Abstract

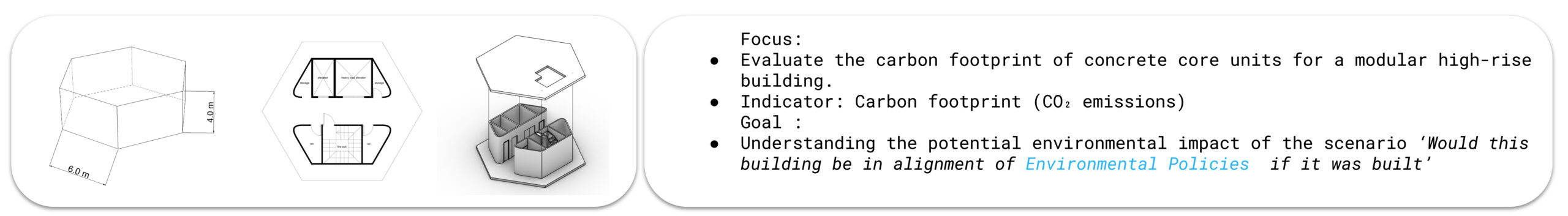

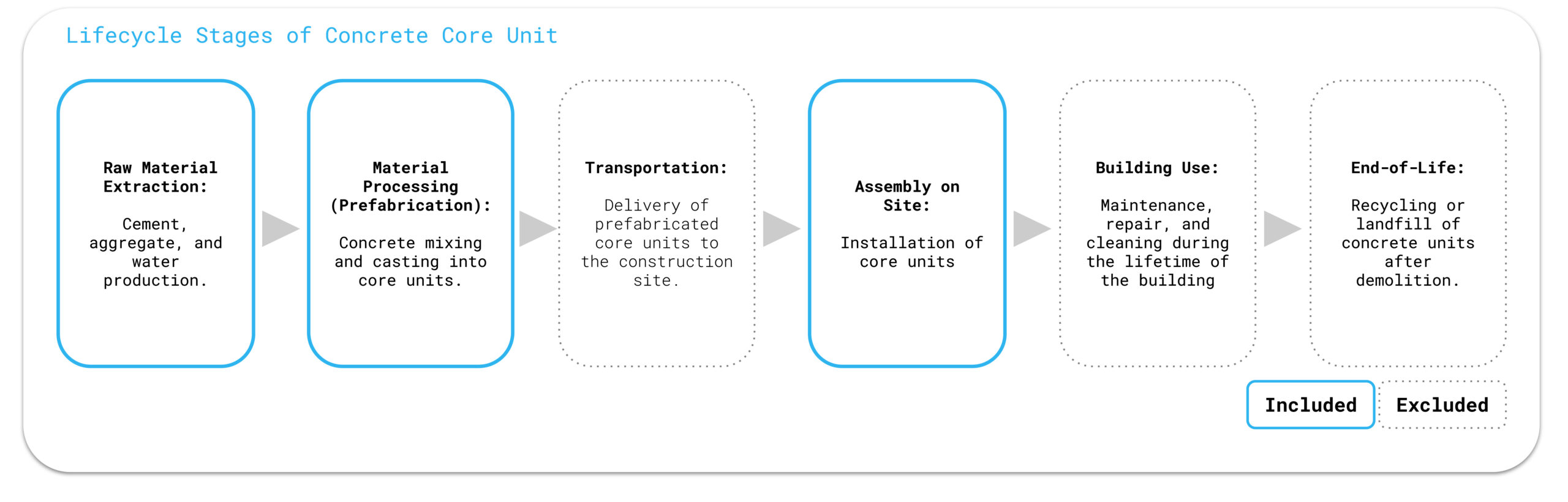

This project evaluates the carbon footprint of concrete core units in modular high-rise construction, using CO₂ emissions as the primary indicator. The goal is to assess the potential environmental impact and determine if the proposed building aligns with environmental policies. Lifecycle stages analyzed include raw material extraction, material processing, transportation, assembly, and end-of-life, with data sourced from various regional databases, analytical tools, and software tailored to specific construction site regulations.

Key findings highlight the benefits and challenges of modular design. While it reduces construction waste and extends the building’s lifetime during use, its processes require optimization to further minimize environmental harm. Cement production is identified as the most impactful stage, contributing 58.7% of the total carbon footprint. Potential improvements include the use of recycled aggregates and alternative materials like fly ash to replace Portland cement. Furthermore, leveraging concrete’s recyclability at the end-of-life stage can facilitate a circular construction process, enhancing overall sustainability. These insights aim to guide environmentally conscious design practices in modular construction.

System Boundaries Diagram

Relevant Sources for the Life Cycle Inventory

Relevant sources to each step within our scope of the the life cycle can come from different databases, analytical tools, and software’s and can depend on the country of the construction site and what governor body sets the regulations and standards

Some examples include: NMD on the Dutch construction industry, ELCD on Europe, USLCI in the USA, DEA v.2 on Japan , AusLCI on Australia

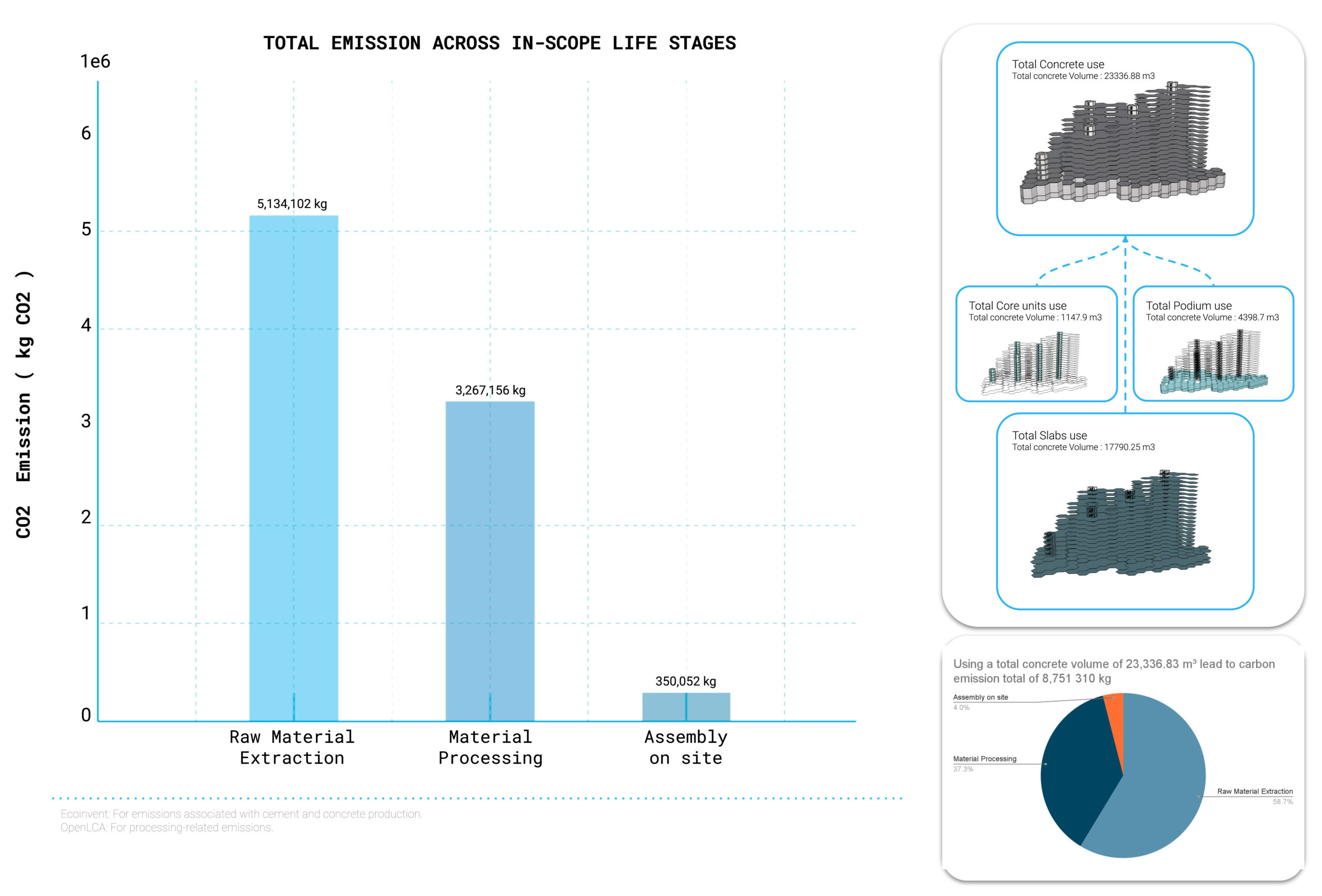

Data Visualization of Results

Key Findings:

- Modular design consideration: While modular design minimizes construction waste and extends building lifetime during the use stage, its construction process can still be optimized to further reduce environmental harm.

- Cement production dominance: The cement production stage dominates over other stages and accounts for the highest environmental impact, with 58.7% of the in-scope analysis.

- Potential improvements: Among possible improvements are the use of recycled aggregates or replacing Portland cement with fly ash to reduce CO₂ emissions.

- End-of-life opportunities: utilizing concrete high recyclability potential can complete a circular construction process.