The emergence of additive manufacturing has expanded the horizon for developing designs that are not only more environmentally sustainable but also commercially viable, addressing critical issues in our surroundings. In the field of architecture, multi-material 3D printing opens up a compelling opportunity to imbue intelligence into the surfaces of our built environment by thoughtfully selecting and pairing materials, streamlining intricate multi-part systems into a unified, composite component.

Our innovative concept, named ShadeSculpt, utilizes the self-shading capabilities of materials to create walls and structures that can autonomously regulate exposure to sunlight. This is achieved through the incorporation of materials with inherent shading properties, reducing the need for external shading devices.

The genesis of our project lies in a one-week workshop focused on additive manufacturing. Throughout this workshop, we acquired the skills to program an ABB IRB 140 – 6 Axis Robot to perform single-nozzle, multi-material 3D printing. The primary objective was to leverage the rotational capability of the nozzle to control the extrusion of two distinct materials. In our case, we employed materials with self-shading properties to illustrate the functional advantages of multi-material additive manufacturing, exemplified by the concept of ShadeSculpt.

State of the Art

01. State of the Art printing techniques and Strategies

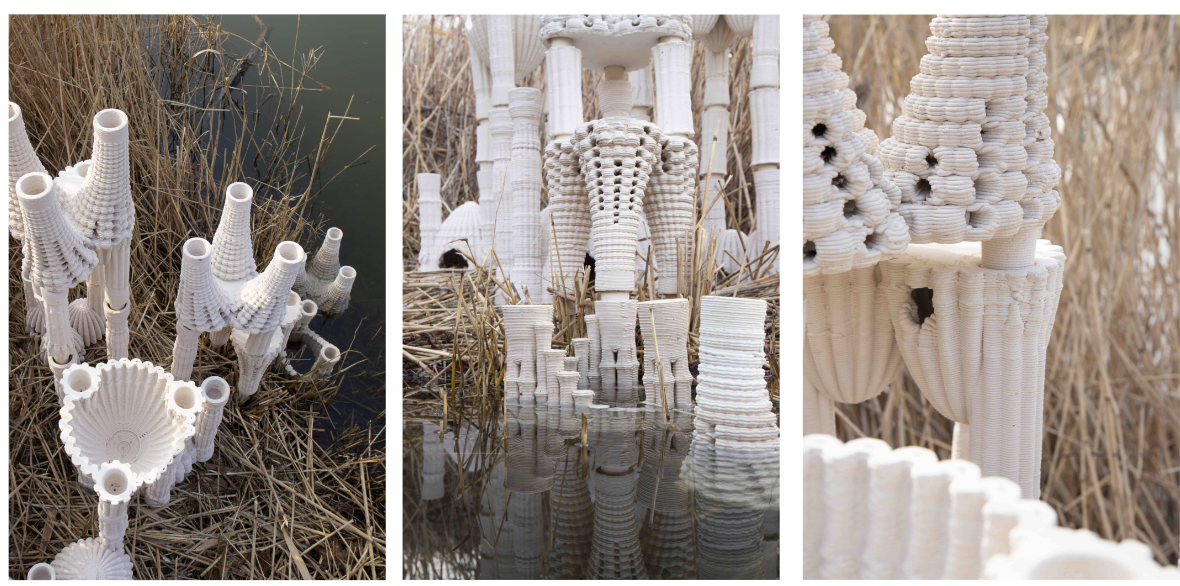

02. Multispecies habitat for urban wildlife. Modular ceramics 3D printed in clay

(Reference: https://symbioticspaces.net/symbioticspace-in-hildesheim/)

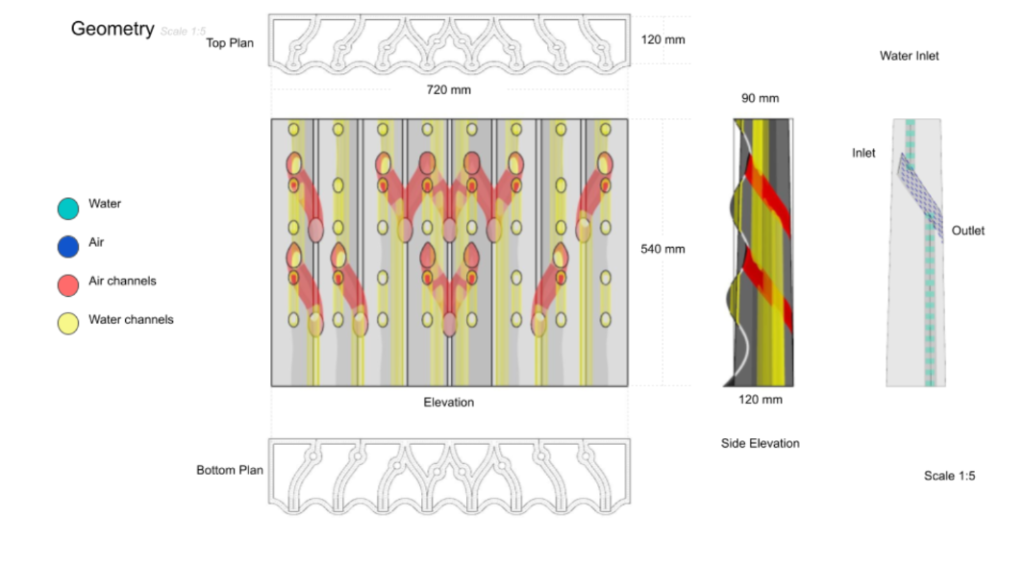

03. A Passive Cooling Wall System

(Reference: https://www.iaacblog.com/programs/bio-fence-c-biom-thesis-studio/)

Computational Strategy

Delineating and diagramming the computational rules for the geometry system based on the robotic performance analysis

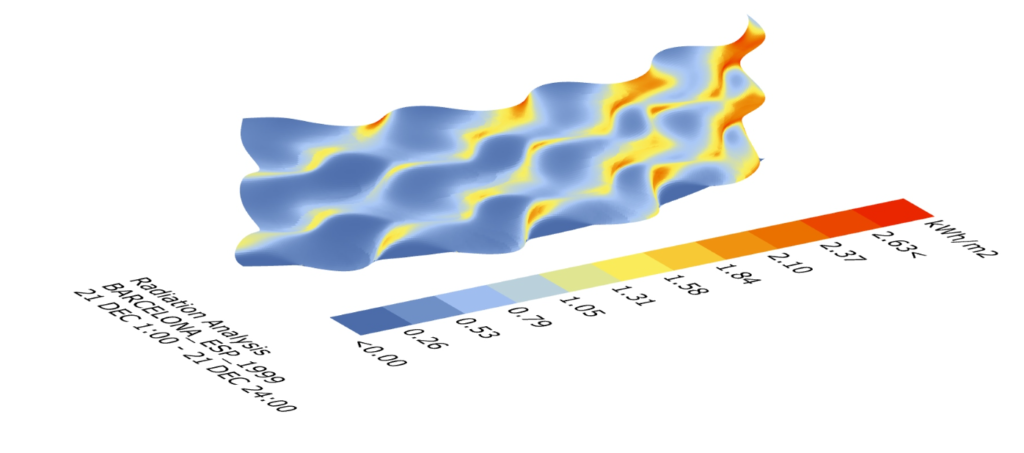

Solar Radiation Analysis

Overhang Angle Analysis

Refining design through iterative exploration of wall openings, emphasizing purposeful insect inclusion.

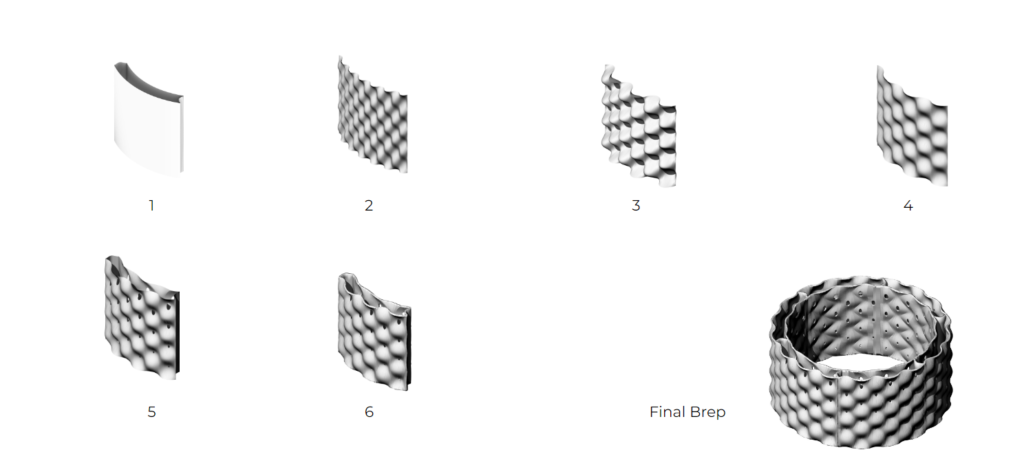

Surface Development

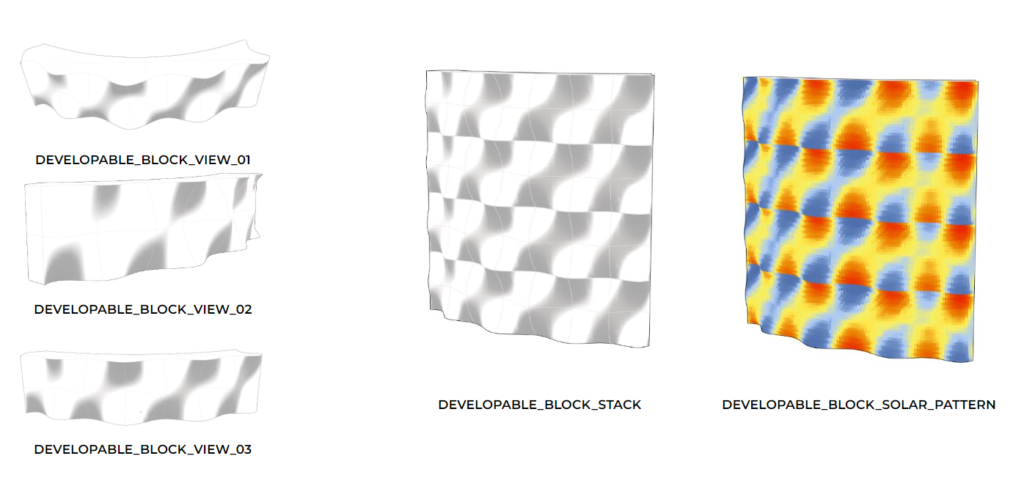

Deriving Surface Solar Pattern

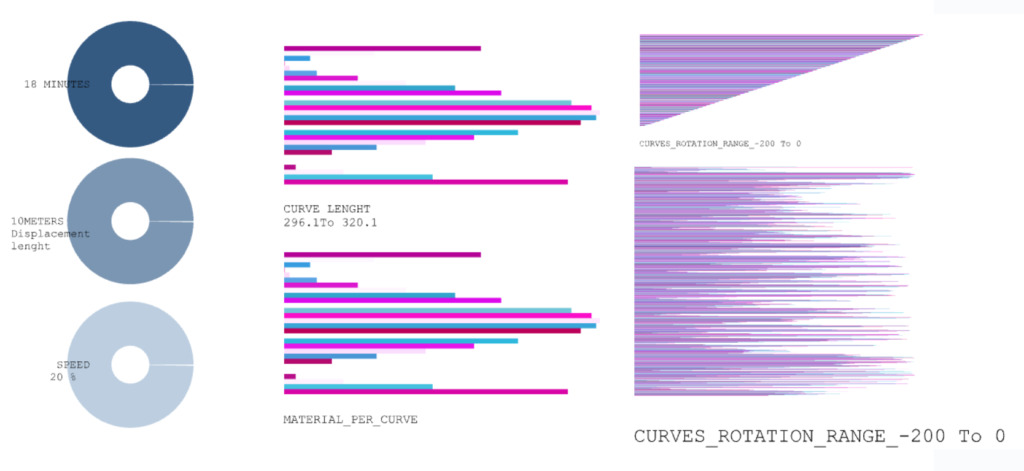

Time Estimation based on Rotation and Curve Lengths.

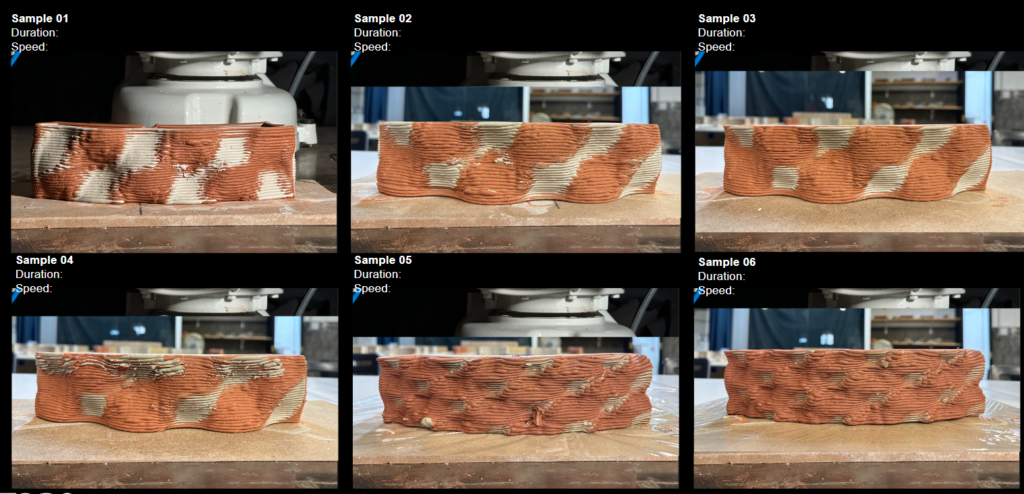

Sample Analysis

Application Iteration

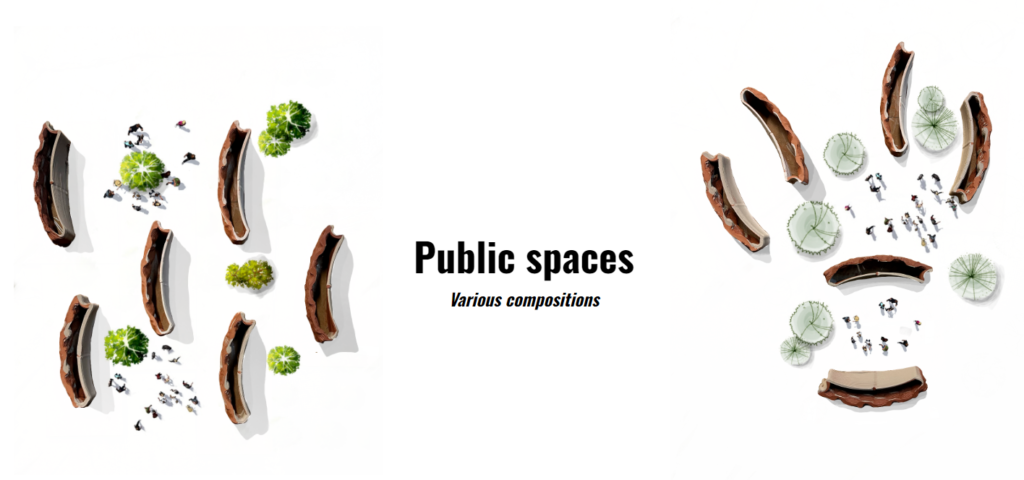

Final Outcome