The Digital Fabrication Collection showcases four prototypes developed through distinct making techniques. Each project explores how form, material, and geometry respond to CNC milling, laser cutting, 3D printing, and robotic fabrication, highlighting the diverse possibilities of digitally driven design.

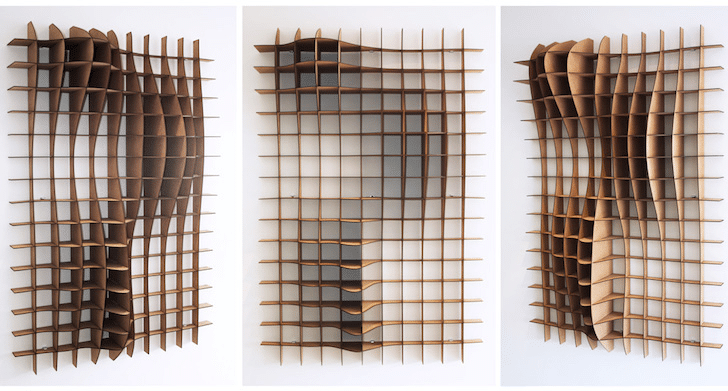

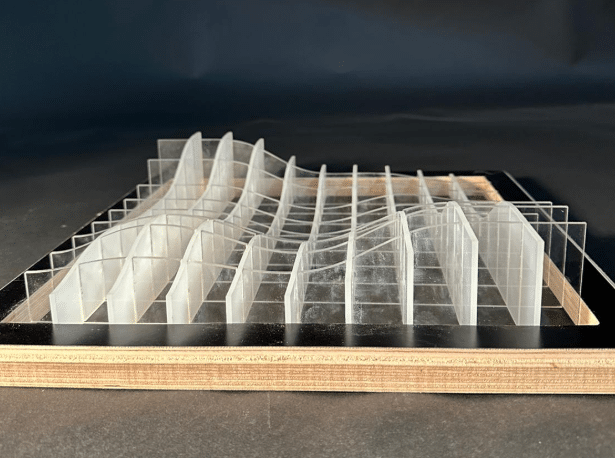

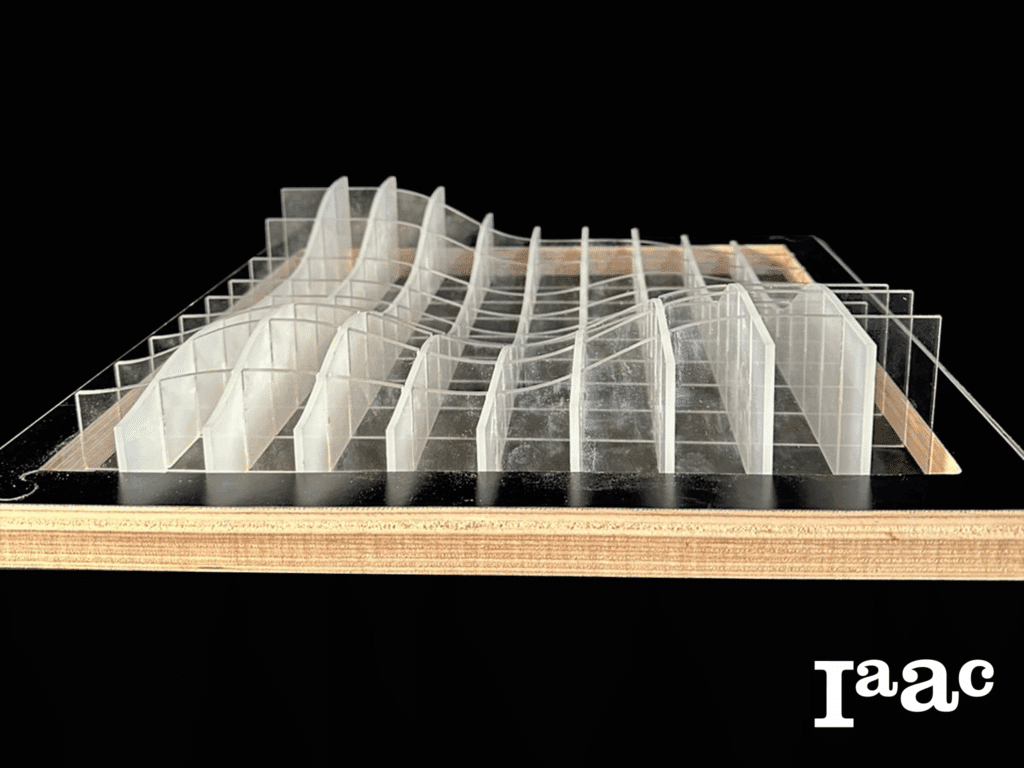

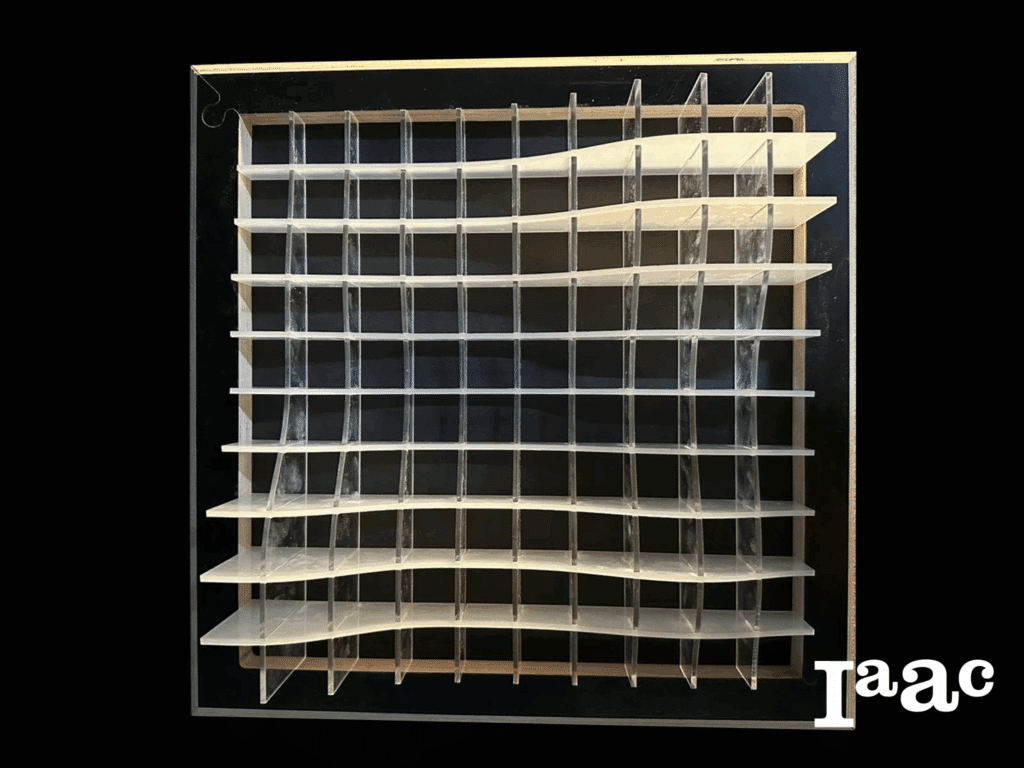

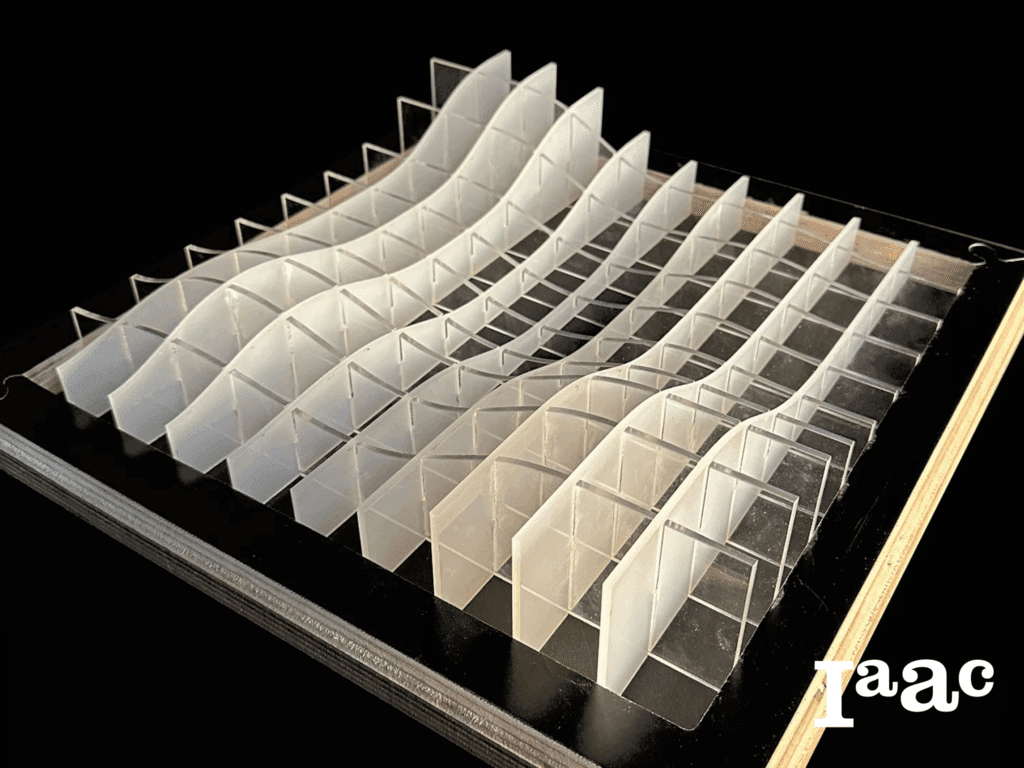

Light Lattice

The Light Lattice project explores how laser cutting can translate digital geometry into tangible physical prototypes. By testing how two-dimensional linear patterns can fold, interlock, and form spatial structures that cast expressive light and shadow, the project focuses on using cutting strategies and material properties to generate forms that feel both lightweight and tensioned. Using acrylic sheets as the primary material and employing a sequence of precise cutting, sanding, and assembly processes, the work demonstrates how digital tools support the creation of complex structures and refined visual effects.

Concept and References

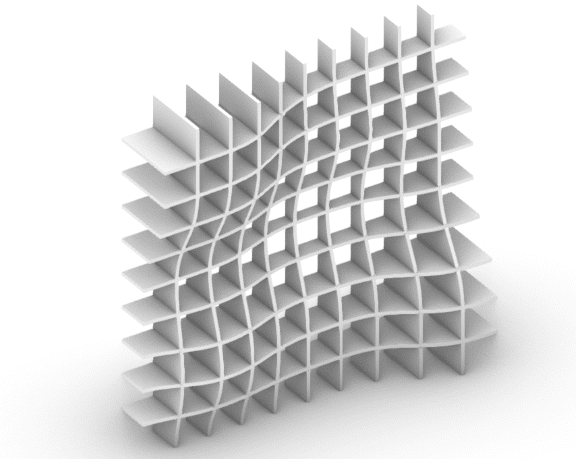

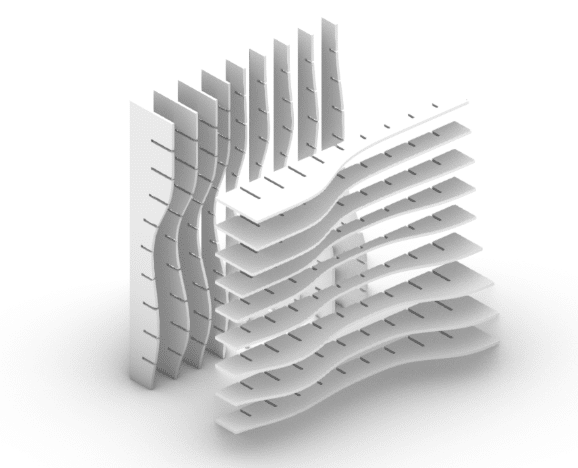

Light Lattice is a grid structure made of interlocking slotted plates. It is lightweight, strong, and material-efficient, often used in temporary exhibitions and experimental architecture. Its layered form creates rich light and shadow effects, giving the space a unique visual rhythm.

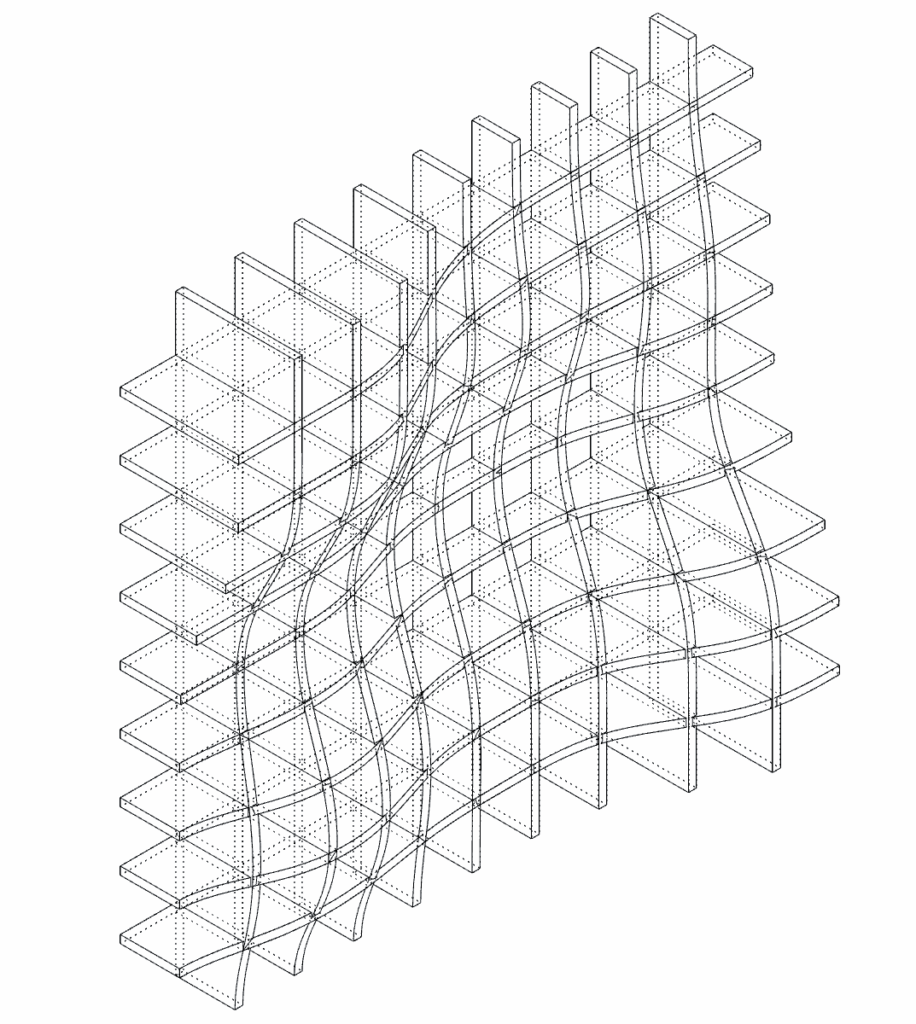

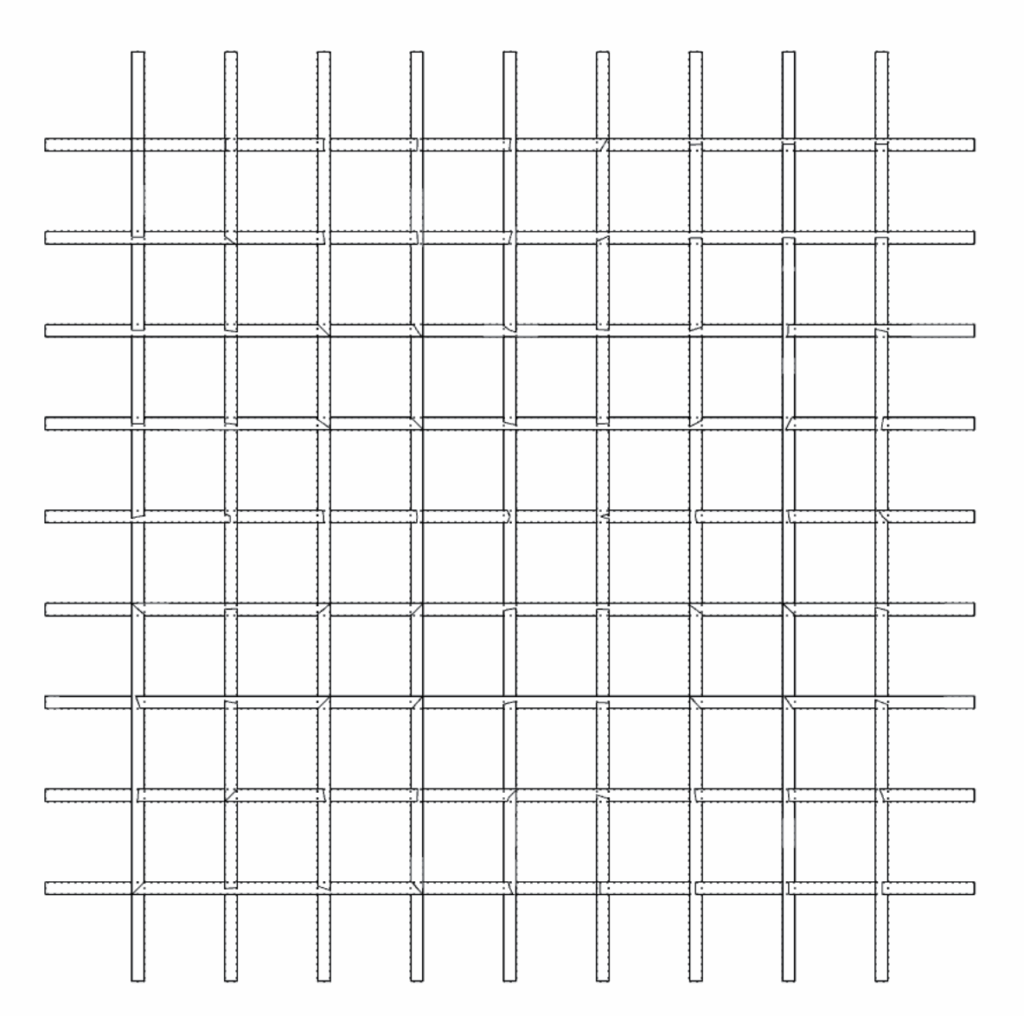

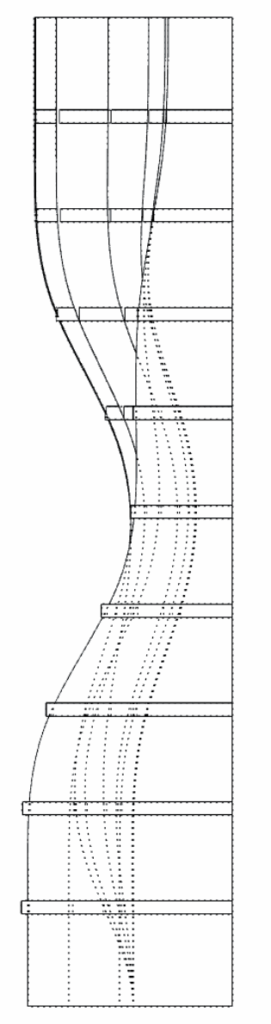

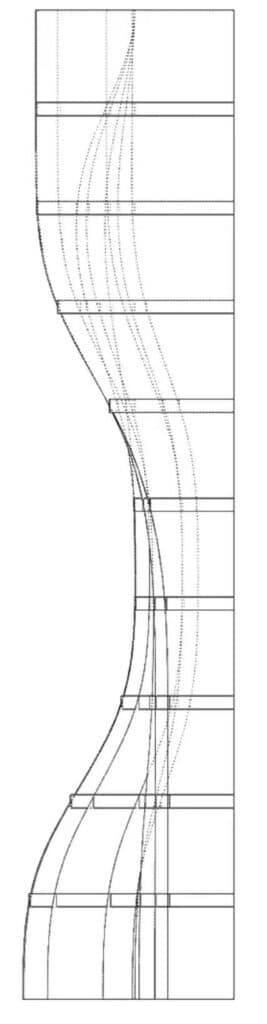

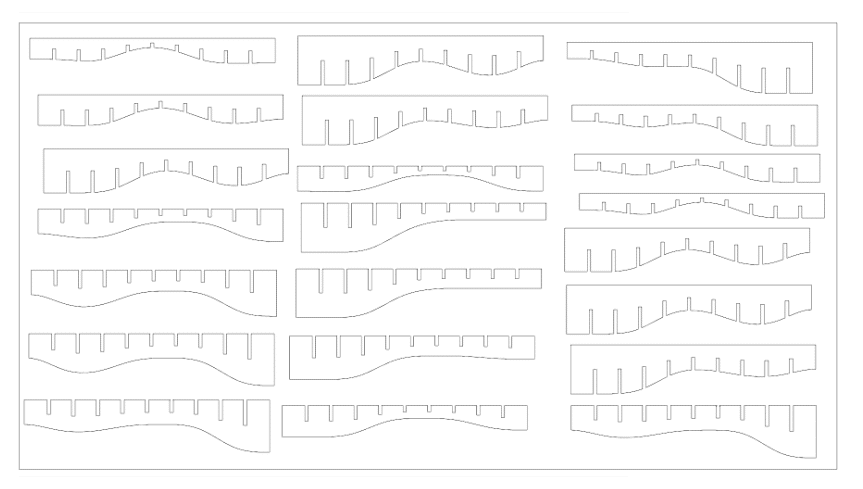

Technical Drawing

Fabrication Strategy

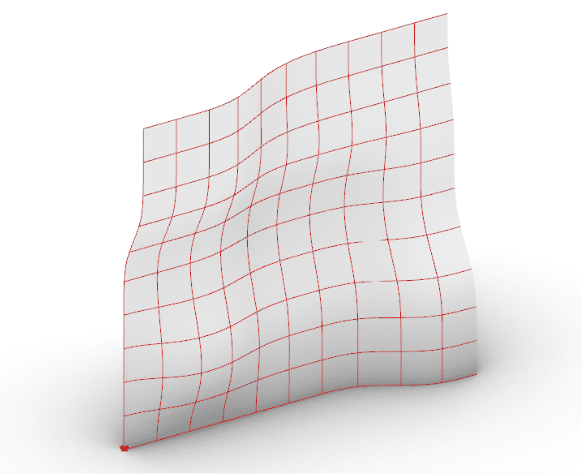

01 – Setting

Setting curves for the surface and number of horizontal and vertical lines

02 – Shape Construction

Extrude and shape the design

03 – Slicing

Slicing and setting joint and tolerance

04 – Cutting

Use machine to cutting the pieces

Material: 3mm Acrylic sheet

Power: 90

Speed: 1.2

05 – Assemble

Assemble all the pieces and place them into the frame

Final Design

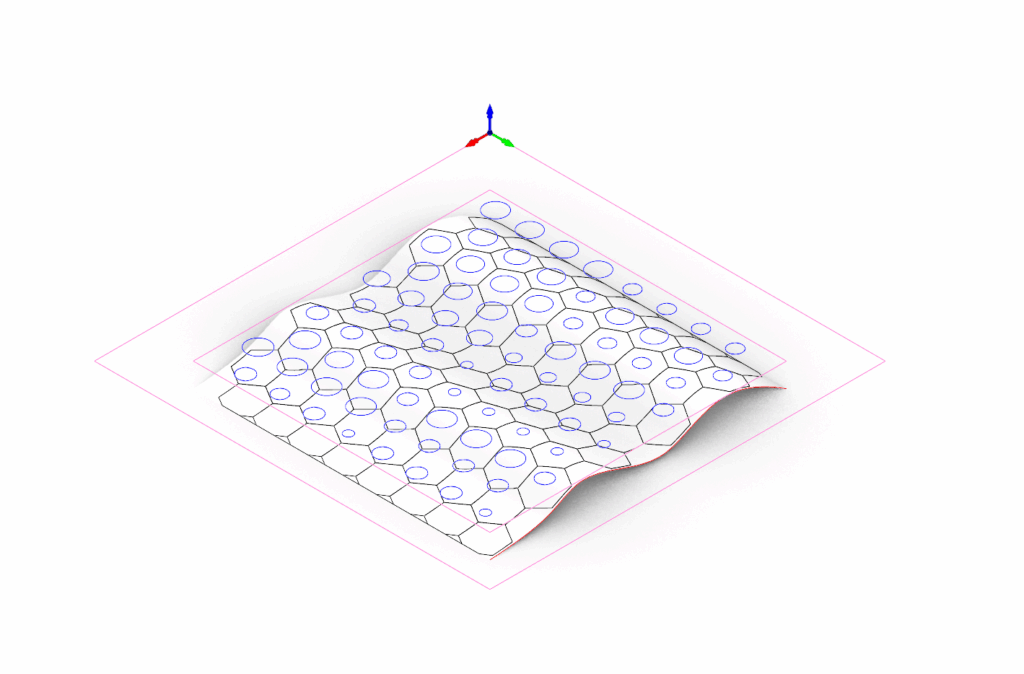

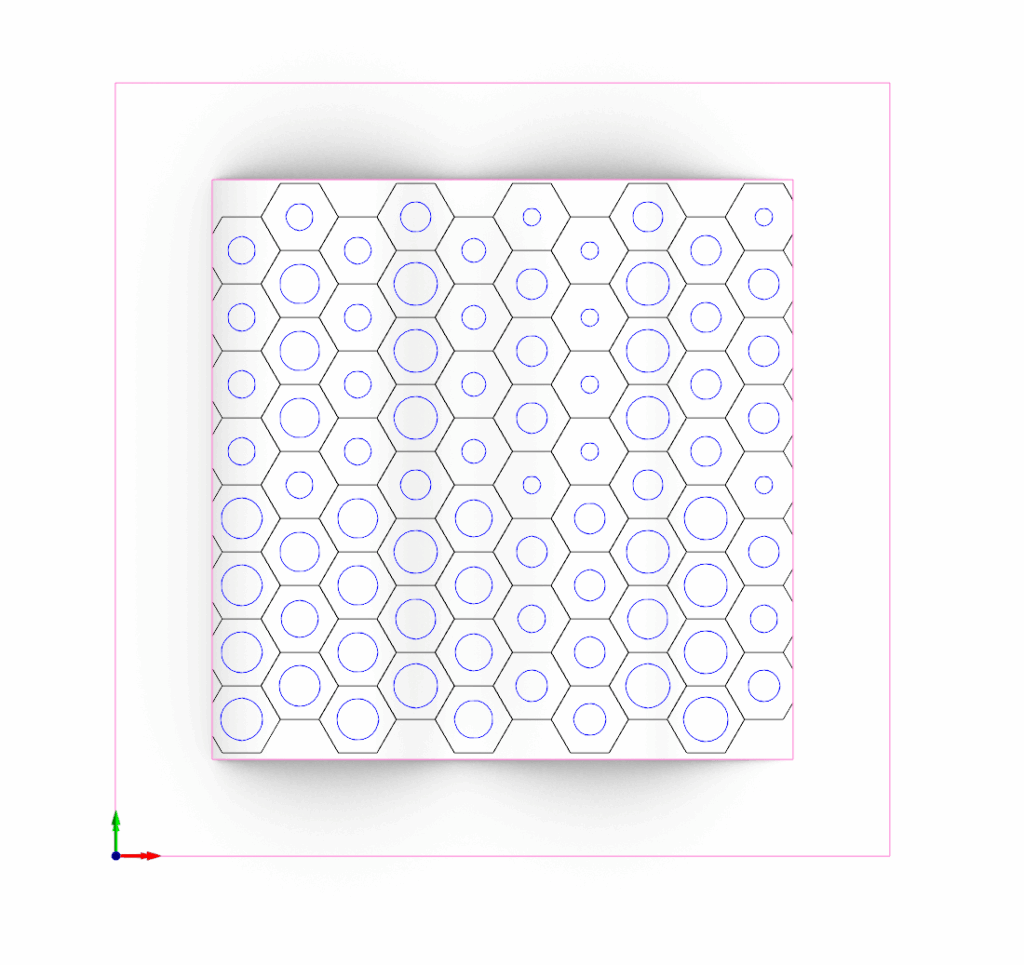

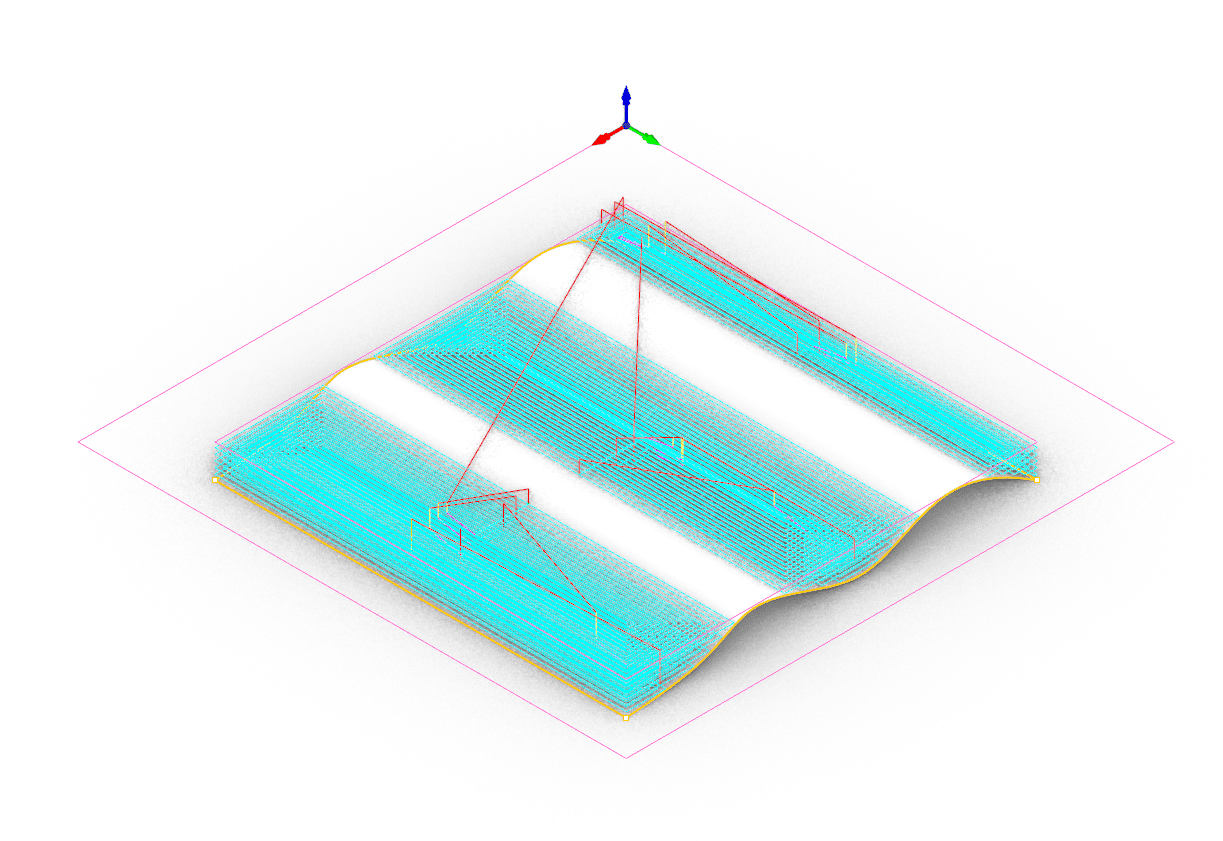

HexaFab

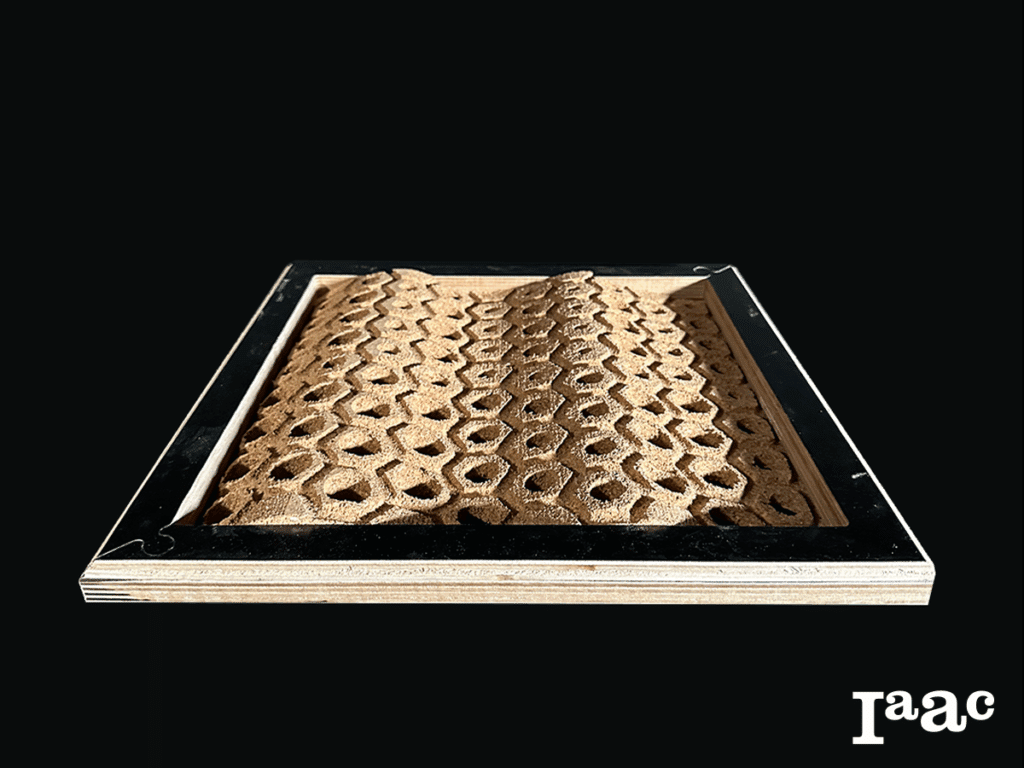

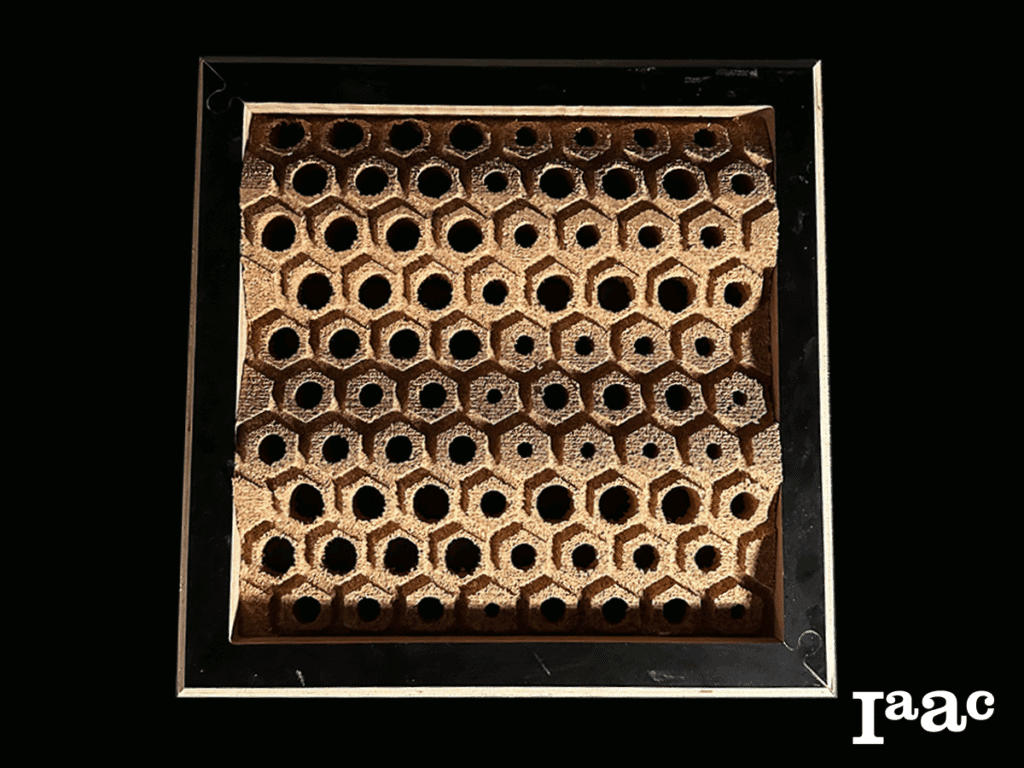

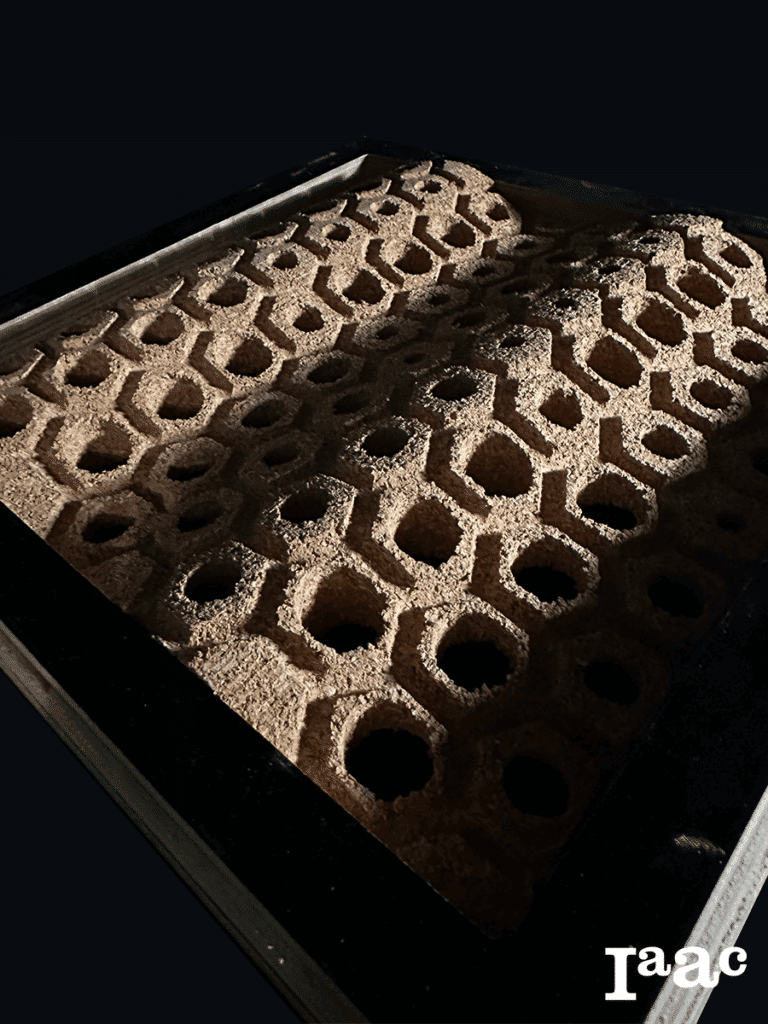

HexaFab project explores the use of CNC fabrication to translate digital geometry into a tangible prototype. By testing how curved surfaces interact with projected patterns, it focuses on generating fluid forms through precise machining. Using cork and a sequence of controlled milling operations, the work highlights how digital tools support the creation of refined design pieces.

Concept and References

The design focuses on combining two geometries (hexagon and circle) in a curved surface.

With the projection of these geometries, it is possible to get a flowy design with the feeling of movement.

CNC machine enables this process by combining fabrication techniques.

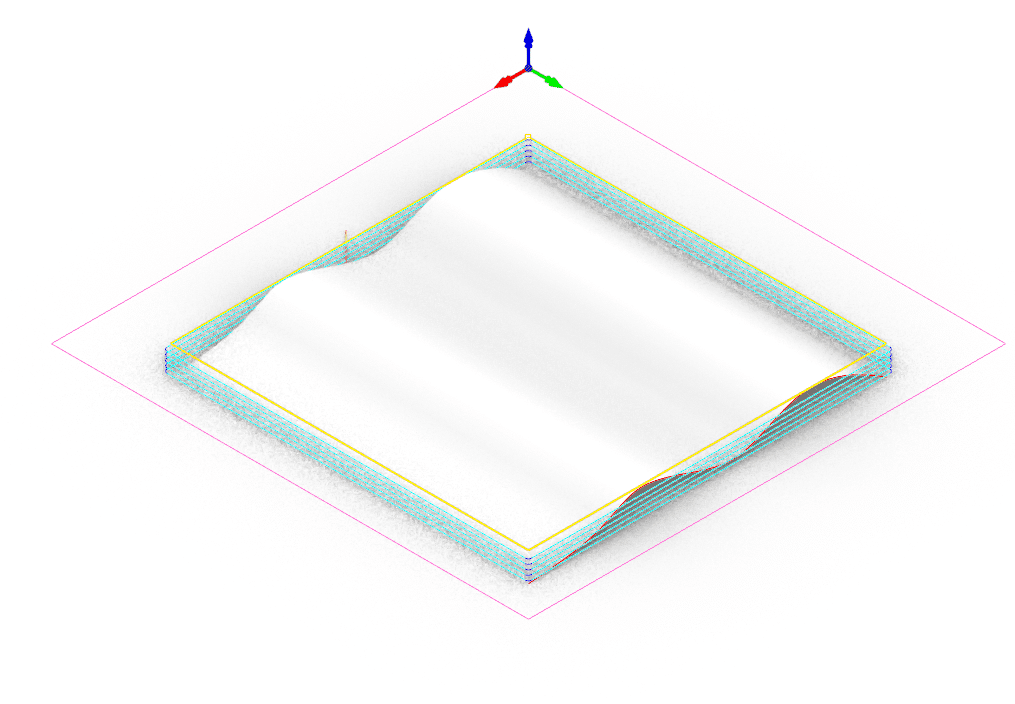

Technical Drawing

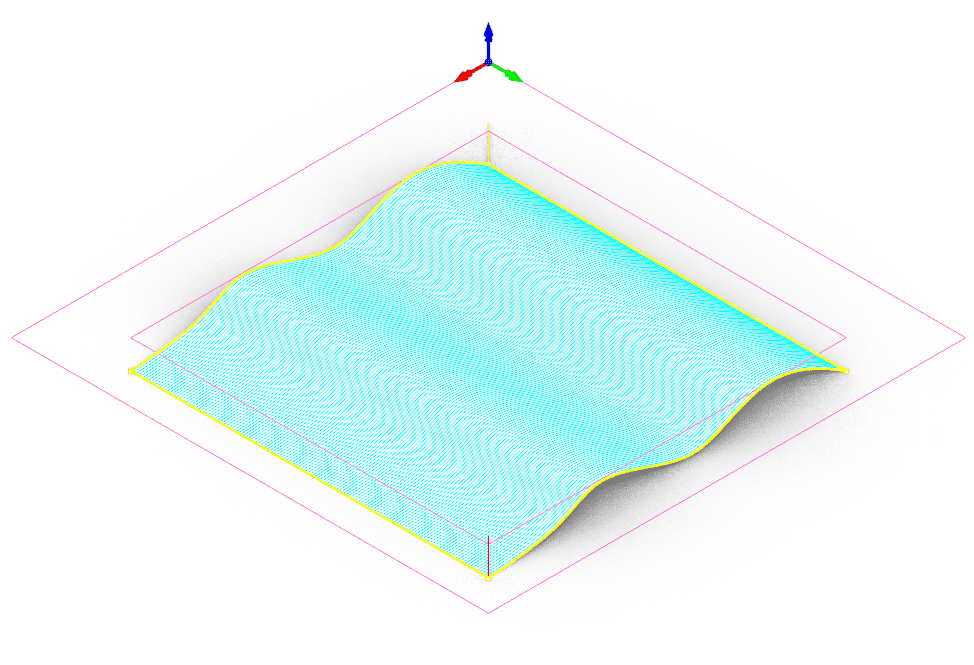

Fabrication Strategy

01 – Workpiece

Material: Cork

Machine: Raptor

Post Processor: CNC_STEP_BCN Raptor

Workpiece volume: 300x300x30mm

02 – Secure Workpiece

The workpiece was secured to the CNC bed with nails and a wooden board to ensure stability during machining.

03 – Horizontal Roughing

Ball Mill

Flute: 2

Diameter: 8mm

Spindle Speed: 12000

Cut Direction: Upcut

Stepdown Control (dZ): 70%

Stepover Distance: 50%

Total mill time: 20.32 minutes

04 – Parallel Finishing

Ball Mill

Flute: 2

Diameter: 8mm

Spindle Speed: 12000

Cut Direction: Mixed

Stepover Control (dZ): 25%

Total mill time: 22.84 minutes

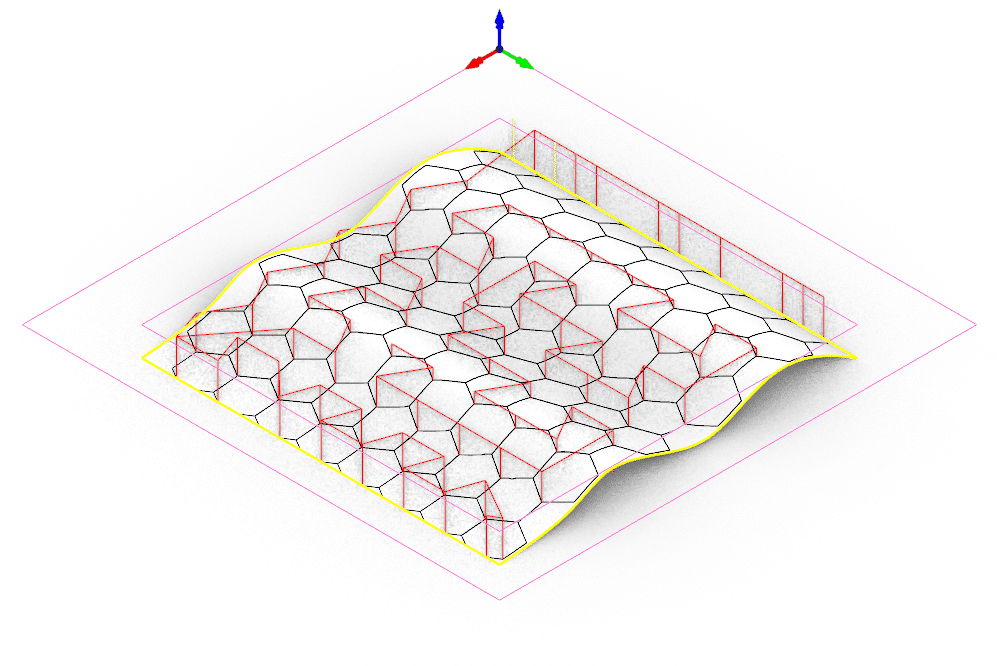

05 – Engraving

Ball Mill

Flute: 2

Diameter: 8mm

Spindle Speed: 12000

Cut Direction: Natural

Location of cut geometry: at top

Total cut depth: 16mm

Total mill time: 11.32 minutes

06 – Profiling

Flat Mill

Flute: 2

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Mixed

Location of cut geometry: at top

Total cut depth: 30.5mm

Cutting side: Right of curves/Inside

Total mill time: 12.89 minutes

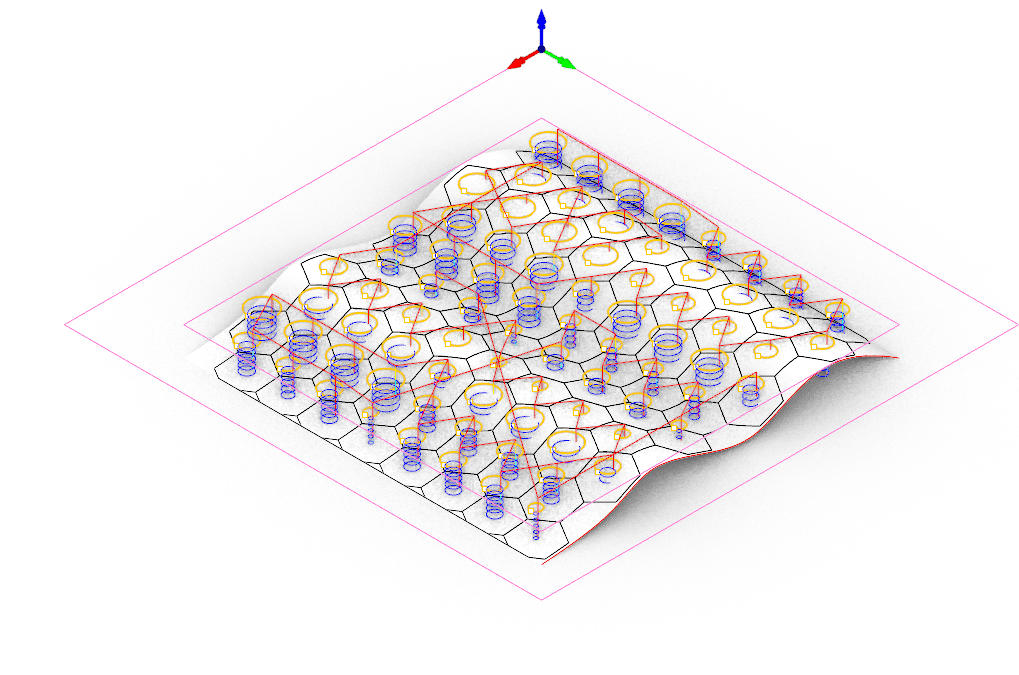

07 – Profiling (Offset Frame)

Flat Mill

Flute: 2

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Mixed

Total cut depth: 20mm

Cutting side: Right of curves/Outside

Total mill time: 2.46 minutes

08 – Profiling (Detach Model)

Flat Mill

Flute: 2

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Mixed

Total cut depth: 30.5mm

Cutting side: Right of curves/Outside

Total mill time: 4.10 minutes

09 – Fabrication

Final Results

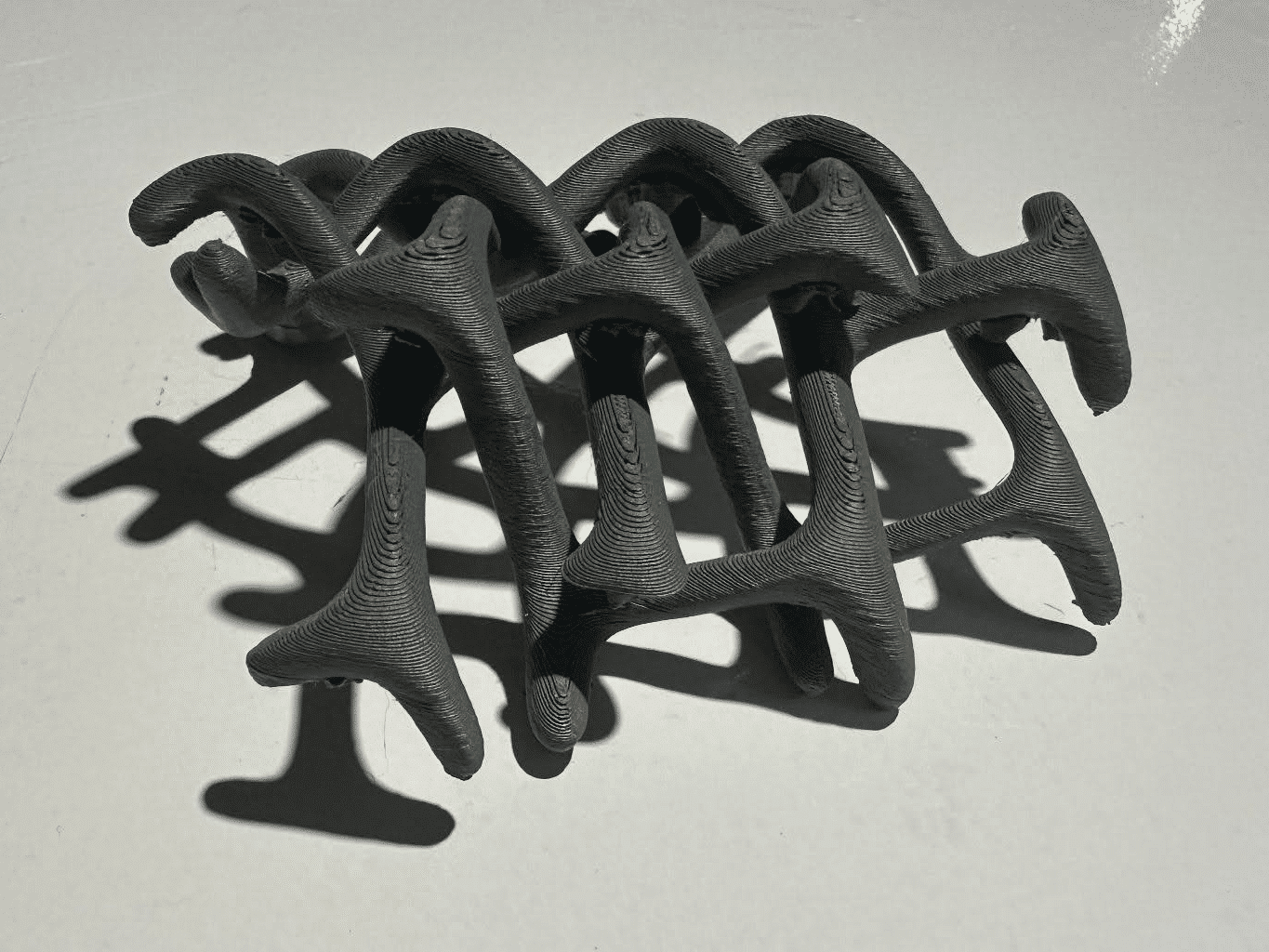

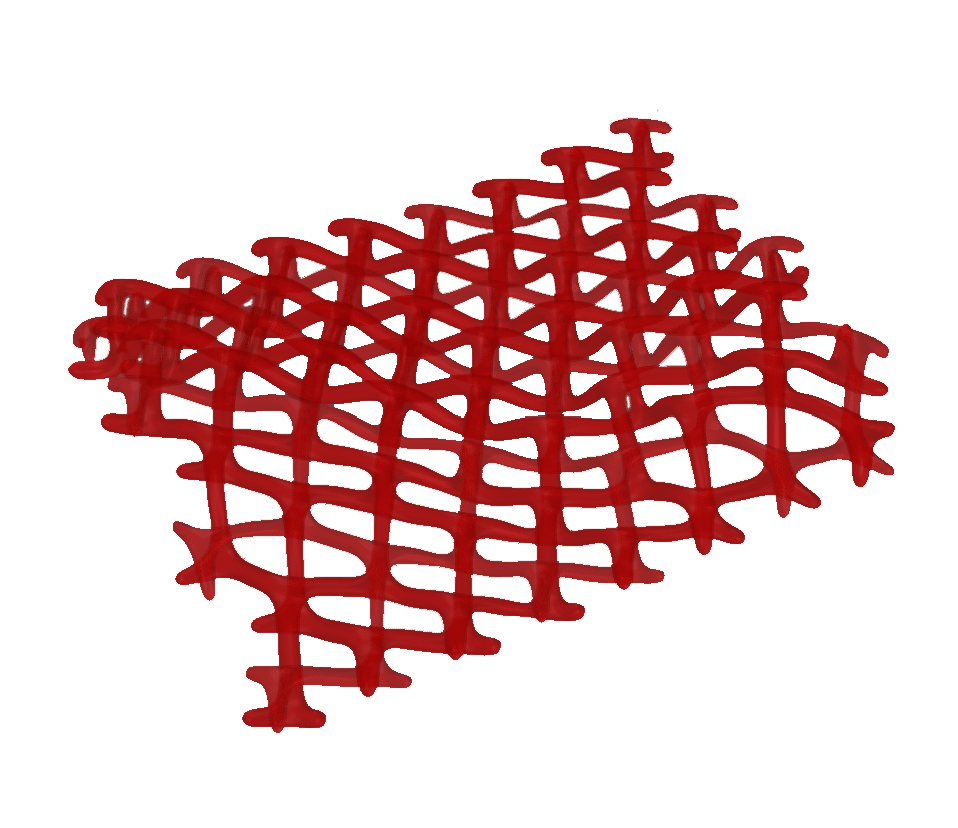

Interwoven Skin

This project investigates how digital fabrication can generate complex spatial structures through 3D printing. The study focuses on converting a digitally modeled pattern into a physical piece by testing form, geometry, and material behavior during printing. The prototype serves as an exercise in understanding how additive manufacturing manages curvature, structural continuity, and support requirements within a compact architectural model.

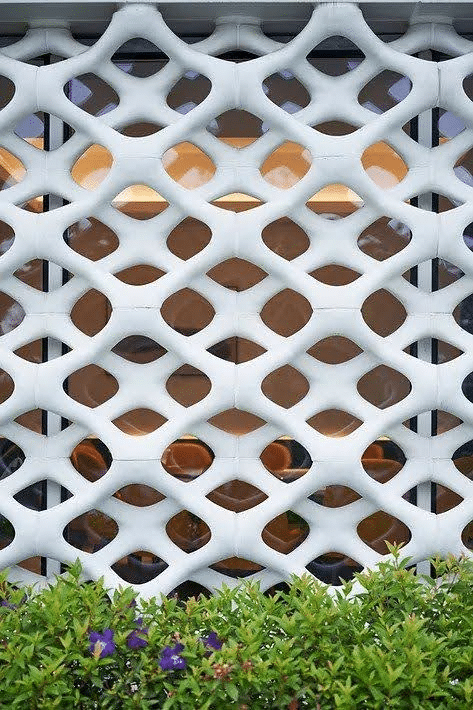

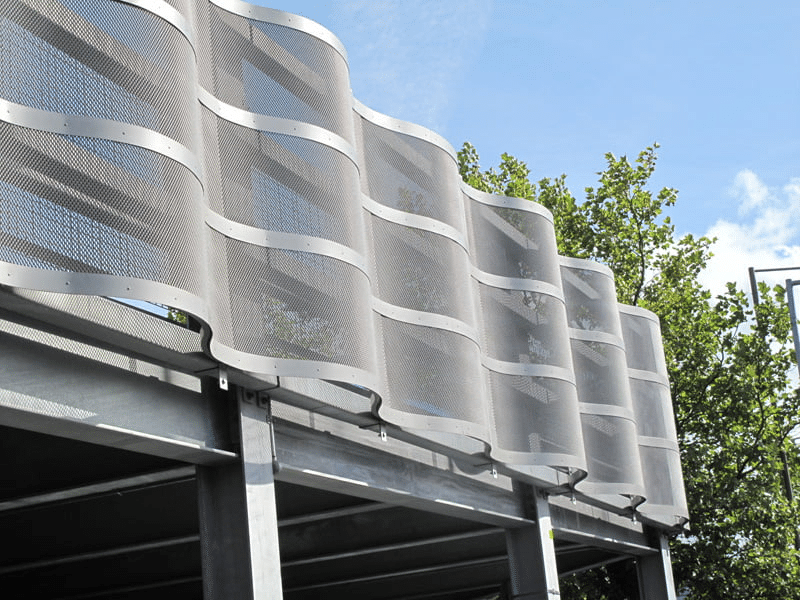

Concept and References

Interwoven Skin is inspired by the woven texture aesthetics of architectural facades.

It transforms the rhythmic pattern and perforated facade system into a three-dimensional form through additive manufacturing.

Its form centers on an interlocking woven structure.

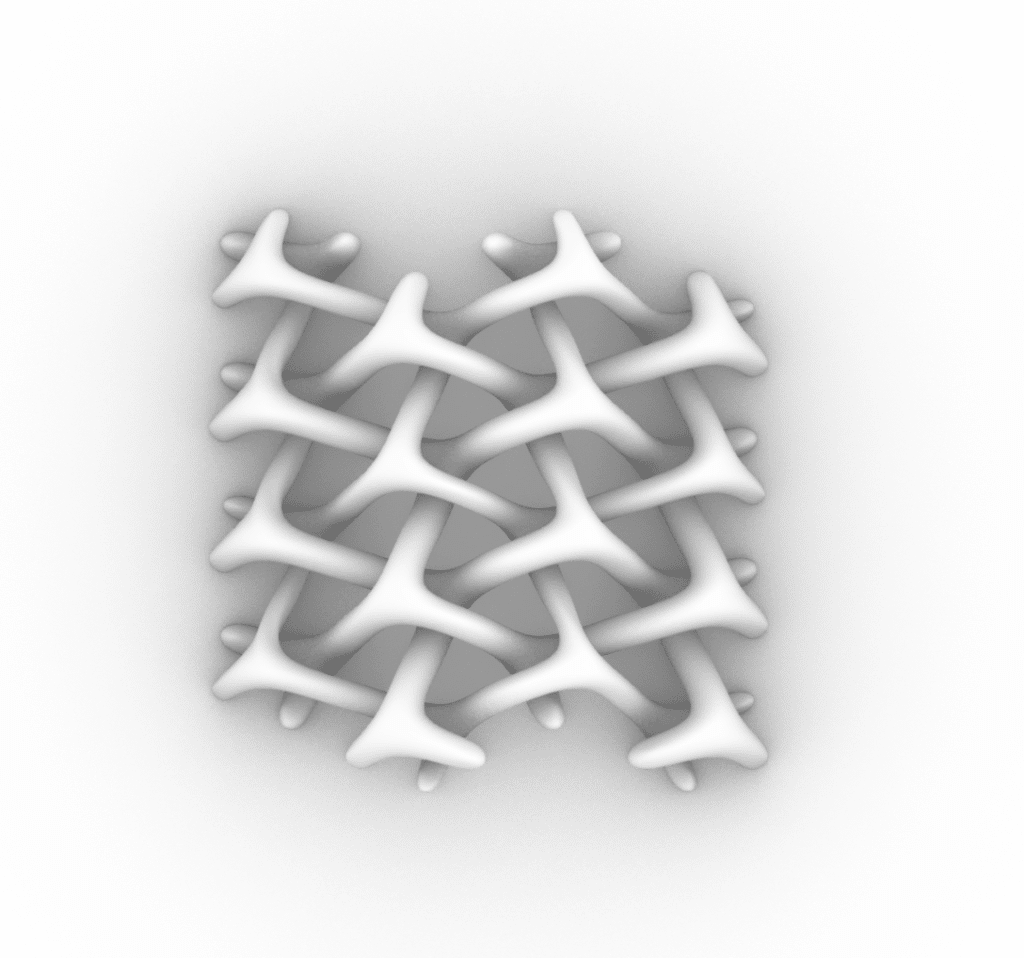

Process and Design

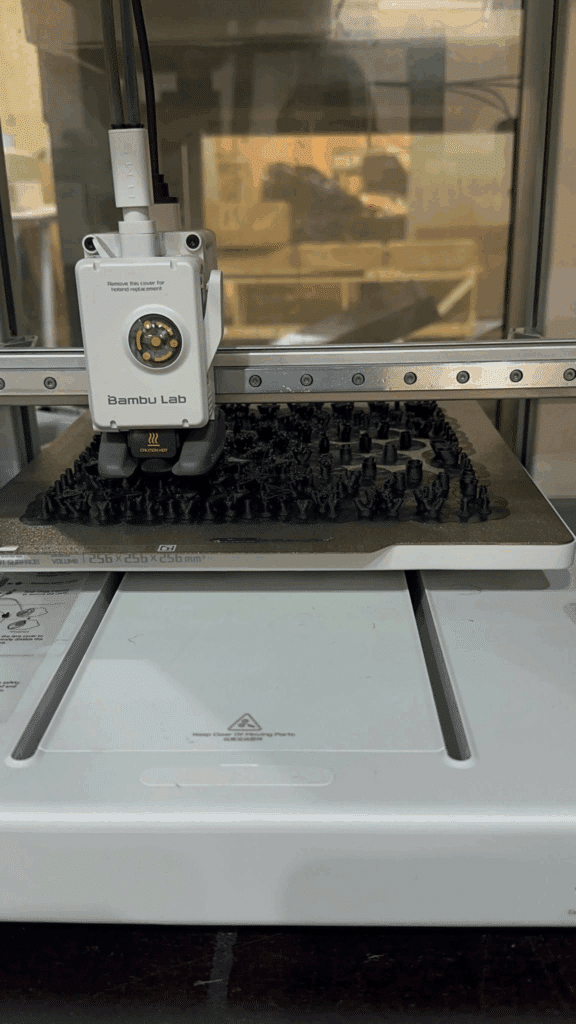

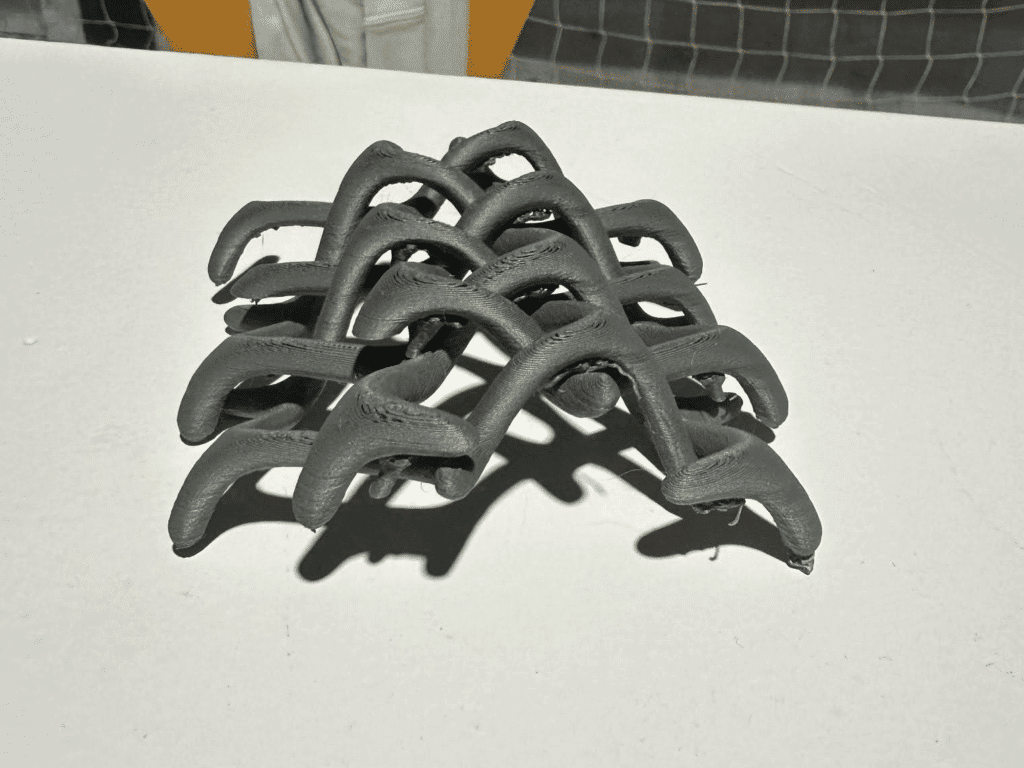

Test Protorype

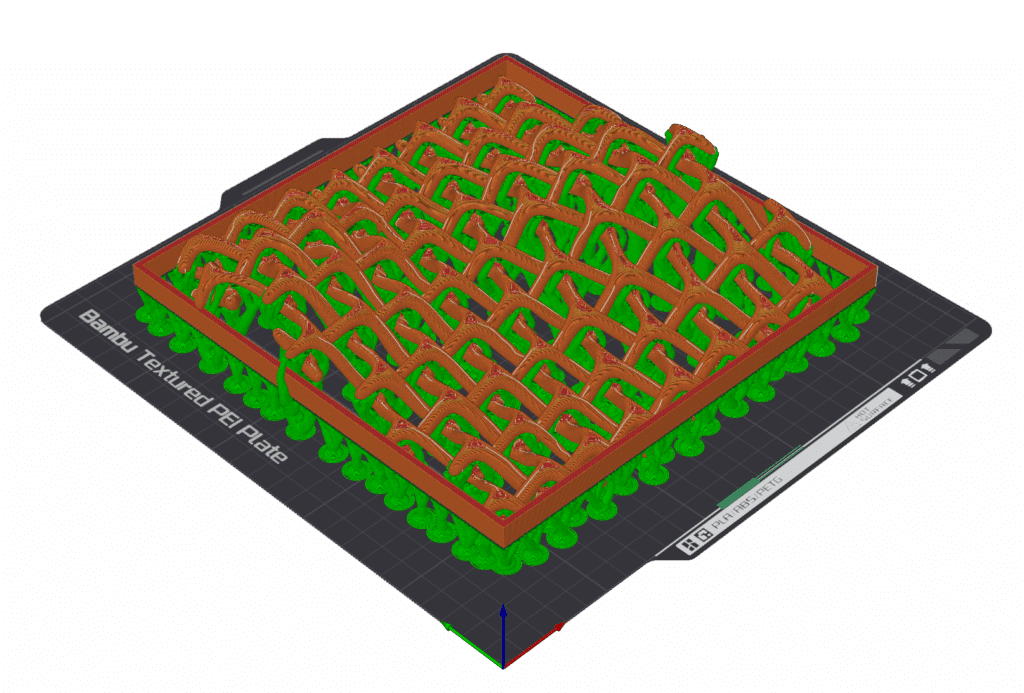

1 – Modeling

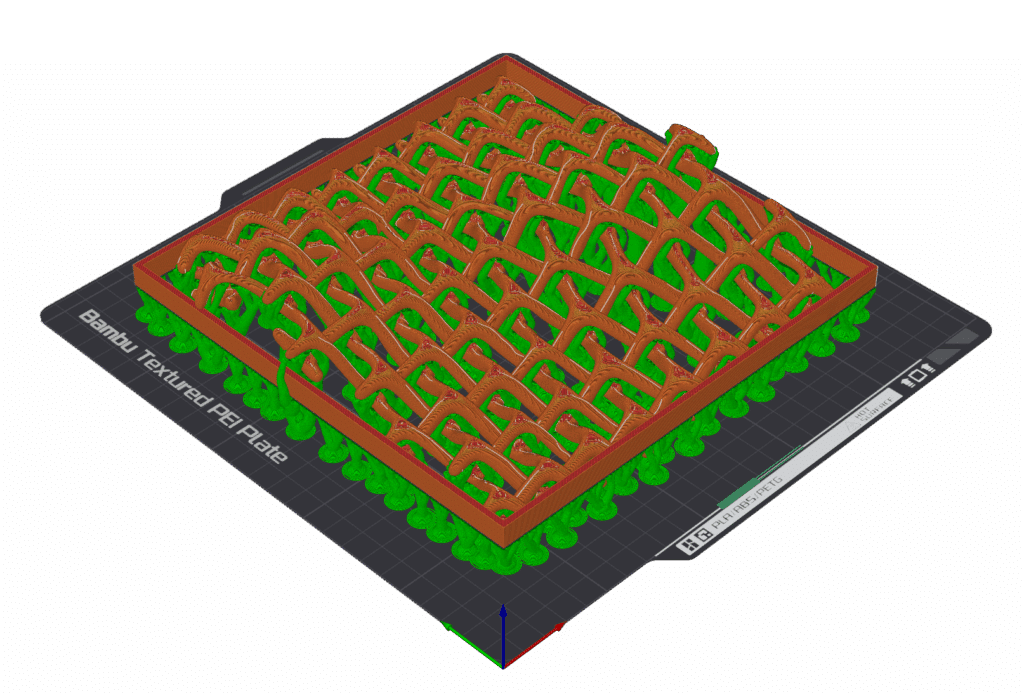

2 – Import to Bambu Lab

3 – 3D Printing

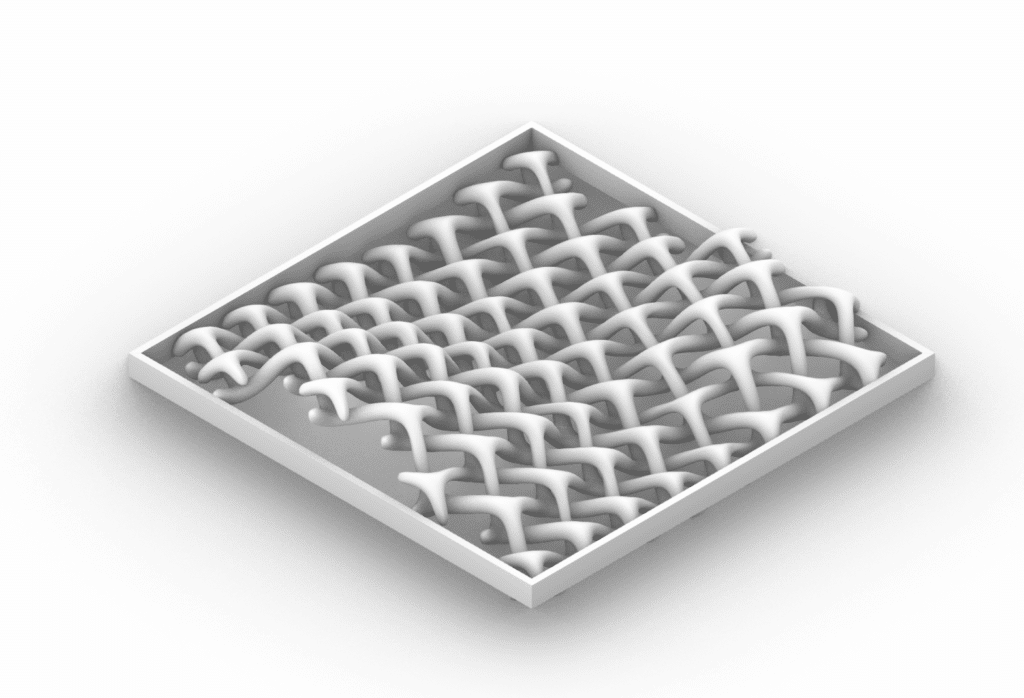

Final Design

1 – Modeling

2 – Framing

3 – Import to Bambu Lab

4 – 3D Printing

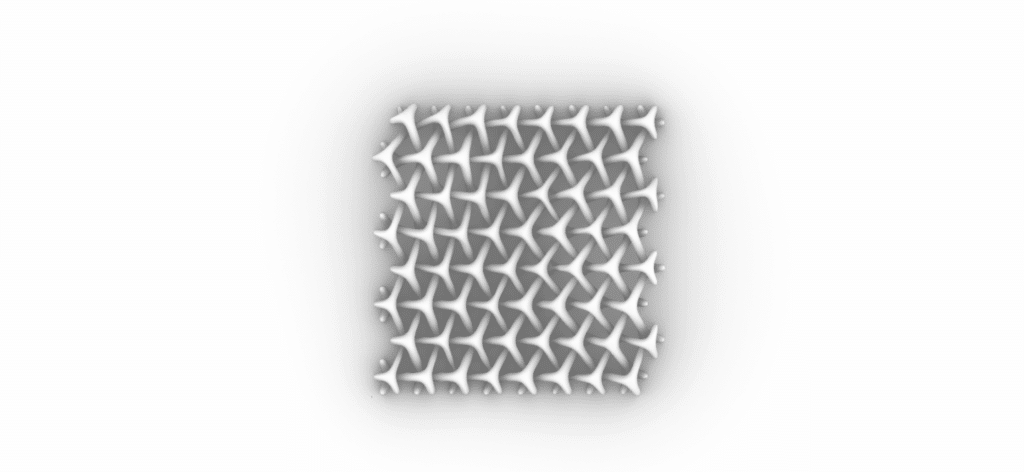

Design Process

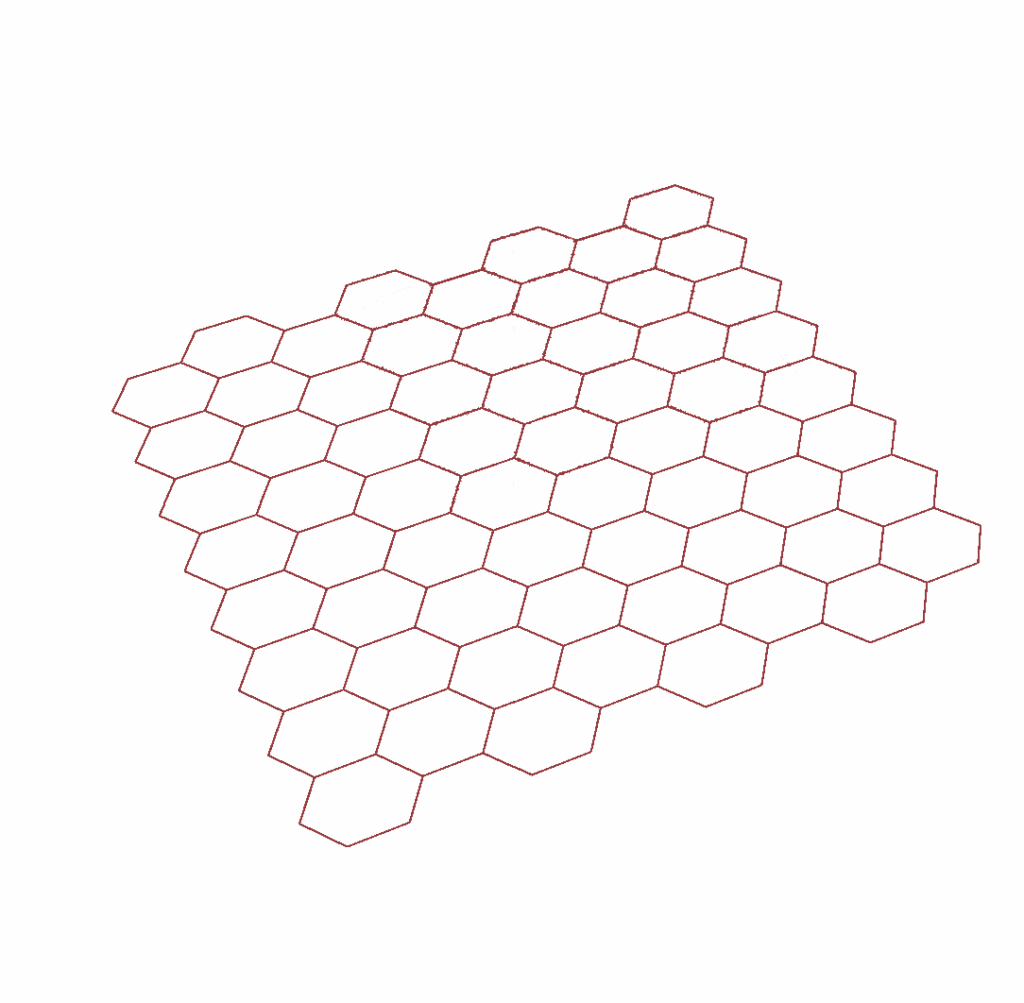

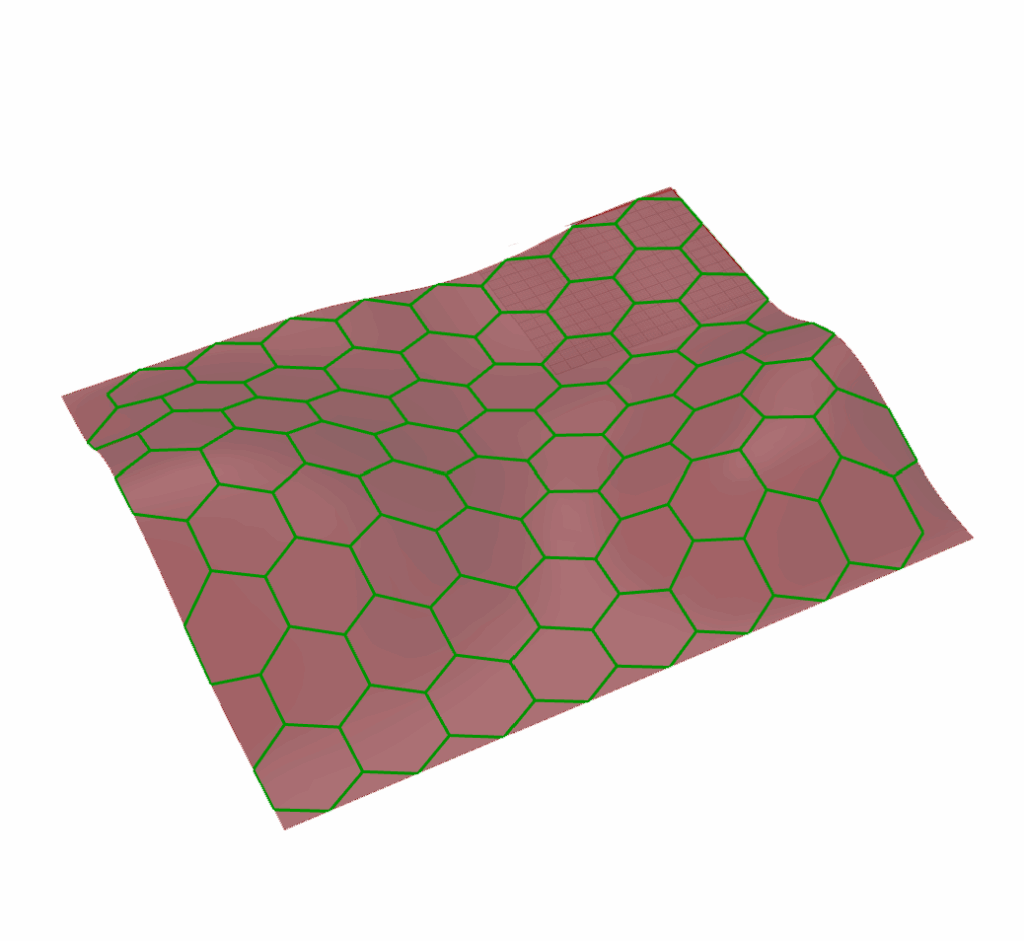

1 – Hexagonal Grid

Hexagonal grid with parameterized columns and lines.

2 – Apply grid on surface

Surface manipulation into a curved one and application of the hexagonal grid.

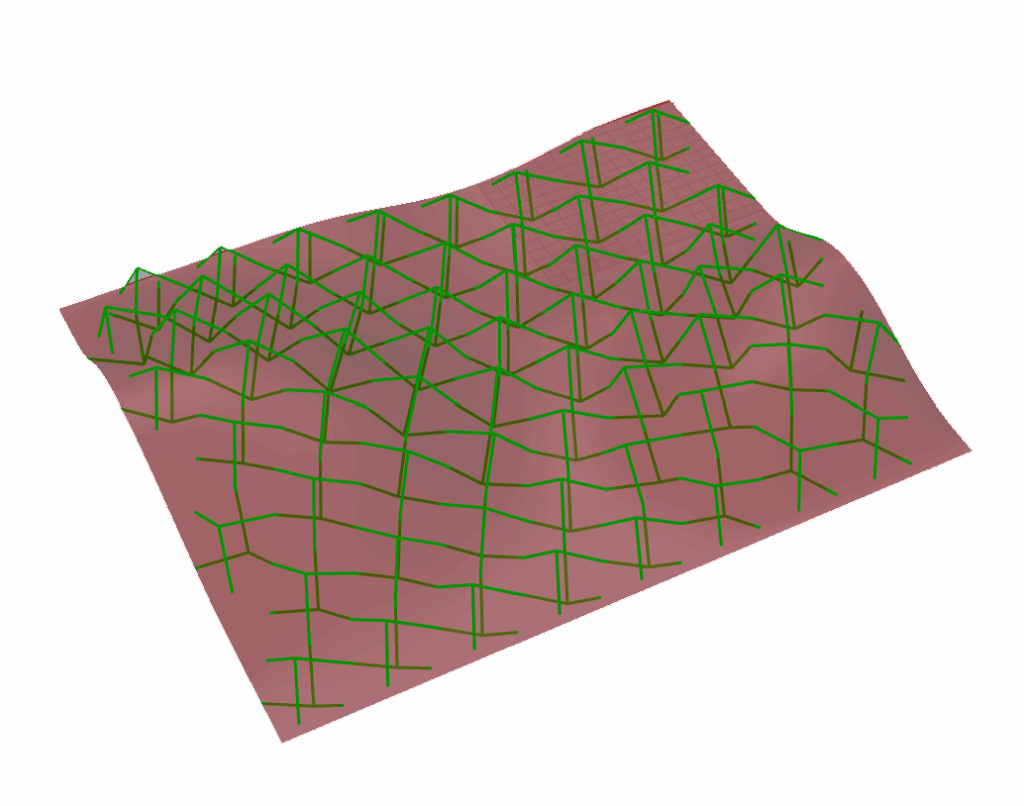

3 – Mesh’ Skeleton

Connect average point (moved in -z e +z) of the hexagon with the middle point of each edge.

4 – Meshes created

Through the lines, create meshes and apply thickness.

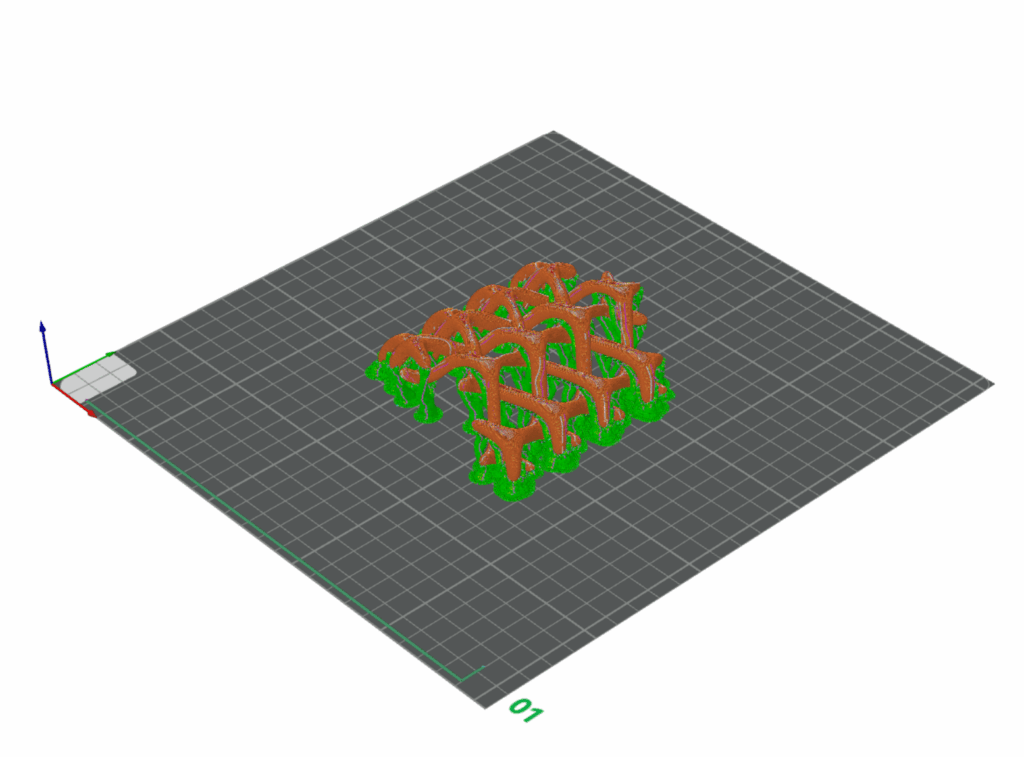

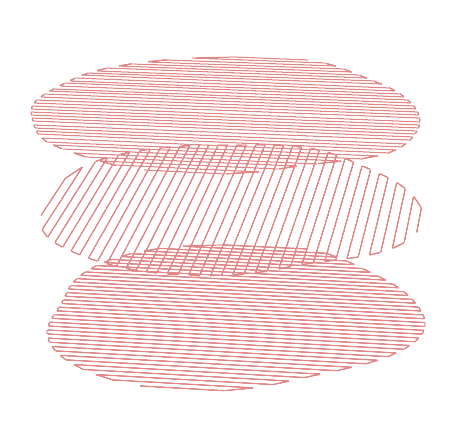

Fabrication Strategy

Parameters

Material: EPLA

Machine: Bambu Lab A1

Workpiece volume: 200x200x30mm

Total Filament: 186.84 g

Model Filament: 126.49 g

Support Time: 3h42m

Top Z Distance: 0.25

Model Printing Time: 13h17m

Total Time: 13h30m

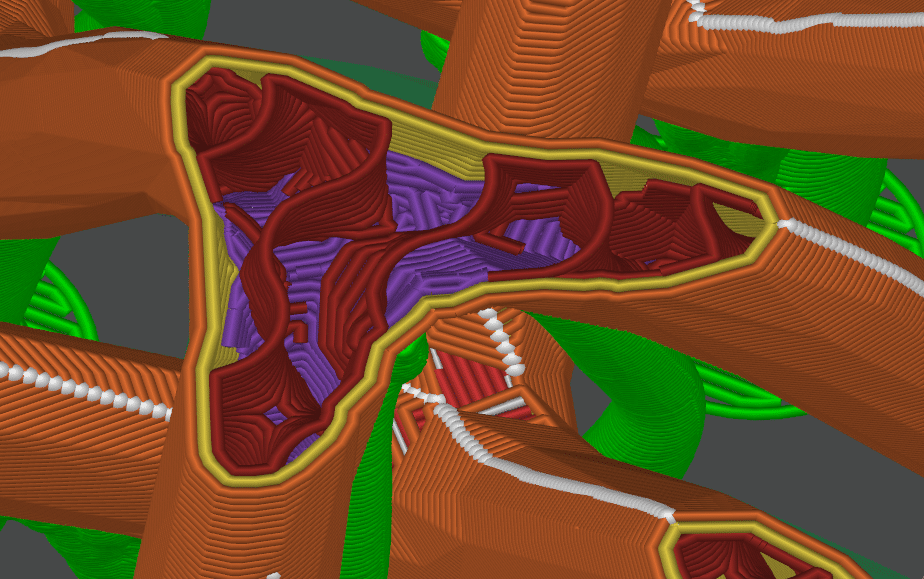

Optimization

In separating the support and the prototype, some pieces broke due to the thinness of the model. The prototype was a shell.

The solution was to transform the model into a solid and to increase the number of wall loops to 2. This way, the model is less fragile and can be separated from the supports without breaking.

Prototype

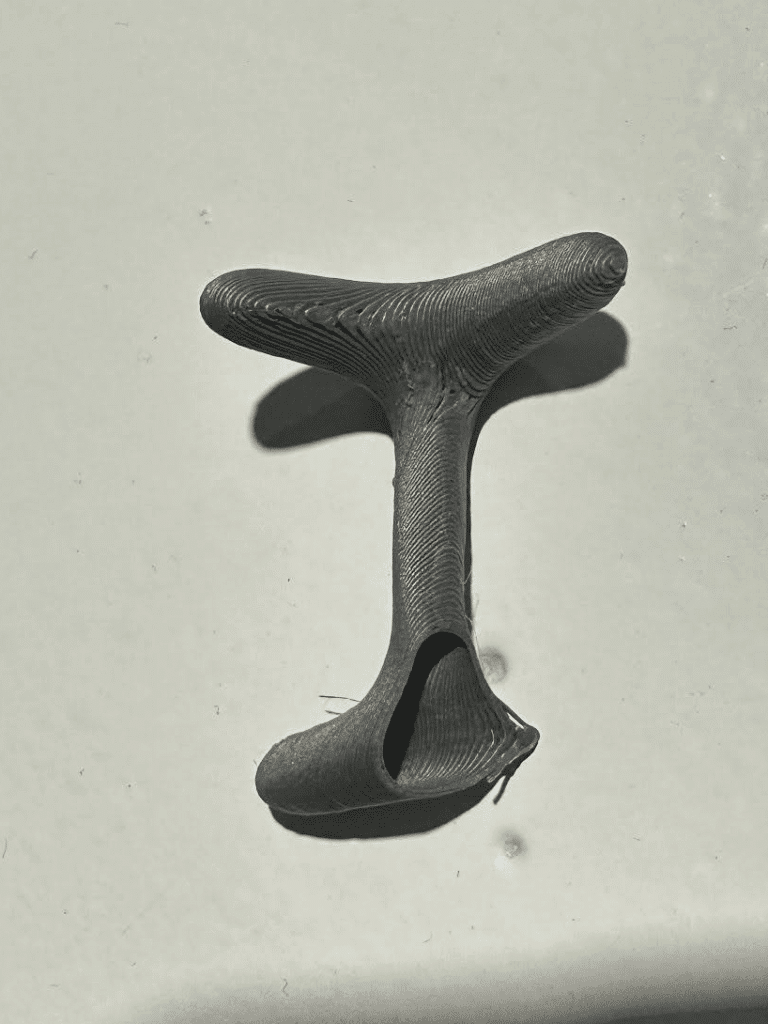

Final Design

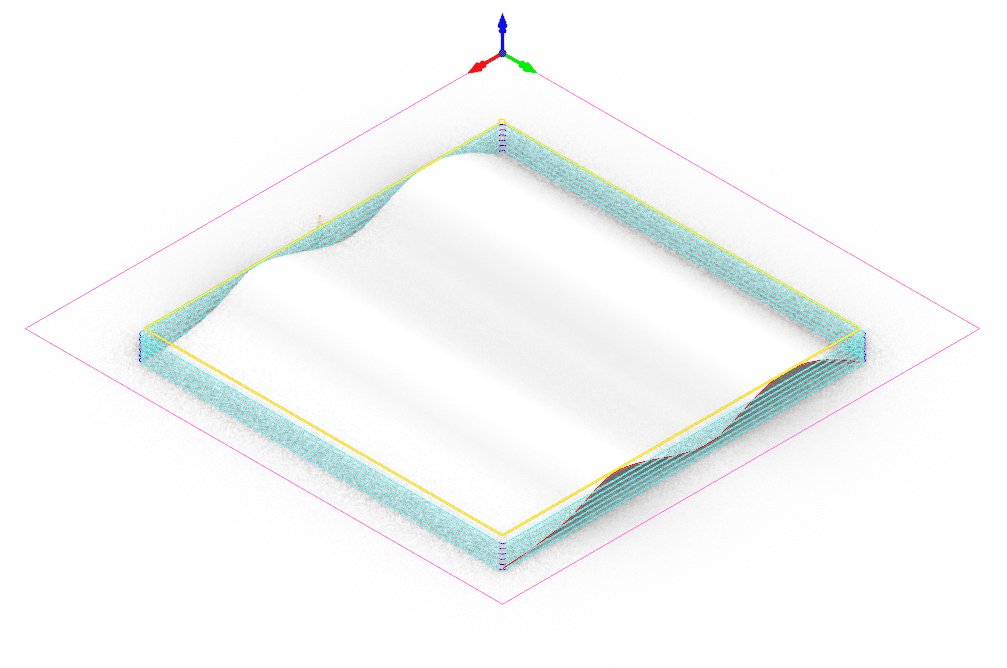

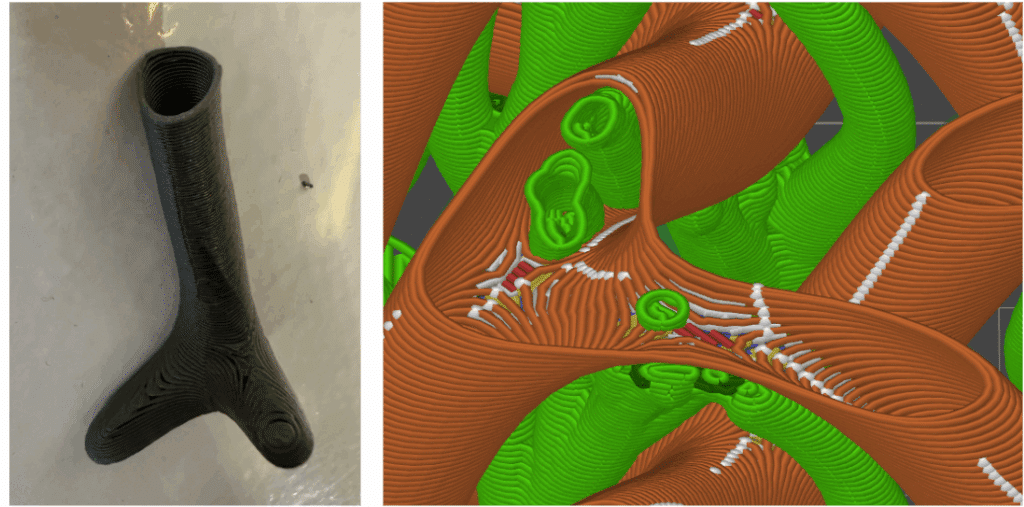

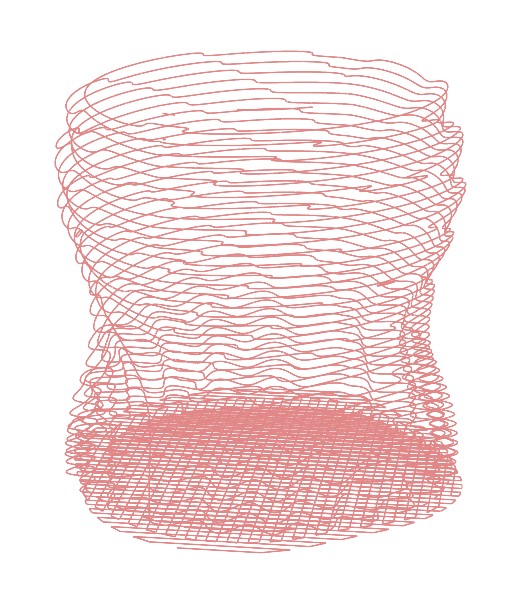

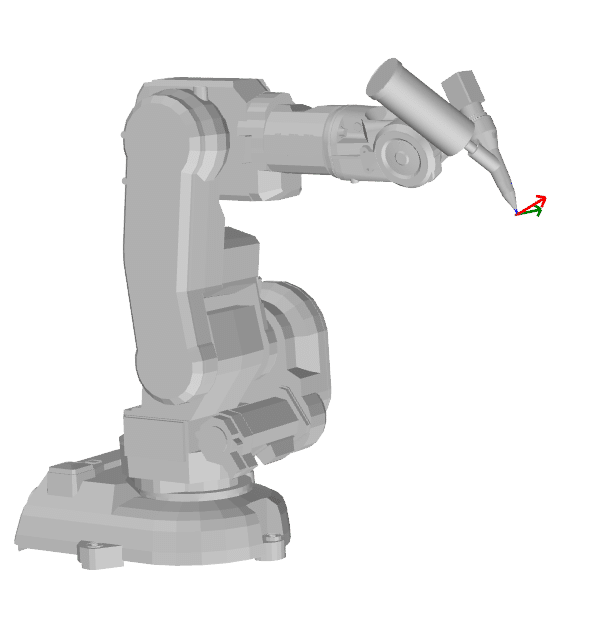

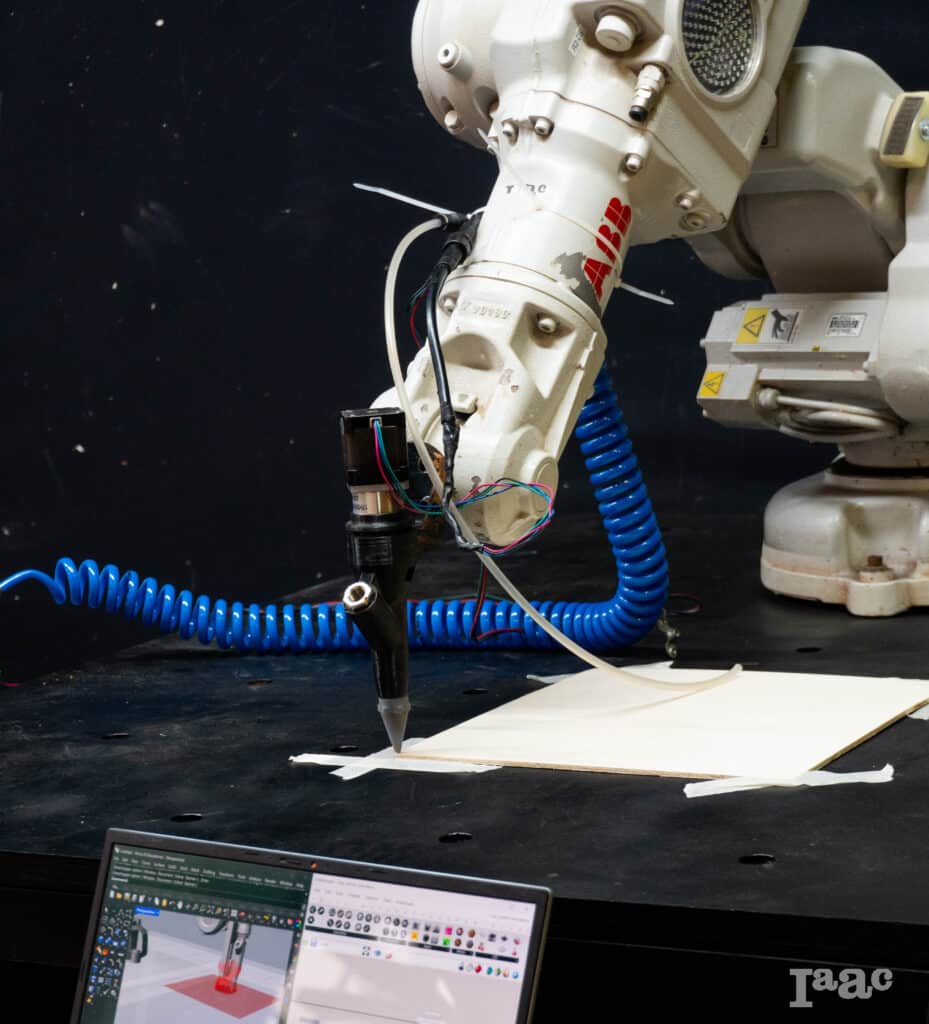

Claywave

This project is the result of an iterative exploration into clay 3D printing with a six-axis robotic arm. Starting from a digital model, we generated the toolpaths, calibrated the robot, and prepared the clay to ensure a stable and consistent extrusion. Through hands-on testing, the design evolved in response to material behavior and robotic constraints. The final piece reflects this dialogue between digital precision and the natural variability of clay, showing how computational design can adapt to the nuances of physical fabrication.

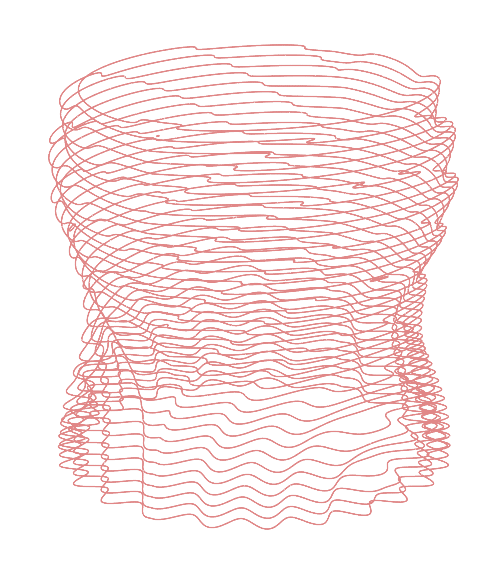

Design generation

1 – 3D Model

2 – Contour

3 – Base Generation

4 – Final Geometry

Fabrication

1 – Material Preparation

2 – TCP calibration

3 – Base plane calibration

Fabrication Tests

We encountered issues during material preparation. The clay was not properly loaded into the cartridge, which caused air bubbles to form during printing and compromised the final piece. In addition, we realized that the original design was not suitable for this printing method: the vessel narrowed too much in the central section and risked collapsing. We reduced the width of that area, achieving a more efficient and stable design.

Final Design