This project comprises of 5 rapid prototypes developed over the course of 3 weeks. Each prototype is developed with a focus on a material and a process. These investigations were a means of developing the skillset of rapidly developing a robotic process and simultaneously became the palette from which we select our research lines for Studio II.

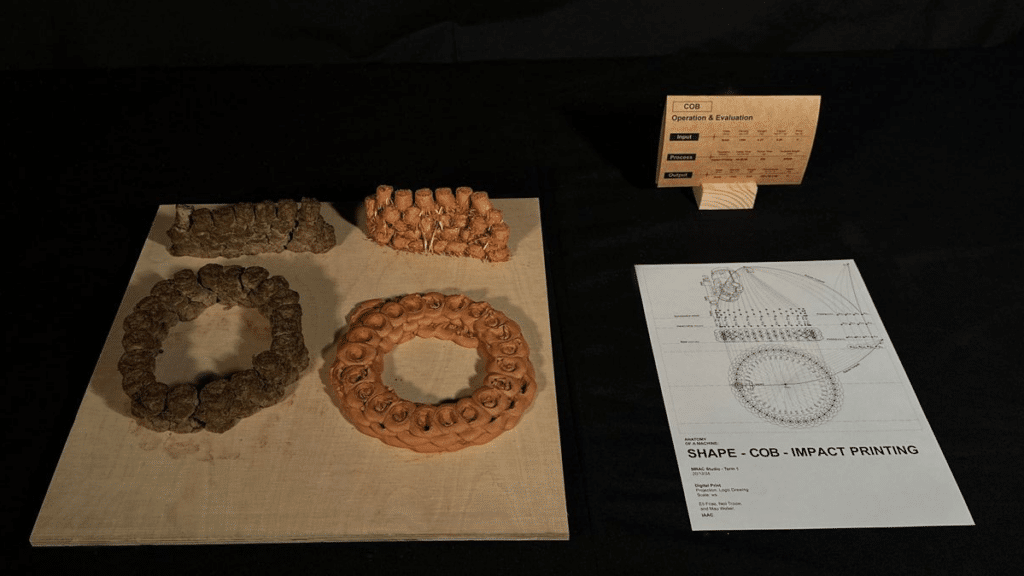

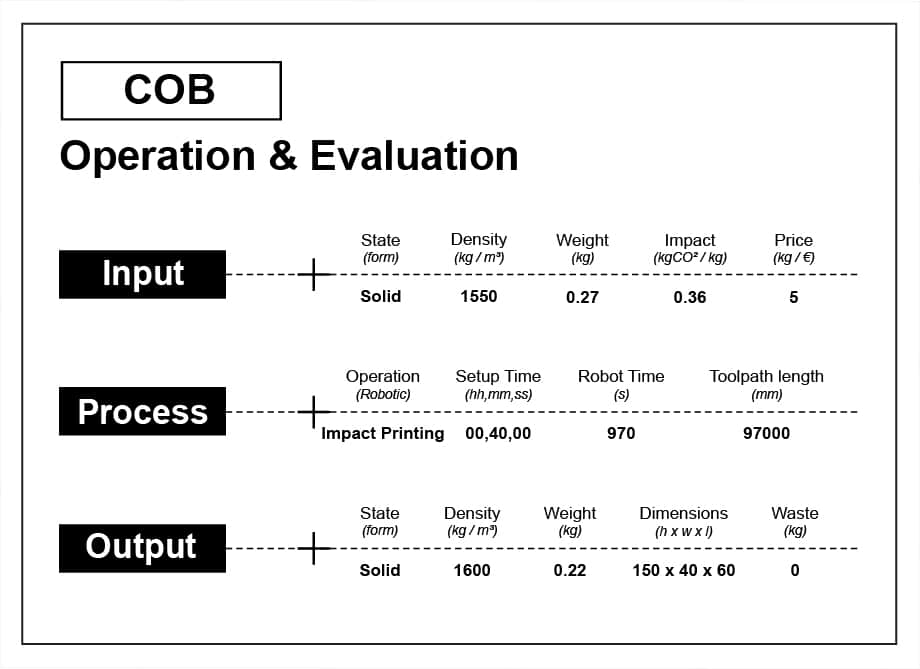

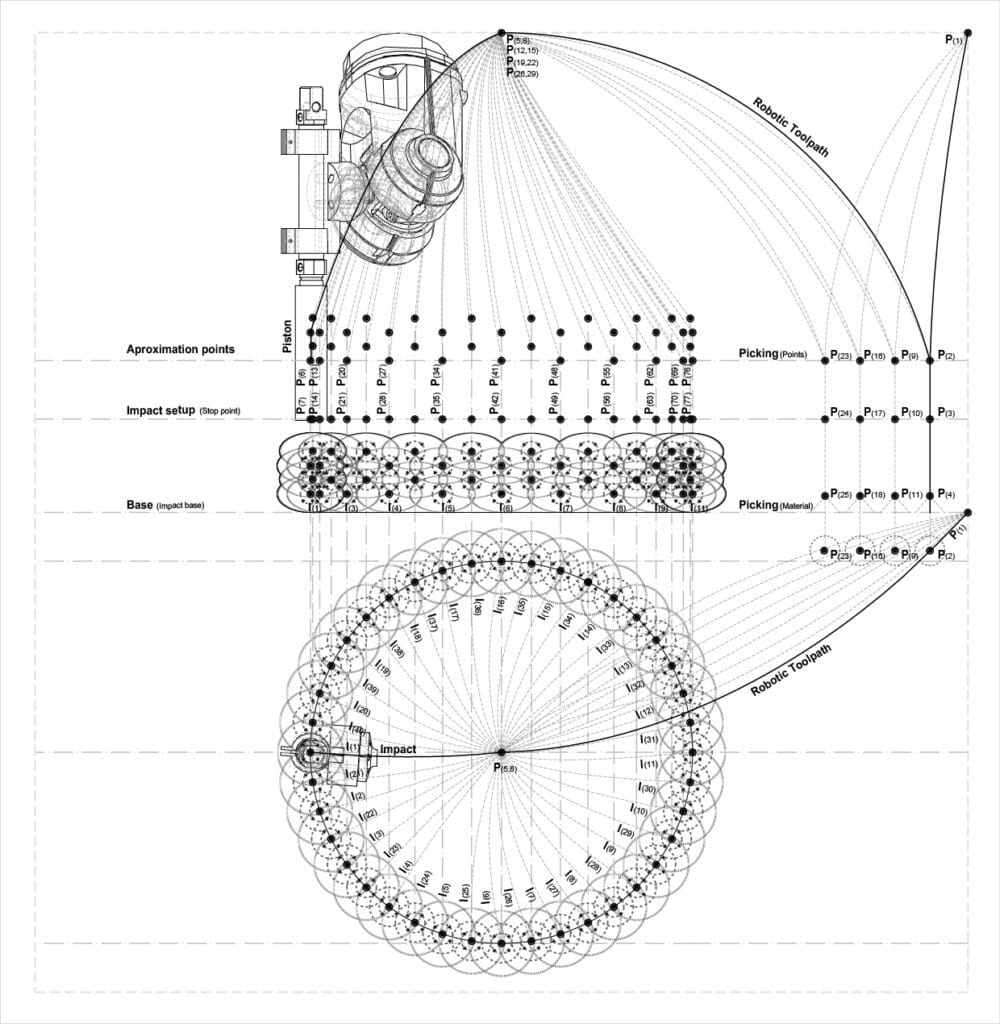

Prototype 1: Cob x Impact Printing

The first prototype utilizes an additive manufacturing technique known as impact printing. The material we used for this is cob, a biomaterial made from a mixture of earth, straw, and clay, similar to adobe. Cob construction is an ancient technique, and what’s exciting about integrating it with impact printing is the similarity in material application. Cob construction involves making earth balls and throwing them onto one another to build up mass. Impact printing does exactly this.

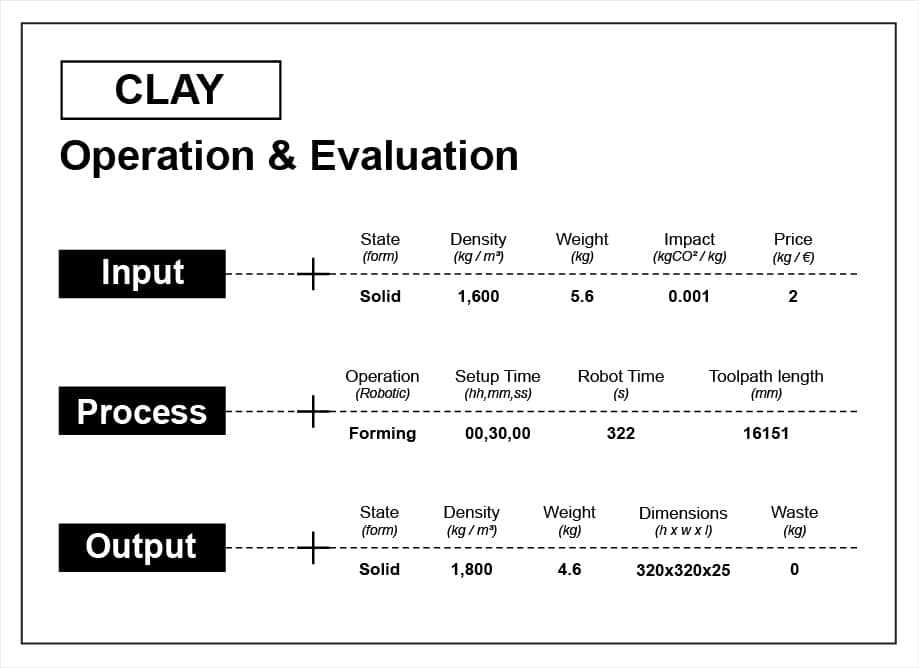

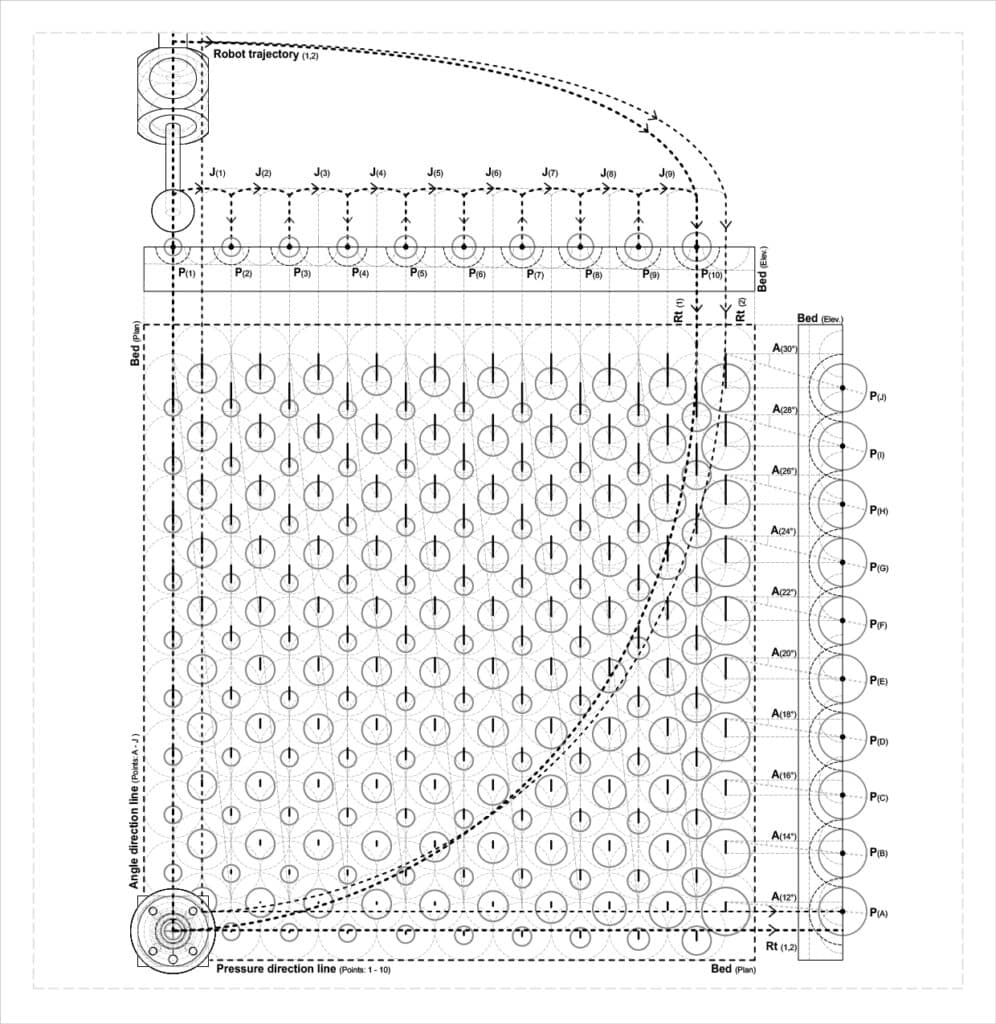

Prototype 2: Clay x Punching

Our second prototype involves material manipulation. Here, we investigated the potential of a material to retain memory. In simple terms, we strike the material with a spherical object from multiple angles and depths to compare the results. The material we chose is clay due to its high plasticity. This technique of shaping clay, rather than printing it (the most common method used in robotic fabrication), is much closer to how we’ve intuitively worked with the material for thousands of years.

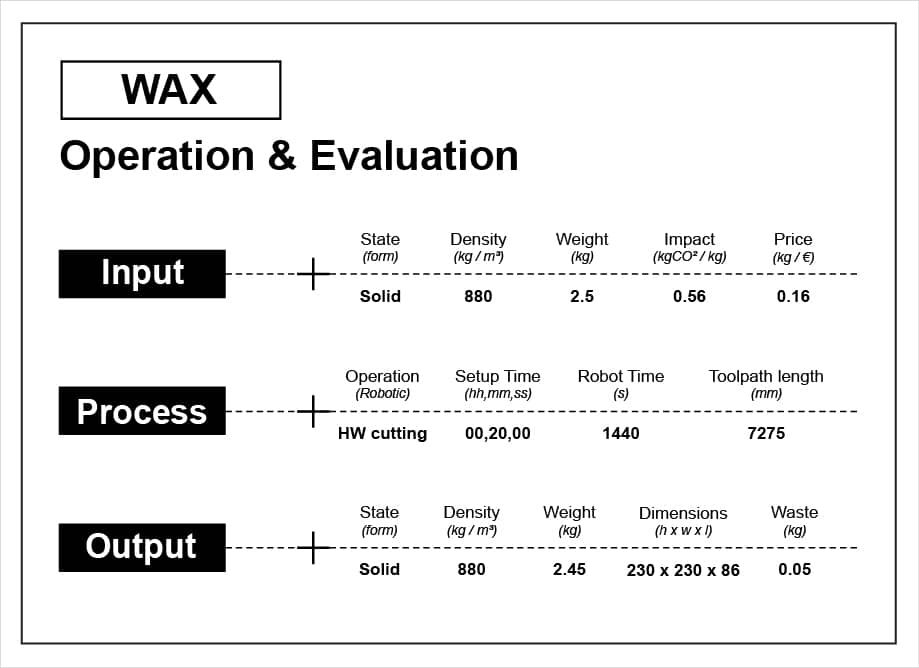

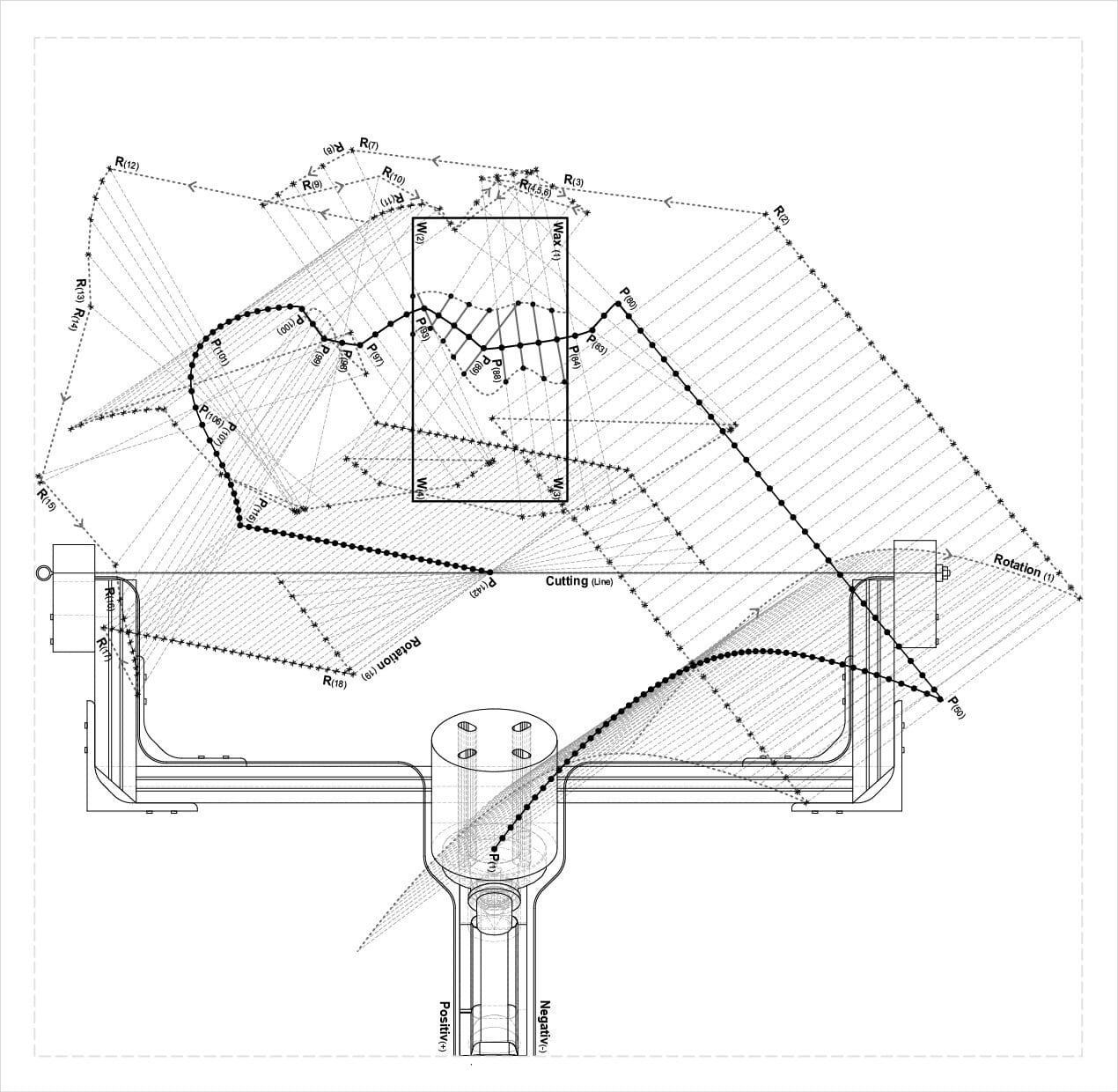

Prototype 3: Wax x Wire Cutting

Wire cutting is a fabrication method commonly used to create ruled surfaces. The advantage of ruled surfaces is that they are highly constructible 3D shapes. The easiest way to create a wire-cut ruled surface is through hot wire cutting of foams like polystyrene. The issue with this approach is the environmental impact of working with petrochemical-based materials, as well as the noxious gases released when heated. In this sense, wax offers a reusable, natural, and non-toxic alternative for hot wire cutting.

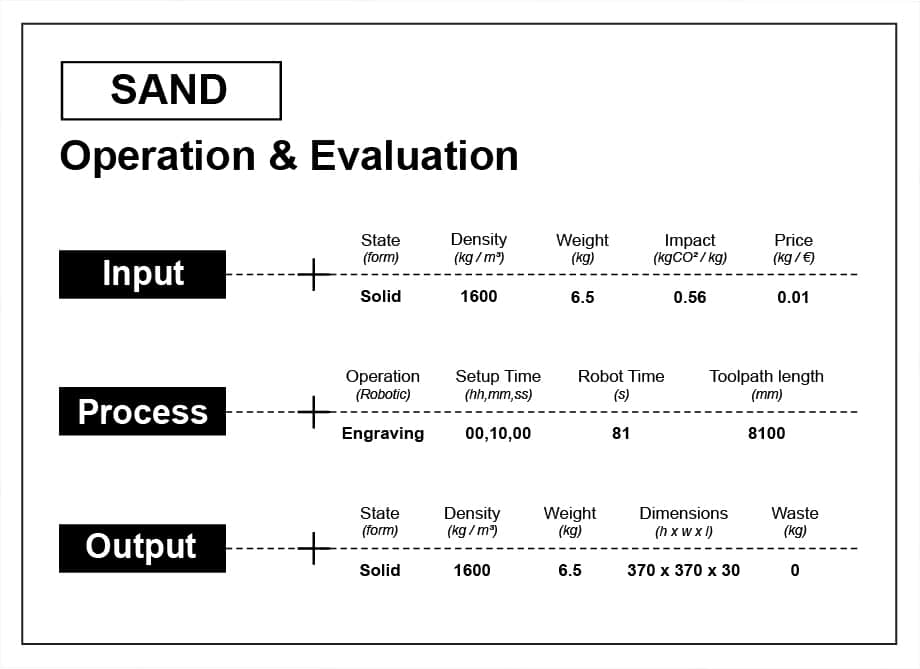

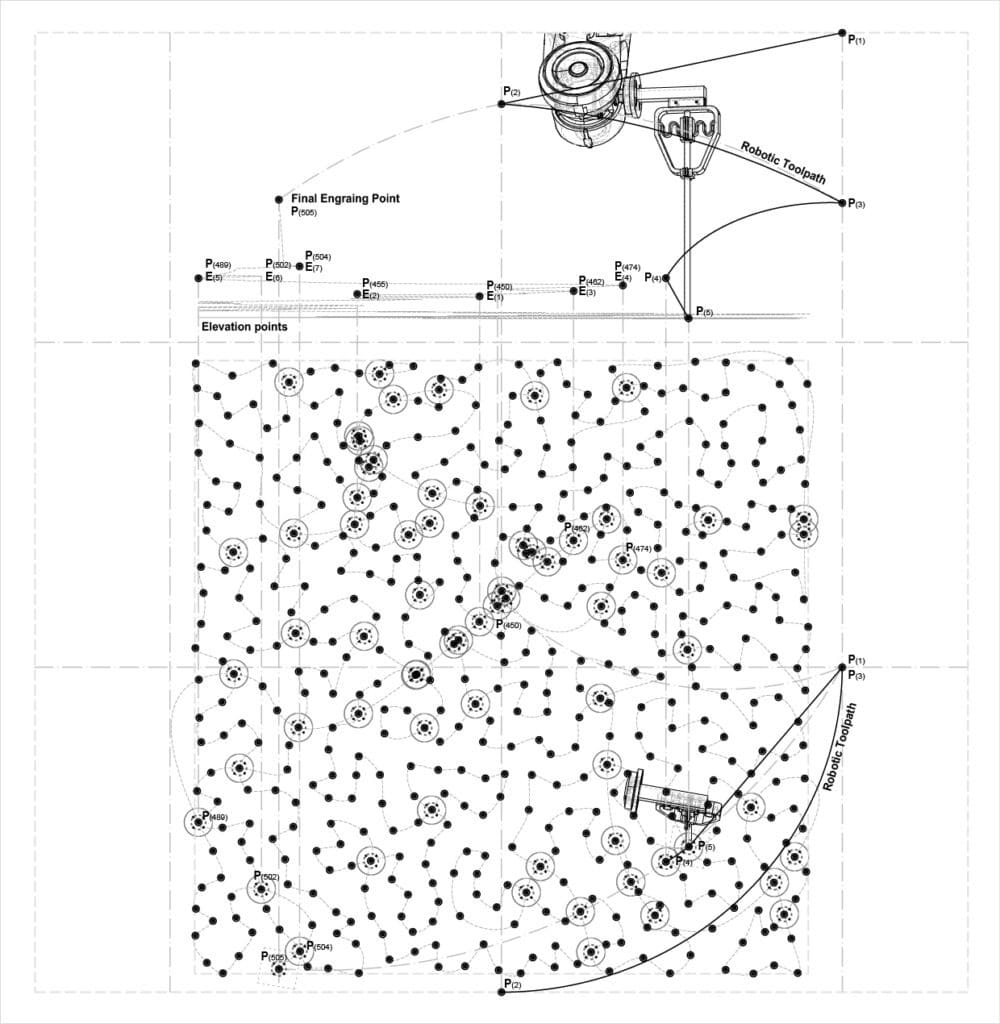

Prototype 4: Sand x Engraving

Zen Buddhist gardens make use of patterned raked sand. This requires extreme precision and patience, as sand easily shows any imperfection in the lines drawn in it. Its fragile and delicate nature means it leaves an imprint of anything that interacts with it. However, this troublesome characteristic offers significant potential when coupled with robotic motion, as the engraving can be both fast and precise. Furthermore, being sand, it requires very little input energy to produce results and can be quickly redone and tested. In this sense, sand is a perfect medium to showcase the delicacy and precision of CNC.

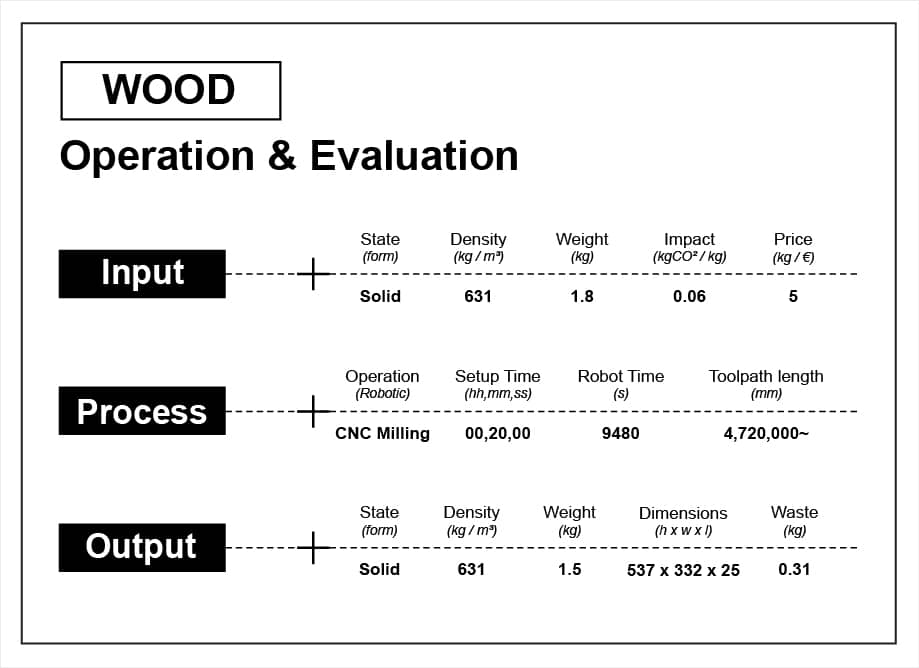

Prototype 5: Wood x Milling

Wood milling is one of the most prevalent fabrication techniques in robotics today. However, what we sought to investigate beyond the standard work being done is the use of non-standard timber members, such as found wood. This involves scanning, careful planning, and an understanding of the stock being used. Compared to standard boards, found wood has many imperfections and idiosyncrasies that can interrupt the milling process. The prototype itself highlights the irregularity of the wood while celebrating the beauty inherent in this fabrication technique. Due to time constraints, we used a CNC mill for the wood milling, so there is no logic drawing for the robotic process.