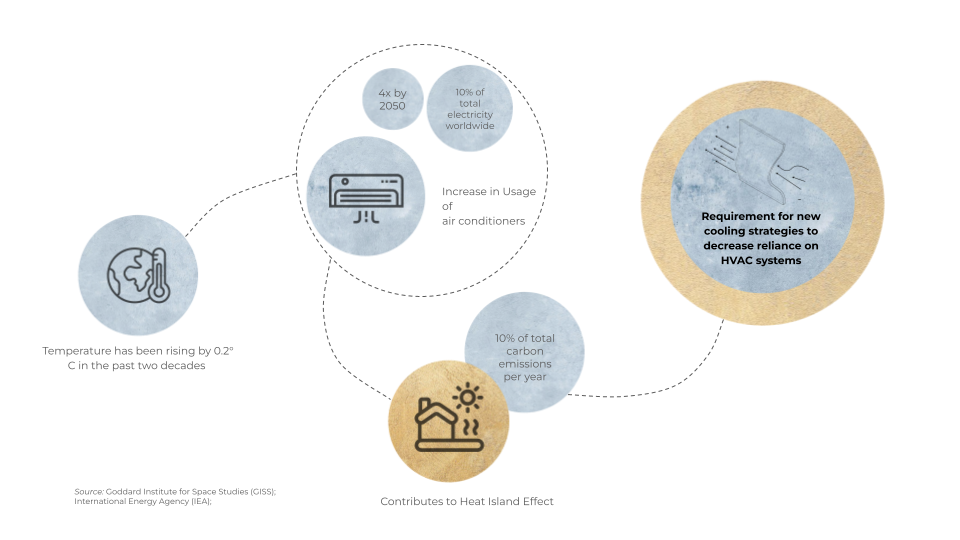

Wind Wave is a secondary facade system engineered in response to the escalating environmental demands faced by our planet. Climate change is resulting in an increase in heat waves, with some reaching lethal intensities.

As global temperatures rise, reliance on air conditioning systems has surged. However, these systems exacerbate external environmental heating by expelling hot indoor air to the outside and by consuming fossil fuels, which further contributes to global warming. The development of Wind Wave was driven by the necessity to address these challenges.

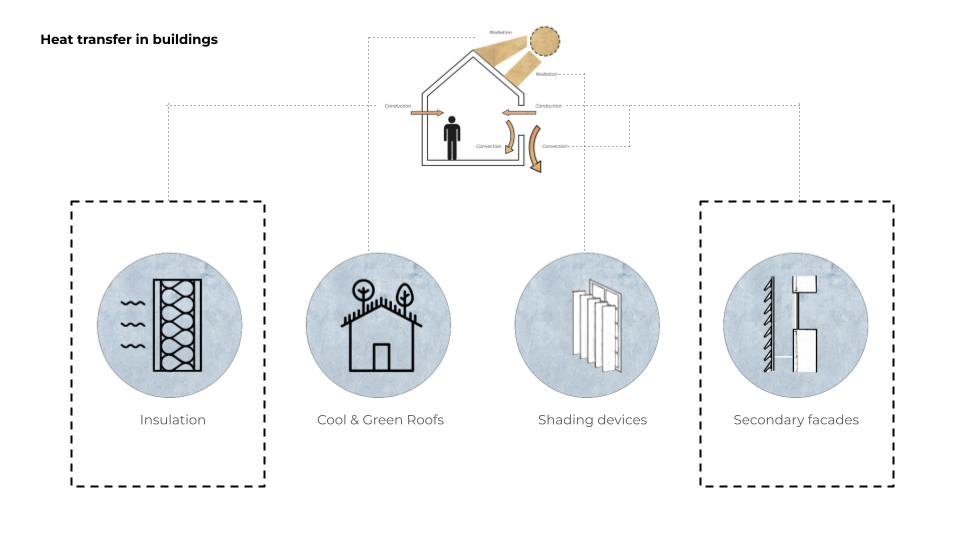

To address this challenge, we investigated various types of heat transfer in buildings to determine whether it is possible to prevent heat from entering the building. By doing so, we aim to reduce or eliminate the need for air conditioners and other electricity-dependent cooling aids.

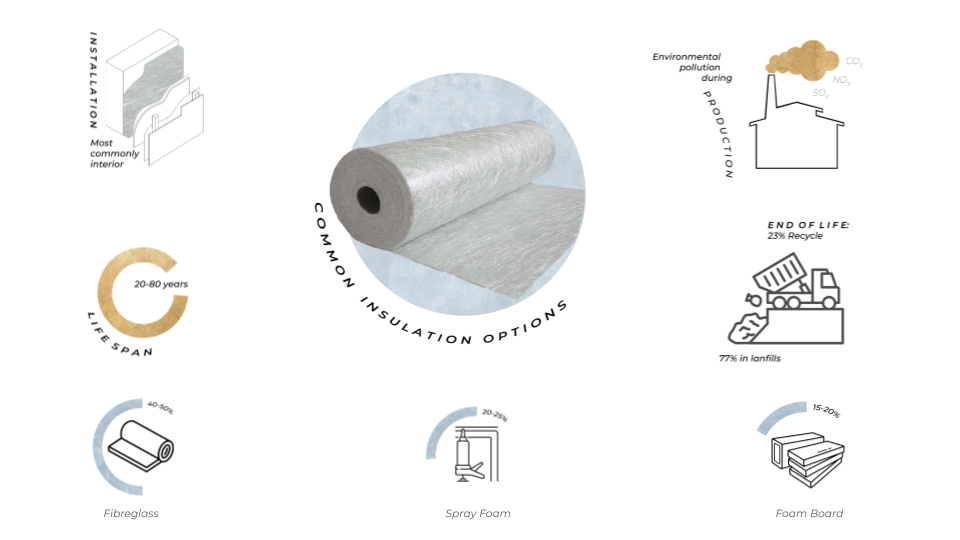

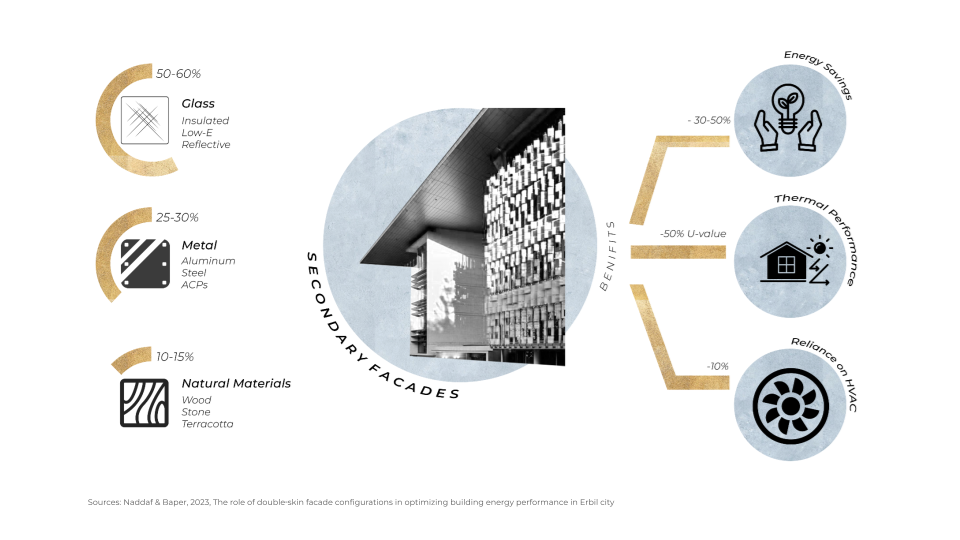

We examined secondary facade systems, which are widely utilized for cooling buildings through methods such as increased insulation or secondary facade skins. However, conventional approaches often prove ineffective or contribute to landfill waste.

Although secondary facades have demonstrated their efficacy in cooling buildings, traditional building materials require greater adaptability to address the rising heat effectively.

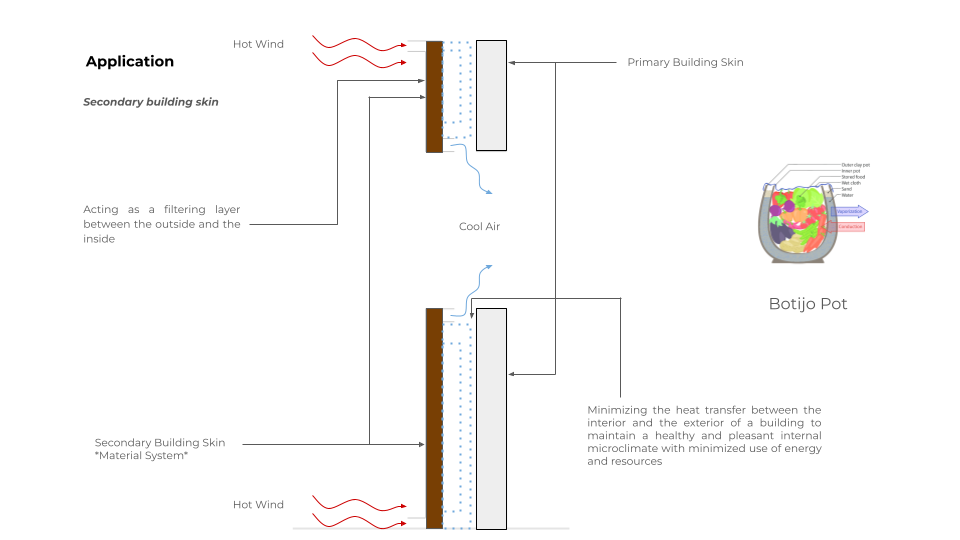

To address this, we explored secondary facade systems in relation to the Botijo pot, an ancient device used to cool water and food by utilizing a hollow clay interior filled with water. We adopted this concept as a precedent for our facade system.

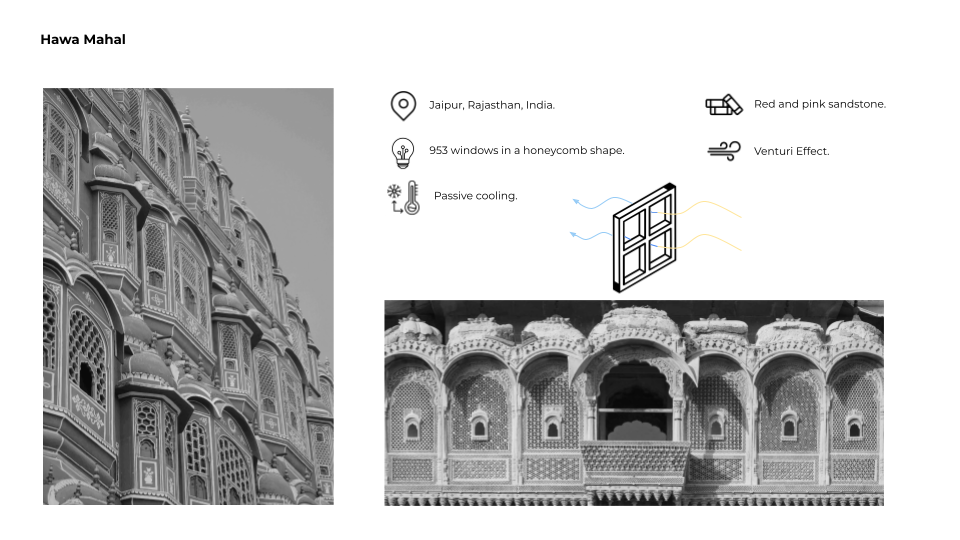

Other precedents and inspirations included the Hawa Mahal, a palace that utilized the movement of wind through a series of small openings to accelerate airflow and create a cooler interior environment. This phenomenon, known as the Venturi effect, served as a significant influence on our facade system design.

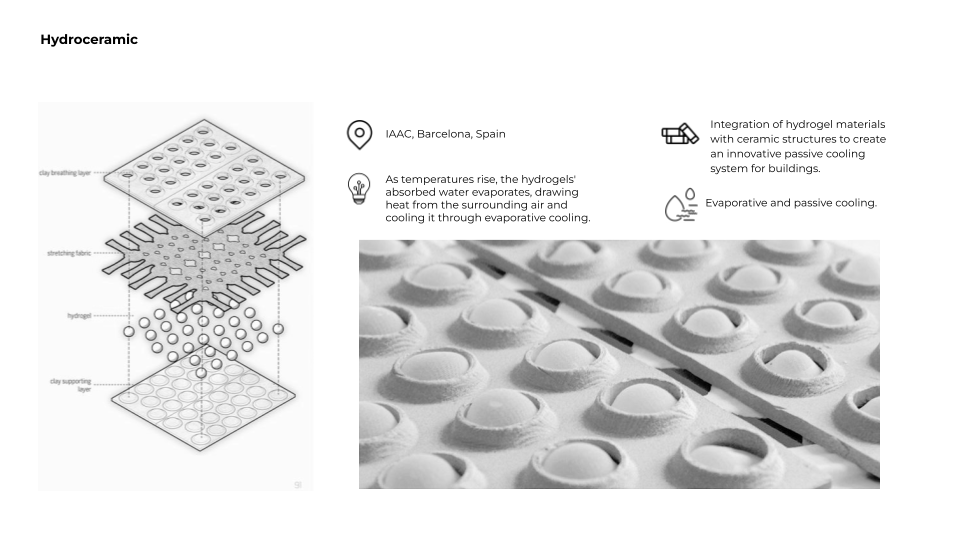

We also examined IAAC’s Hydroceramic, which employs hydrogels and clay as cooling facade materials.

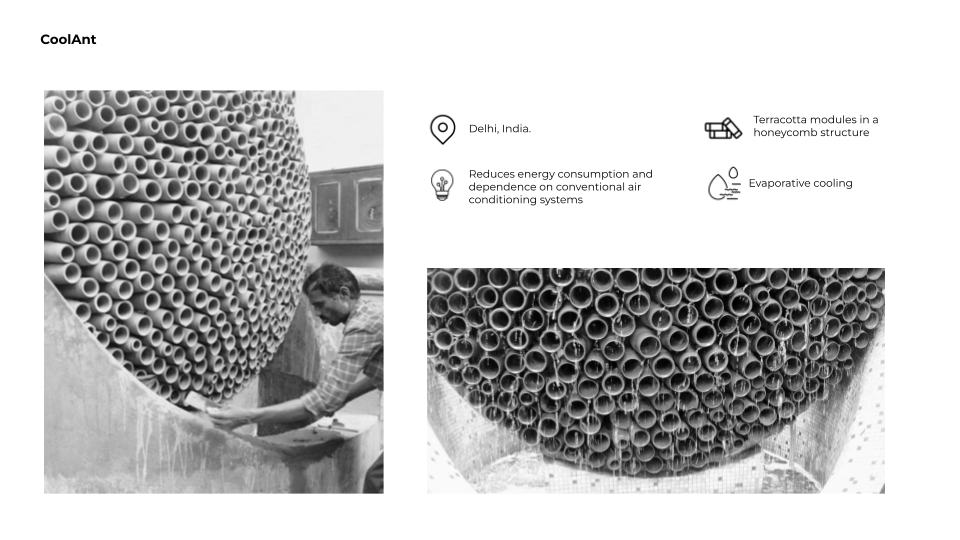

Additionally, we studied CoolAnt, a project that utilized evaporative cooling and liquid water to effectively mimic the function of an air conditioner.

By learning from these examples of cooling solutions and integrating their principles, we developed our design: Wind Wave.

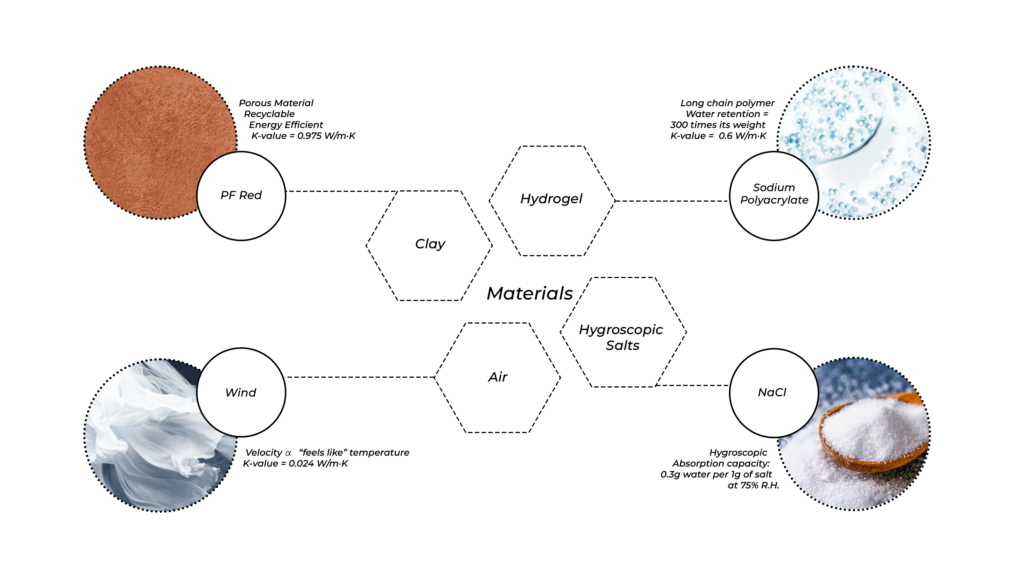

Our material system includes the following components:

- Clay: A porous and recyclable material.

- Hydrogel (sodium polyacrylate): Used for water retention.

- Hygroscopic salts (specifically NaCl): Incorporated within the hydrogel to enable the absorption of humidity in addition to liquid water.

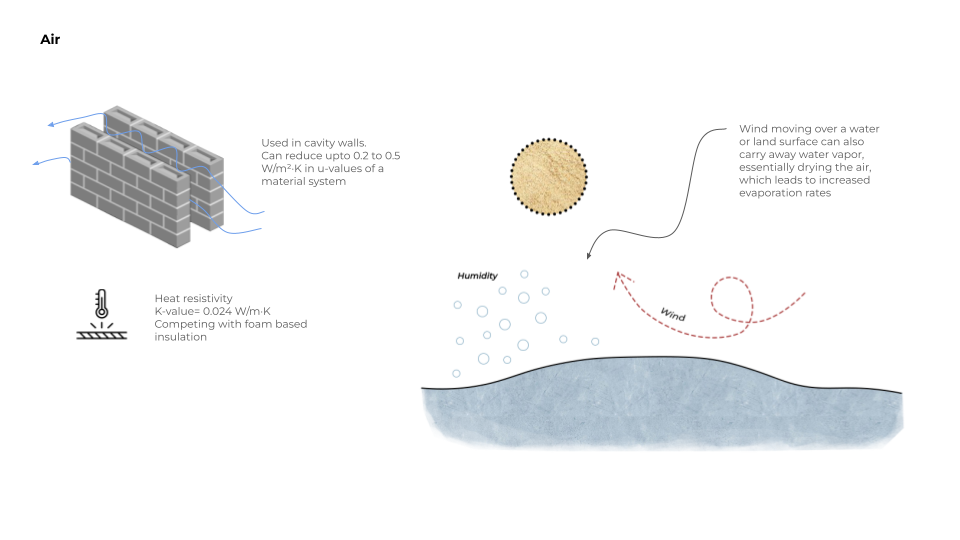

- Wind: Considered a material due to its critical role in the system. Wind is highly effective at cooling and has a low thermal conductivity (K value), making it an ideal component for heat transfer reduction.

By combining these materials, we aim to create a highly efficient and sustainable cooling facade system.

Regarding clay, fired clay is preferred for its strength and durability. It is crucial that the clay remains unglazed to leverage its high porosity. Glazing, while enhancing aesthetics, forms a barrier that limits the clay’s natural ability to absorb and release moisture, which is essential for effective cooling in our system.

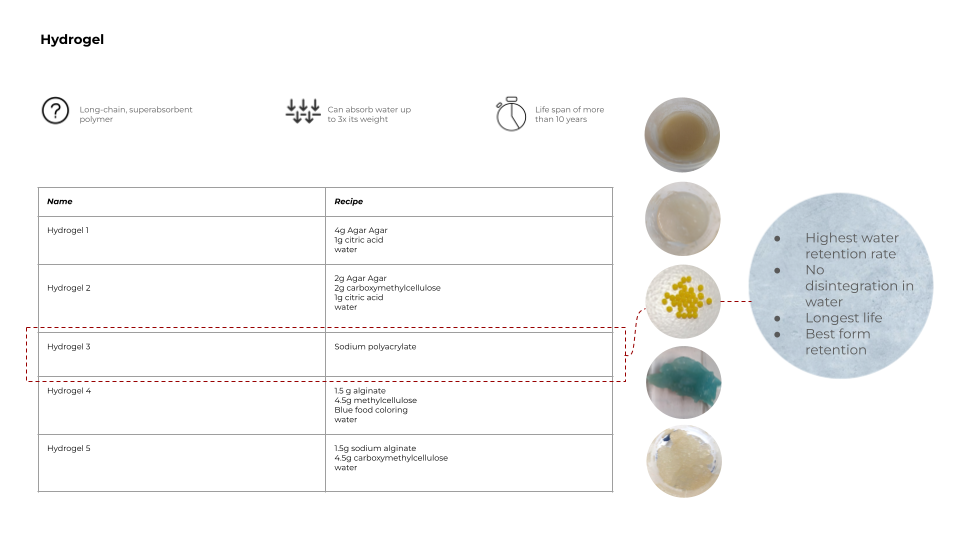

We selected sodium polyacrylate as our hydrogel of choice due to its superior water retention capabilities and extended lifespan compared to other options.

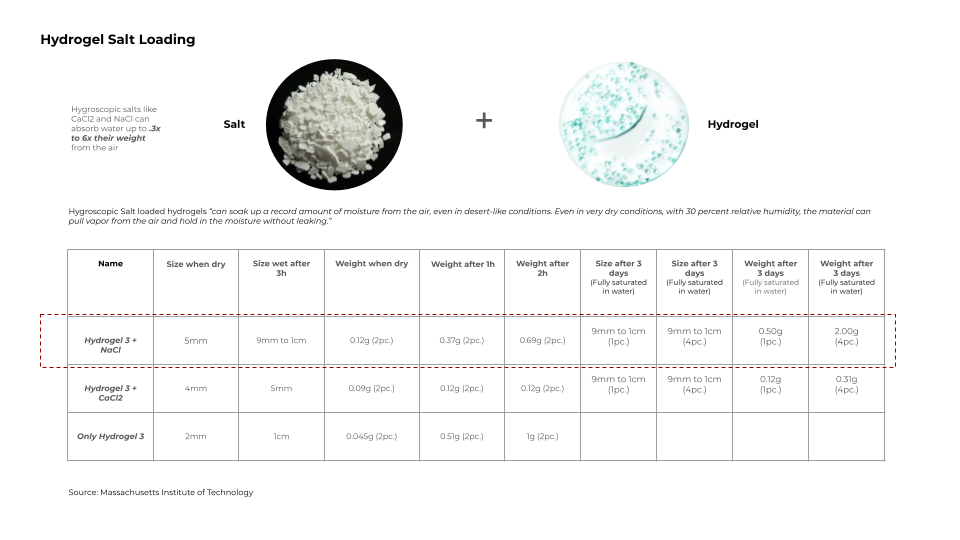

These hydrogels were then enhanced with salts, paralleling a study conducted at MIT. Sodium chloride (NaCl) proved to be the most effective in humidity absorption due to its finer grain size.

NaCl is capable of absorbing 150% of its weight in humidity within one hour, making it particularly effective in high-humidity climates. This dual functionality aids cooling by both dehumidifying the air and retaining water, which allows the wind to pass over and facilitate evaporative cooling.

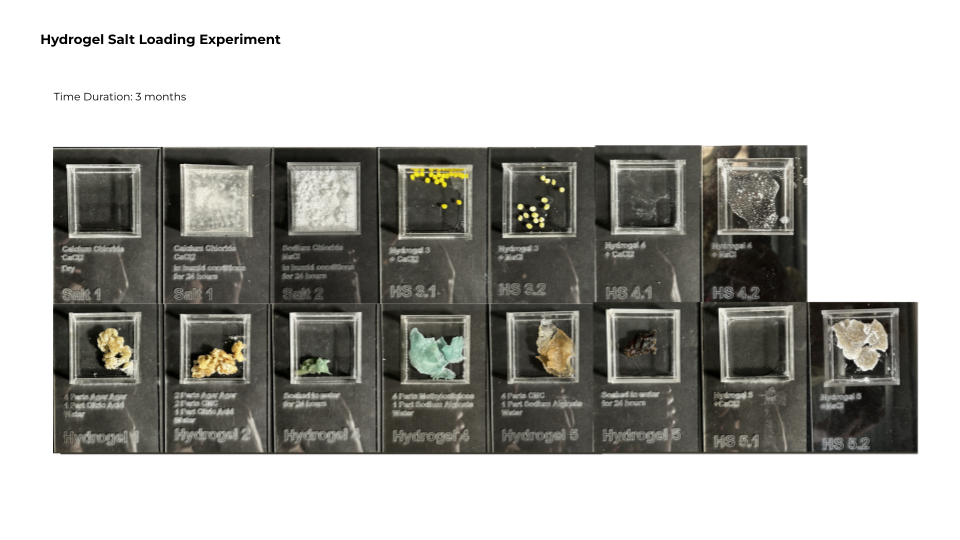

We observed the various hydrogels we had created over a span of three months and selected the final salt-loaded hydrogel based on the results of this study.

Wind was also chosen as a material due to its critical role in the success of the cooling system. A significant part of the WINDWAVE design process focused on understanding and optimizing air movement, particularly over bodies of water, to effectively reduce air temperature.

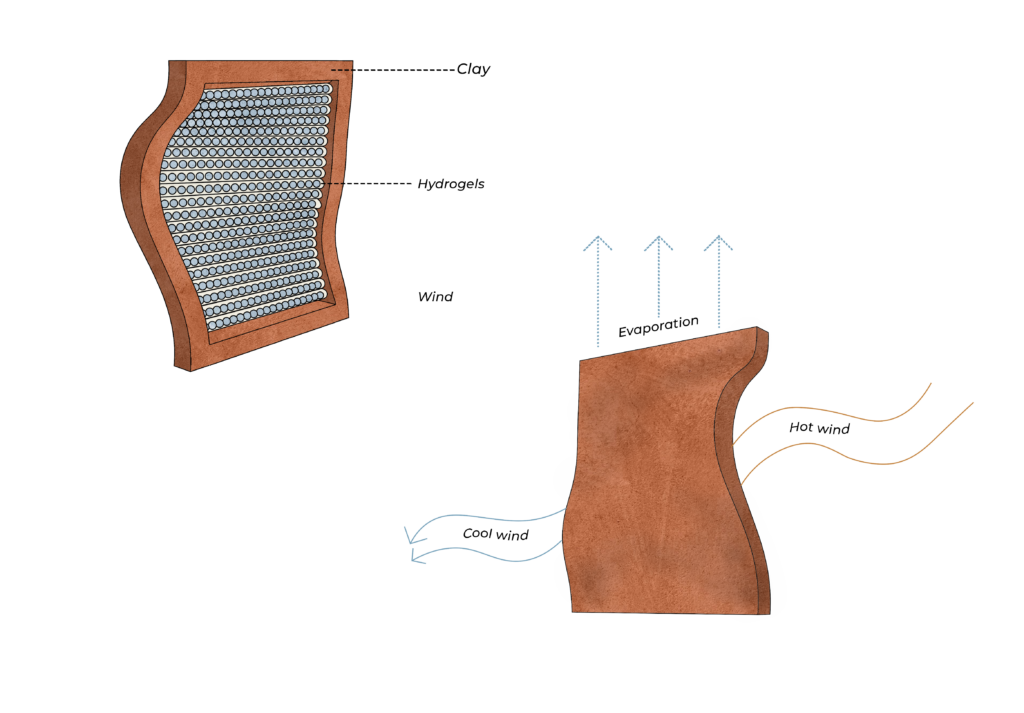

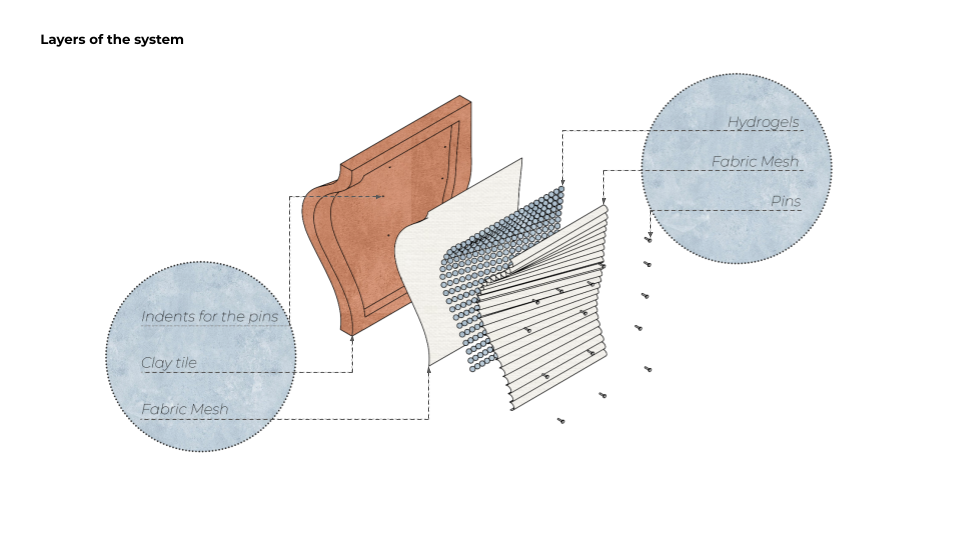

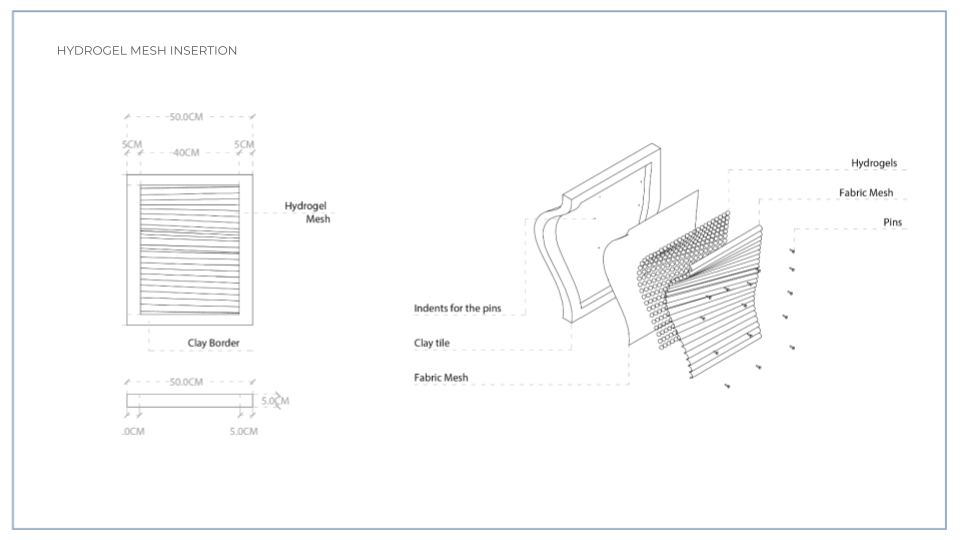

These materials are then integrated into a tile system: clay, hydrogels within a mesh, and the wind that passes over these hydrogels.

This is the system’s composition:

- Clay tile.

- Hydrogels embedded within a mesh.

- Wind passing over the hydrogels for cooling.

The system is designed for sustainability, allowing for the renewal of hydrogels after their end of life. The mesh can be easily removed and replaced, ensuring long-term functionality and minimal waste.

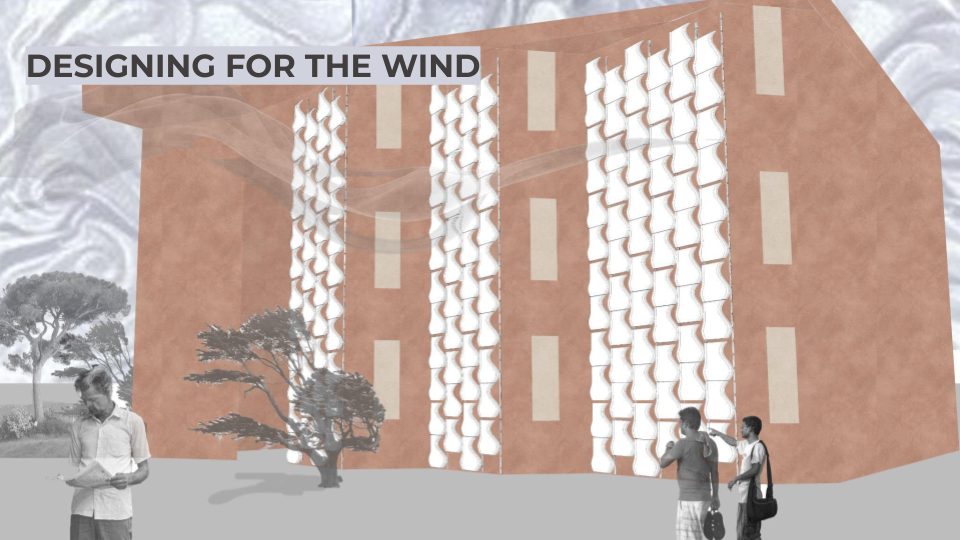

Designing Based on Wind

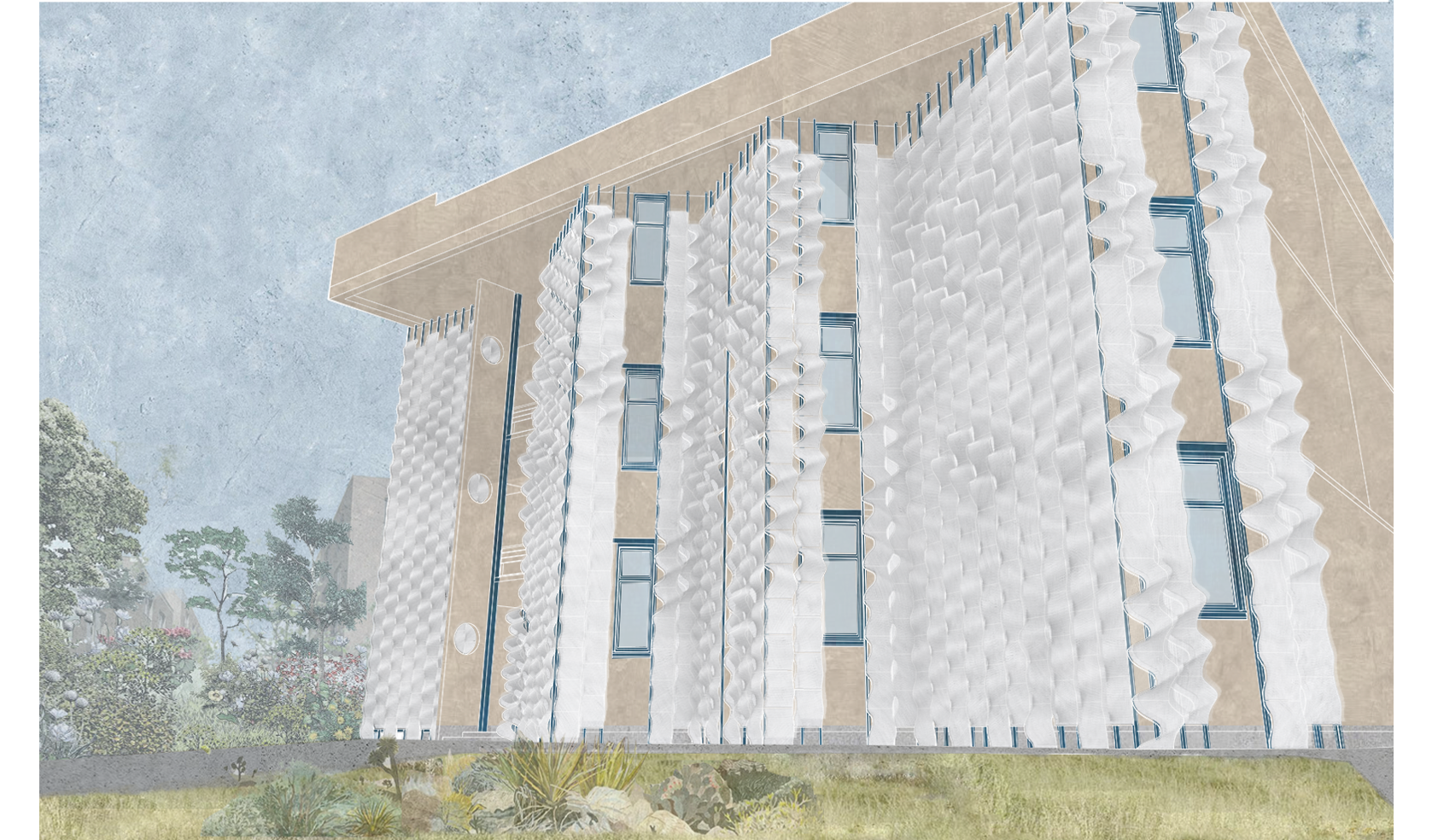

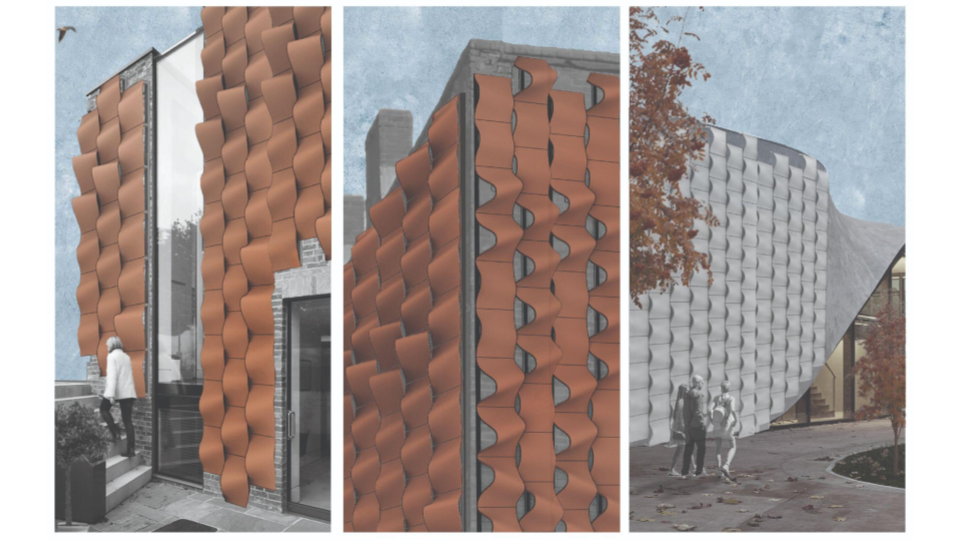

To design effectively with wind, we needed to collect specific data, which necessitated selecting a particular site. We chose a university library for this purpose. The library was selected due to its low insulative building materials and its location in New Delhi—a city currently experiencing numerous extreme heat events, including one in the past couple of weeks. This site provided an ideal testing ground for our cooling system due to its environmental challenges and the need for improved thermal comfort.

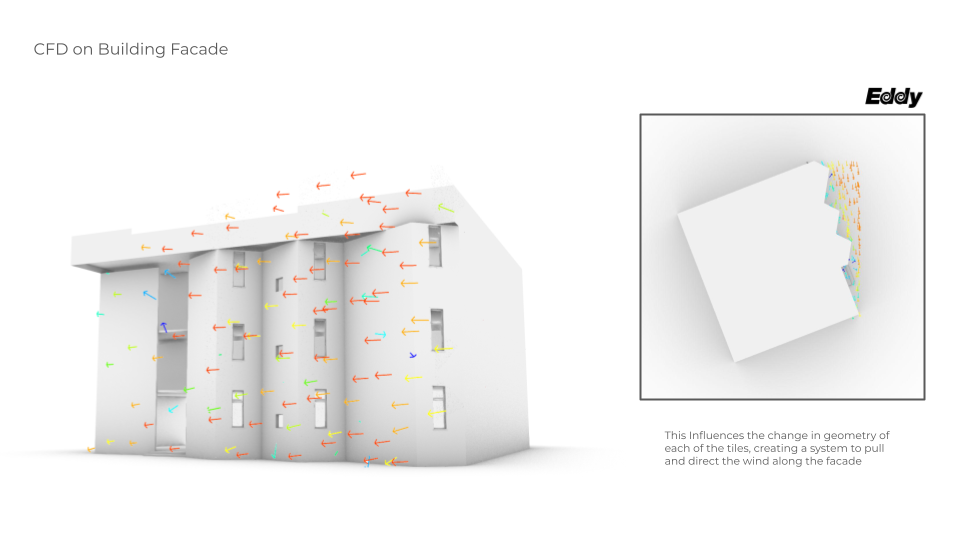

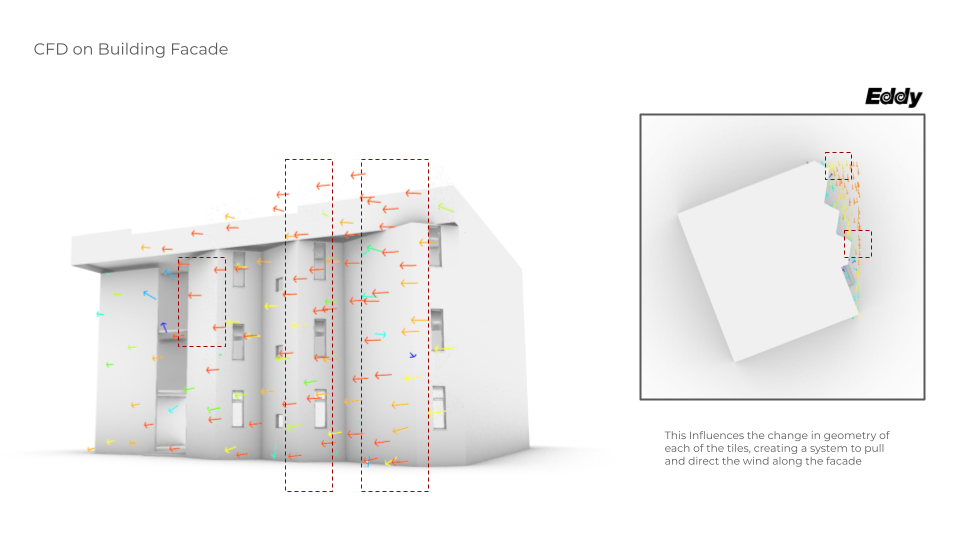

Wind analysis was conducted on the site using Computational Fluid Dynamics (CFD) wind modeling to assess wind directions and strengths throughout the year. An average of these data points was then calculated to ensure optimal wind collection with a static panel design. This approach allows for maximizing the cooling efficiency of the WindWave system by leveraging prevailing wind patterns.

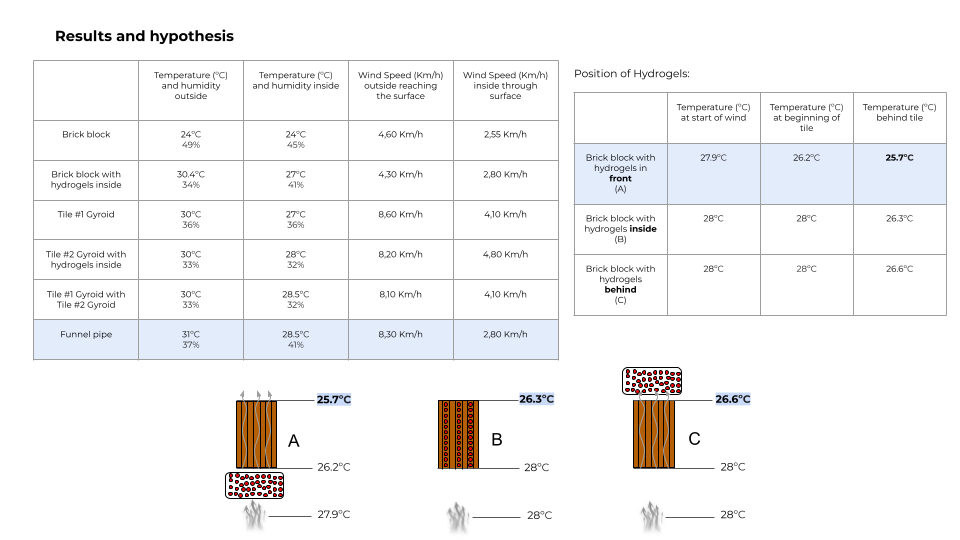

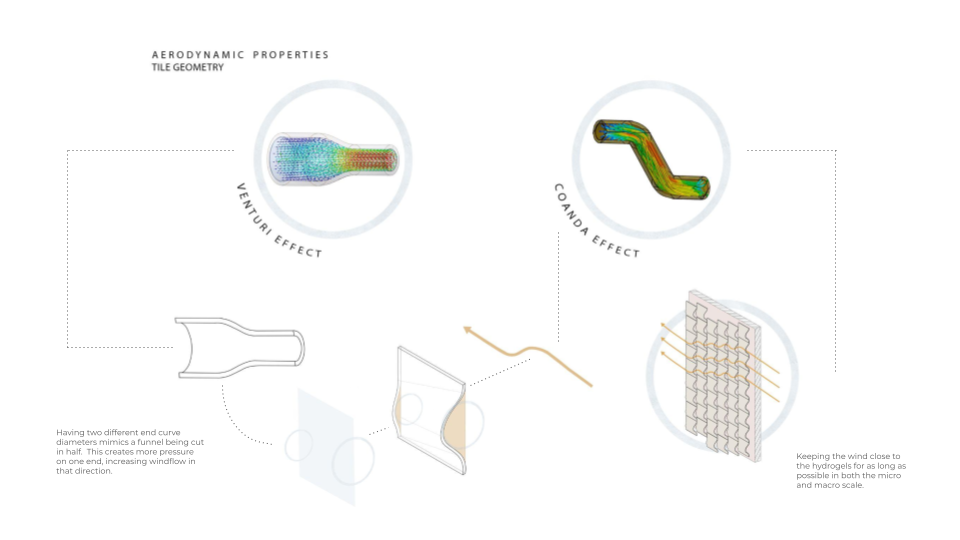

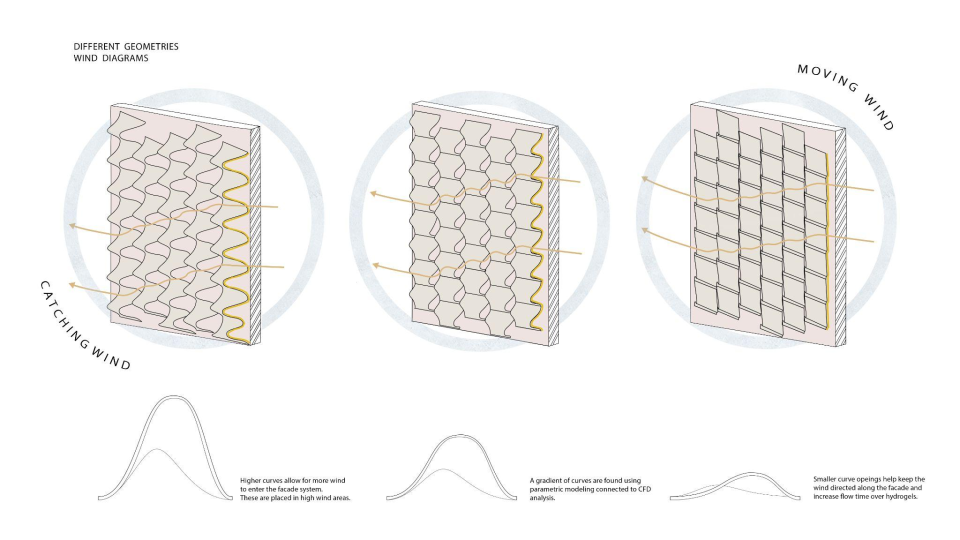

Within our tests of various geometries, the funnel pipe design, which harnesses the Venturi effect, proved to be the most effective. Placing the hydrogels as close as possible to the openings enhanced cooling performance. Consequently, this design was directly incorporated, influencing both the placement of the hydrogels and the overall geometric configuration of the system.

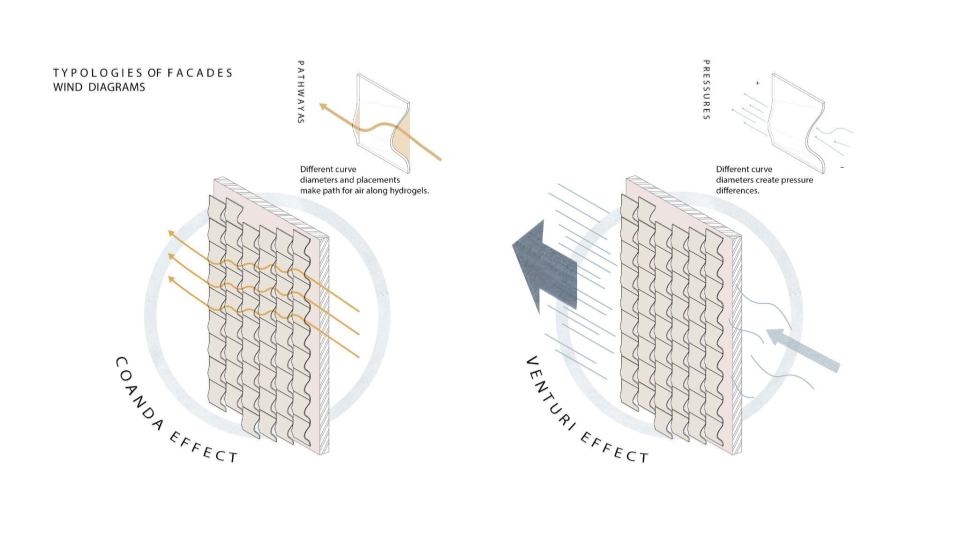

We aimed to utilize both the Venturi effect and the Coanda effect in our design. The Venturi effect occurs due to pressure changes within a space, pulling air from areas of higher pressure to lower pressure, thereby increasing velocity. The Coanda effect involves air becoming attached to a surface for an extended period of time.

By combining these phenomena, we designed a system that gathers air and maintains its flow along the surface of the hydrogels, enhancing cooling. This approach also retains air within the entire facade for a longer duration, further increasing the cooling effect. Consequently, both the individual tile and the overall facade system incorporate these principles, functioning effectively at both micro and macro scales.

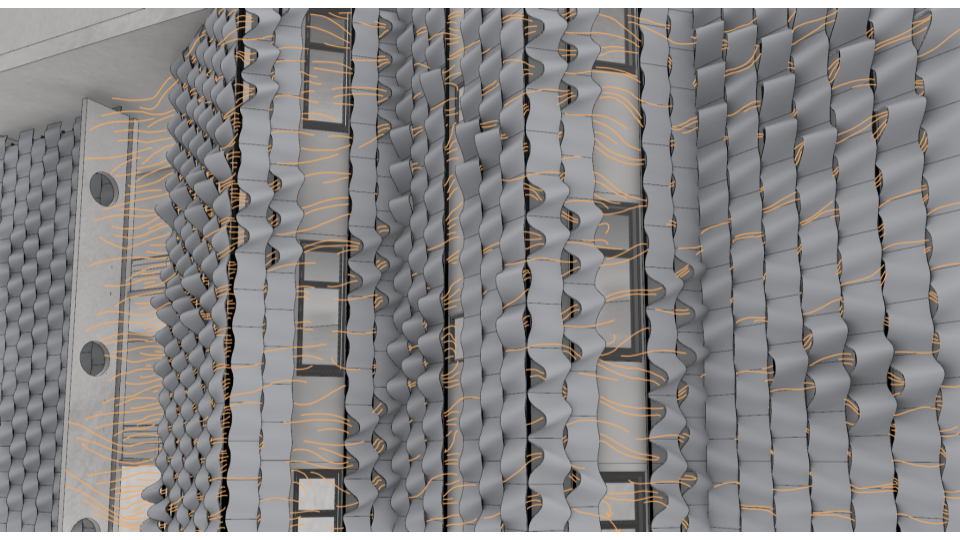

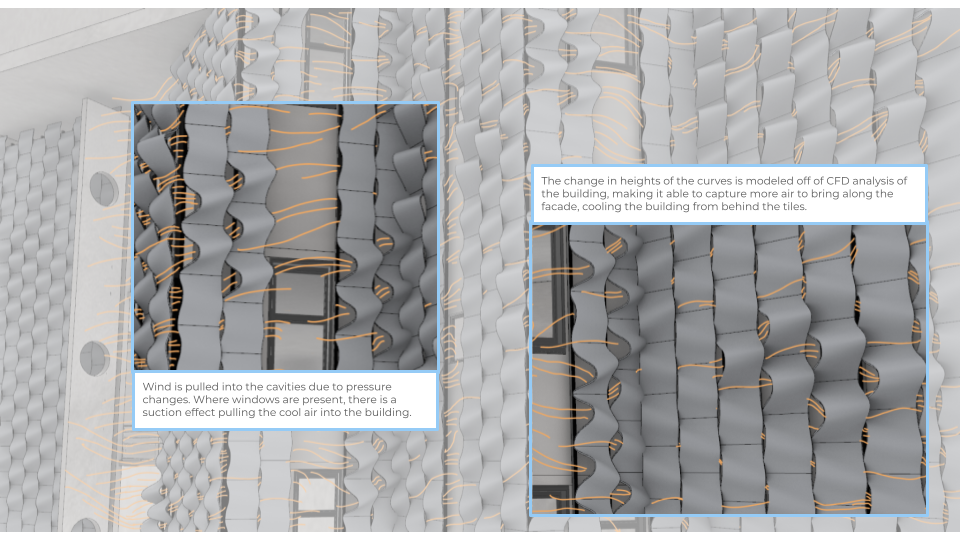

We employed CFD analysis with EDDY3D to demonstrate the effectiveness of our design on the tile itself. The analysis reveals that the air within the space between the hydrogels and the clay surface accelerates, showcasing the Venturi effect. This visualization confirms that our design effectively leverages the Venturi effect to enhance cooling performance.

This effect was demonstrated on both micro and macro scales, illustrating how the system pulls air in and directs it down the facade. This dual-scale approach ensures that the air is effectively channeled throughout the entire facade, enhancing the overall cooling efficiency of the system.

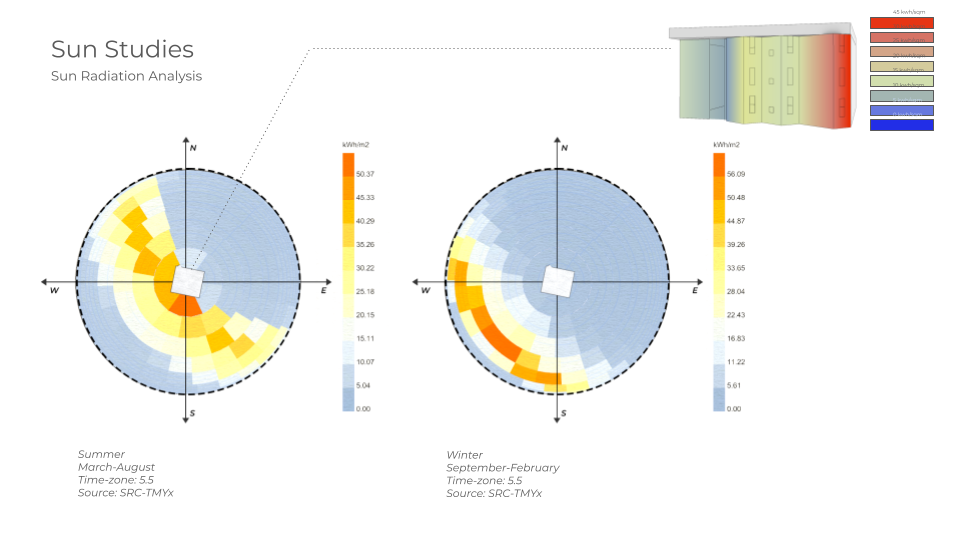

Sun analysis was also conducted to ensure comprehensive coverage of the primary building skin, aimed at minimizing heat transfer. This analysis helps optimize the placement and orientation of the WindWave system components to effectively shield the building from solar heat gain, thereby enhancing its thermal performance.

CFD analysis of the facade itself was conducted both manually and parametrically. This analysis was used to understand where air movement is strongest and weakest.

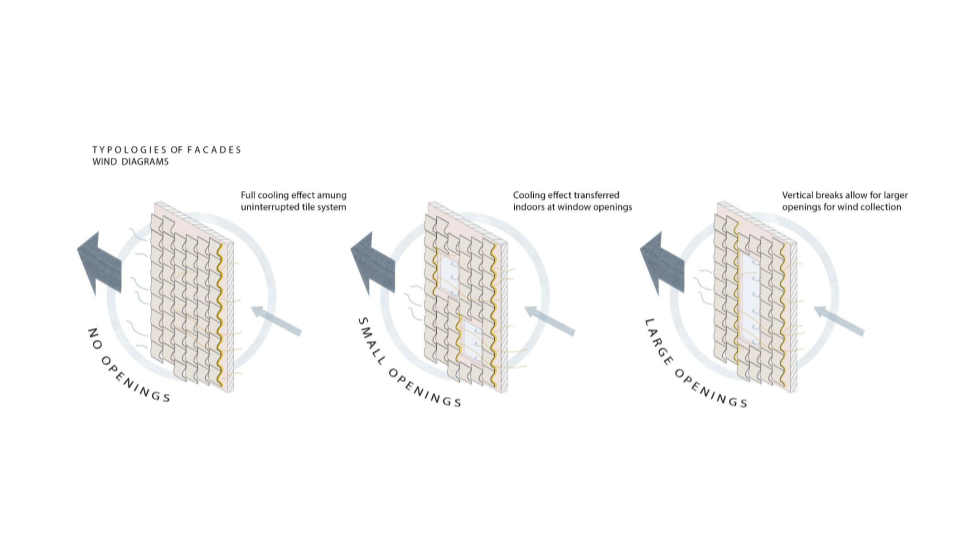

These findings informed a system that creates a gradient of curve sizes in the facade design. Larger openings were strategically placed in areas with high wind velocities to maximize air intake into the facade system. Conversely, smaller openings were placed in areas with lower wind velocities to optimize the retention of air within the space between the facade system and the existing building wall. This design approach ensures that air spends more time passing over the hydrogels, enhancing the cooling effectiveness of the system.

In the facade design, larger openings were strategically placed in areas calculated to have higher wind velocities, while smaller openings were positioned in areas with lower wind velocities. This gradient of openings facilitates maximum air intake into the facade system where wind is strongest, while ensuring efficient retention of air within the system where wind is weaker.

Furthermore, the placement of these openings allows for directed airflow into the building, optimizing the cooling effect by effectively channeling cooled air over the hydrogels and into the interior spaces.

This system operates based on pressure differentials that guide airflow in specific directions. When a window is opened, the cool air generated by the facade system is drawn into the building due to these pressure differentials. However, increasing the number of openings in the facade can reduce the time available for air to cool within the system, potentially impacting its overall cooling efficiency.

That sounds like an innovative approach to dynamically adjust facade geometries based on real-time wind direction inputs. This capability ensures optimal air collection efficiency for any facade configuration, leveraging CFD analysis of the site and building to adapt the system accordingly. This adaptive design not only enhances cooling performance but also demonstrates a versatile application of your technology across various architectural contexts.

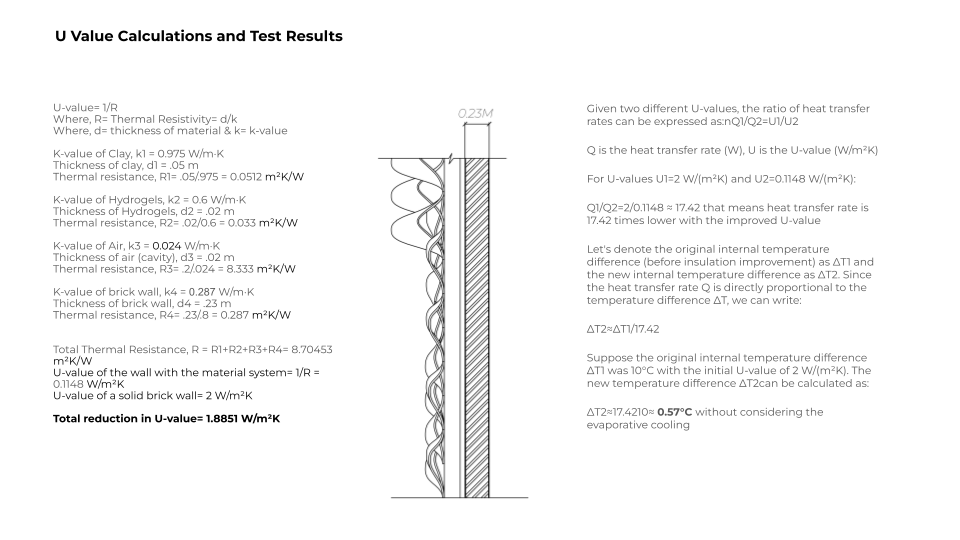

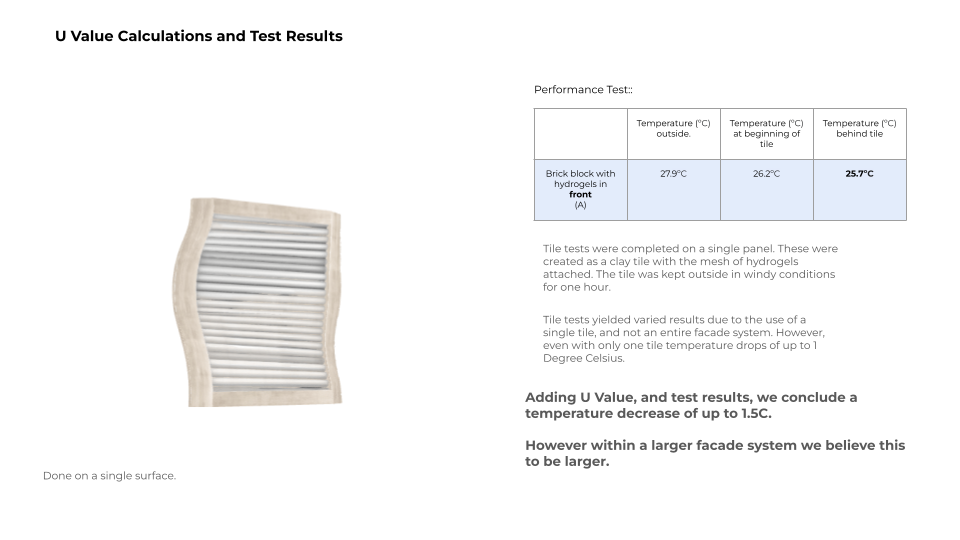

To assess the performance of our system, we calculated the overall U-value of the wall, considering a thickness of 20 cm. Our findings indicated that the application of our system significantly reduces the U-value of the wall. This reduction in U-value translates to a temperature decrease of approximately 0.57 degrees Celsius, highlighting the cooling effectiveness of our system in improving thermal comfort.

Through our testing, we observed temperature reductions ranging from 1 to 2 degrees Celsius up to 4 degrees Celsius when implementing our system. These findings demonstrate the substantial cooling impact achieved by our technology, contributing to enhanced comfort and energy efficiency in buildings.

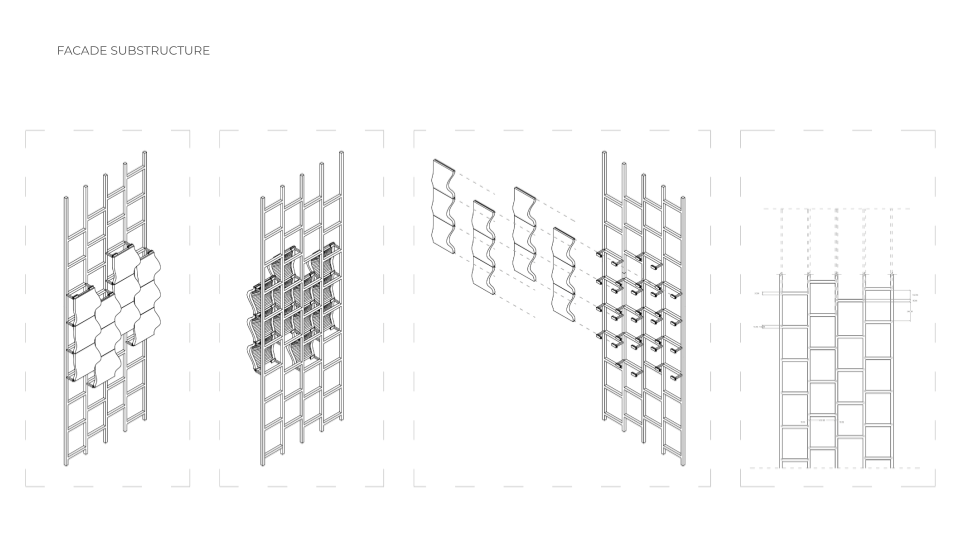

The assembly of the system begins with the clay tile as the base layer. On top of this tile, a mesh fabric is placed, followed by the hydrogels. Another layer of mesh fabric is then positioned over the hydrogels, securing them in place. This assembly ensures that all components are effectively held together within the facade system.

Following assembly, the system is slid onto the facade using specific brackets designed to securely hold the clay tile in place. These brackets ensure there is a gap between the building skin and the facade system, facilitating airflow for cooling purposes.

Once mounted on the facade, the system is then secured onto the substructure, providing structural support and ensuring stability of the entire assembly. This installation method ensures efficient operation and longevity of the WindWave cooling system.