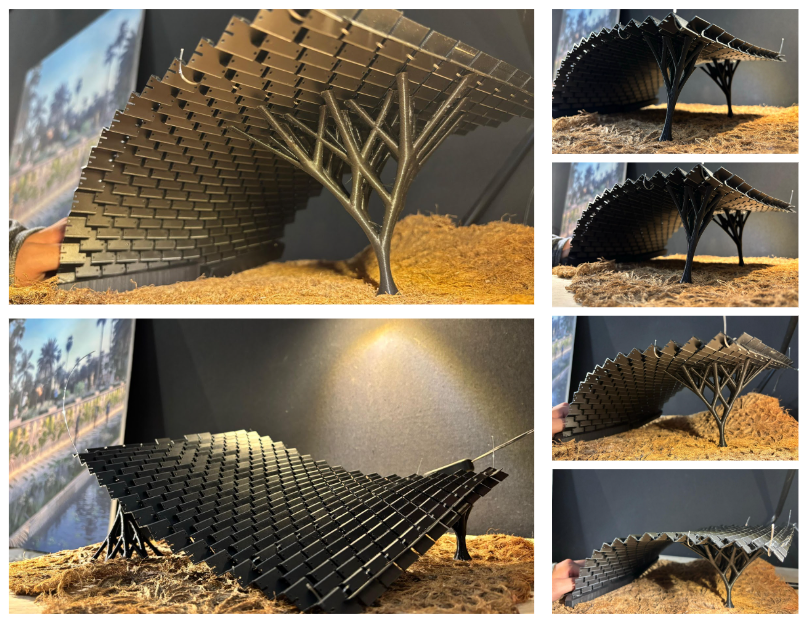

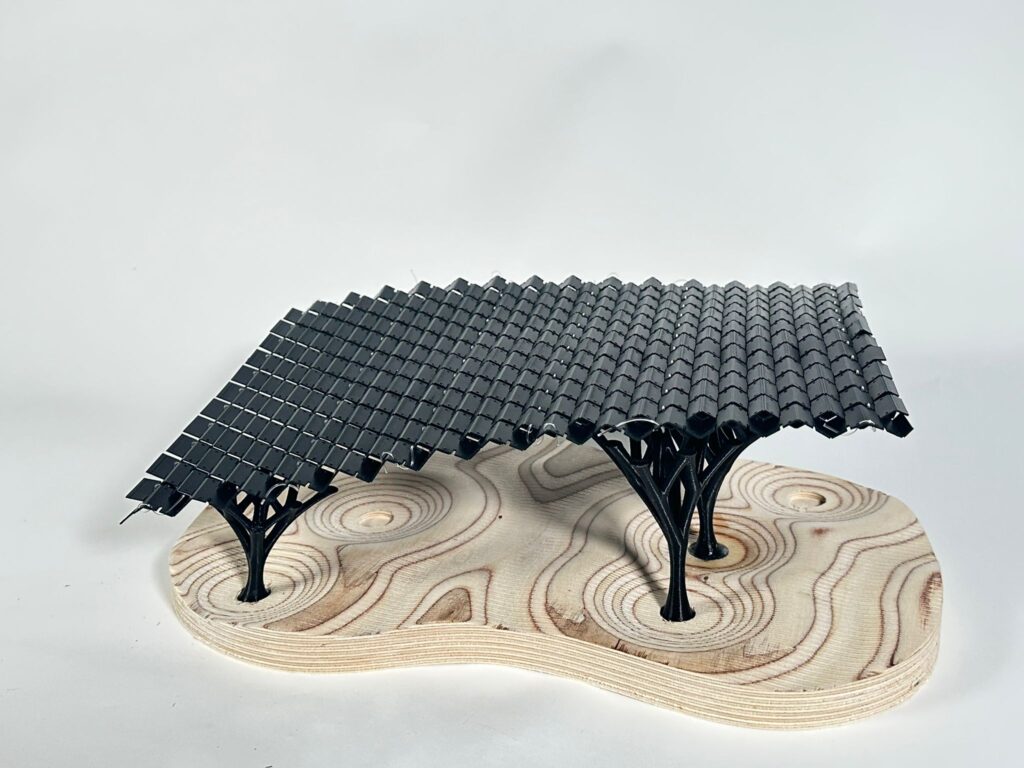

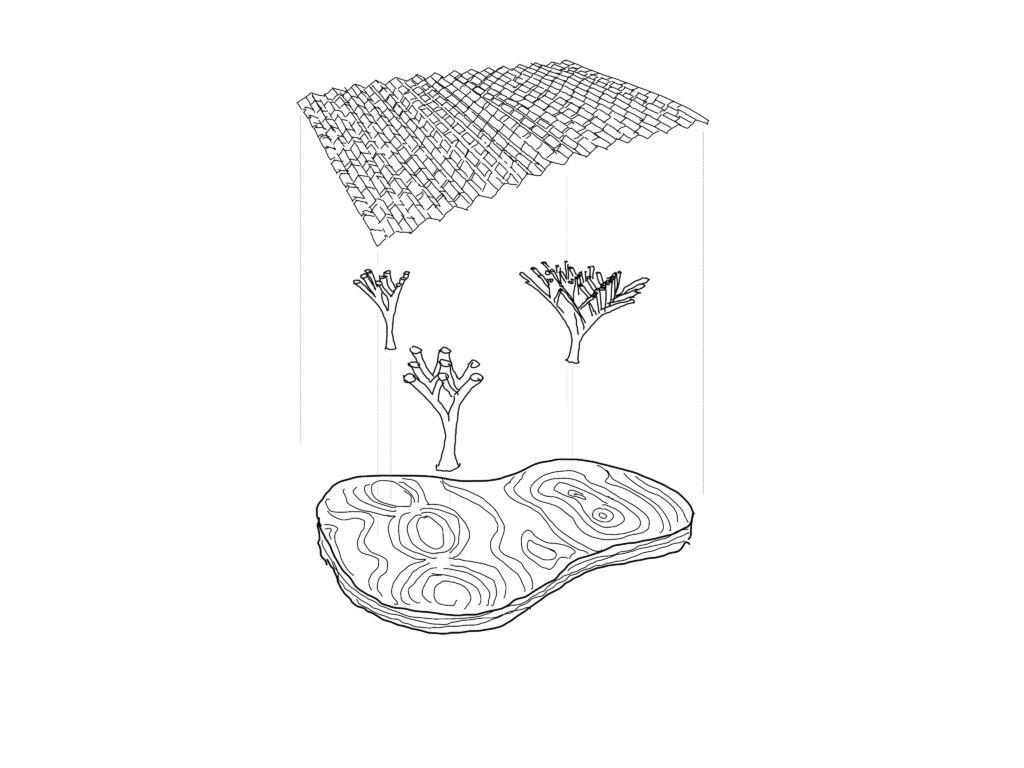

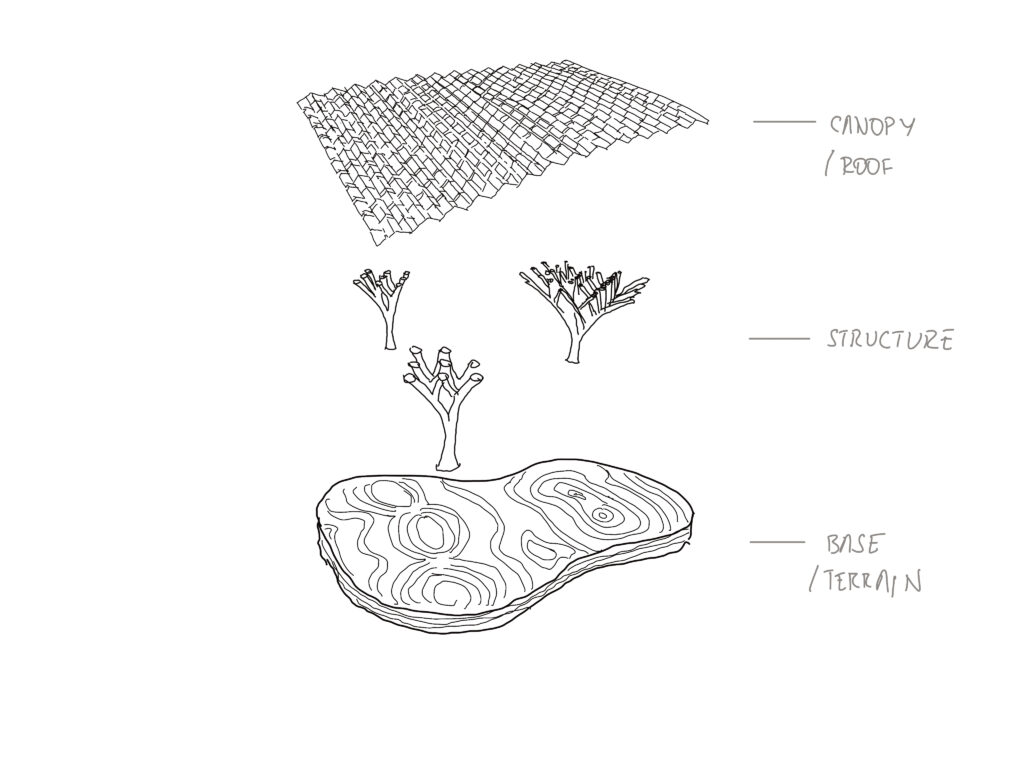

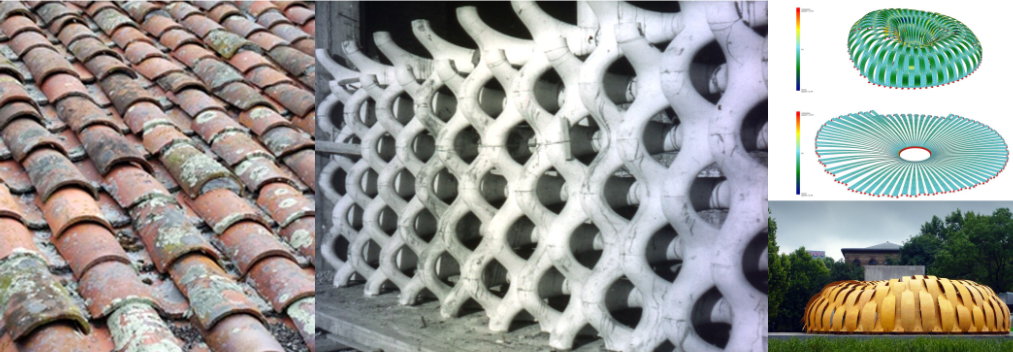

The project Warded explores the concept of a “cabin of the future.” When considering future projections, it is difficult to estimate the exact needs and conditions; therefore, Warded is designed for flexibility. For its canopy structure, a traditional tile roof-like pattern is reimagined and interwoven further, like fabric, produced through laser cutting. A fractal tree, created with 3D printing, serves as its vertical/structural element, with a varying number of branches according to the size of the space. Finally, a terrain visualization from CNC illustrates the adaptability of this design across various landscapes.

Fab Tool 1: Laser Cutting

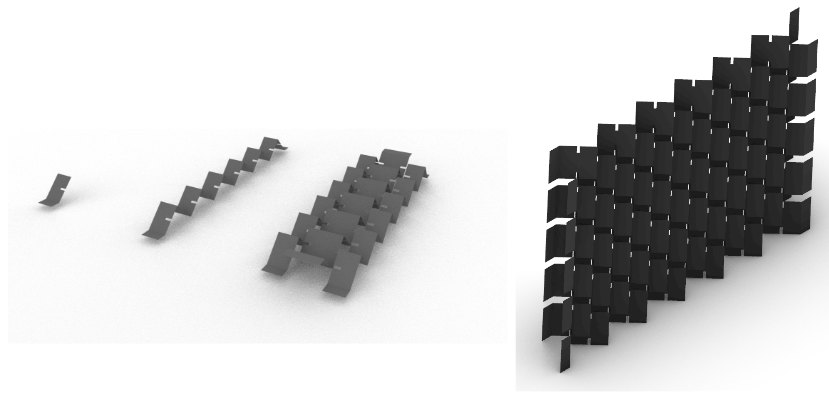

for the laser cutting part of our fabrication, a woven, fabric like surface is generated. through prototyping we arrived at the joinery of several components interlocked and braided with each other through a nylon thread, allowing for its stability as well as curve. our intention is to have a flexible surface that can curve and stretch.

References

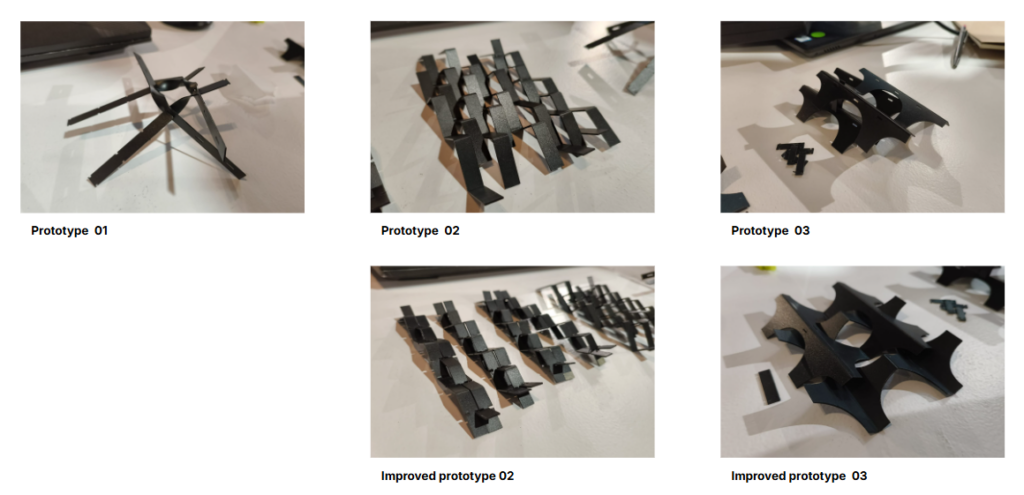

Fabrication & Prototyping

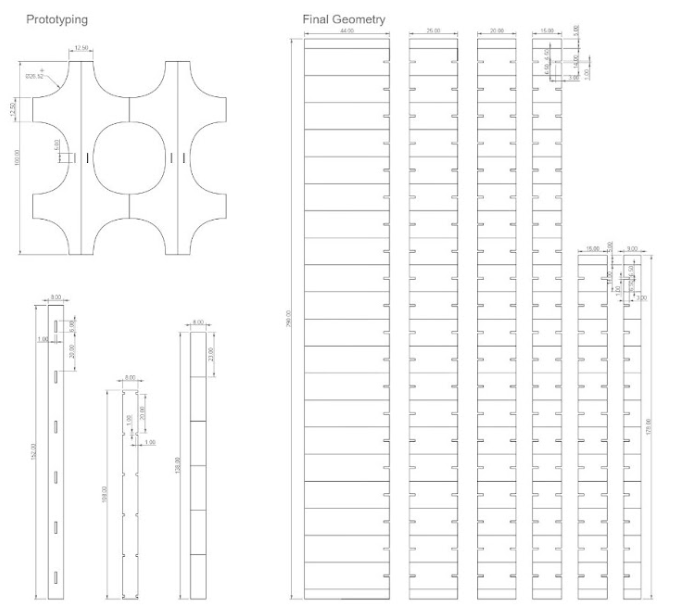

Polypropylene 8mm / Braiding

The initial step in starting fabrication was understanding the material and constraints of the joinery method.

3 different prototypes were produced in trial phase

2 of which were improved in second phase of prototyping

1 was chosen as final geometry

The discontinued prototypes were limited in their growth and/or flexibility.

Laser Cutting Parameters

- Engraving:

- Speed: 3.5

- Power: 6

- Cutting:

- Speed: 3.5

- Power: 50

Final Product of Laser Cutting

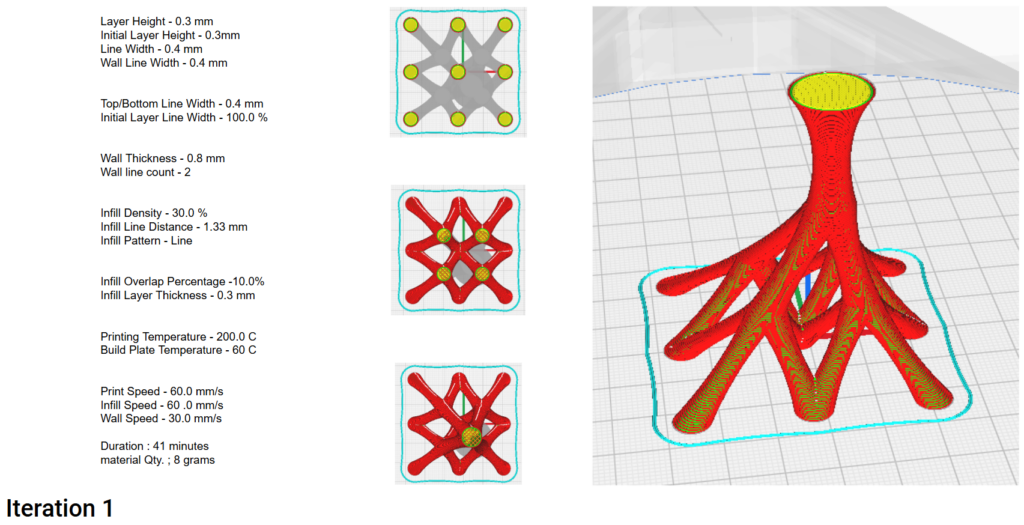

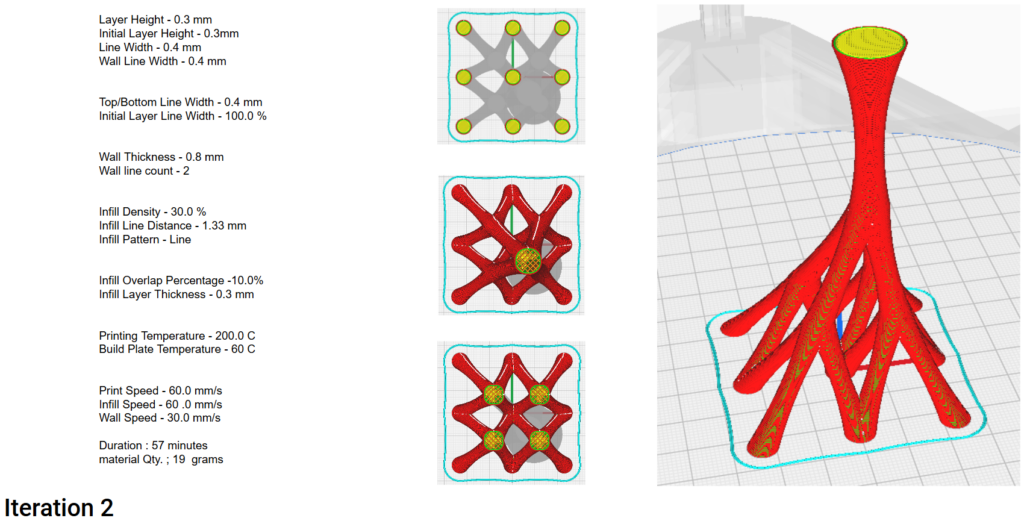

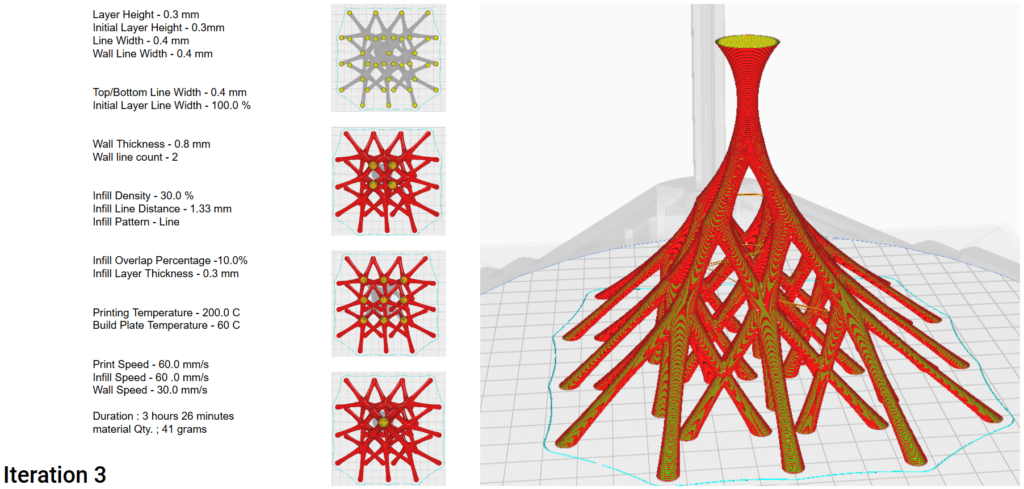

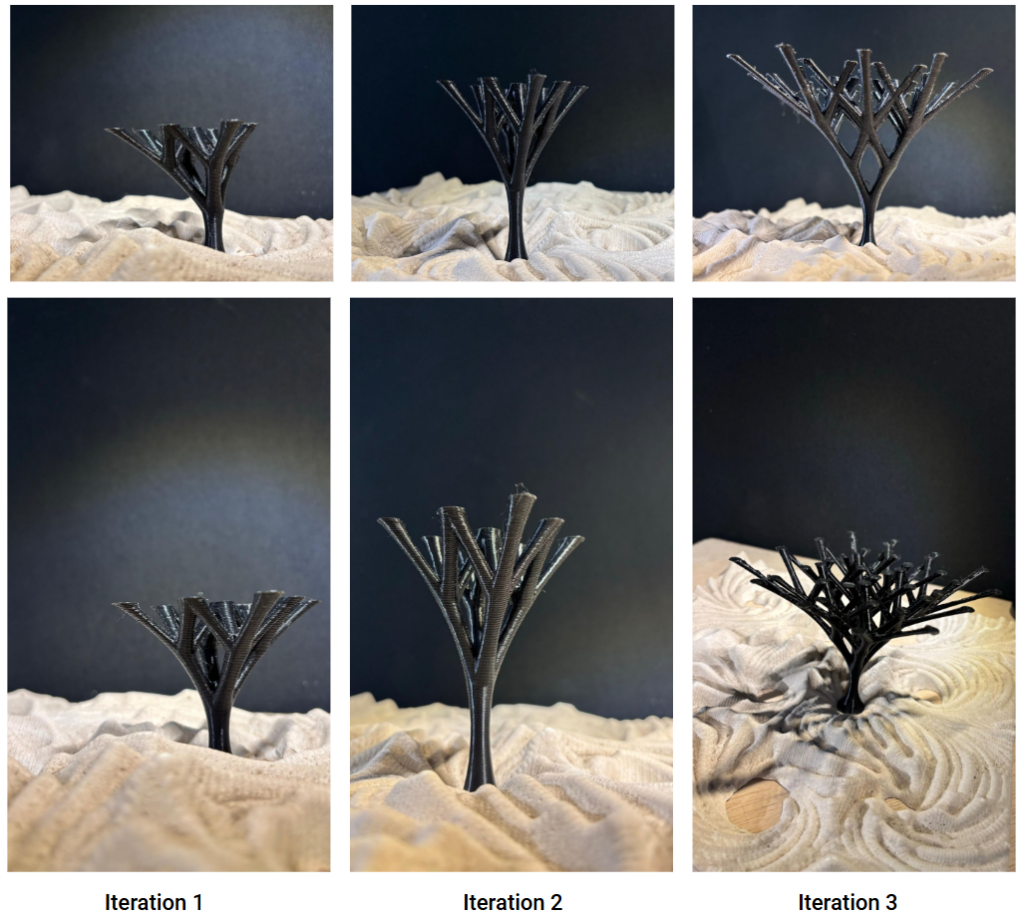

Fab Tool 2: 3D Printing

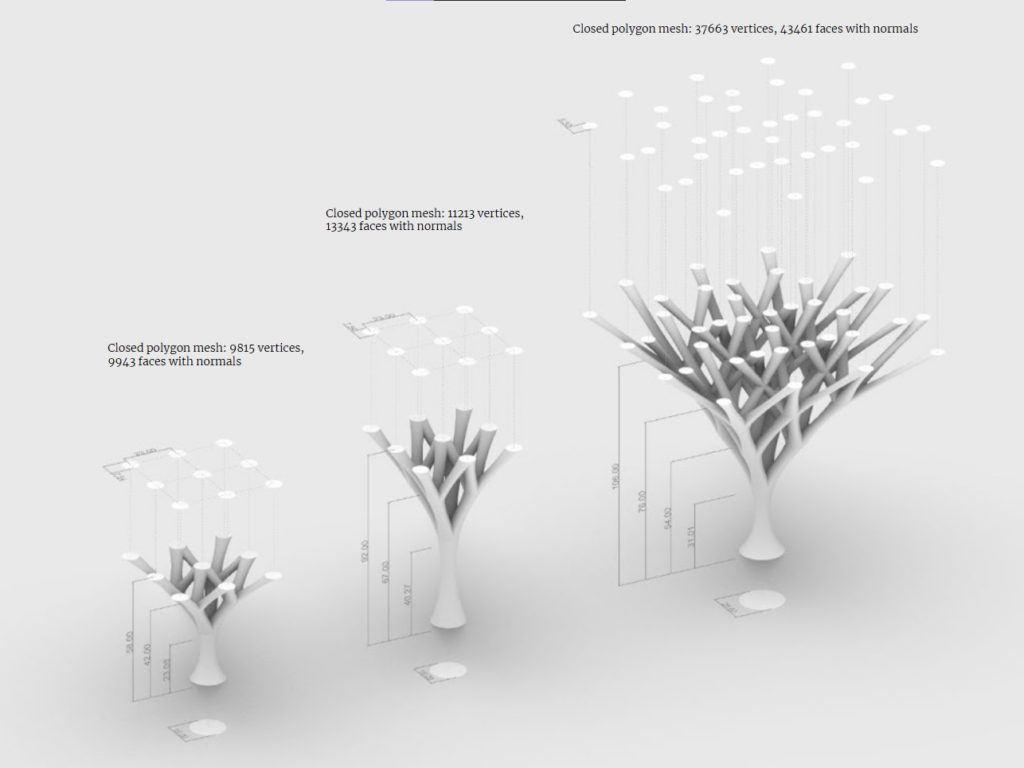

the 3D printing part of our fabrication is used to create an anchor/column for the surface. the fractal like tree with its varying numbered branches allows us to accommodate different sizes of surfaces.

References

Fabrication & Prototyping

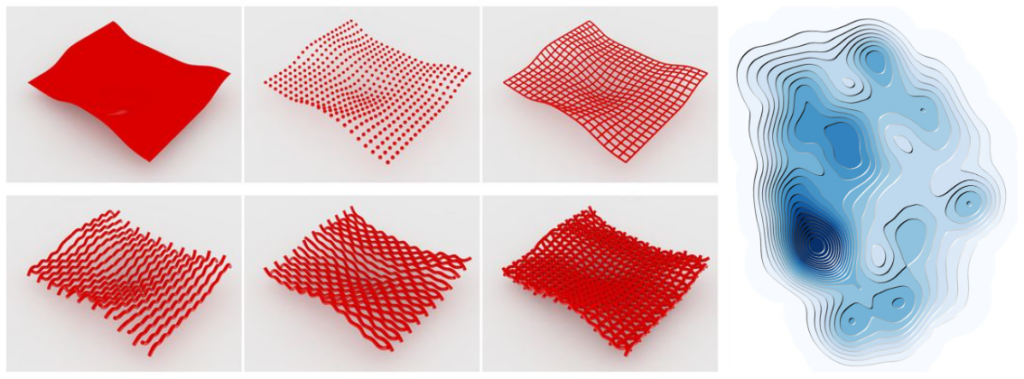

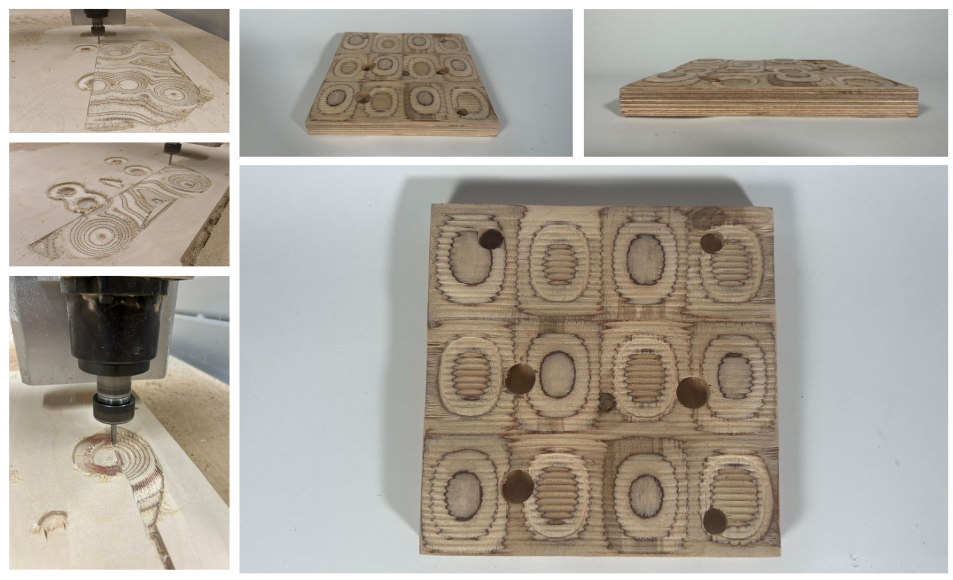

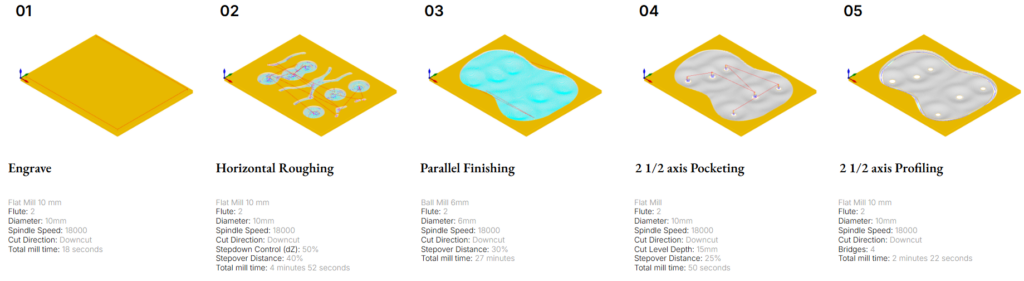

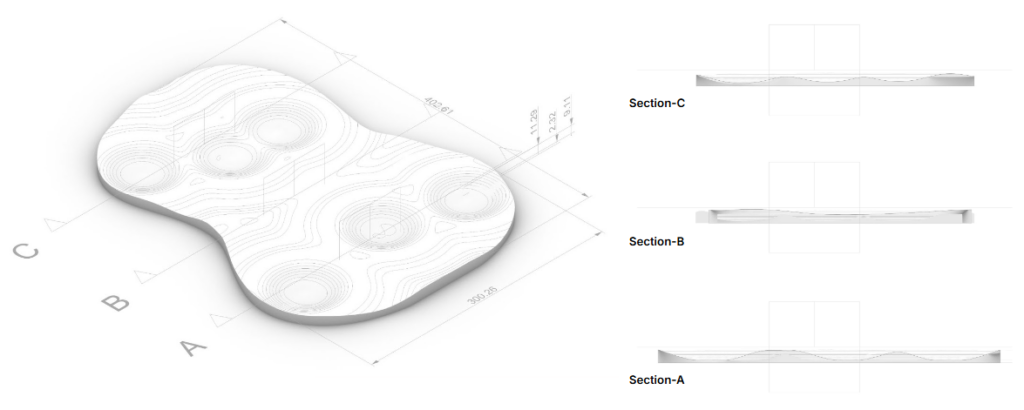

Fab Tool 3: CNC Milling

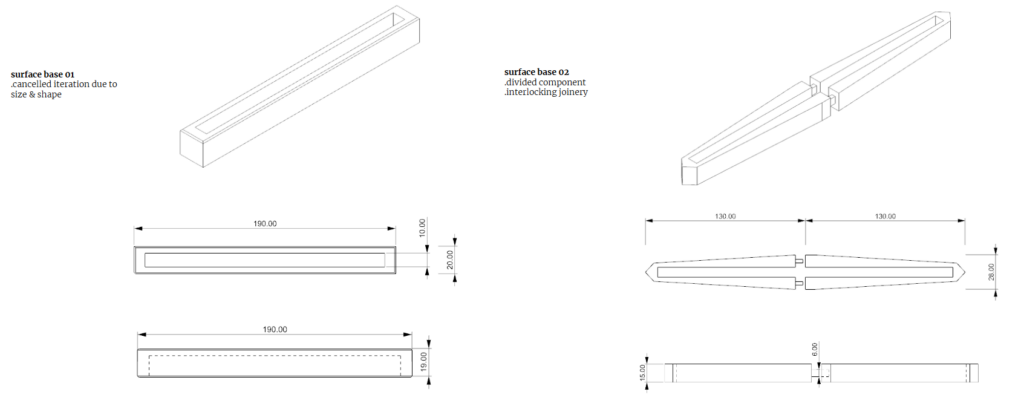

the CNC milling part of our design is used to create a platform for the canopy and its anchor. the base is produced with several holes to allow varying positions of the fractal tree therefore different curves resulted in the canopy.

References

Fabrication & Prototyping

Material Plywood 24mm

Machine Raptor CNC

Post Processor CNC_STEP_BCN Raptor

Workpiece Volume 400x350x24mm

Final Assembled Geometry