As an underlying theme we chose to explore the various movements of water, as a catalyst that drives each of our fabrication process.

Laser Cut – Oscillation | 3D Printing – Coral Growth | CNC Milling – Ripple Effect

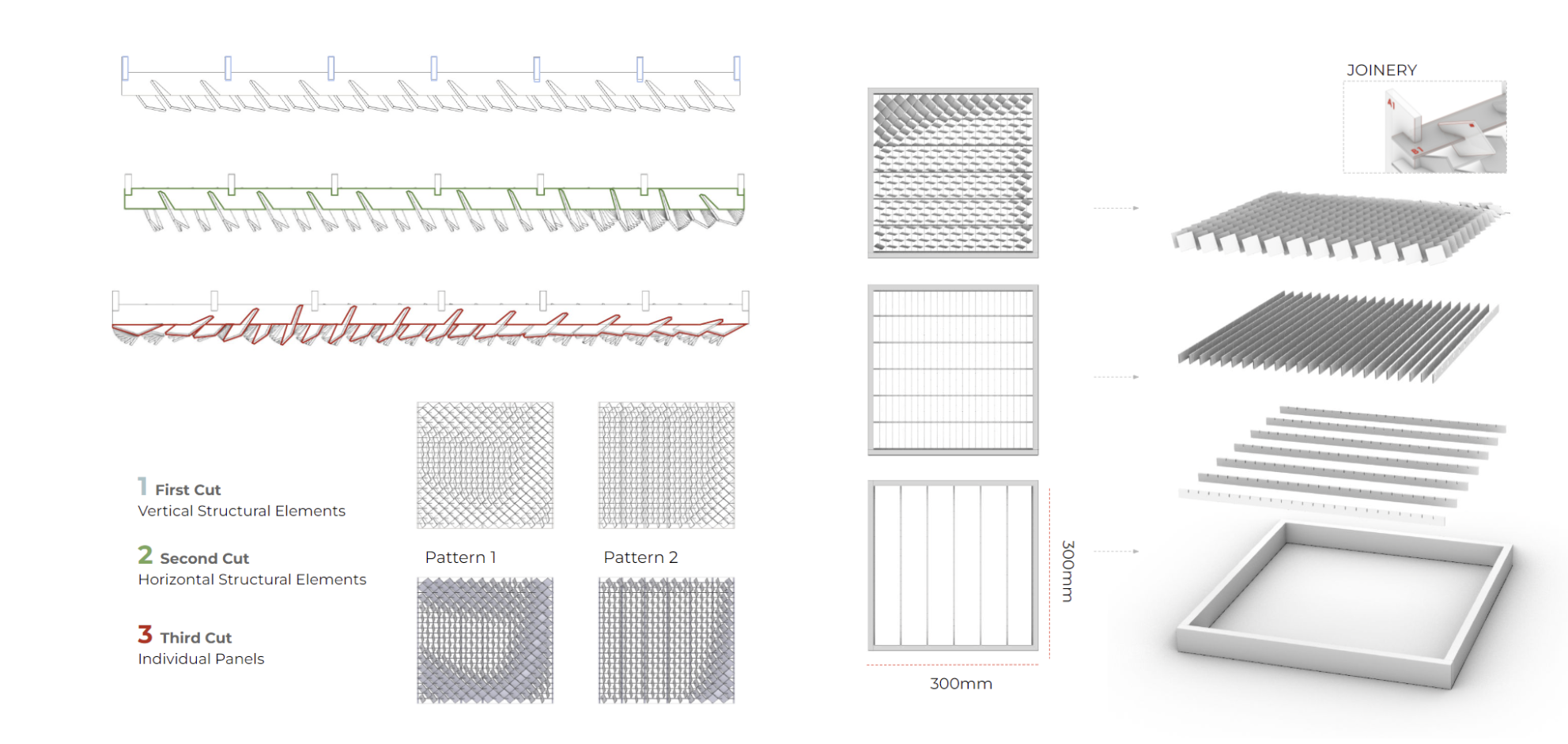

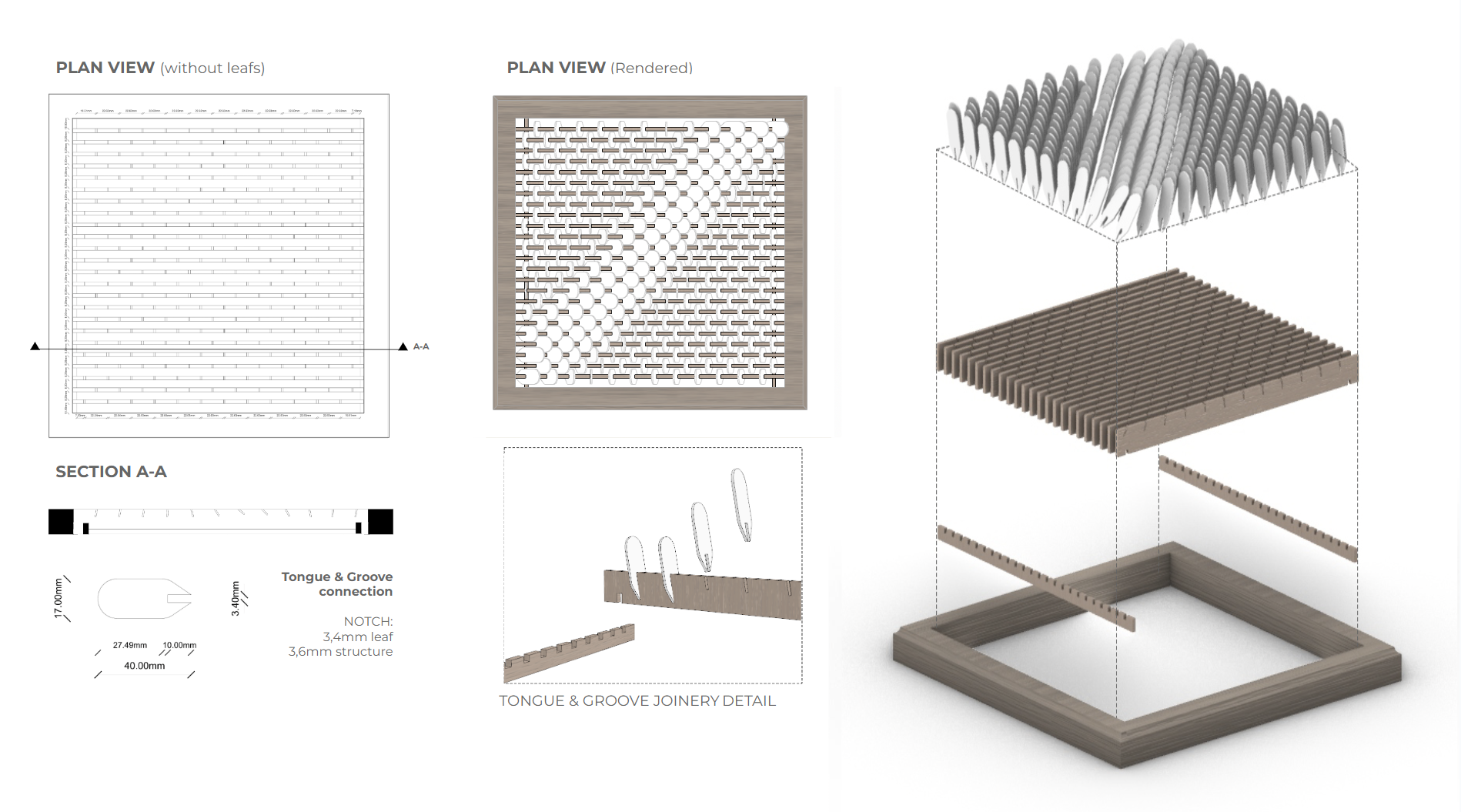

LASER CUTTING | OSCILLATION

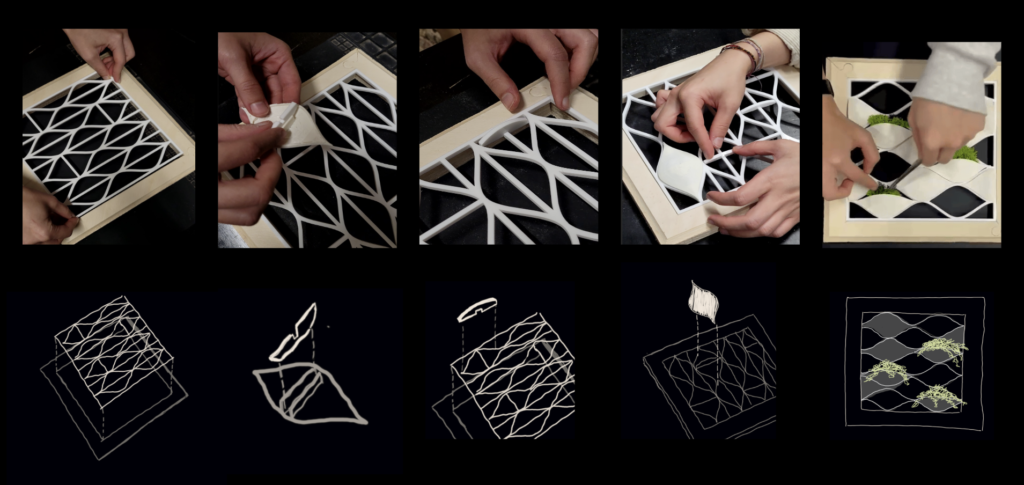

The concept behind this design gets its inspiration from oscillating waves and kinetic facades, to create a pattern which appears to be fluid. Through a series of prototypes and iterations we were able to fine tune the tongue and groove system between leaf and substructure – creating a seamless connection that overall depicts the tranquil blaze of an oscillating wave.

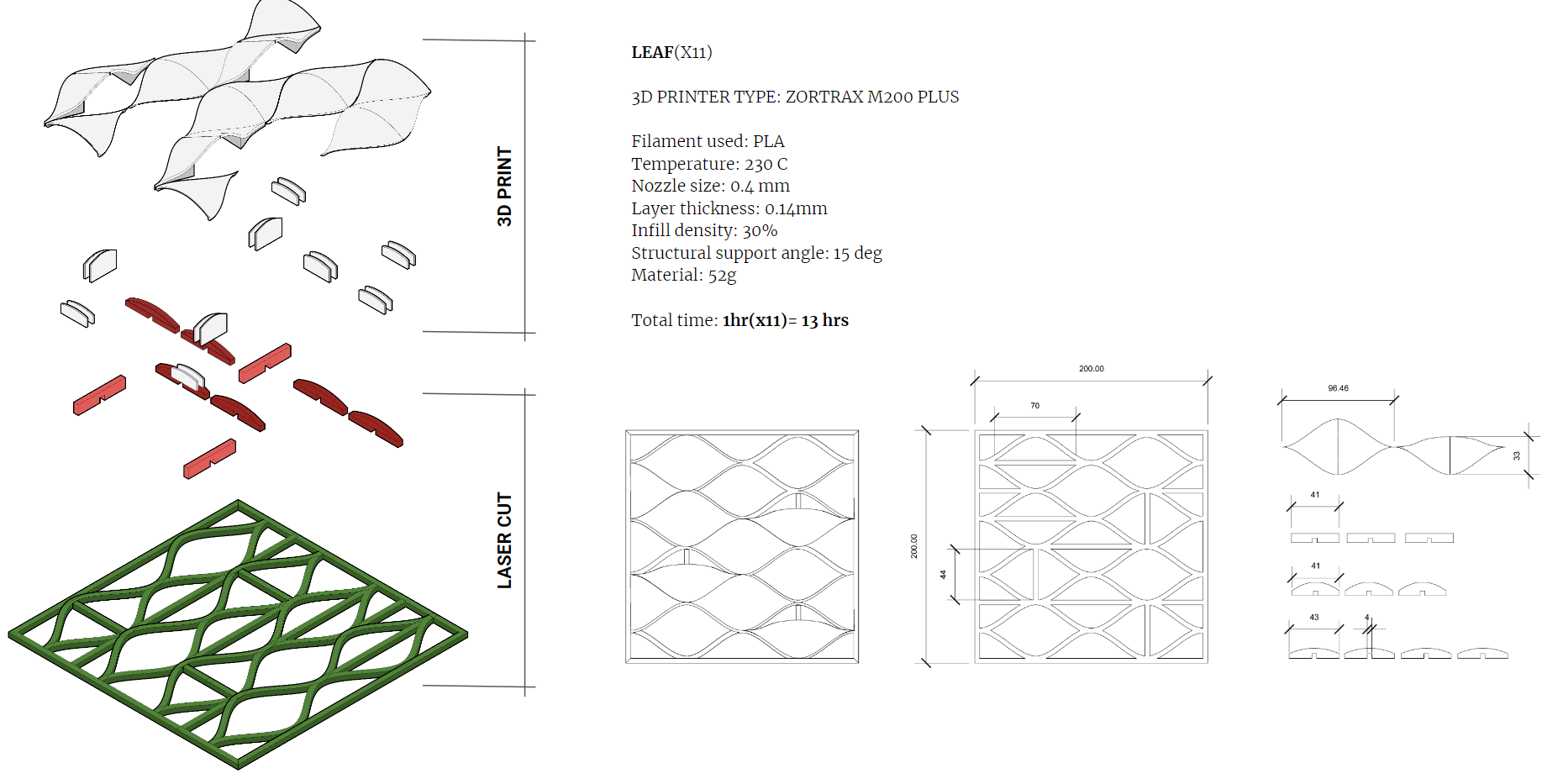

3D PRINTING | CORAL GROWTH

The initial idea started with creating an ecosystem, inspired by biophilic facades and 3D printed coral reefs. From there, we began experimenting with solids and voids within the structural frame system and incorporation of planters.

The design went through a series of iterations eventually opting for a combination of 3D printing for the leaf’s and laser cutting Acrylic for the substructure. This allowed us to significantly reduce the printing time which initially peaked above 30 hrs.

The final product with the leaf’s attached to the substructure, showing the addition of punctures leaf cavities to assist in giving depth & variability to the design.

The final product is imagined as the possible extension of a facade system.

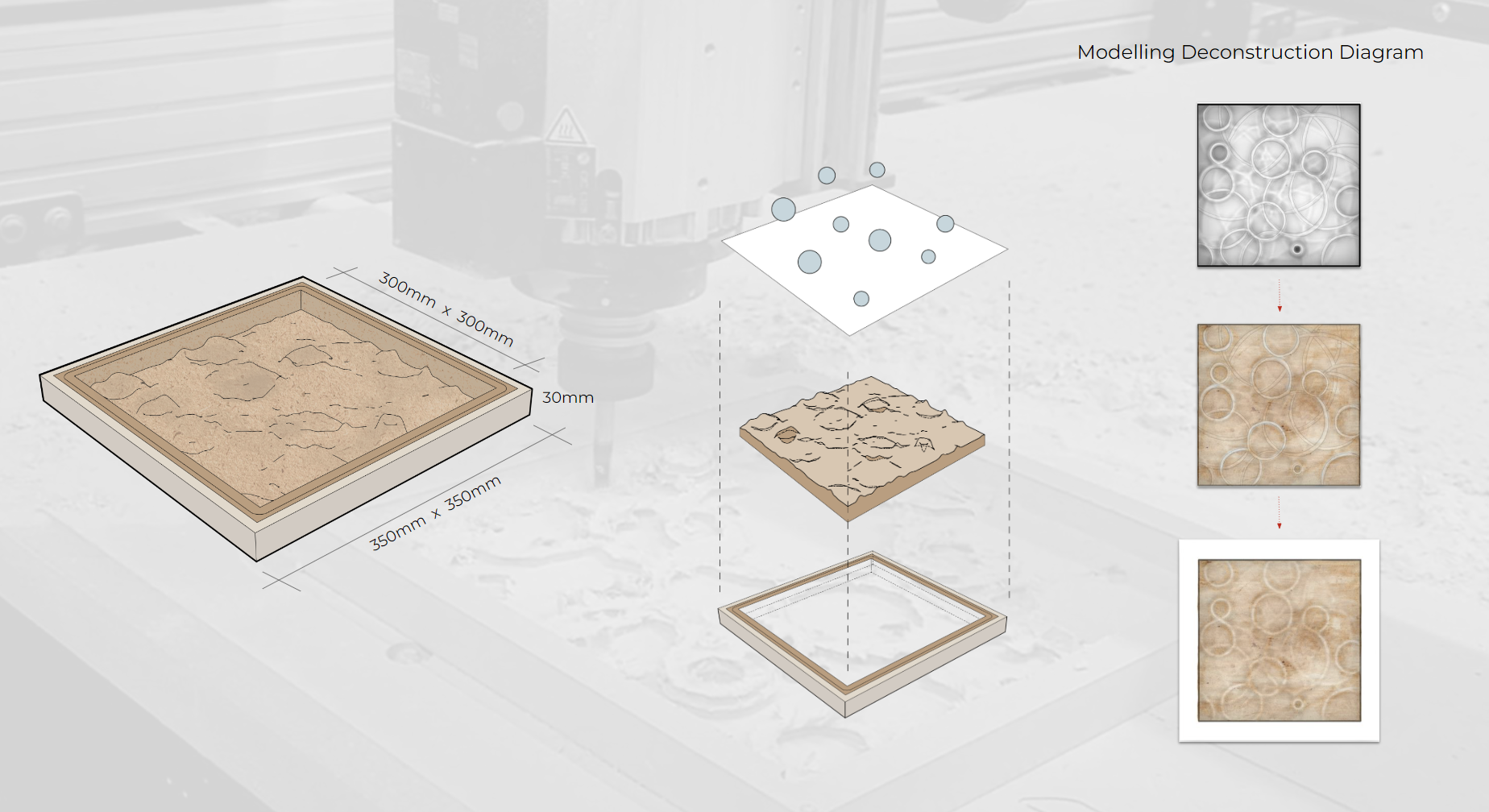

CNC MILLING | RIPPLE EFFECT

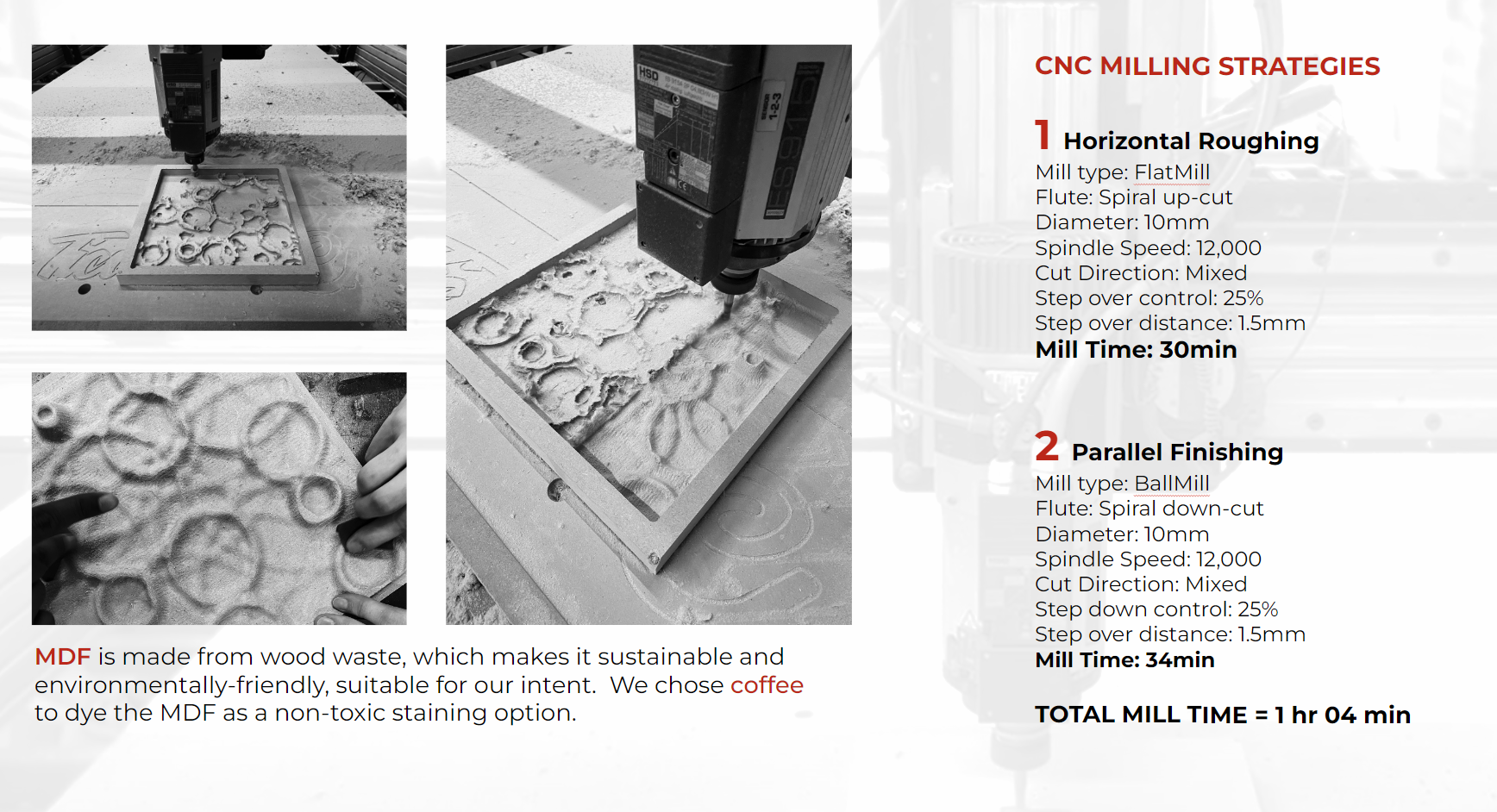

The milling design takes its inspiration from the captivating phenomenon produced when water droplets descend into a body of water and the ripple effect that results as the water disperses outwards. We limited our process to two techniques in order to reduce production time; utilizing horizontal roughing, followed by Parallel finishing.

We opted to find a sustainable method for finishing, using coffee to stain the surface which absorbed well into the MDF material.