Introduction to Digital Fabrication

In contemporary architectural practice, digital fabrication has opened new possibilities for designing and producing building components with precision, efficiency, and expressive complexity. Among the most widely used methods—laser cutting, CNC milling, 3D printing, and robotic fabrication, each offers unique material, geometric, and performative potentials. For this assignment, we explore these techniques through the creation of a modular façade system. Rather than remaining static, our module is conceived as a kinetic element: a component capable of movement, responsiveness, and spatial transformation. By integrating motion into the logic of digital fabrication, we aim to redefine the façade not only as an enclosure, but as an active, adaptive interface between the building and its environment.

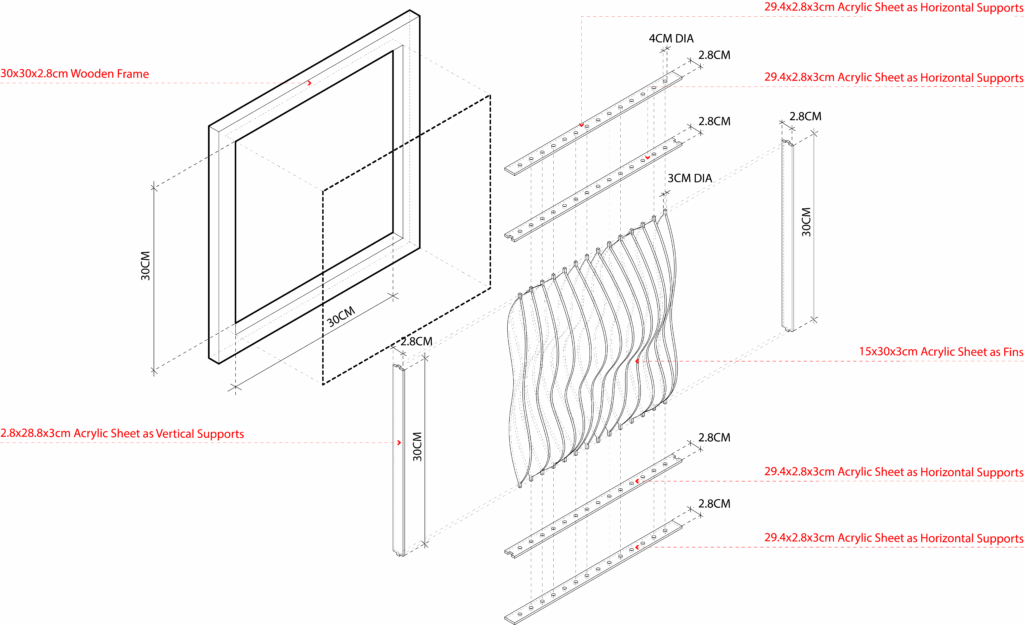

Laser Cutting-KineFold

A Dynamic Laser-Crafted Kinetic Facade Module

A modular kinetic façade where interlinked vertical elements move in a cascading chain reaction, creating fluid wave patterns across the surface. Made from transparent acrylic, the system produces calming motion and soft ambient sound as each element triggers the next. It transforms the façade into a living, responsive skin that brings lightness, rhythm, and sensory comfort to urban environments.

The assembly of the kinetic façade module is based on a simple but effective laser-cut system. Two primary supports—positioned at the top and bottom—contain precisely cut holes that accommodate the pivots for the rotating panels. These pivots allow each laser-cut panel to move freely, enabling the kinetic behavior of the façade. Additional side supports are integrated into the structure to stabilize the module, ensuring it remains self-standing while maintaining the alignment and smooth motion of the panels. This assembly strategy allows the façade to be lightweight, modular, and easily fabricated and reconfigured.

This kinetic module can be deployed across façades of varying scales, from small pavilions to large architectural envelopes. At smaller scales, the module can function as a shading device, privacy screen, or interactive surface that responds to user input. When expanded to larger building façades, the same system can operate as a dynamic environmental mediator, modulating light, ventilation, and visual permeability across the façade surface. Its modular nature allows it to adapt to different geometries, densities, and structural logics, making it suitable for both low-rise and high-rise applications. By scaling the components and adjusting the actuation strategy, the system maintains its kinetic qualities while integrating seamlessly into diverse architectural contexts

CNC Milling- The HIVE

A Dynamic CNC-Crafted Kinetic Facade Module

The Hive is a kinetic façade made using CNC techniques to precisely craft each hexagonal panel. Each panel revolves around its axis, creating a moving surface that changes with its environment. Kinetic façades like The Hive represent the future of building design, adding motion and adaptability to otherwise static surfaces.

For the CNC-milled module, the system is organized around a central pivot that enables full 360-degree rotation. The components are machined with high precision, allowing the pivot to fit securely while permitting smooth, continuous motion. This rotational capability makes the module highly adaptable, enabling it to modulate light, airflow, and visual openness simply by adjusting its orientation. When aggregated into a façade, the CNC-based modules can be calibrated at different angles to create dynamic patterns, responsive shading systems, and variable porosity across surfaces of any scale. Whether applied to compact installations or large building envelopes, the CNC fabrication process ensures structural accuracy, geometric consistency, and a robust, fully rotational kinetic performance.

In the future, this product can evolve into a versatile kinetic system for both architectural and interior applications. Its modularity and simple rotational mechanism make it suitable for adaptive façades, responsive shading systems, and customizable privacy screens. With further development, the product could incorporate sensors or automated controls, allowing it to react dynamically to environmental conditions such as sunlight, wind, or occupancy. Its lightweight, digitally fabricated components also make it ideal for temporary installations, exhibitions, and retrofit projects where quick assembly and flexibility are essential. As it matures, the product has the potential to become a scalable, intelligent solution for creating dynamic, performance-driven surfaces across a wide range of design contexts.

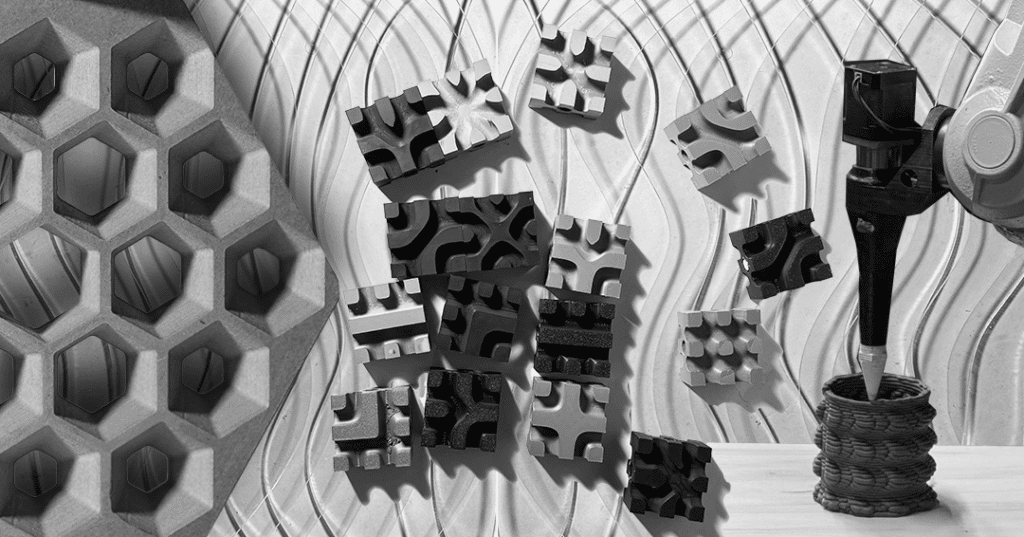

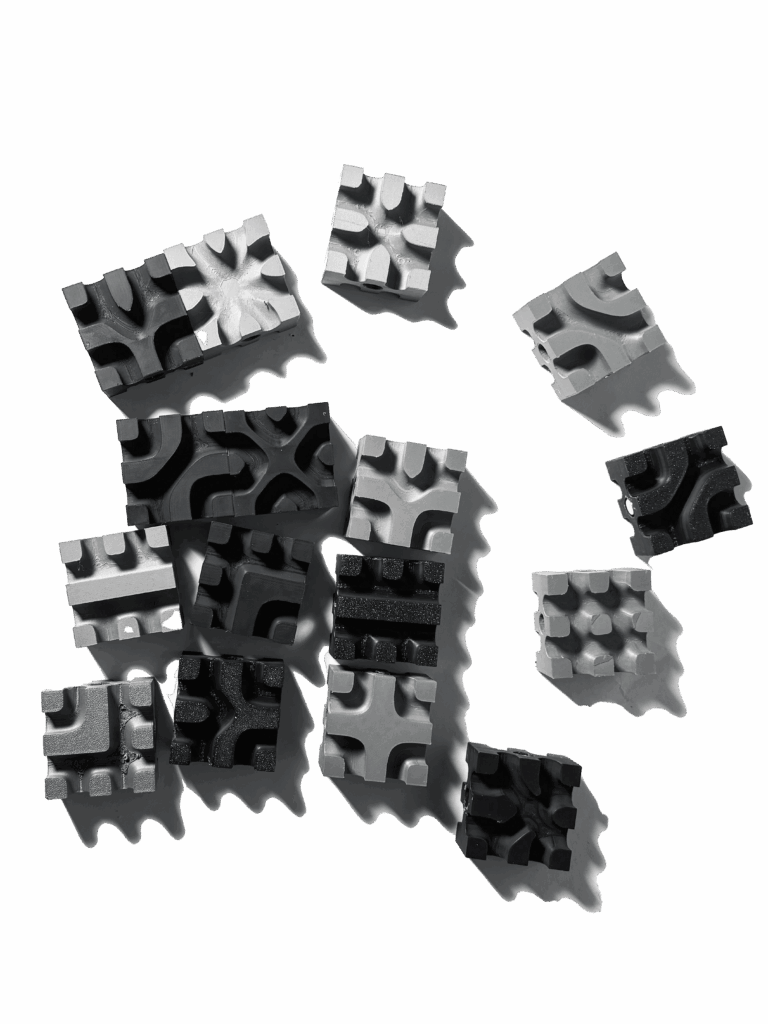

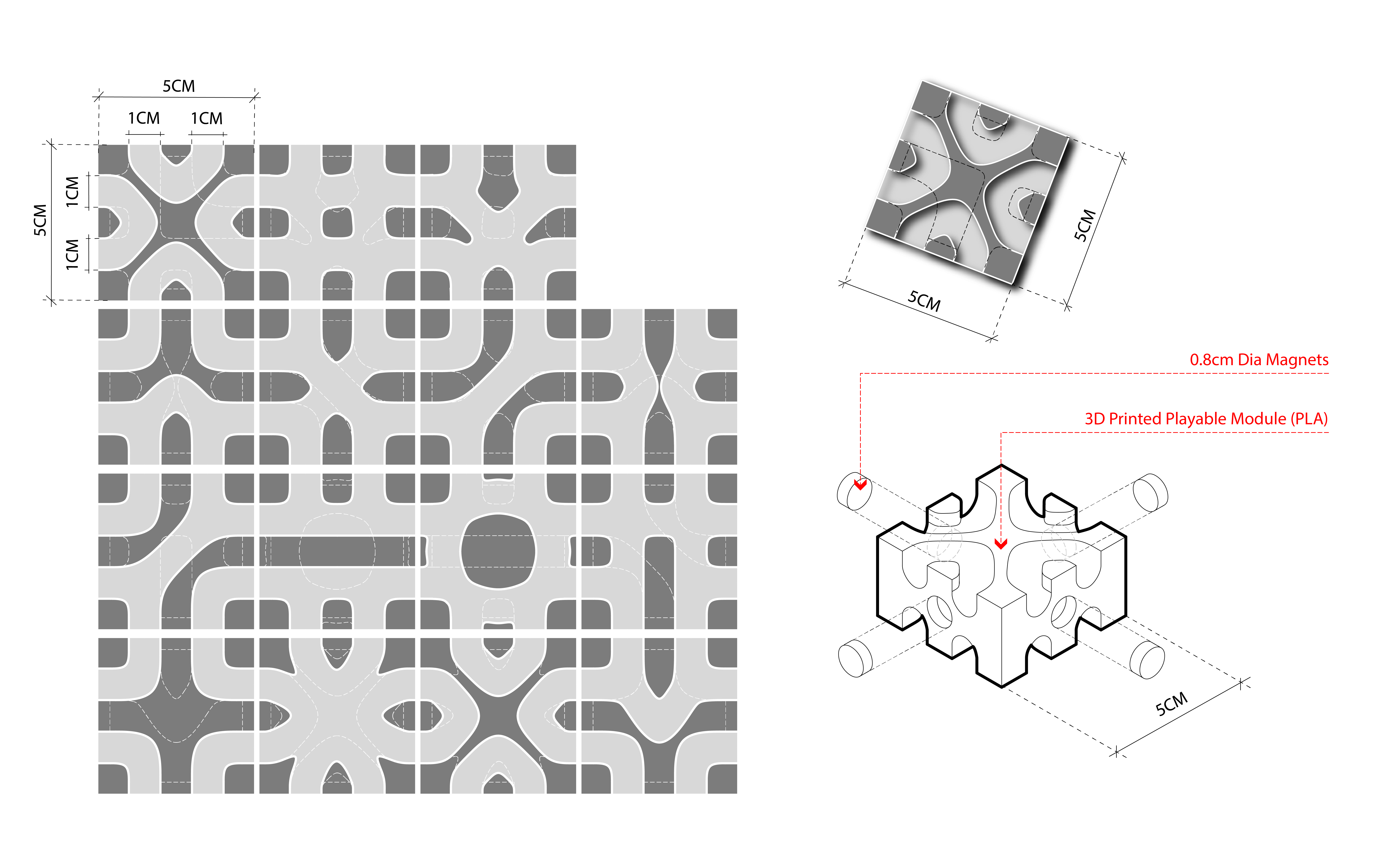

3D Printing- Knotic

A Dynamic 3d Printed Playable Facade Module

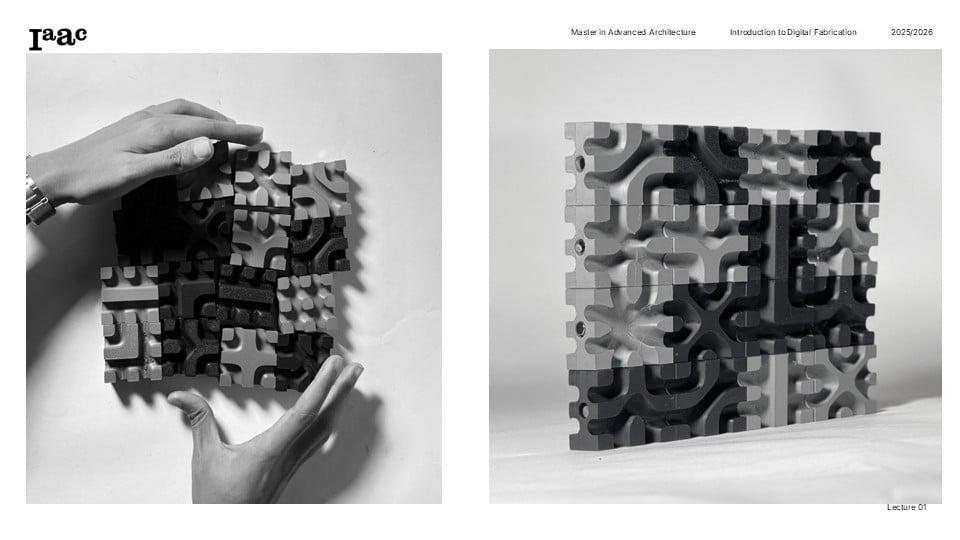

Playable Facades transforms building surfaces into spaces of play and interaction through 3D-printed modular maze panels. Each double-sided module features unique patterns that can be rotated, rearranged, or replaced, creating ever-changing facades that invite touch and exploration from both sides.

Inspired by the modular logic of a jigsaw game, this system uses parametric design and additive manufacturing to create highly customizable geometries that generate dynamic shadows, tactile engagement, and spatial play. By merging architecture, interaction, and digital fabrication, Playable Facades reimagines the building envelope as a living, responsive surface—one that can be reorganized, touched, and experienced differently over time as it evolves with its users and environment.

The model is printed in PLA on a Bambu Lab P1S with a workpiece volume of 200×200×30 mm. The total filament required is 56.98 m (172.65 g), consisting of 51.77 m (156.90 g) for the model and 5.20 m (15.75 g) for supports. The print uses a 0.12 mm layer height and includes 1 h 47 m of support-generation time. The estimated printing time for Part 1 is 10 h 45 m. Additional settings include top-surface ironing and a 15° threshold angle for support generation.

The playable modules have a magnet attacher inside that allows them to stick seamlessly to one another, and since both faces have different patterns, an infinite number of permutations and combinations can be created.

The playable modules use built-in magnetic connectors that allow them to snap together seamlessly, with two faces carrying different patterns, enabling an infinite range of permutations and combinations. In architectural facades, these modules can function as a dynamic and reconfigurable surface system, allowing designers to easily alternate between static ornamentation and kinetic responsiveness. Their modularity supports applications across small-scale pavilions, interior feature walls, and large building envelopes, where patterns, porosity, shading, and light behavior can be continually adapted to environmental conditions or user interaction.

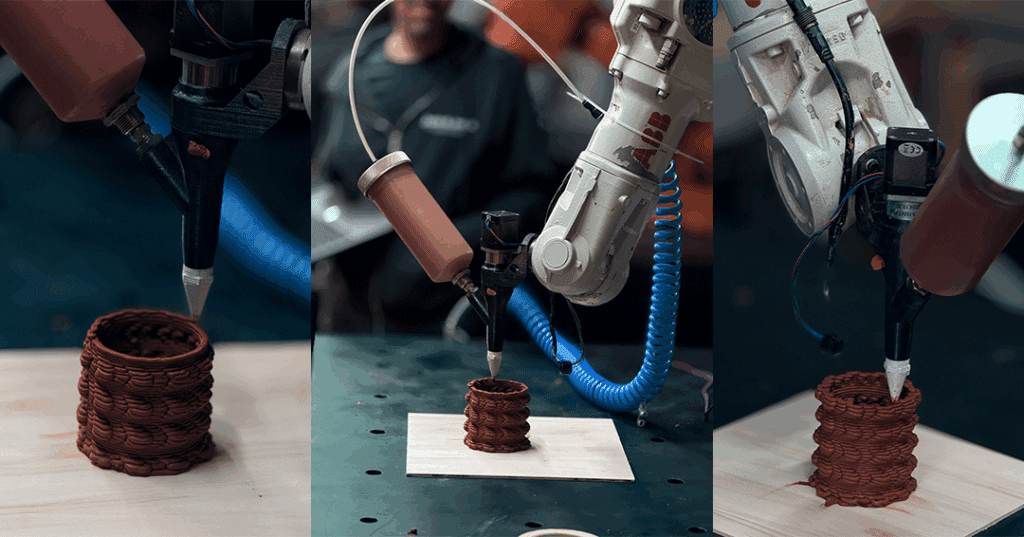

Robotics-The ClayWeaver