Context

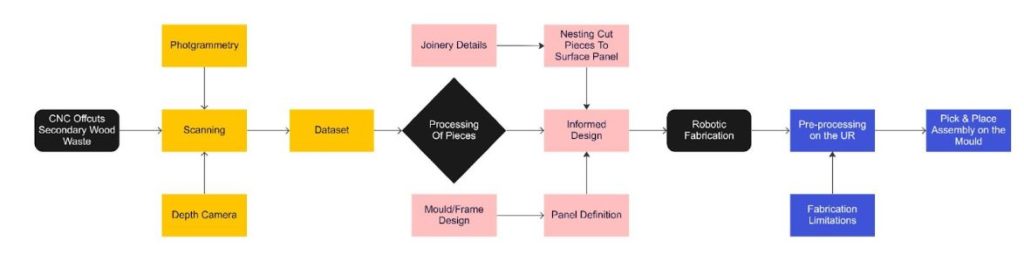

This blog documents the negotiation of a System of Scan to Fabricate workflows related to dealing with irregular raw materials, Namely offcuts from the saw-mill logging industry and

CNC – Offcuts in the digital fabrication workshop.

A negotiation between design input and the raw material topology necessitates research.

With each material presenting unique Opportunities and Challenges in

a)The Design Space

b) Digital fabrication

c) Data management system.

Design – Process

A top down approach of sending objects into Space.

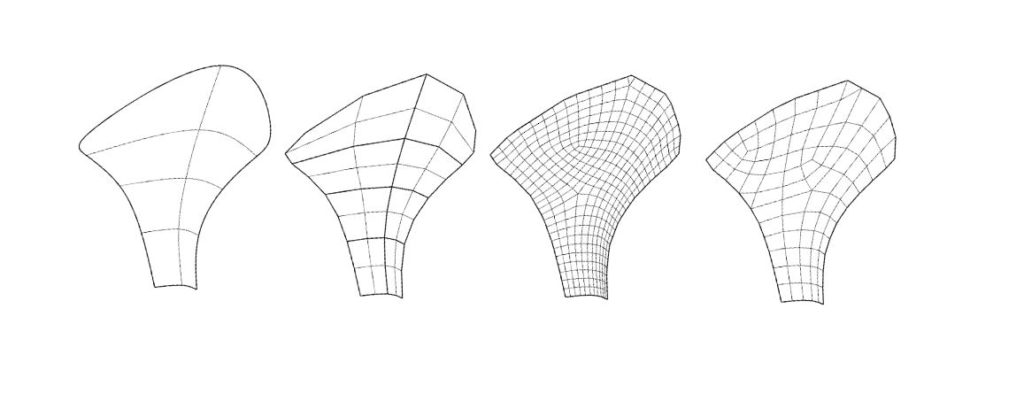

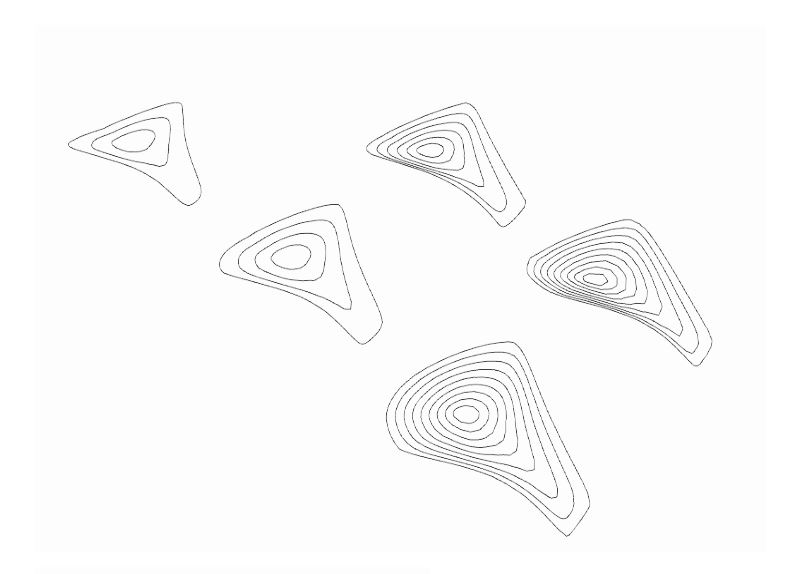

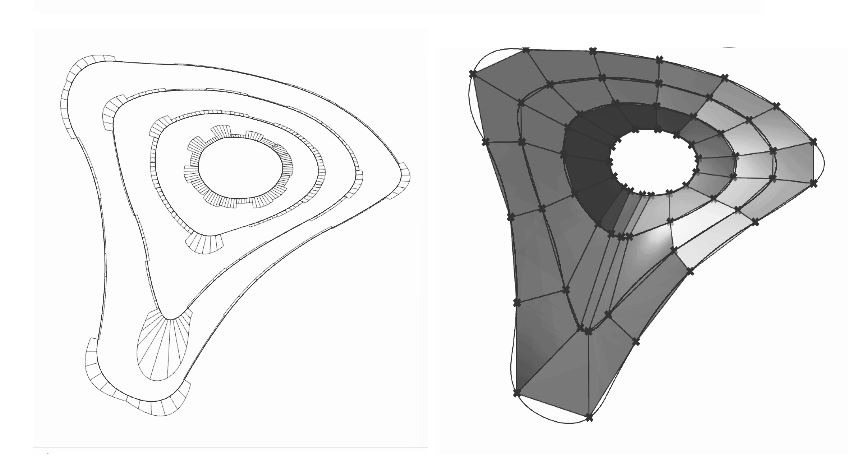

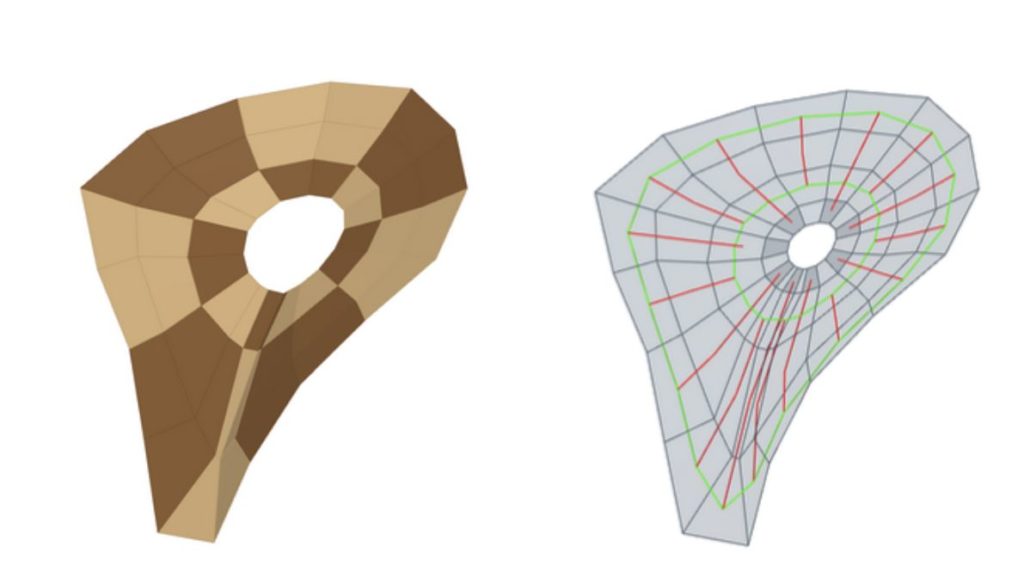

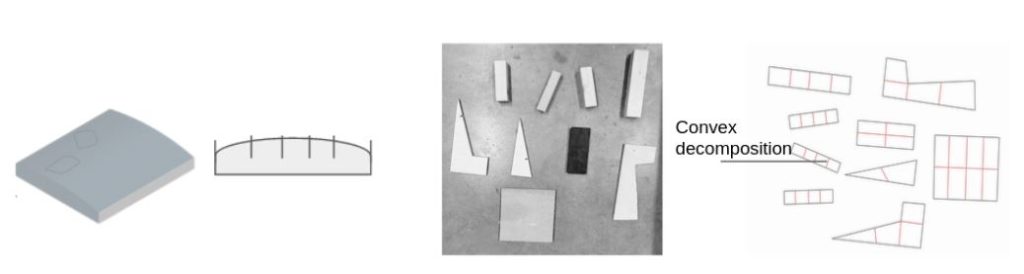

A canopy – Sub-D to Quad meshes – understanding surface geometry and Mesh Subdivisions.

A Design control to Nest objects or control the Size of the segments.

Selected Material- Prototype 1

Design to Fabrication Idea – 1.1

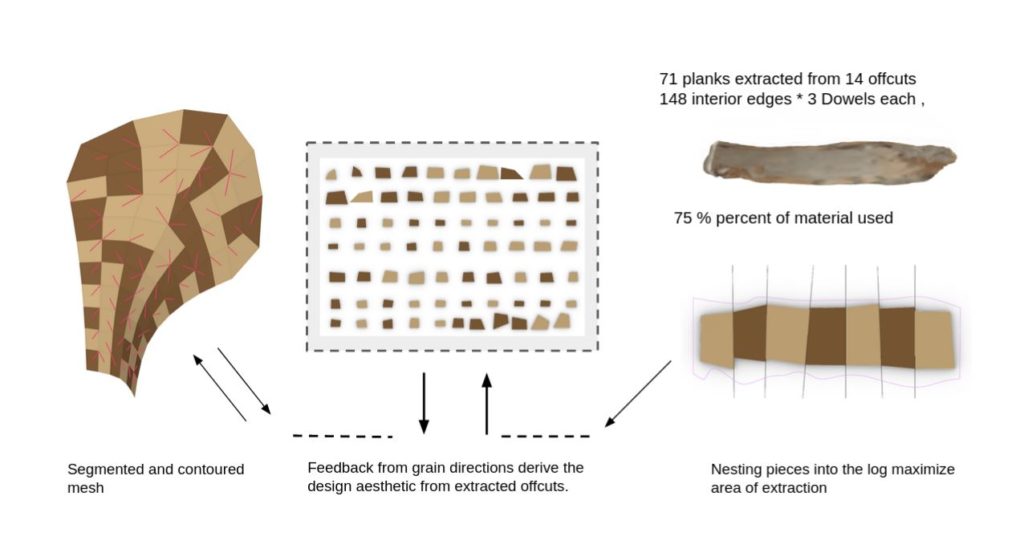

Offcuts from the sawmill industry , i.e. which can be processed into plain sawn logs for our purposes.

Scan – Photogrammetry

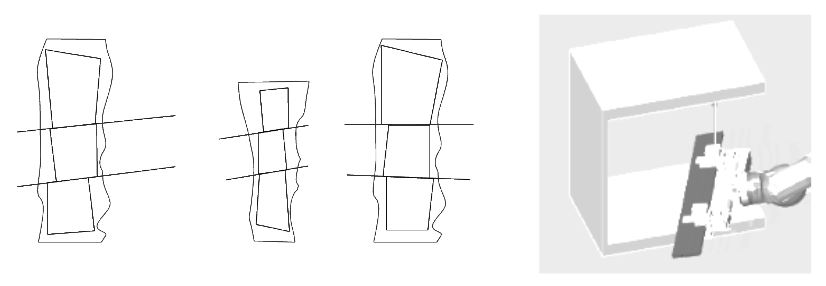

Scan to Cuts Generation

Prototype – 1.0

Design to Fabrication Idea – I

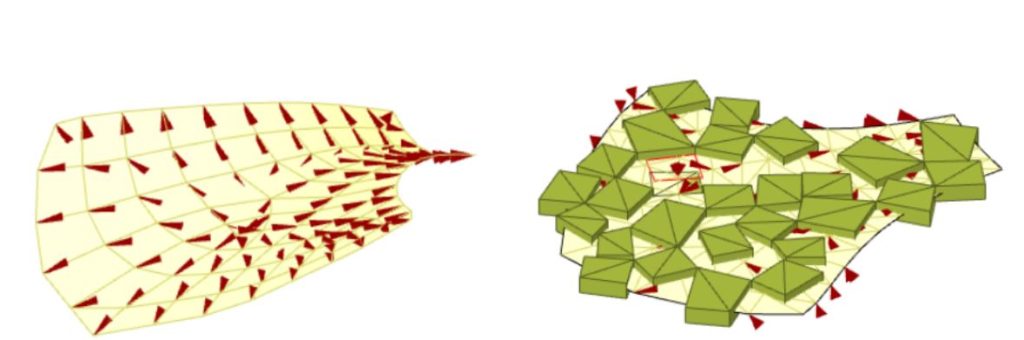

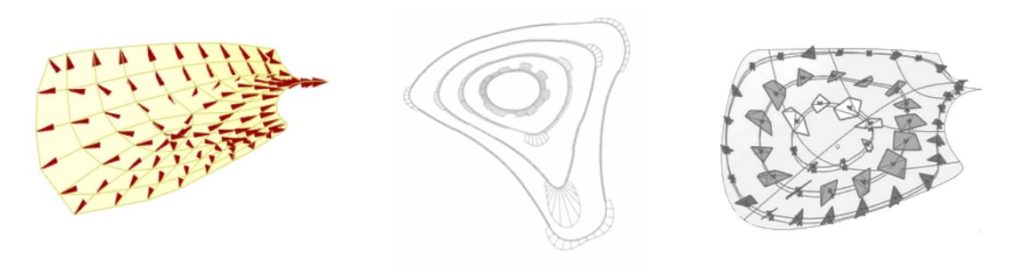

Distance heat method to segment meshes

Segmenting/contouring meshes according to curvature

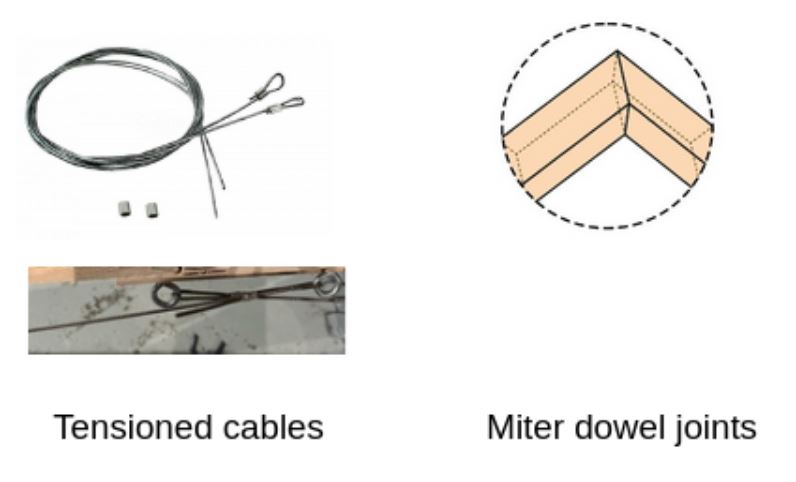

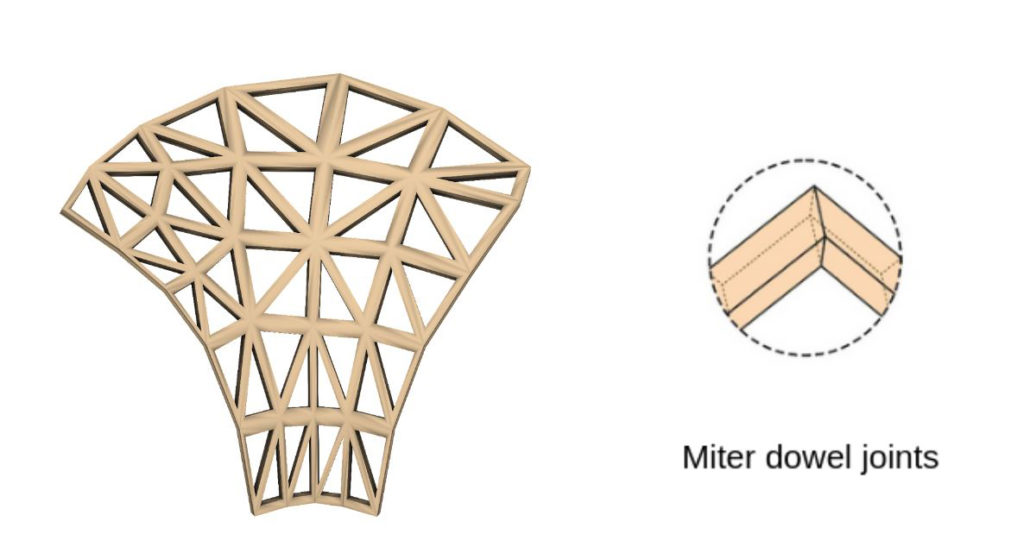

80 interior edges * 3 Dowels each

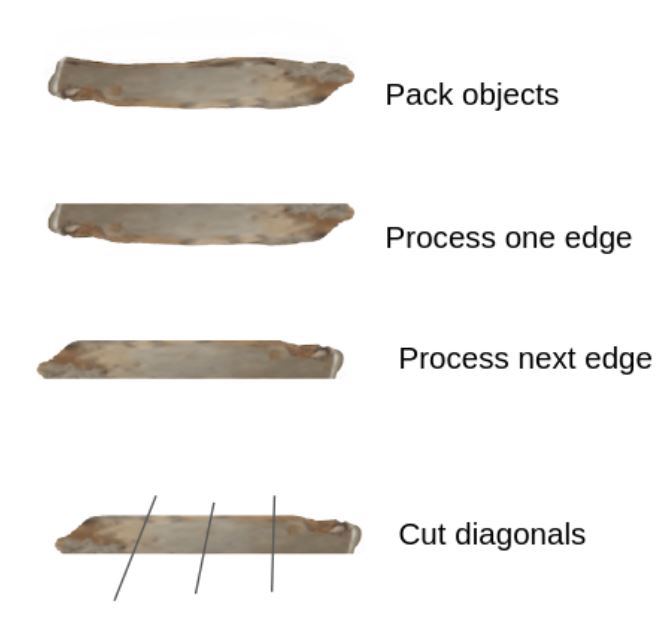

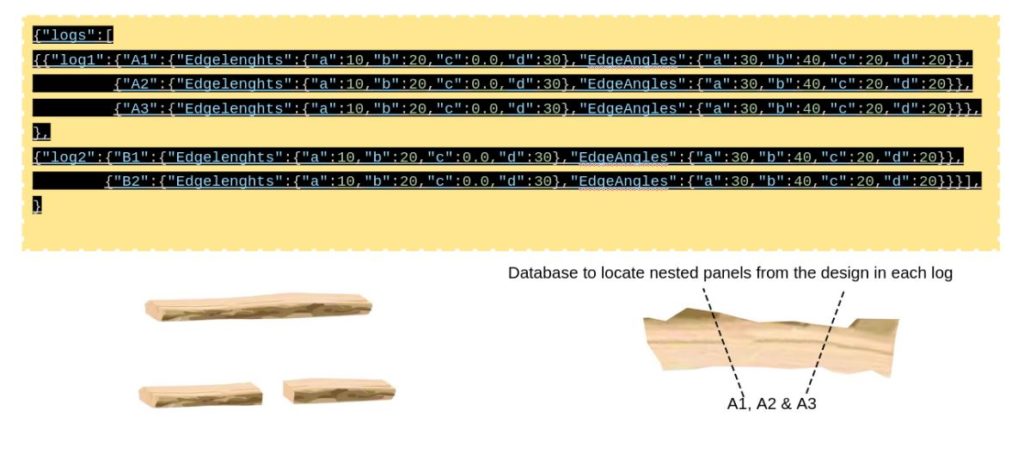

Nesting Segments in Planks

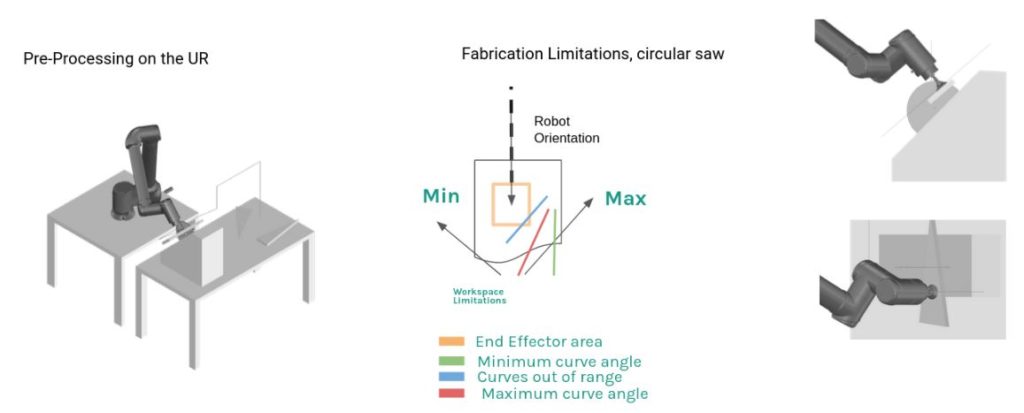

30 – 60 Horizontal angle limits

Cut diagonals

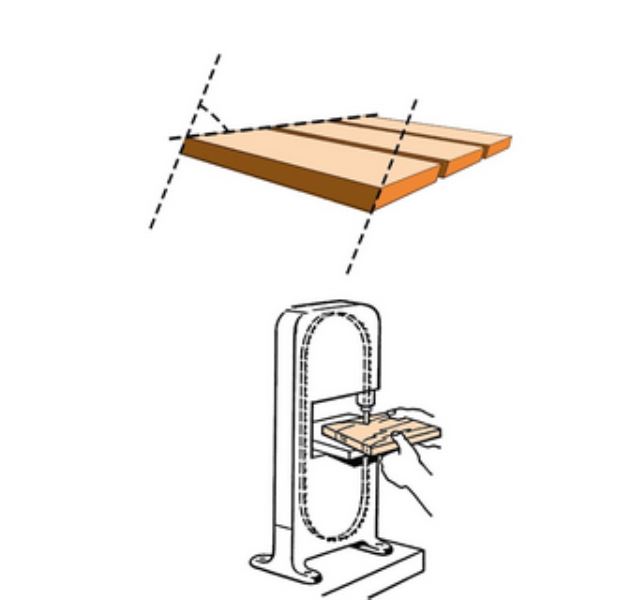

Robotic Simulation

Considered Robotic Processing tools

- Bandsaw

- Milling

- Circular saw

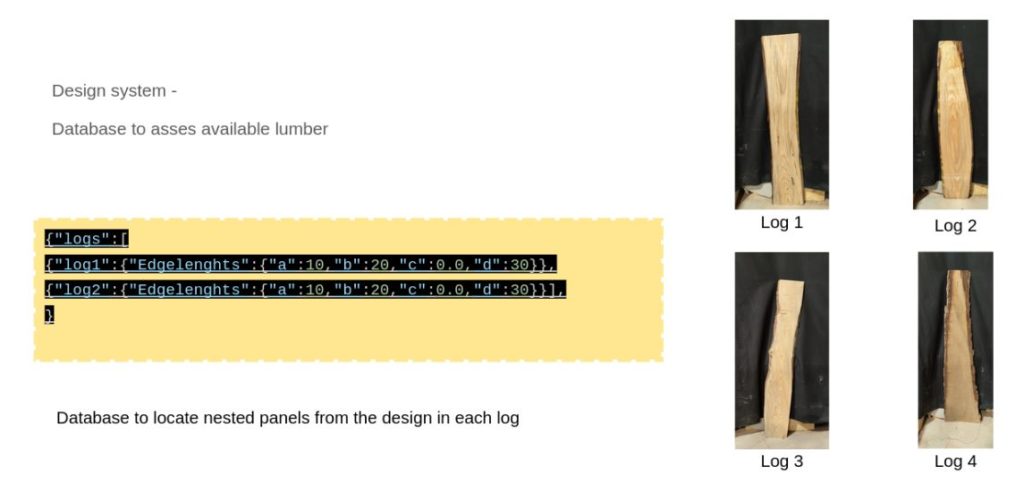

Design to Assembly – Database

The documentation of the logs to assist Robotic Fabrication.

The following data are recorded in a .json file for ease of information exchange between software platforms.

A Triangulated Framework to support panels

Design exploration of a framework for the panels.

Reasons to avoid – Produces too much waste in production.

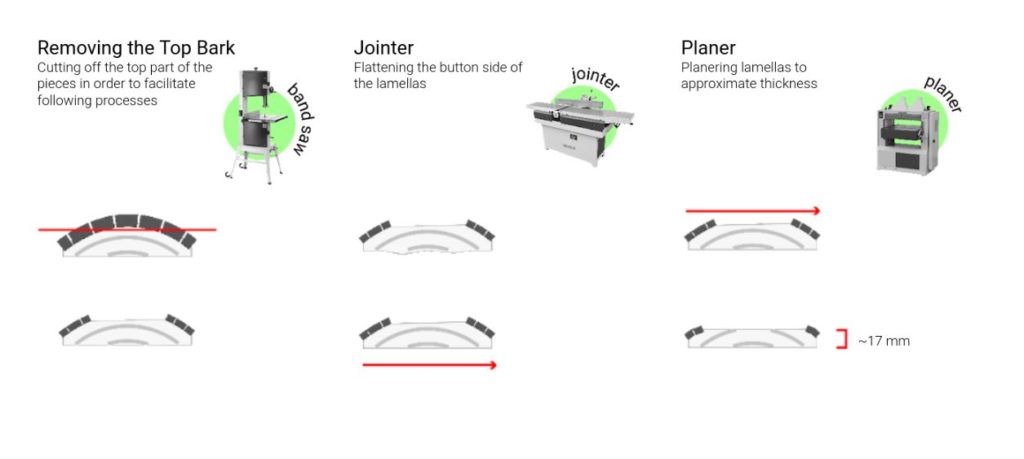

Production plan –

Planarise all logs – 5 min each , 10 logs.

Bandsaw:

Cuts on the bandsaw – 35

Cut length on the saw

Maximum 0.72m

Minimum 0.15m

- 2 min (500 mm/min)

- 1 typical cut = 2m = 4 min

Total edge travel of curves – 45.1 meters

Cut length on the bandsaw – 22.5 meters

Dowelling:

Edges joining – 84 * 3 Dowels

Finishing and extraction by Milling

Milling edge and depth reduced

1 m of milling = 0.3 min (3000 mm/min)

Design to Fabrication Idea – II

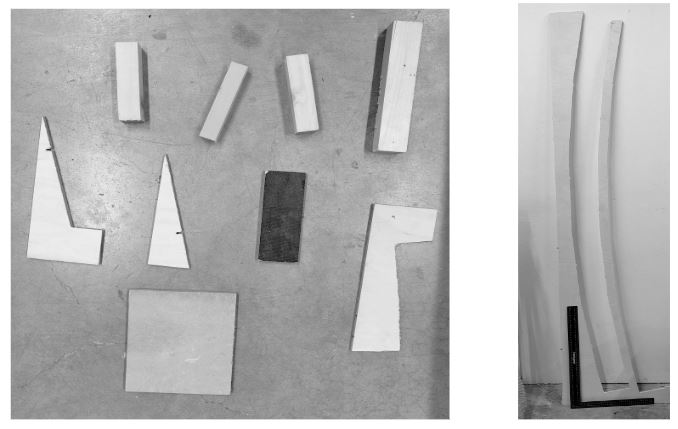

Material – CNC off-cuts

CNC Offcuts – Secondary Waste

Description: Large – leftover blanks in the stock from CNC milling & Small – offcuts Milled around

References of similar projects:

1 Still Alive

2 Robotic Mosaic

Processing pieces into the dimensions of the planar surface:

Heights & Planar Dimensions:

Range of heights – 10mm ~ 20mm

Planar Dimensions – 200mm ~ 500mm

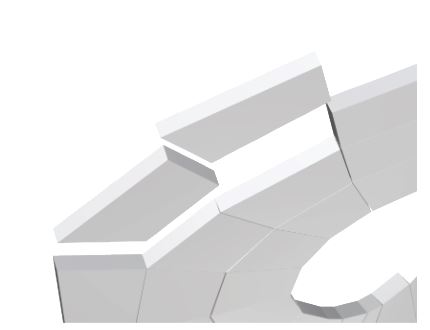

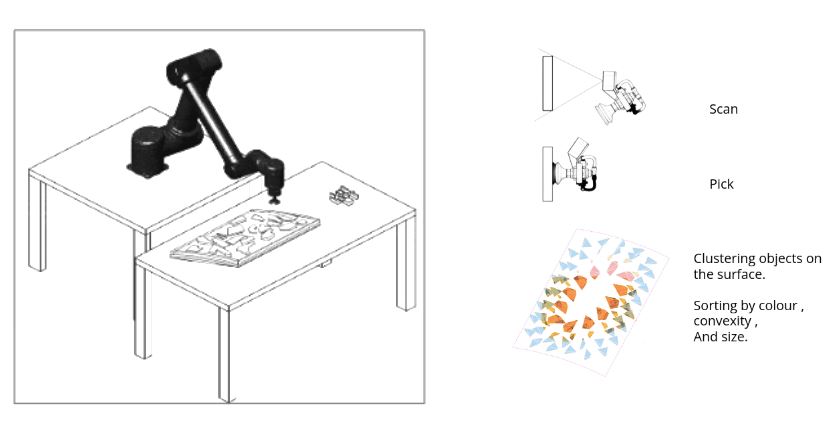

Design System – Surface Tiling

Nesting objects on the design surface:

1 Adjusting contouring to achieve packing on the surface

2 utilizing K-means clustering to map the objects onto the Contours (heat method) of the surface

3 Sorting the pieces by color, convexity and size

Alternative:

Physics simulations to

Nest on the surface. In 2D and 3D

Technology Overview

Technology Overview [Solution]

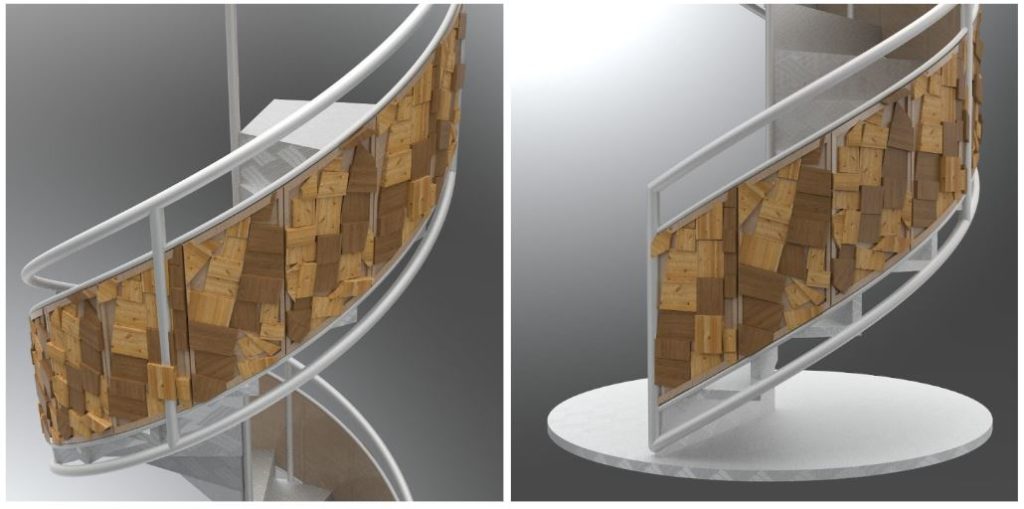

Proposal

A Balustrade from Tiling System:

Proposal – 1 week /4 week of production

Design Input

Nesting Cut Pieces on Surface Panel:

- Define the Mold / Frame

- Resin on the Mould

- Nesting Cut fragments on Surface panel

Production Estimate – Prototype II

Processing Time per panel

Scanning

- Pick & Place (Bin picking and Sorting) – 40 operations. 30 minutes per panel

- Scanning on the UR – 10 minutes

Robotic Fabrication

- Algorithm Solution Time – 2 minute

- Cutting on the Circular Saw – 1 typical cut = 2m = 4 min

20 cuts – 30 minutes.

- Pick & Place (Assembly)- 40 operations. 30 minutes per panel

Per panel – 2 Hours

Material and opportunity Cost

Secondary Wood Waste – Free

Moud – To be manufactured once, reusable

Resin Binders – Bio resins can make it sustainable

Robot Runtime – Assembly might be manual and AI assisted