An Intelligent, Shape-Shifting Sound Control System

01 | Project Abstract

Acoustic Skin is an acoustic panel that morphs its surface geometry in real time to control the way sound interacts with the environment. It uses an array of miniature pistons embedded in a felt-covered membrane, behaving like a living, breathing skin that adapts its texture and porosity to the acoustic conditions of a space.

System behaviour

Listen → Detect noise → Adjust geometry → Measure effect → Return to rest

First idea

This sketch shows how the system could be integrated into a real architectural ceiling. The concrete slab sits at the top, followed by a structural frame holding the piston system. Below that is the ceiling level where the flexible acoustic surface is installed. When the actuators extend, they push the membrane downward, creating a dynamic contour that adapts in real time to sound conditions. The red dashed line represents the limit of maximum extension, indicating how far the ceiling can safely deform without interfering with the space below. This illustrates how the system forms a responsive acoustic layer embedded between the structural ceiling and the interior room environment.

Locating the noice

The system continuously listens to the surrounding environment through an array of embedded microphones distributed across the panel or ceiling field. These sensors measure overall sound pressure level and spatial differences in intensity to identify where the noise is strongest.

02 | Process

3d Printing

Linear servo actuators were fabricated using the open-source design from Thingiverse #3170748. After importing the components into Bambu Studio, the prints were optimised for tolerance and later sanded to ensure smooth piston movement. This stage was critical for minimizing friction and achieving reliable actuation during rapid, repeated shape changes.

Laser Cutting

To prototype the skin’s tactile surface, two materials were tested:

• 3 mm cork — selected for its natural sound-absorbing properties.

• 1.15 mm cardboard — used for fast iteration and pattern studies.

Both were laser-cut with a perforated design that allowed the actuators to imprint gradients of depth and porosity on the surface.The triangular pattern is a parametric perforation grid designed to give the surface uniform flexibility while maintaining structural stability. A triangle-based tessellation distributes stress evenly, so when the actuators push from below, the cork bends smoothly without cracking along a single direction. Unlike square or hexagonal grids, triangles prevent directional bias and allow the panel to deform in multiple directions, creating more organic, controllable curvature. The pattern also increases local porosity, improving sound diffusion while keeping the surface visually consistent across all deformation zones.

03 | Testing (sensor calibration)

Initial system tests involved running each motor individually with a simplified script to confirm proper actuation. Two motors were identified as faulty and removed from the array. Each sound sensor was then calibrated to ensure consistent sensitivity across the grid. Achieving this uniform response was essential for creating coherent shape transformations across the membrane.

04 | Components

Microcontroller | Arduino Uno

Central controller that reads all sound sensor inputs and sends movement commands to the servos. It processes real-time sound data and converts it into coordinated actuator responses across the 9×9 grid.

Sound Sensor | ADRKY-037 LH

Analog microphone module that detects sound intensity in its immediate area. Each sensor feeds a continuous voltage signal to the microcontroller, allowing the system to map sound peaks and activate the nearest actuators.

Motor | MG90S Micro Servo

Mini servo motor that rotates up to 180°. Its rotation drives the 3D-printed gear system inside each linear actuator. Every motor controls one piston, pushing the surface up or pulling it back according to the acoustic input.

Linear Servo Actuator | potentprintables design

3D-printed mechanism that converts the servo’s rotational motion into vertical linear displacement. When the servo rotates its small gear, it drives a rack-and-pinion system that moves the piston up or down, deforming the membrane. This creates localized surface geometry changes that modify how sound reflects, diffuses, or is absorbed.

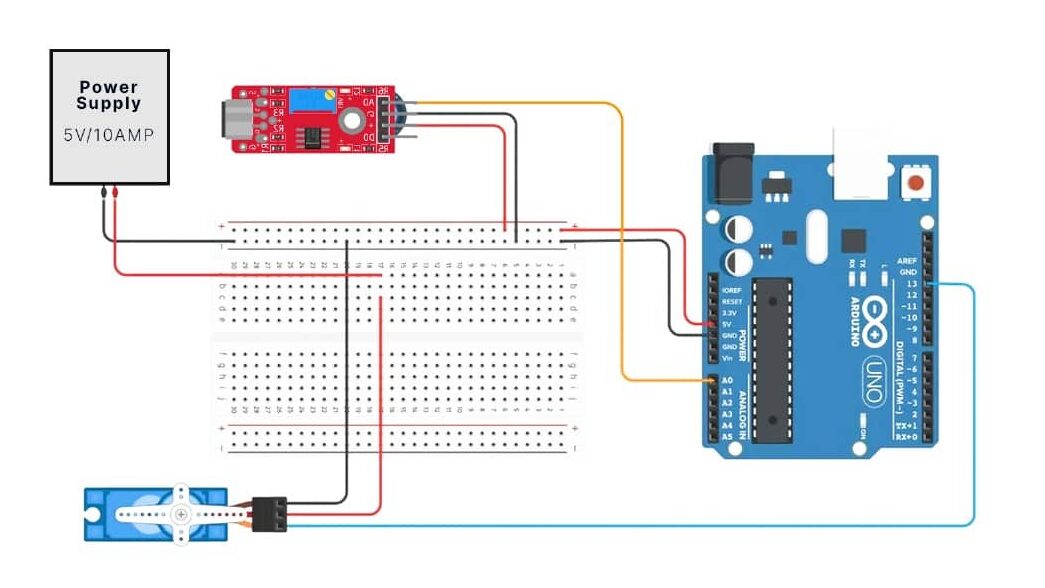

05 | Circuit Diagram

This simplified diagram shows just one sound sensor and one servo motor, but they represent a 9×9 matrix of pairs.

Each of the 9 servos is wired exactly like the one shown, each with its own sound sensor connected in the same way. So you can read the diagram as “pattern for one pair,” then repeat that pattern nine times. All nine sound sensors are connected to a dedicated Arduino analog pin. The nine servo motors are powered directly from the 5 V / 10 A power supply (not from the Arduino’s 5 V pin), with each servo’s control signal connected to a separate Arduino digital pin.

06 | Prototype

To visualize the concept in a clear and controlled format, we built a square prototype that demonstrates how the system behaves as a physical model. The 430 × 430 mm frame allowed us to arrange the actuators, fabric, and cork layer into a precise 3×3 grid, making the deformation patterns easy to observe, record, and analyze. This scaled-down setup helped us test material flexibility, actuator performance, and overall surface morphing before considering larger architectural applications.

Wooden Frame

430 × 430 mm structural base that holds all prototype components. It provides rigidity and defines the boundary within which the actuators, fabric, and cork surface operate.

Wooden Motor Support

Perpendicular wooden beams added inside the frame to elevate and align the actuators. These supports keep the motors at equal distances and consistent height, ensuring uniform deformation when the pistons push the surface.

9 Linear Servo Actuators

A 3×3 grid of actuators that convert servo rotation into vertical motion. Each actuator reacts to sound input at its specific location and pushes upward toward the source, creating localized surface movement.

Lycra Fabric

Highly elastic intermediary layer stretched across the actuators. Lycra (spandex) was chosen for its ability to deform smoothly under pressure and return to its tensioned state when the actuators retract.

Cork Panels

Laser-cut, triangular-patterned cork panel forming the top surface. The triangulated geometry gives the cork mesh-like flexibility, allowing it to bend, stretch, and articulate with the actuators. The 400 × 400 mm panel fits precisely within the frame and provides natural sound-absorbing qualities.

07 | Limitations

- Finding the components in time was challenging. We had to collect 9 micro servos and 9 sound sensors.

- Another issue was the planned extension of the actuators, which relied on the rotation of the servo gears we 3D printed. The servo motors only rotated 180 degrees. We matched our gear sizes to the actuator dimensions, making the gears small. This caused a limited rotation range.

- Since time was short, we had to work with what we had. We were able to make the system function the way we wanted, but not with the intended impact of extension.

- To make all of these servos work with esp32, we needed a bigger power supply: 5V, 10A .

- We also faced issues with the flexibility of the facade (surface). Since the laser-cut cork was too thick, the movement was not as smooth. A lighter material would have been better. Therefore, we only ended up using the fabric for visualization.

08 | Future optimisation

In a perfect setting, the gears extend the linear actuator even further, pushing a light and flexible sound-absorbing fabric. In an architectural setting, it is used as a dynamic sound-absorbing ceiling, taking sound control to another level.

09 | References

Adaptive Acoustic Surfaces for Real-Time Sound Field Control | explores programmable surface geometries for acoustic modulation.

https://doi.org/10.1121/10.0002327

• Shape-Changing Interfaces: Dynamic Materiality in Responsive Systems | research on mechanisms that convert motion into deformable surfaces.

https://doi.org/10.1145/3173574.3174155

• Acoustic Metamaterials and Programmable Sound Control | foundational paper on engineered textures that manipulate sound propagation.

https://doi.org/10.1038/s41578-020-00234-1

• Real-Time Sound Diffusion Using Mechanically Actuated Panels | studies how mechanical actuation alters reflection and diffusion patterns.

https://doi.org/10.1121/1.4921154

• Mechanically Reconfigurable Acoustic Panels for Dynamic Room Correction | experiments on servo-based acoustic tuning systems.

https://doi.org/10.1016/j.apacoust.2019.04.021

• Linear Servo Actuator (original 3D model)

https://www.thingiverse.com/thing:3170748

• Bambu Studio (slicer software used for printing)

https://bambulab.com/en/software/bambu-studio

• ADRKY-037 LH Sound Sensor Module description

https://components101.com/sensors/sound-sensor-module

• MG90S Metal-Gear Micro Servo datasheet

https://www.towerpro.com.tw/product/mg90s-2/

• Arduino Uno documentation

https://www.arduino.cc/en/Guide/ArduinoUno