Introduction to Robotic Fabrication Seminar

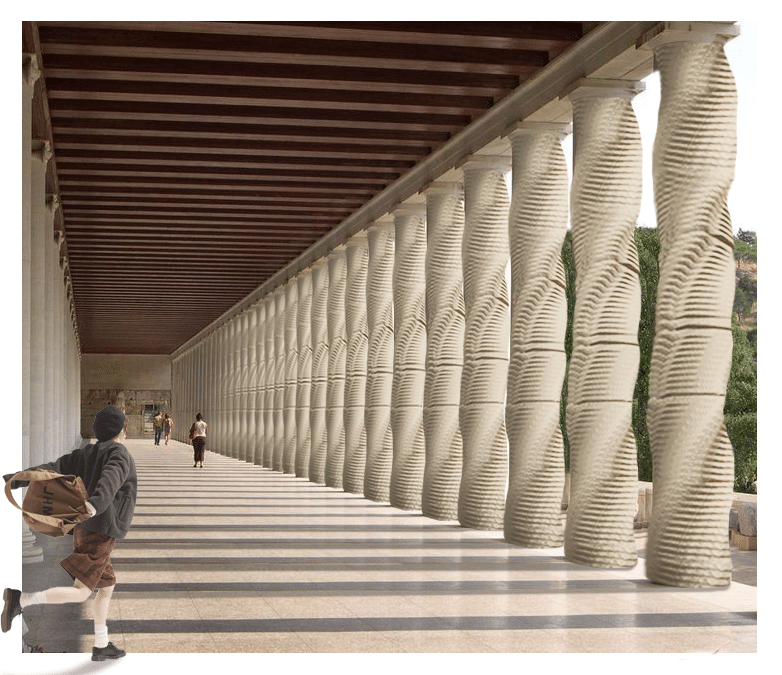

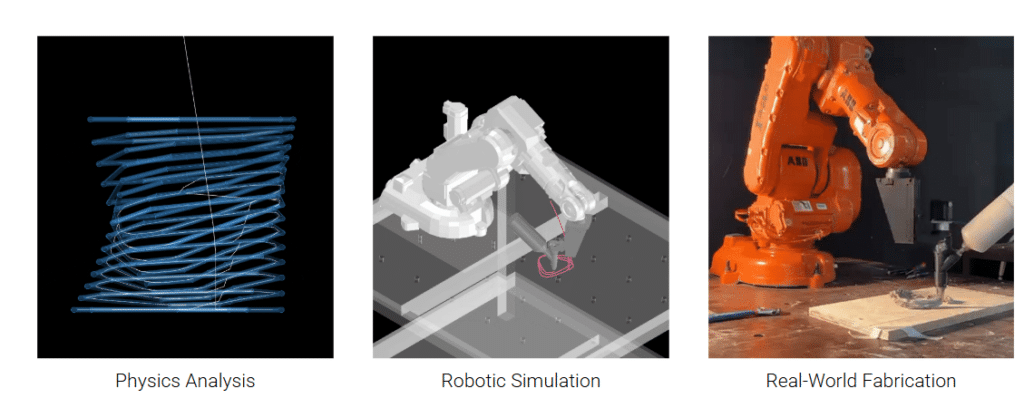

This project explores robotic fabrication techniques for clay-based structures, focusing on non-uniform and non-planar extrusion. Utilizing a six-axis robotic arm, the project investigates material behavior, toolpath optimization, and structural stability through digital simulations and real-world fabrication trials. The column design integrates rotational movements and varying extrusion heights to achieve complex geometries while maintaining structural integrity. Practical applications range from architectural elements to adaptive masonry and bioclimatic design. Future steps involve material testing, hybrid fabrication with bio-based reinforcements, and scaling the technique for sustainable construction. This study contributes to advancing robotic 3D printing in architecture by optimizing material efficiency and design flexibility.

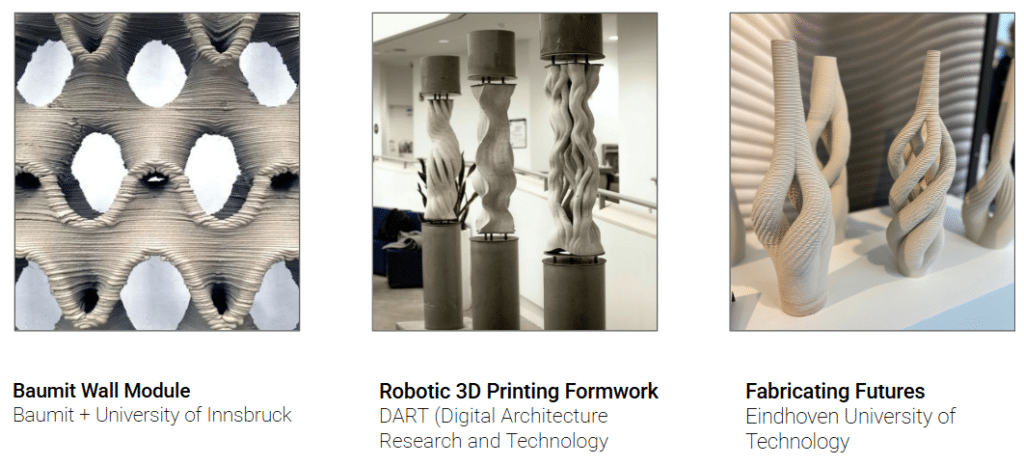

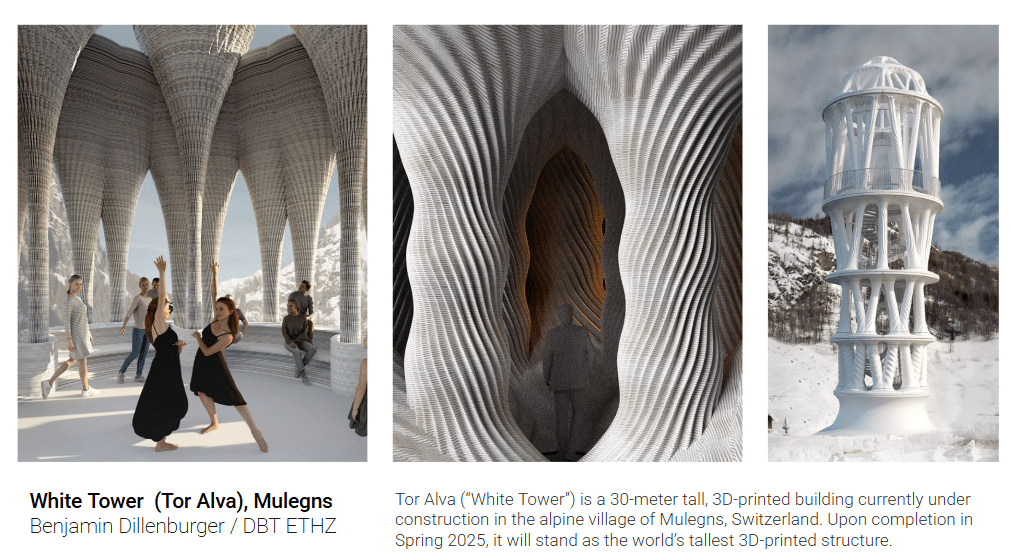

State Of Art

Through an analysis of the works mentioned, we were able to gather inspiration on how we can iterate on our column forms. Playing with twists intrigued us, especially if they are used on a smaller scale within the overall geometry. While inspiring, exploring cantilevers and with the robot and clay working in tandem proved to be exciting and educated us on the (current) limitations of what we can do with 6 axis printing.

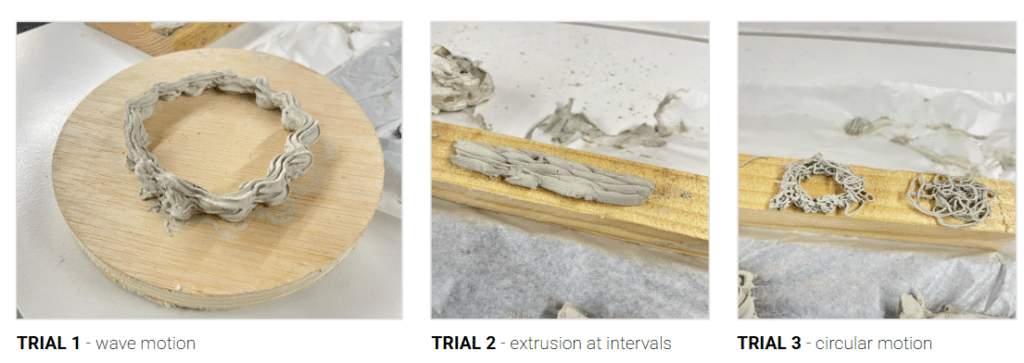

MANUAL FABRICATION EXPLORATION

Factors affecting the fabrication process

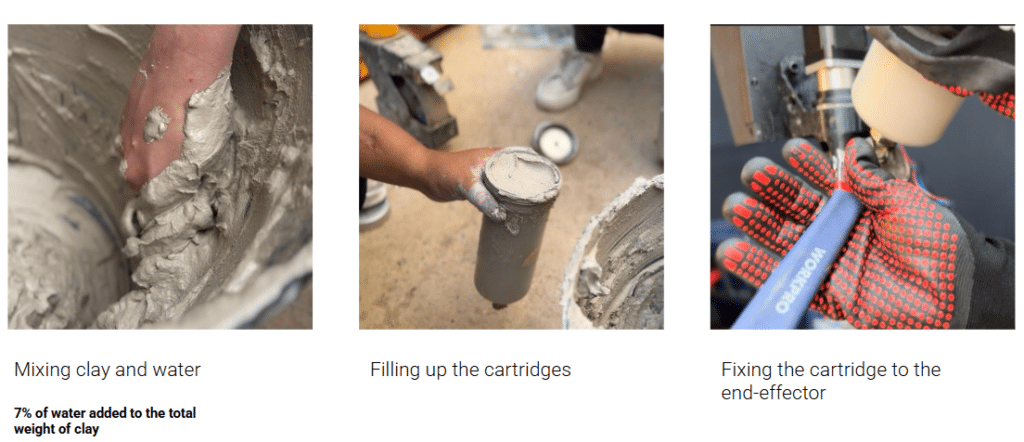

- Consistency of the materials (clay and water ratio)

- Pressure applied

- Nozzle shapes

- Drying time

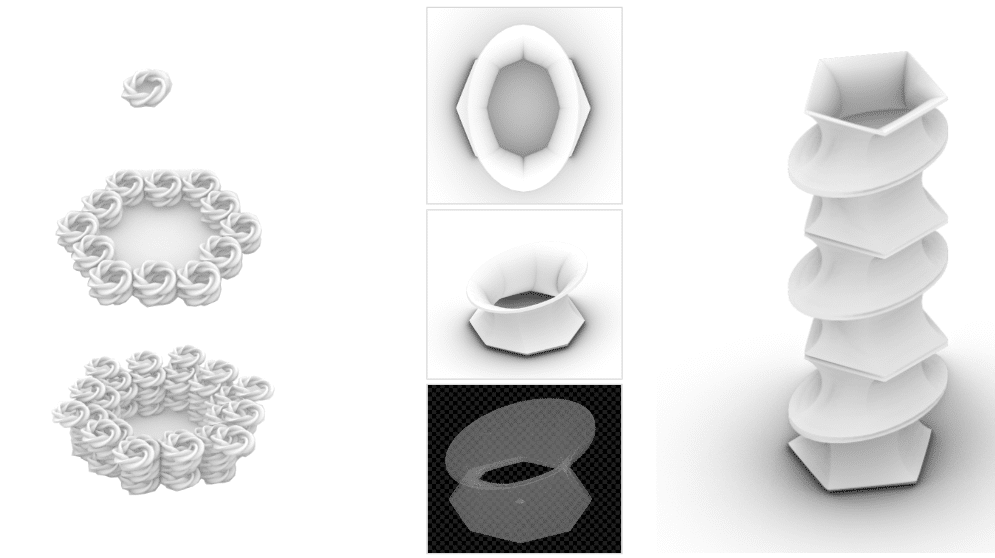

DIGITAL EXPLORATION

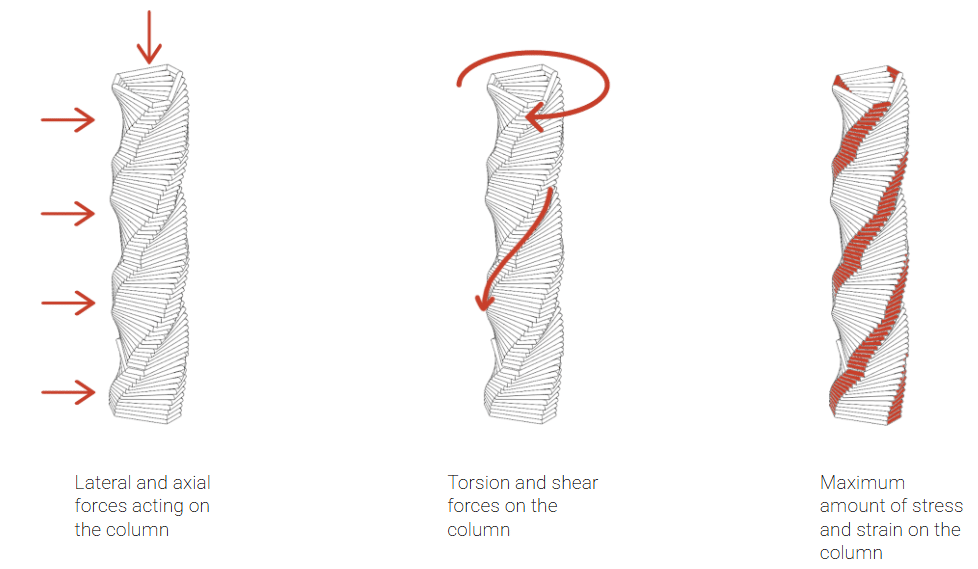

PERFORMATIVE ANALYSIS – STRUCTURAL

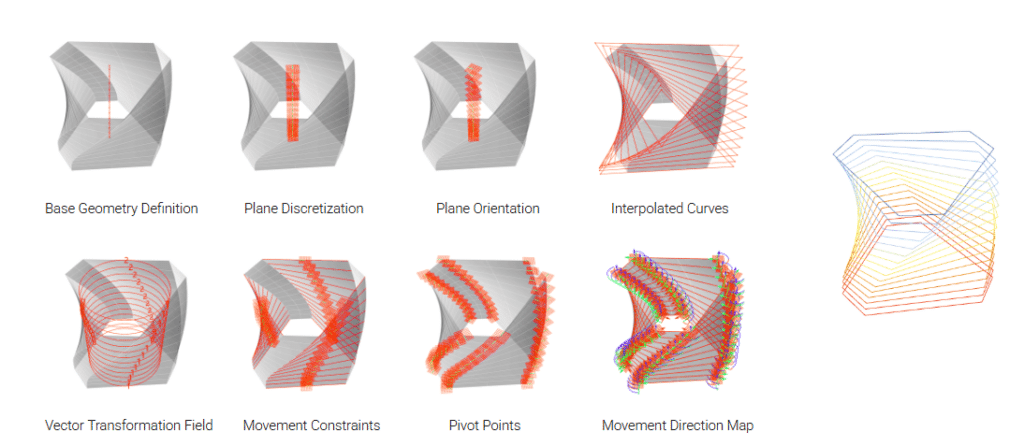

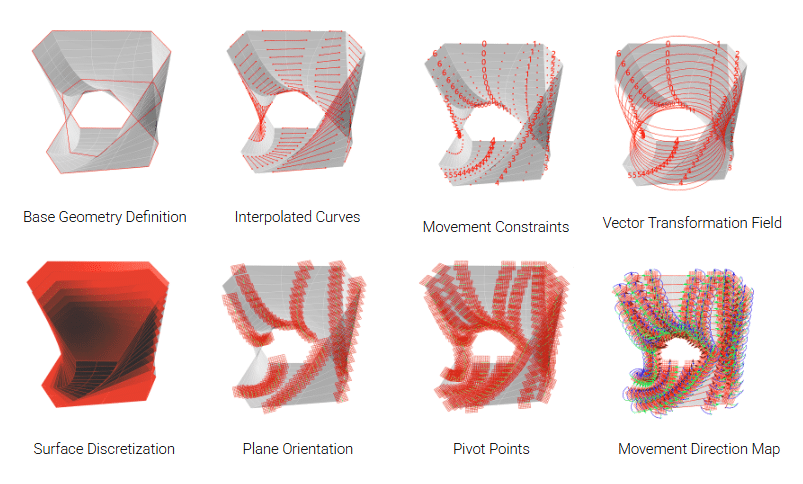

DIGITAL EXPLORATION – DESIGN ANALYSIS

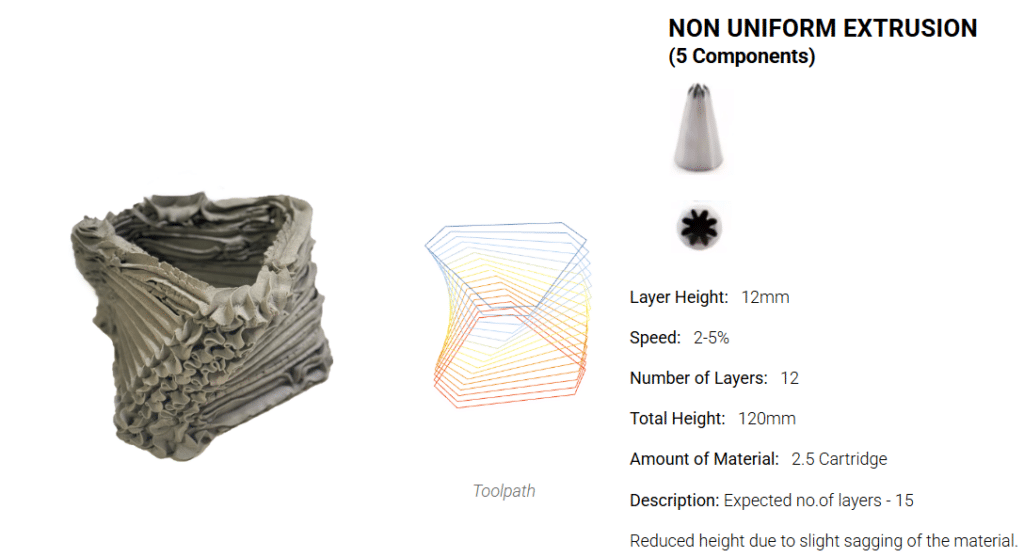

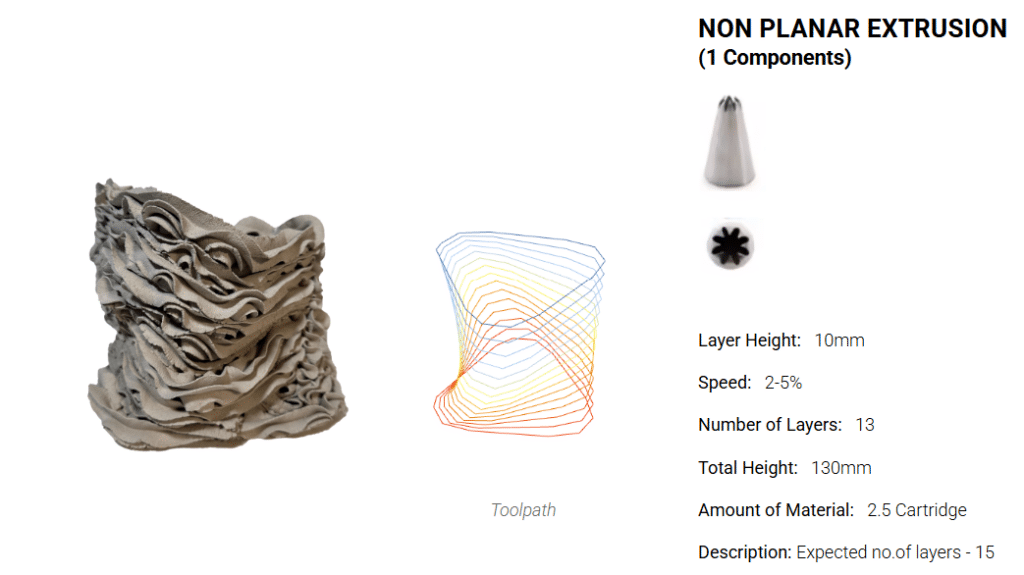

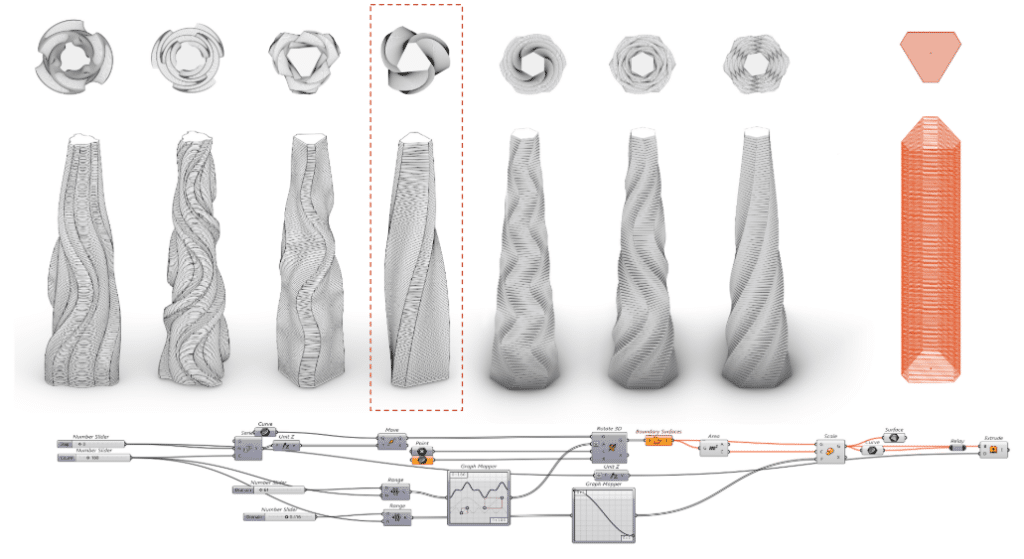

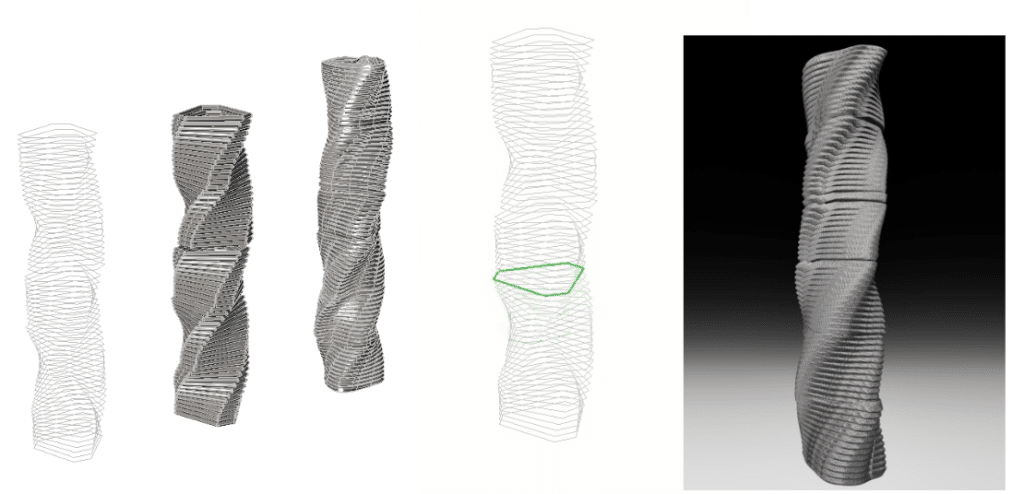

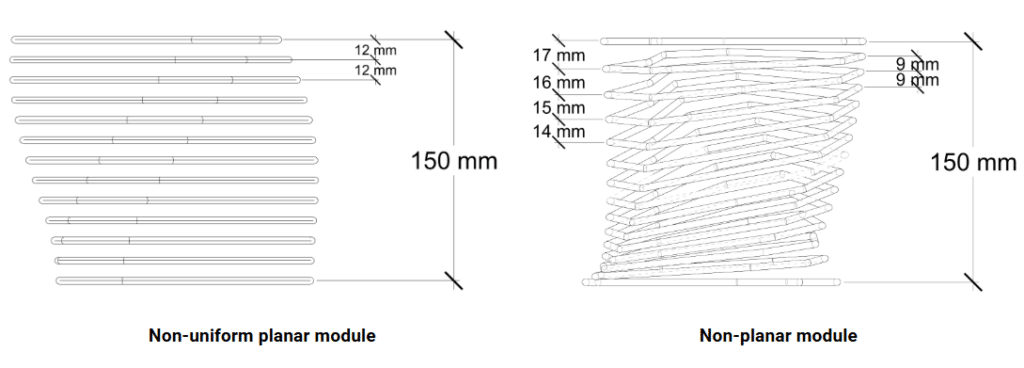

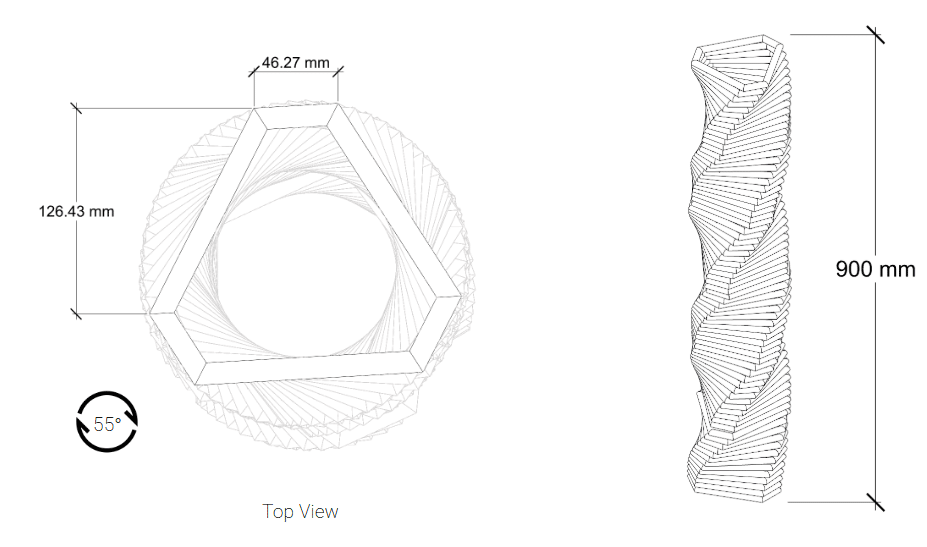

DIGITAL EXPLORATION – Non-Uniform/Non planar Extrusion

GRASSHOPPER EXPLORATION

TECHNICAL DRAWINGS

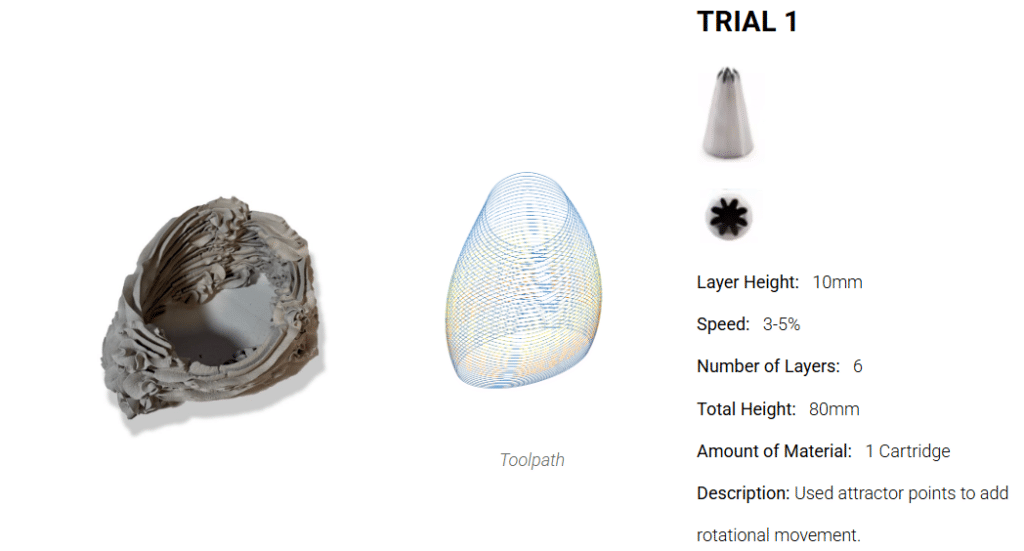

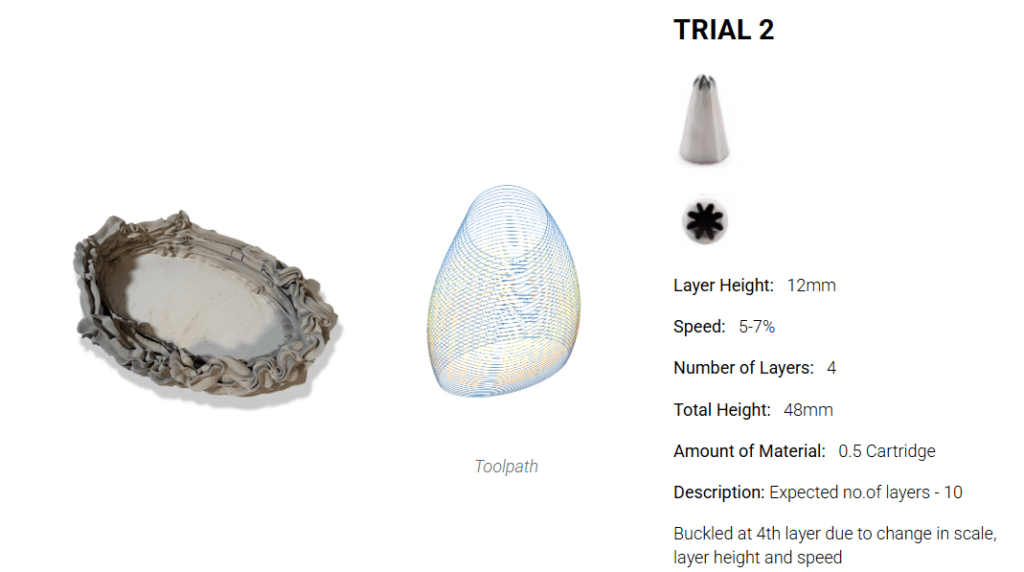

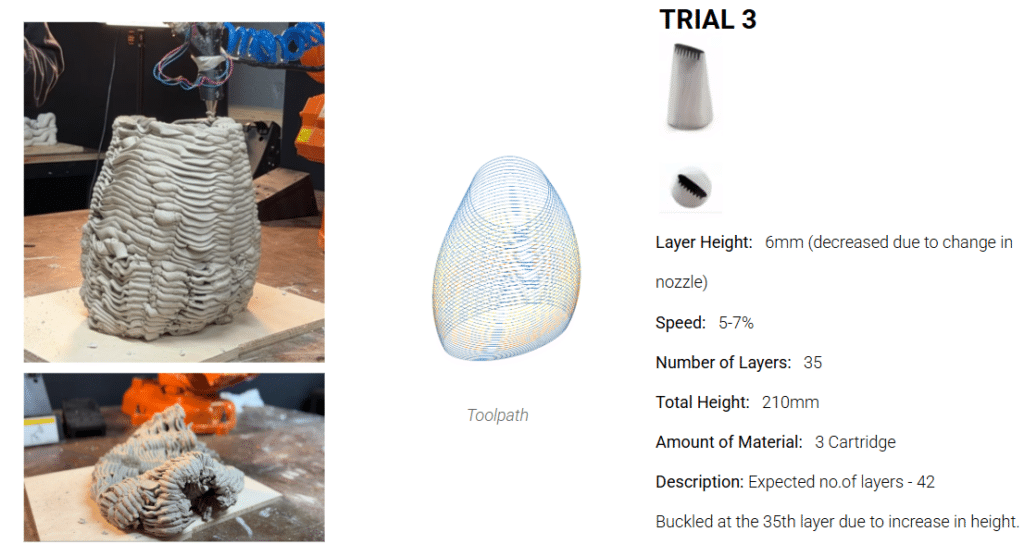

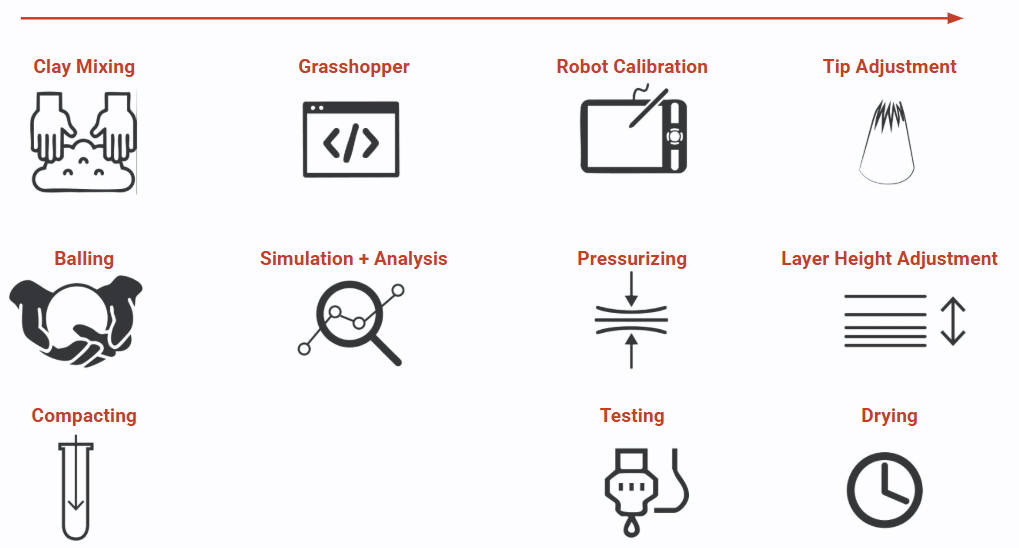

FABRICATION METHODOLOGIES

MATERIAL PREPARATION

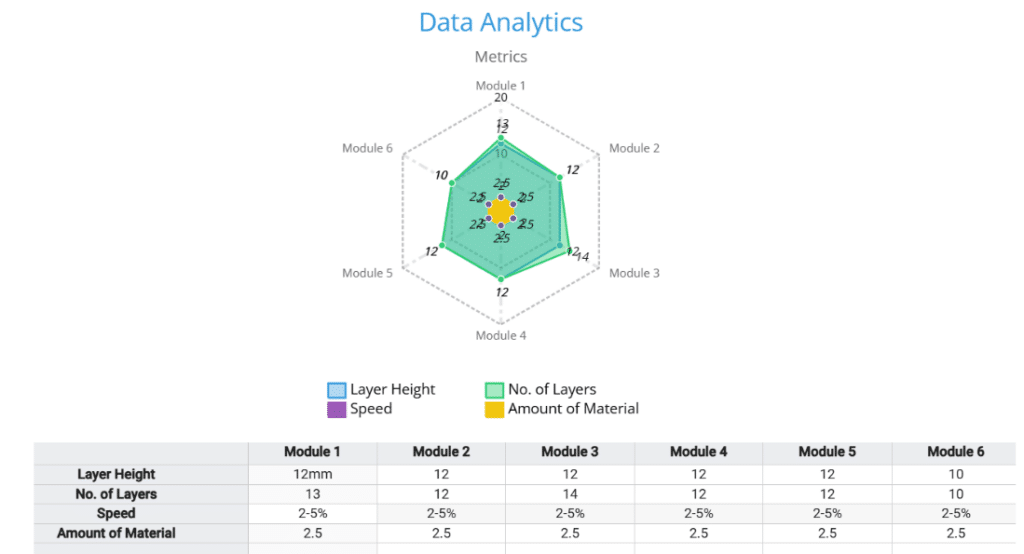

PRODUCTION CALCULATIONS AND DATA