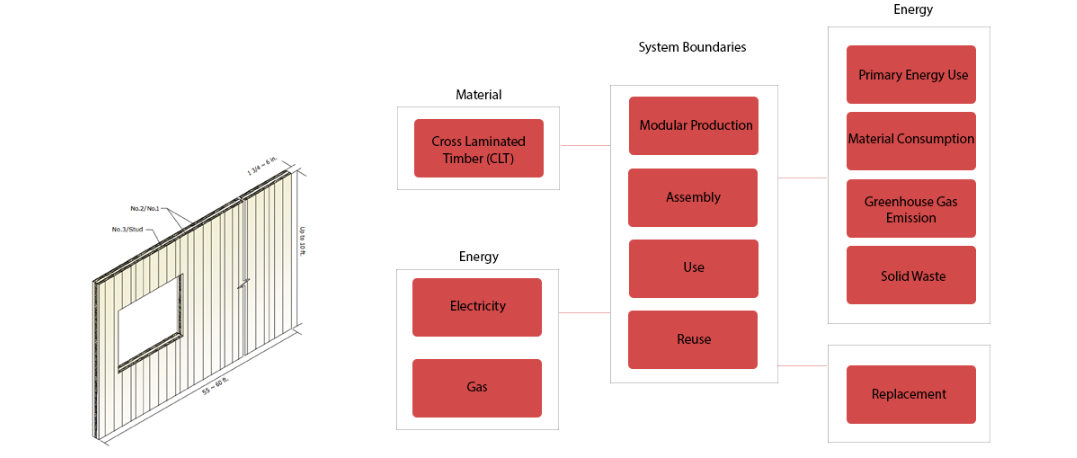

For our MaCAD Studio project, we wanted to explore the idea of circularity during the assembling/disassembling stage of the various programmatic functions housed by the building structure. The main materials employed are CLT and Reinforced Steel, of which we picked the first to be the focus of our study since it is the primary material involved in the construction of the modules. We calculated values for the amount of energy used throughout the fabrication of these pieces, as well as the greenhouse gas emissions and the recyclability factor. After combining these values into a table, we compared the energy used for the construction and assembly of one module from scratch to the construction and then adaptive assembly of another module by replacement/reuse from our kit of parts.

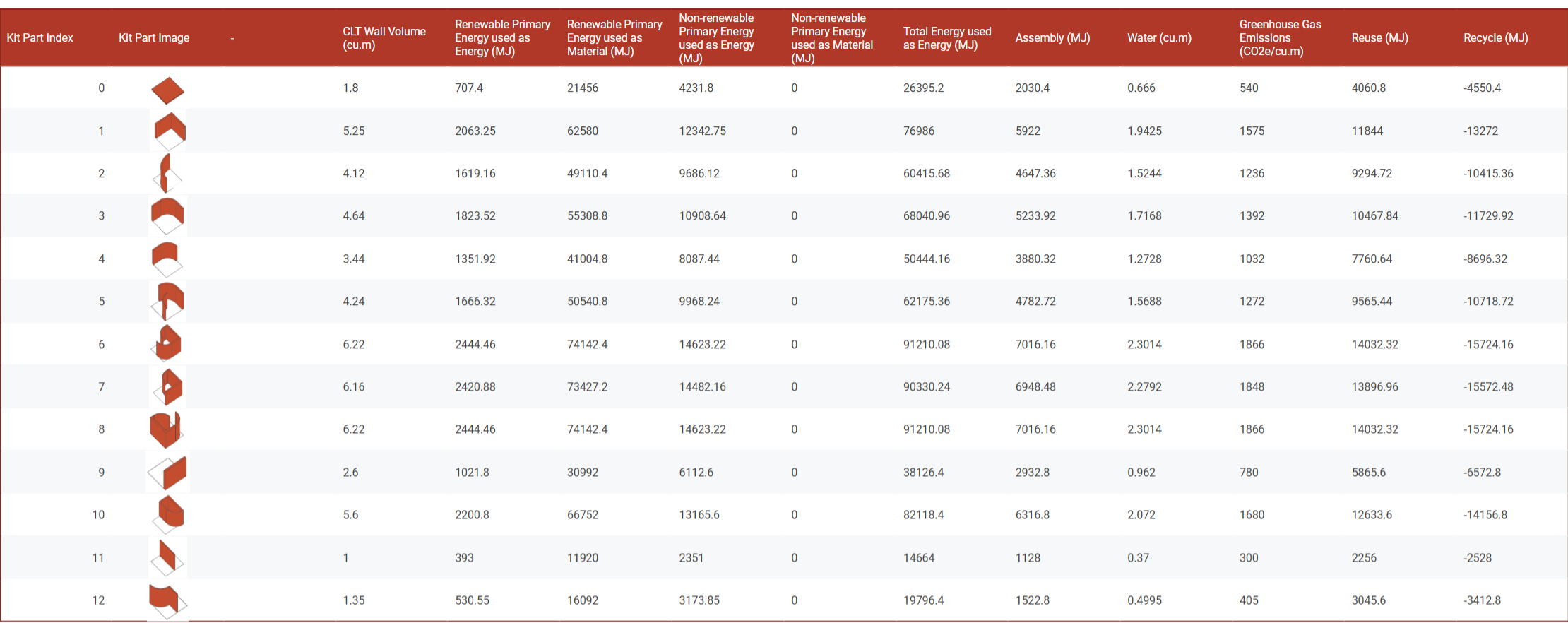

Our modular units are designed to be replaceable with units of the same area dimensions, each following a 3 by 3 m grid. To remodel a unit into another, the ceiling, floor and structural framing can be maintained and only the walls would be replaced. In this study, we compare the total CLT area used in walls of three replaceable modules.

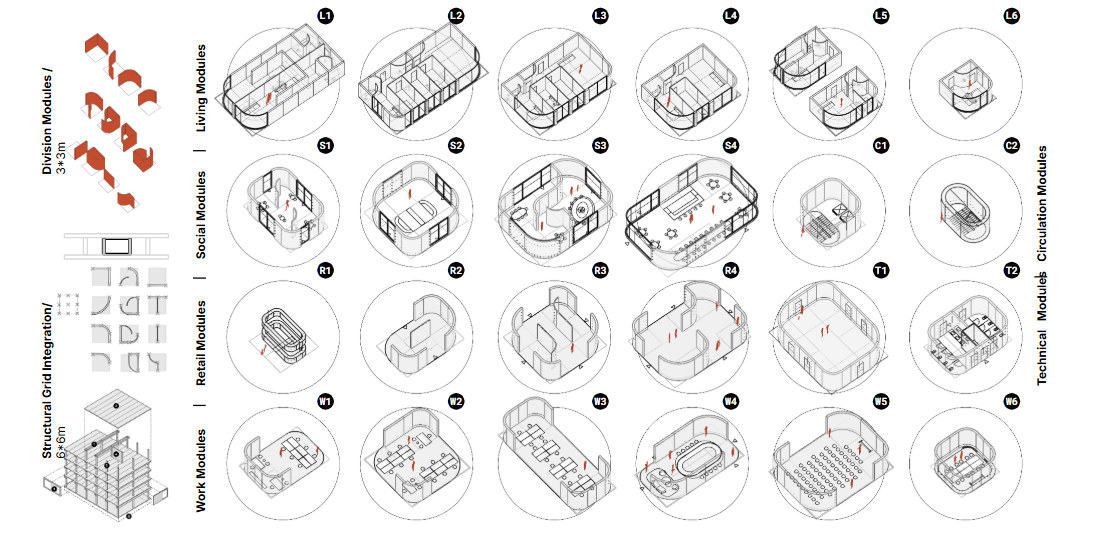

Below is the full module set for our building. The twenty modules are all constructed from the same kit of parts as shown in the upper left corner of the image.

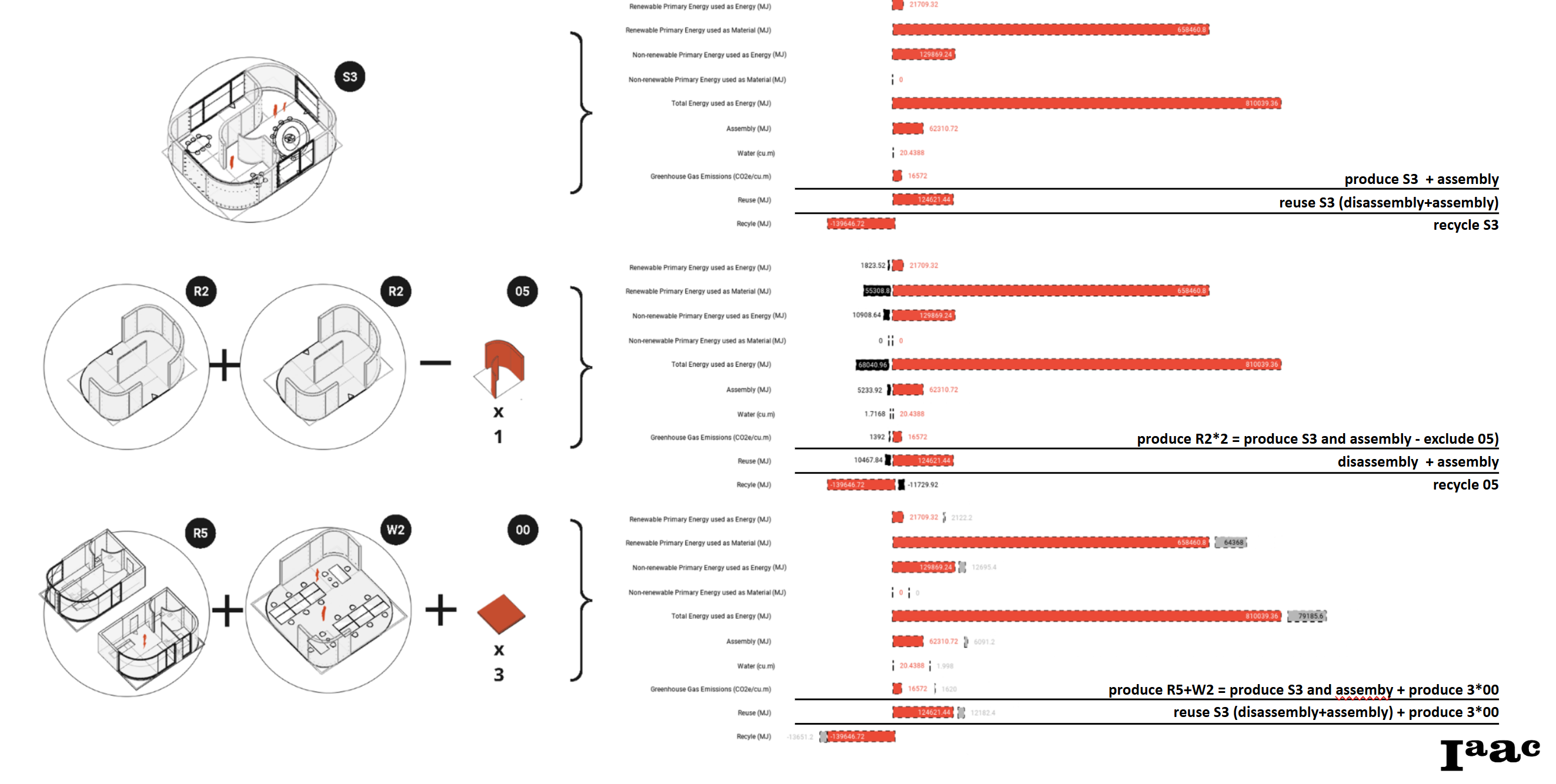

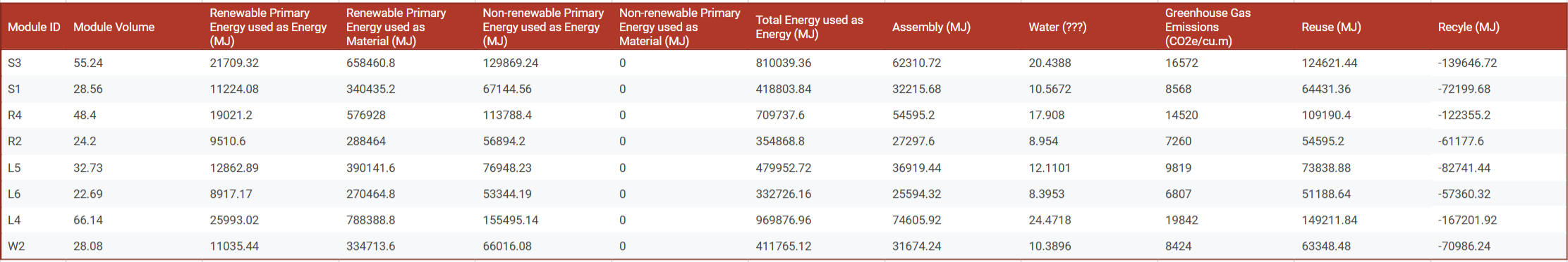

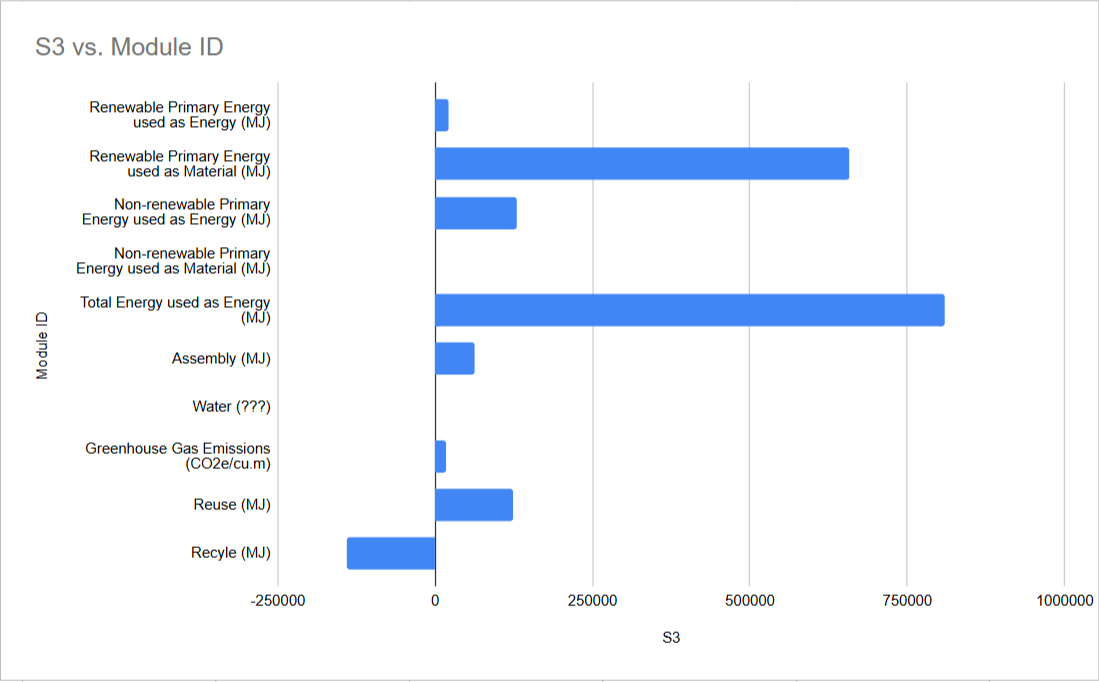

The diagram below showcases a breakdown of three scenarios (S3, R2, and R5+W2), each representing different building configurations and their associated environmental performance metrics. These scenarios include material production, assembly, disassembly, reuse, and recycling processes. Accompanying these scenarios are numerical data for energy consumption, water usage, greenhouse gas emissions, and material reuse or recycling potential.

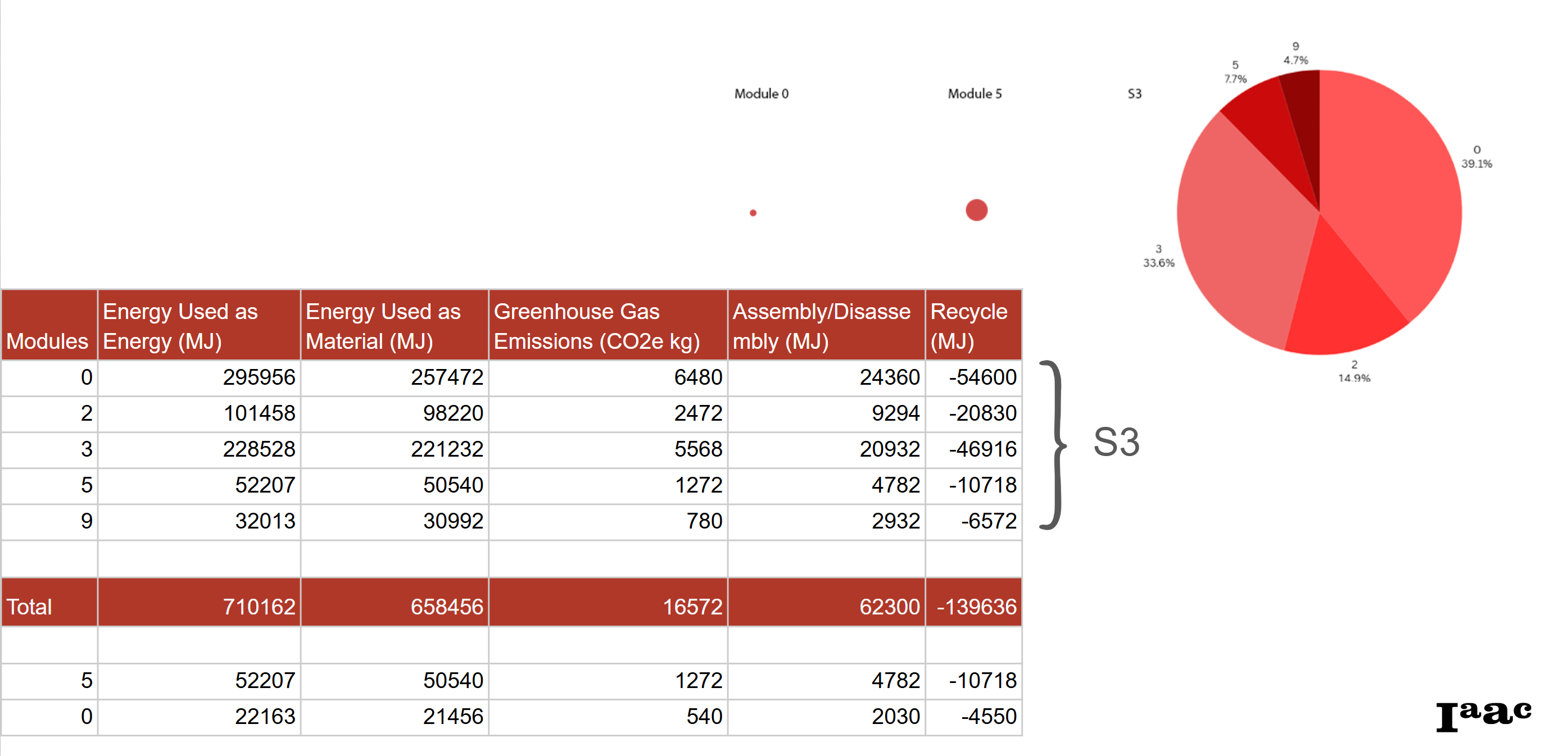

We then list out values extracted for one of our completed module units, S3, and place them next to those that can be added in to create multiple other units as shown in the previous image. This allows us to compare and understand how energy values vary between the different units and their assemblage, with the goal to minimize energy consumption and greenhouse gas emissions as our units cater to multiple programmatic functions and remain interchangeable.

Energy Consumption for Interchangeable Units in a Mixed Use Building Typology is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in Advanced Computation for Architecture and Design – 2024-2025 by the student(s) Mahnoor Fatima, Scott Lebow and Seda Soylu during the course MaCAD 24/25 ACESD Theory with Nadja Gaudillière-Jami.