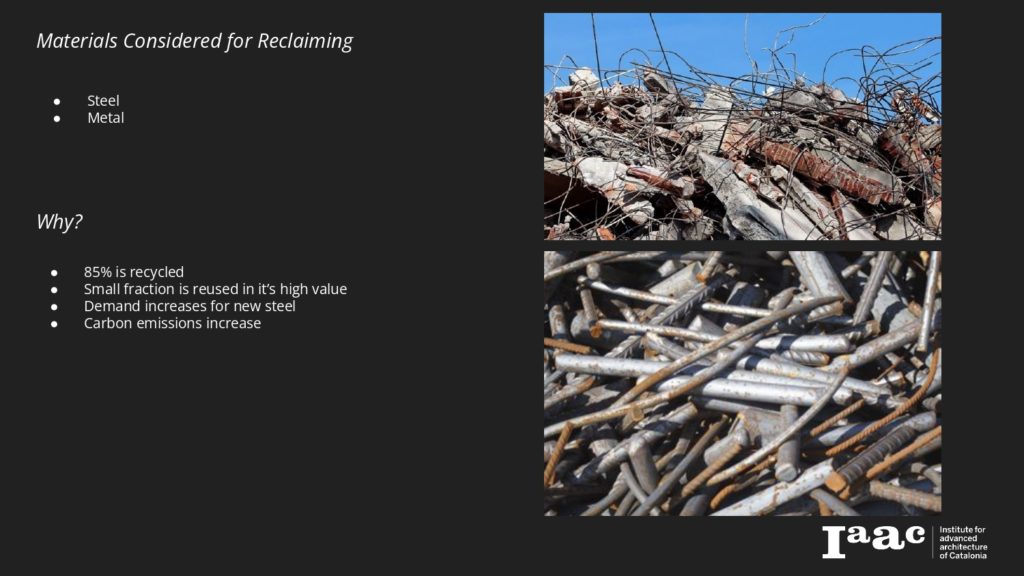

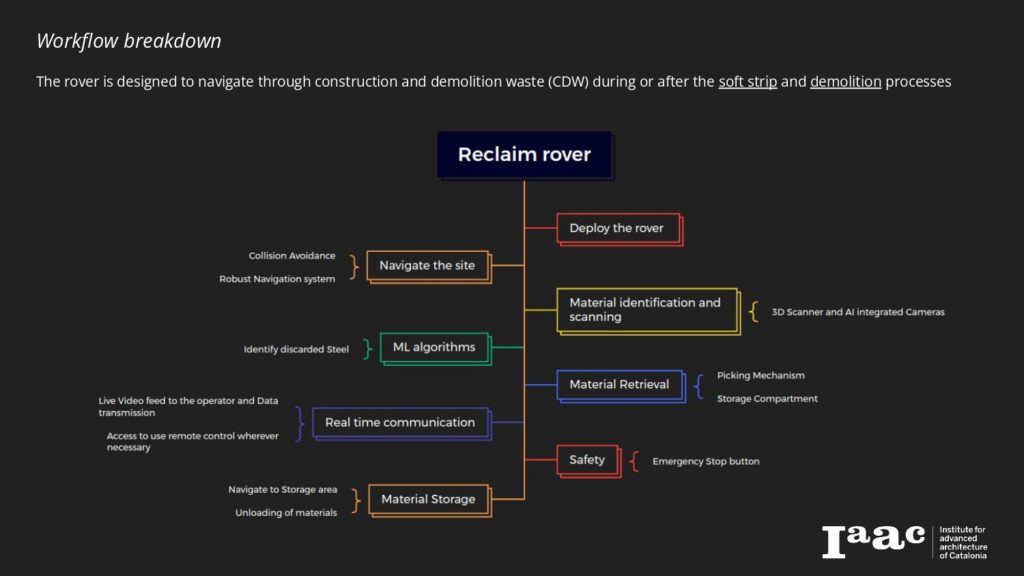

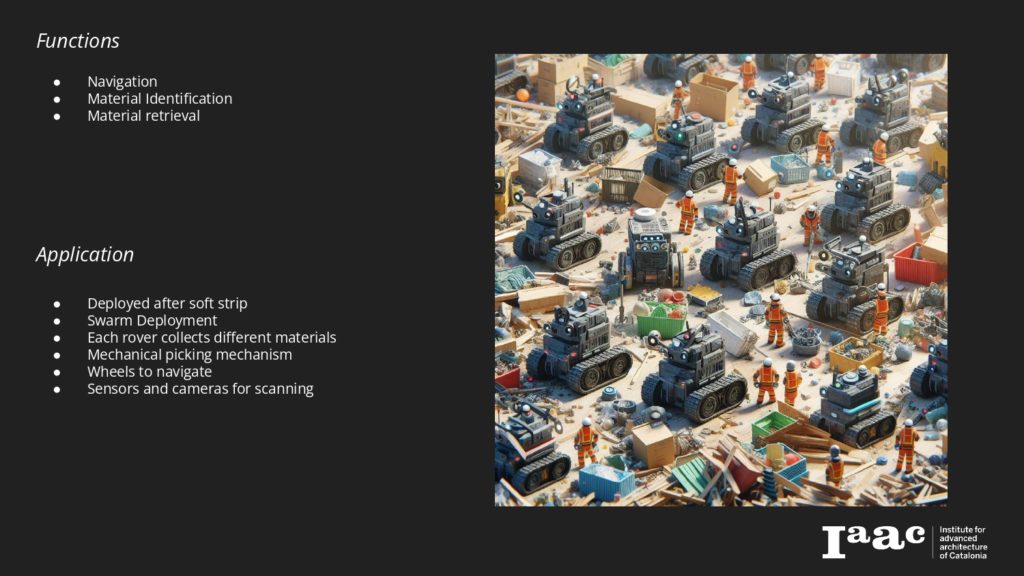

The integration of a rover or swarm of rovers into construction demolition sites represents a paradigm shift in waste management practices. Equipped with advanced sensors and AI algorithms, this rover possesses the capability to accurately identify and segregate valuable materials such as steel and metal amidst debris and rubble. These rovers operate seamlessly alongside human workers during or after the soft strip phase of demolition.

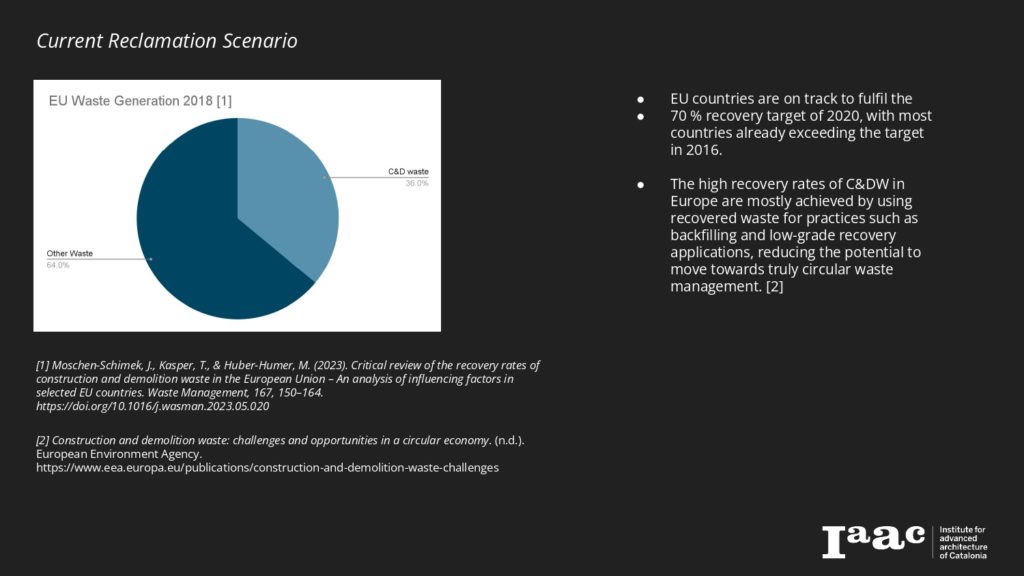

By reclaiming reusable waste materials that would otherwise be discarded, the rover significantly enhances resource efficiency on construction sites. This not only reduces the burden on landfills but also minimizes the need for new materials, ultimately contributing to a reduction in carbon emissions associated with resource extraction and production.

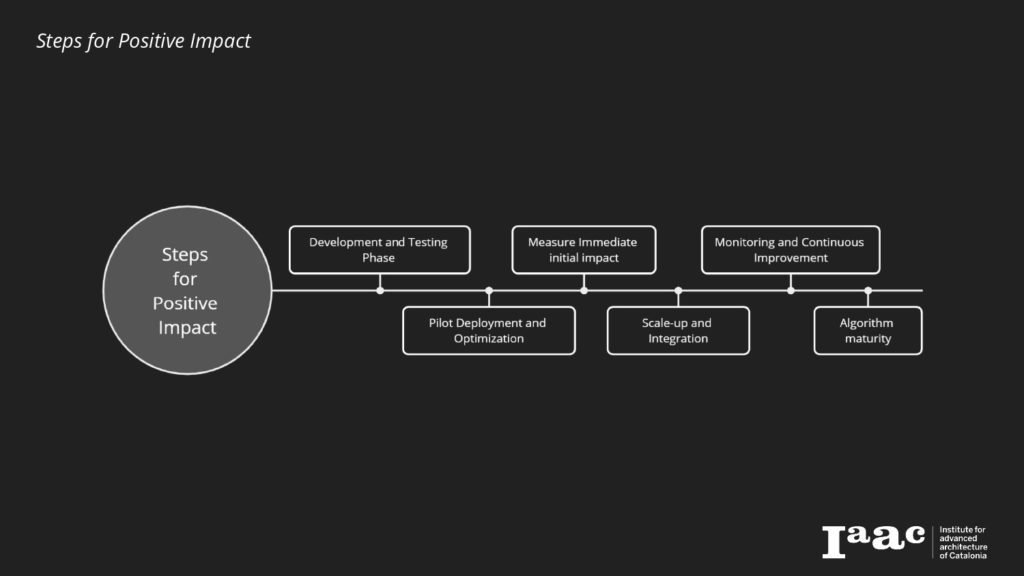

Initially, there may be higher costs and a larger carbon footprint associated with implementing this technology. However, as the technology matures and becomes more widespread, these drawbacks are expected to diminish. Through ongoing advancements and economies of scale, the initial barriers such as high costs and increased carbon emissions will gradually decrease, leading to a more cost-effective and environmentally sustainable solution in the long term

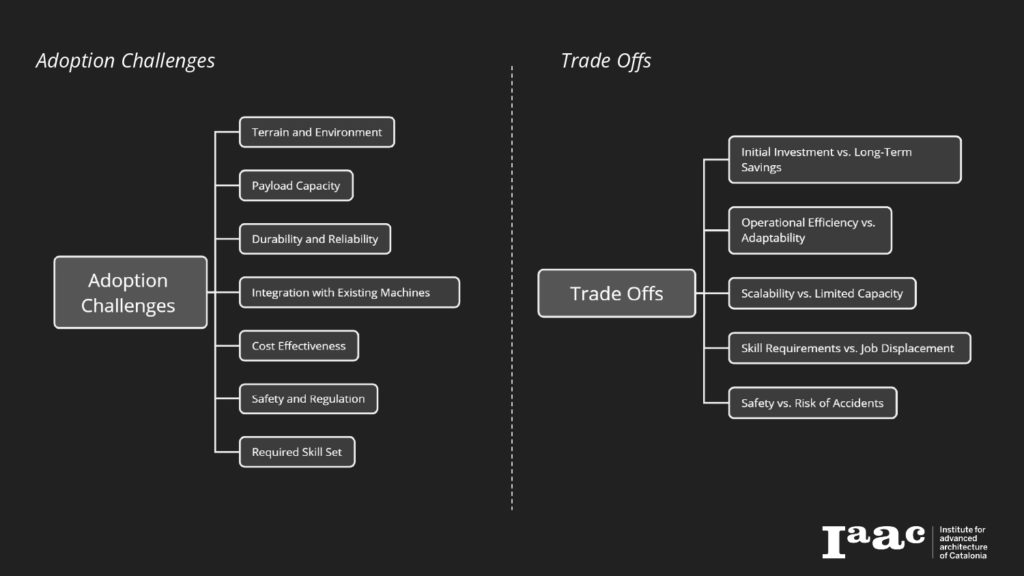

To ensure a positive impact, the rover technology must undergo continuous improvement through research and development, while fostering collaboration with the construction and waste management sectors. Operators must undergo thorough training to optimize rover efficiency, with continuous assessment of its effectiveness in reducing carbon emissions and landfill waste. Regulatory support for sustainable technologies is crucial, alongside public awareness campaigns emphasizing the benefits of waste reduction and sustainable construction practices facilitated by rover technology.