Team member(s):zeyu chao, Elizabeth.frias.martinez,Chi.Lee

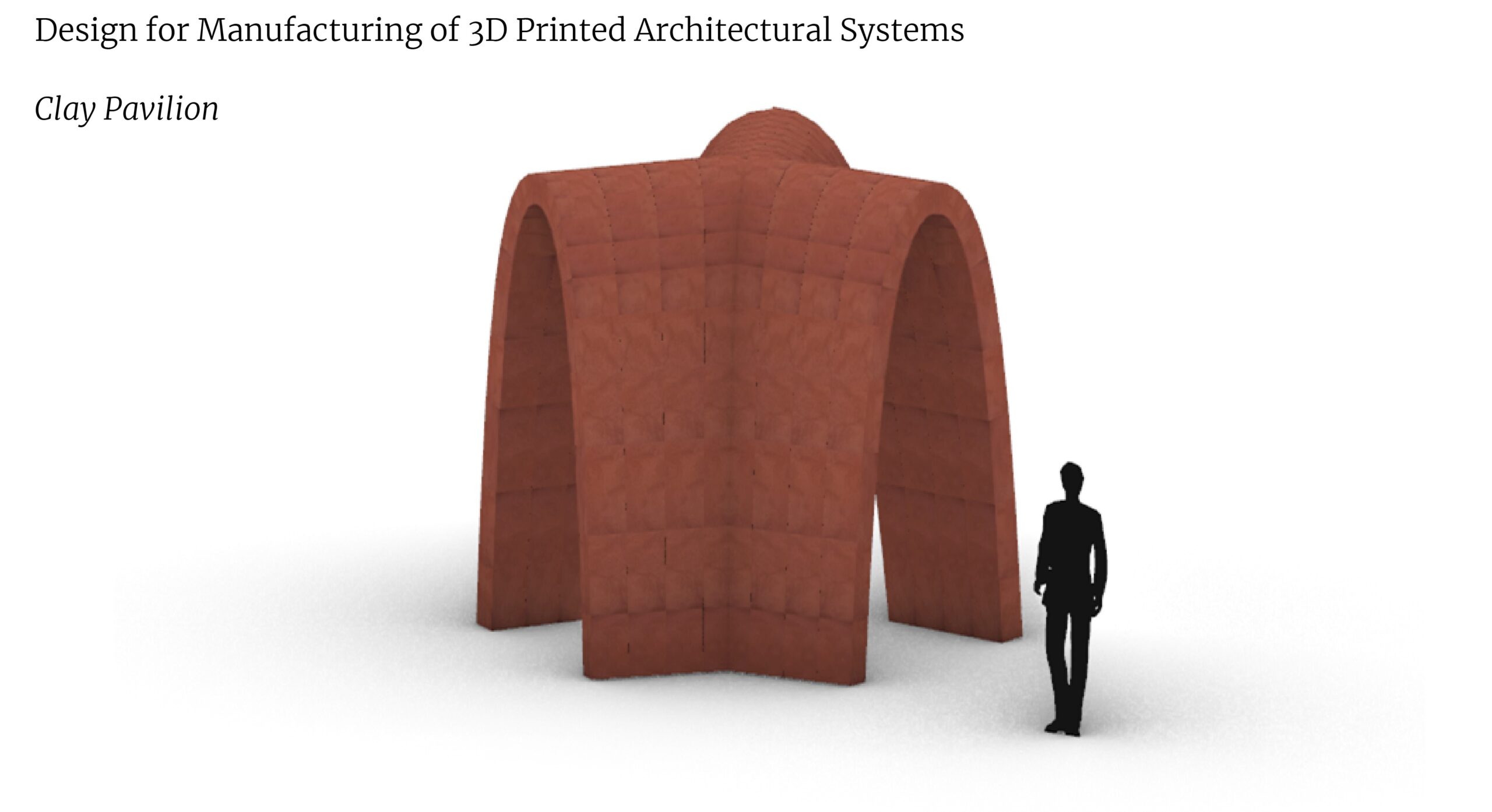

3Dprint pavilion

Introduction

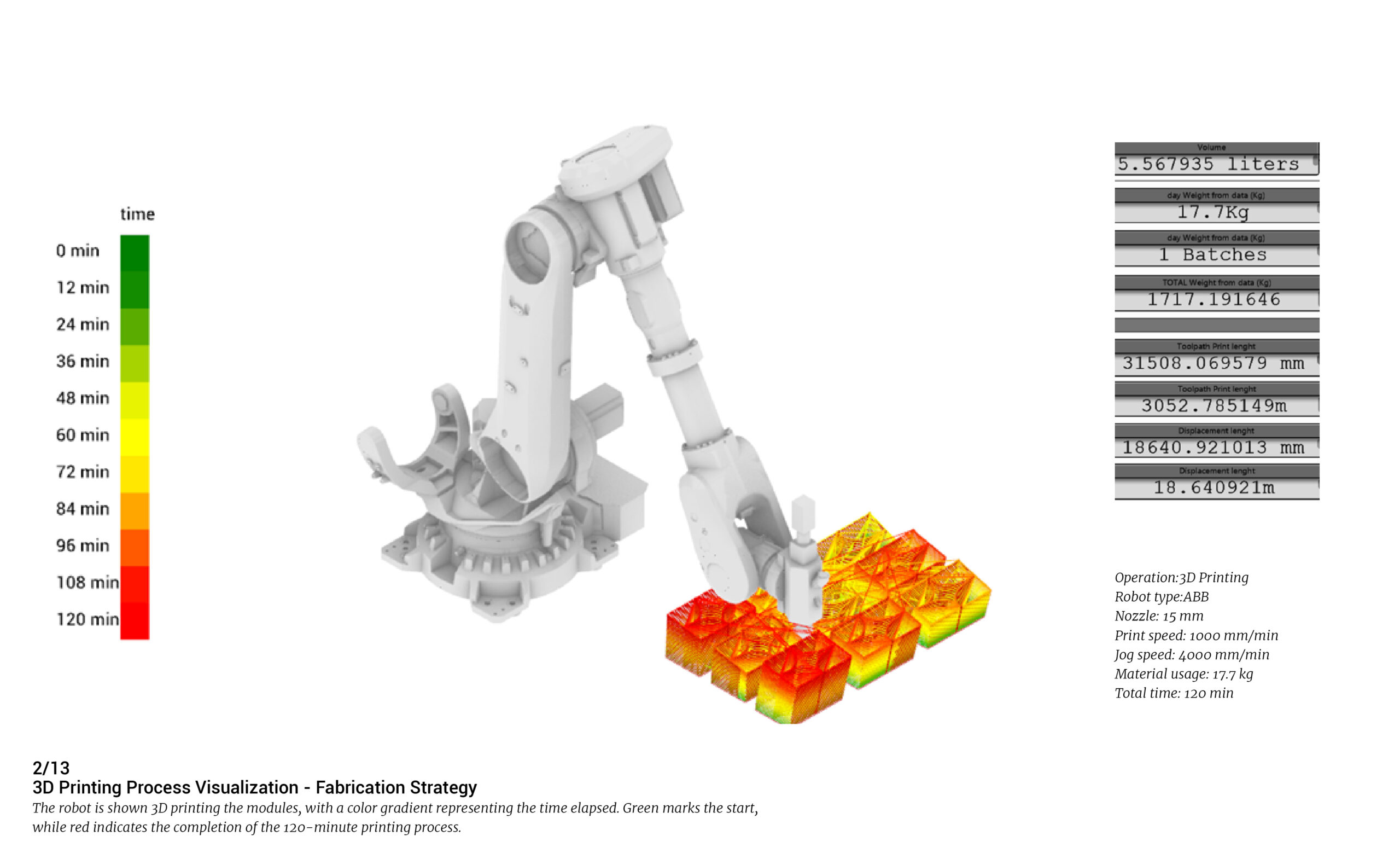

This project explores the large-scale robotic clay printing of a pavilion, with the geometry divided into four equal segments. The chosen geometry, Segment 1, was further developed into modular units to optimize the construction process. The modular approach allows for efficient fabrication and assembly, enhancing the structural and spatial qualities of the pavilion. The robot follows a time-calibrated path, as shown by the color gradient, which indicates the progression of the 120-minute printing process from start to completion

1 | Segmentation of the geometry

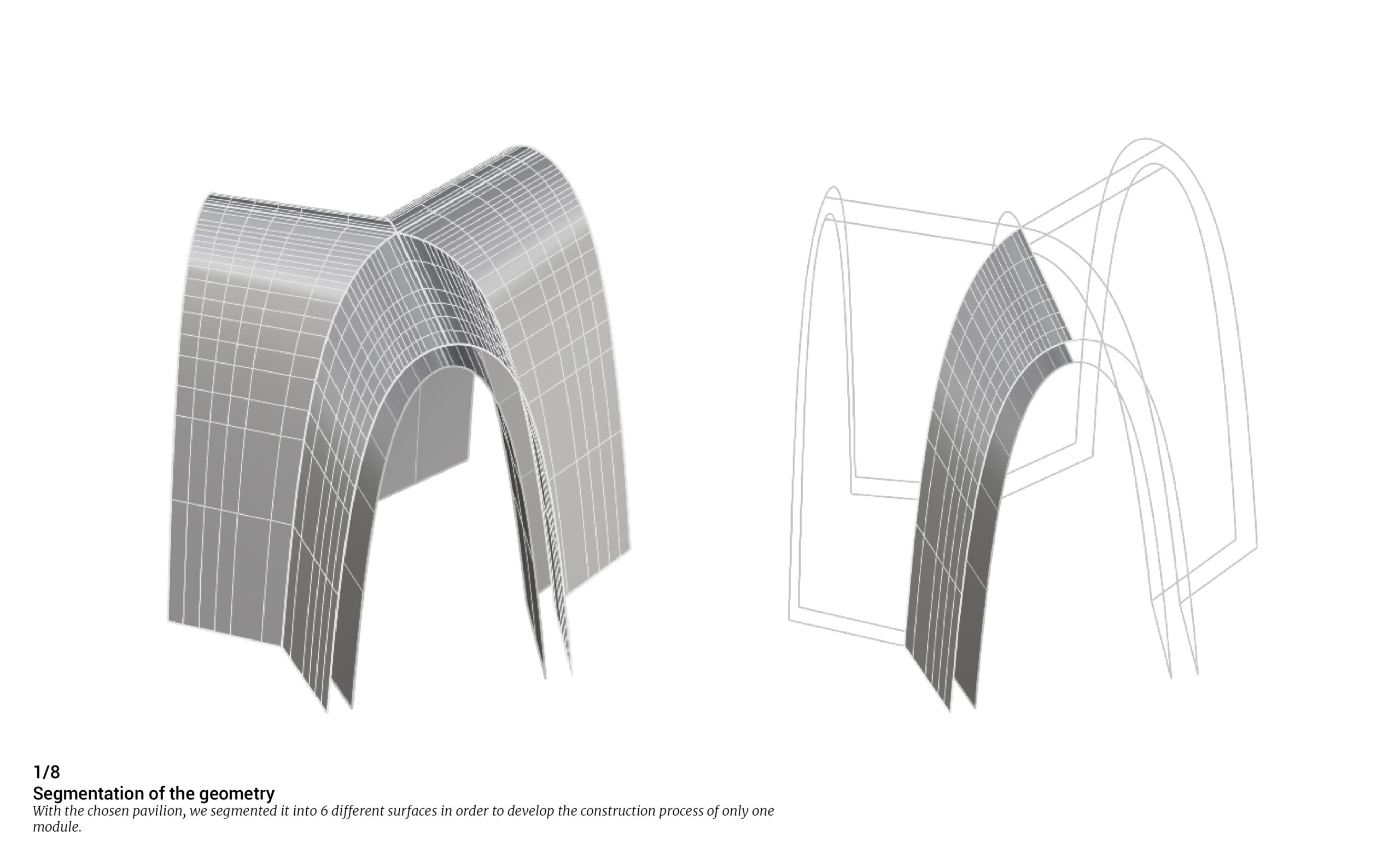

2 | Infill catalogue

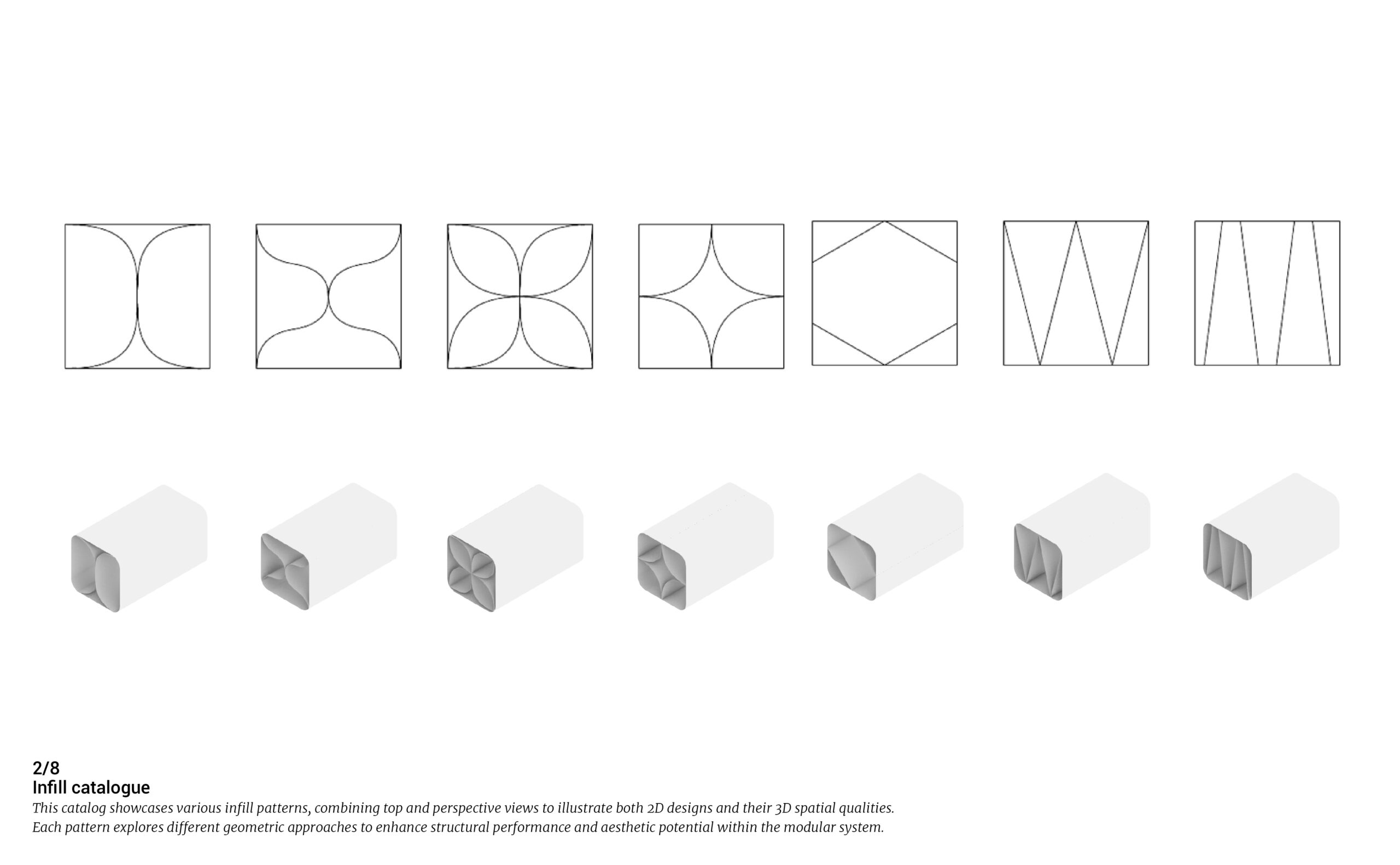

3 | Segmentation of the module

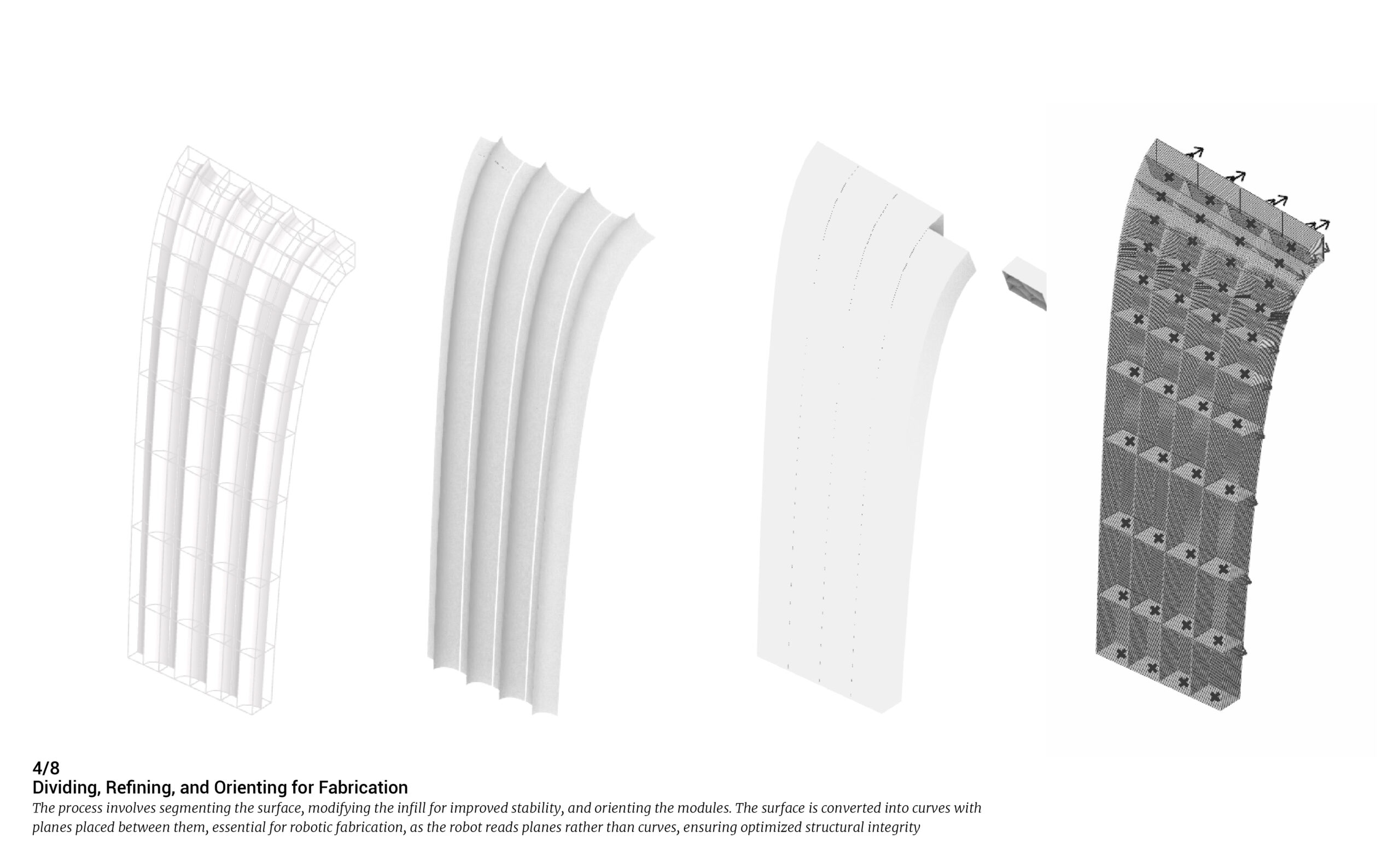

4 | Dividing,Refining,and Orienting for Fabrication

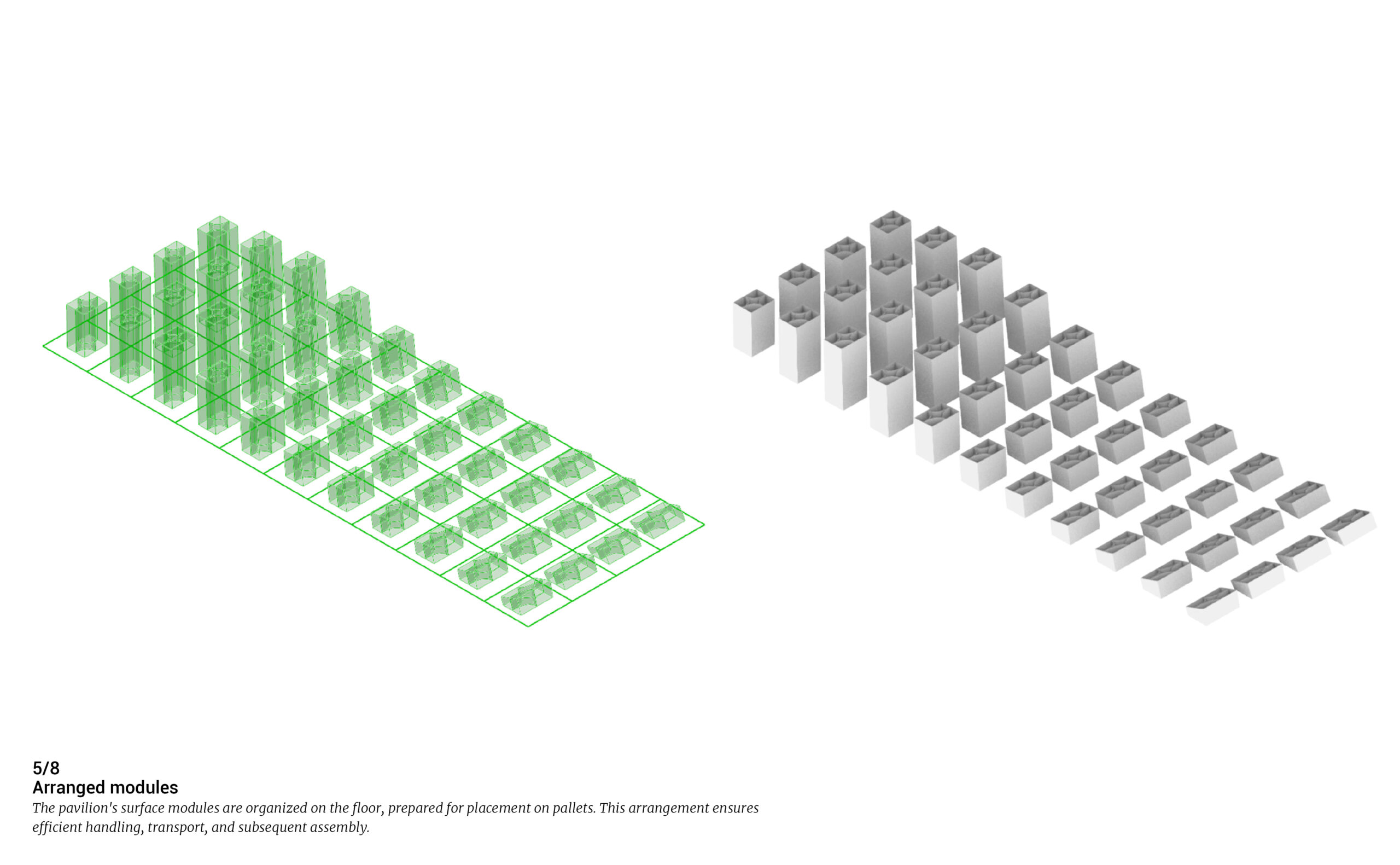

5 | Arranged modules

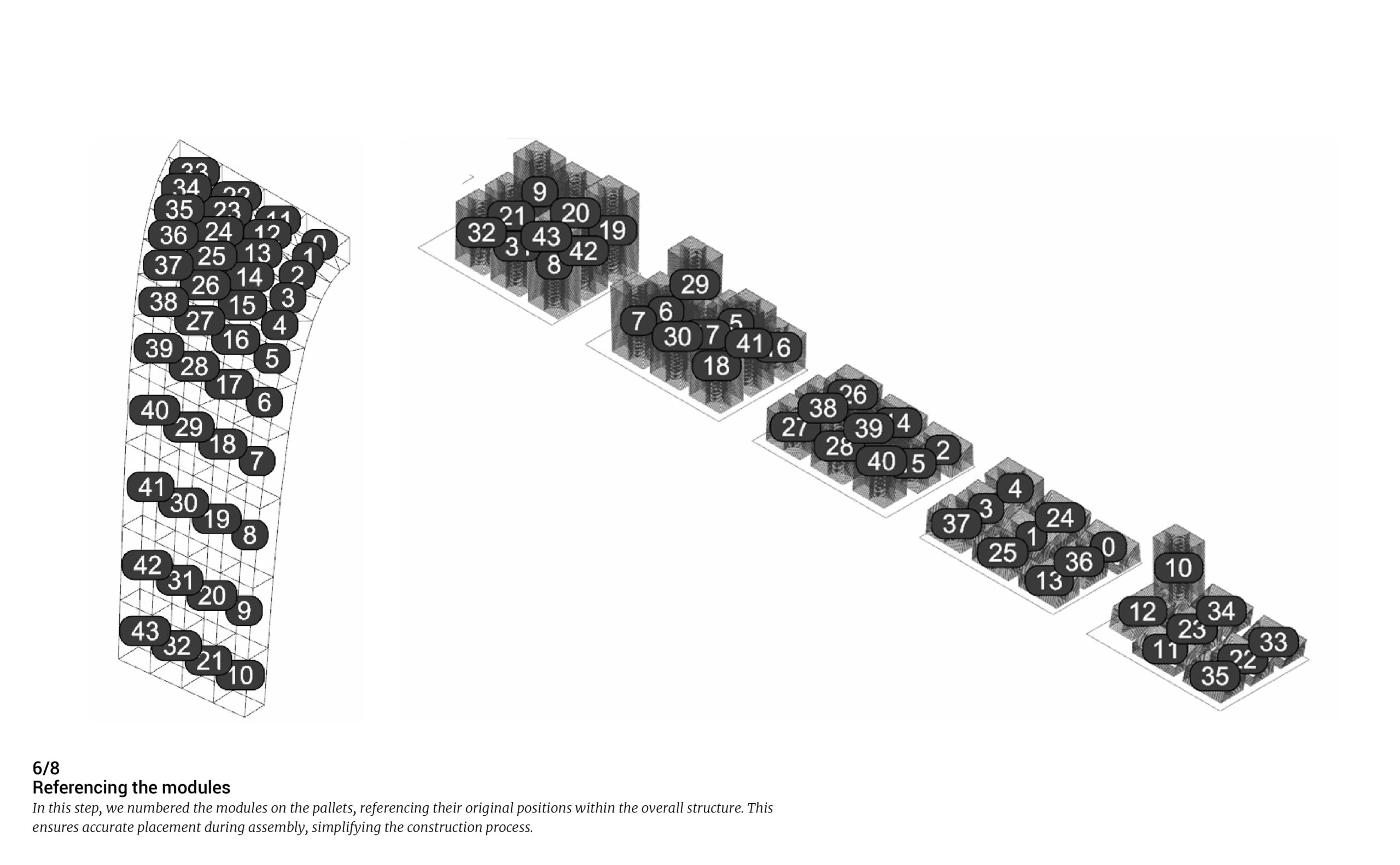

6 | Referencing the modules

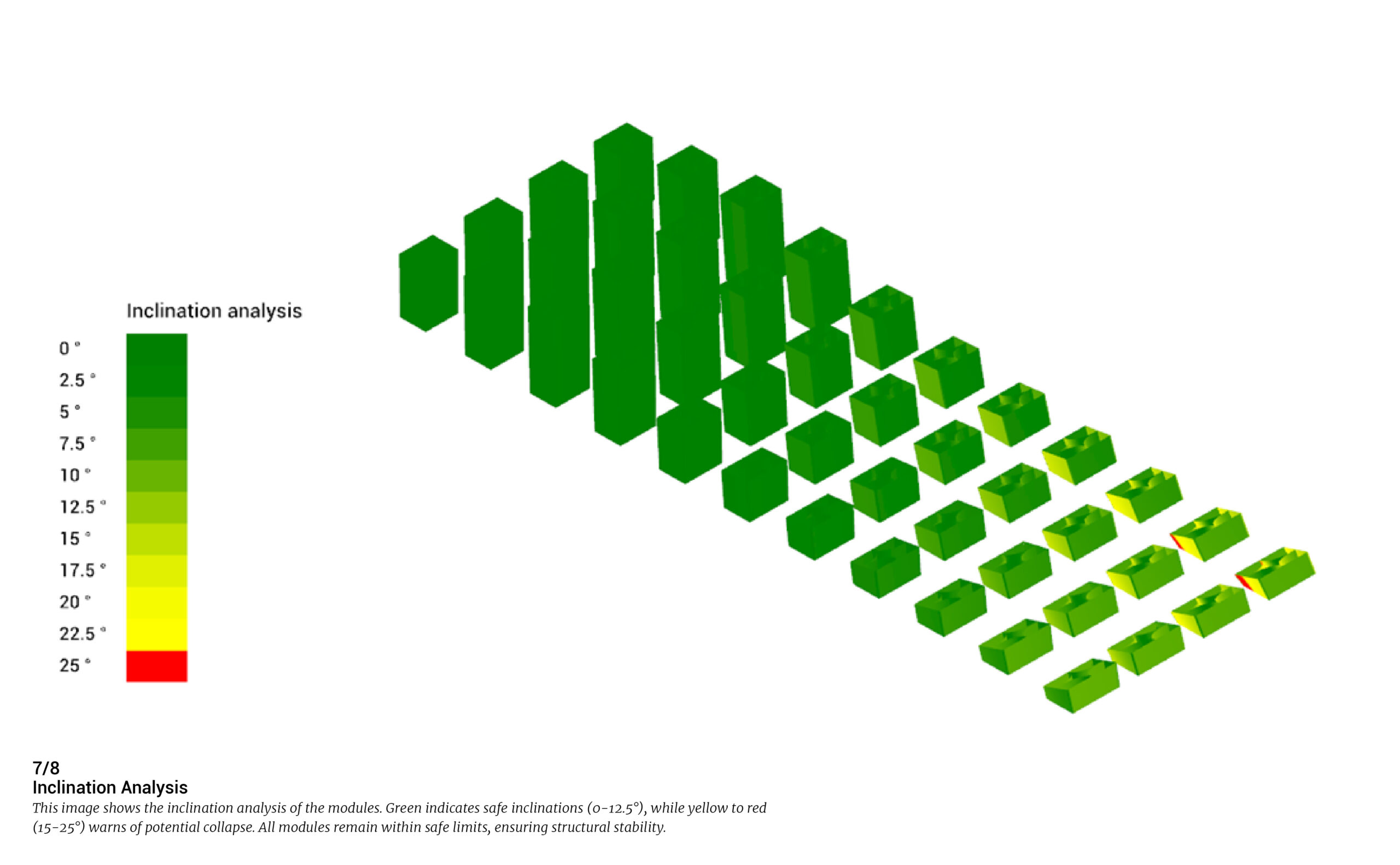

7 | Inclination Analysis

8 | 3D Printing Visualization —— fabrication strategy

9 | Render

CNC Milling Wave interior wall

Introduction

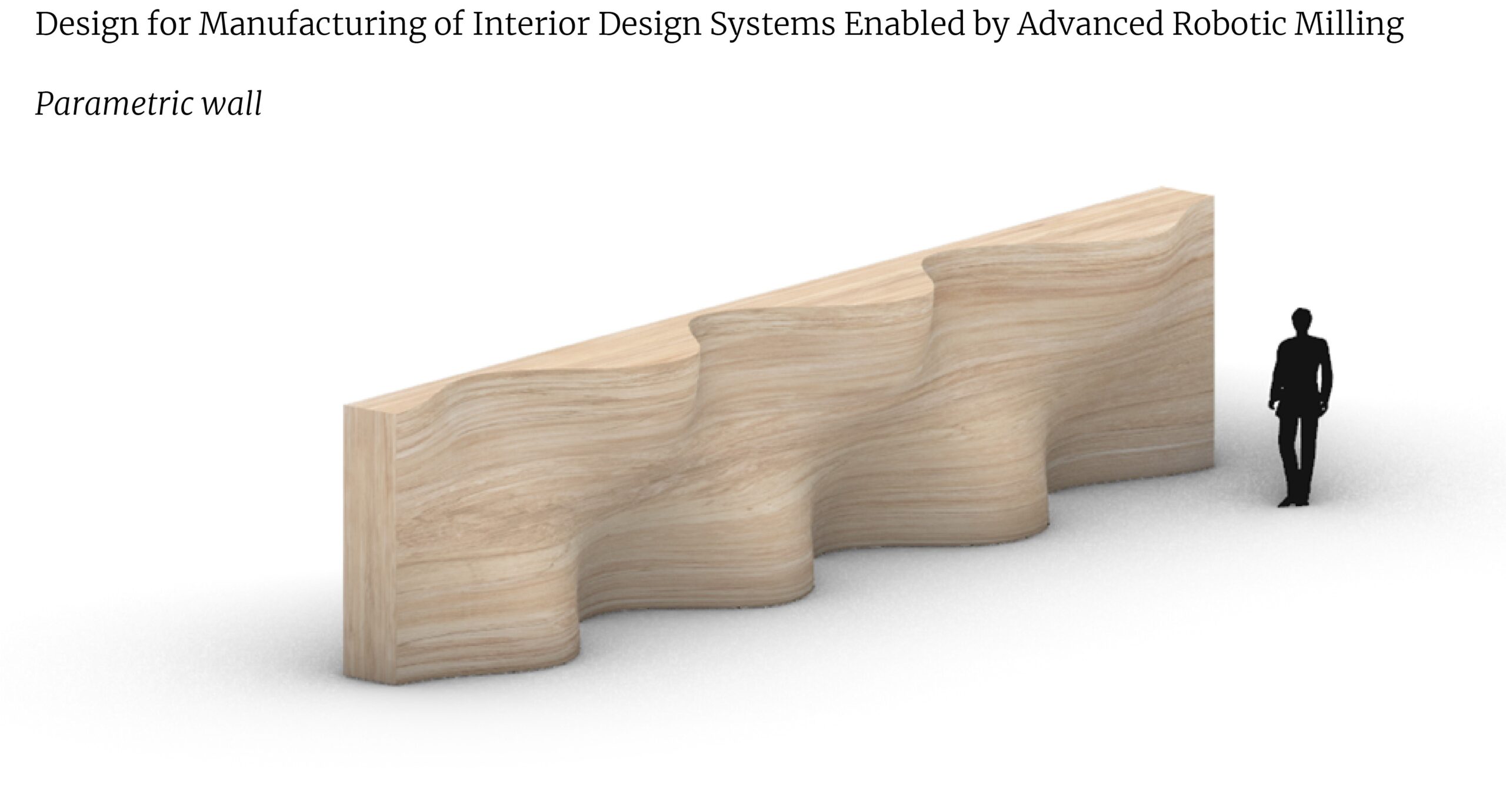

This project focuses on the large-scale milling of timber to create a wall inspired by the gentle flow of waves. To facilitate the fabrication process, the wall is divided into multiple panels, allowing each section to be milled separately before assembly. This modular approach ensures precision and ease in constructing the undulating design, capturing the dynamic motion of waves in a structured architectural form.

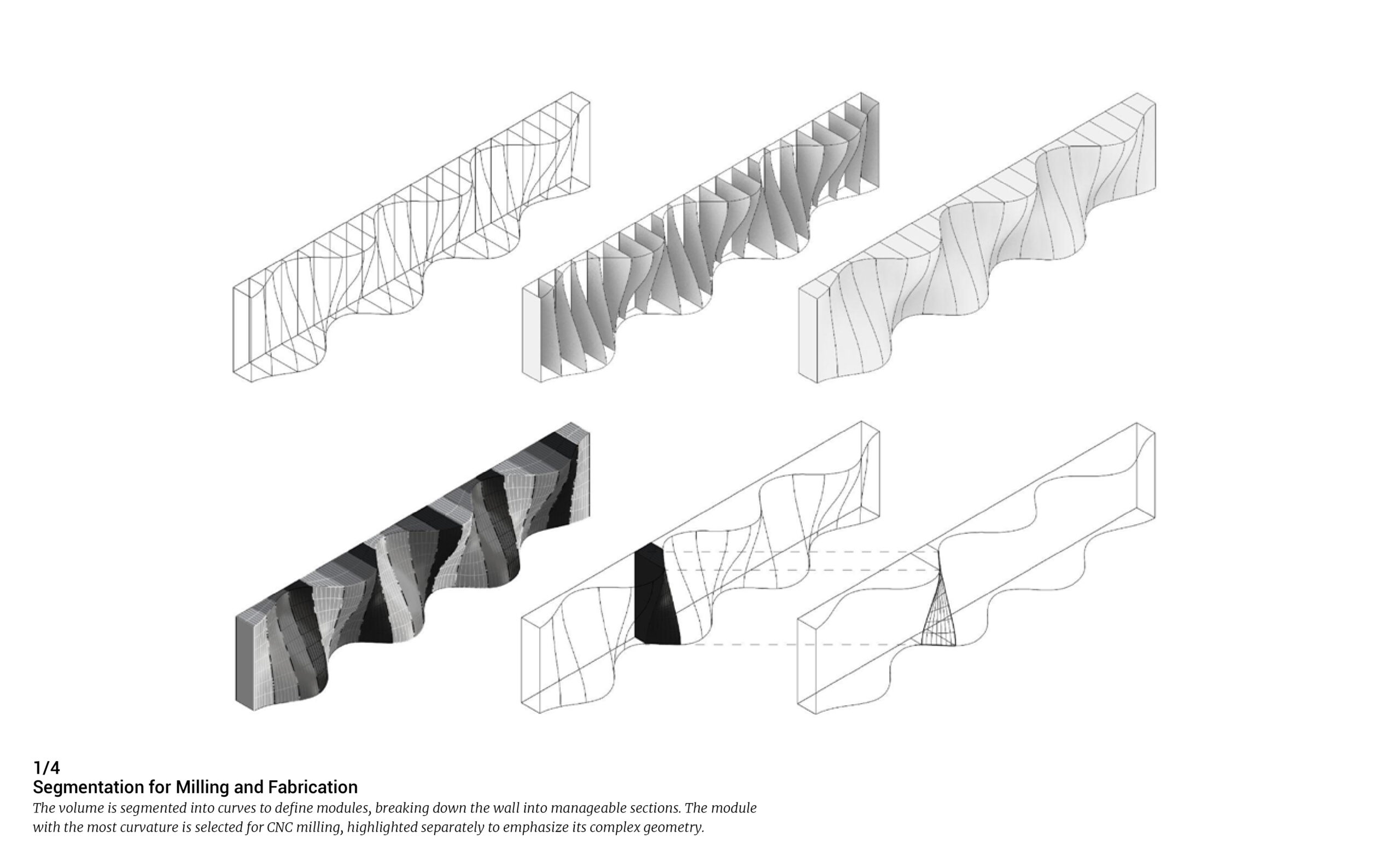

1.Segmentation for milling and Fabrication

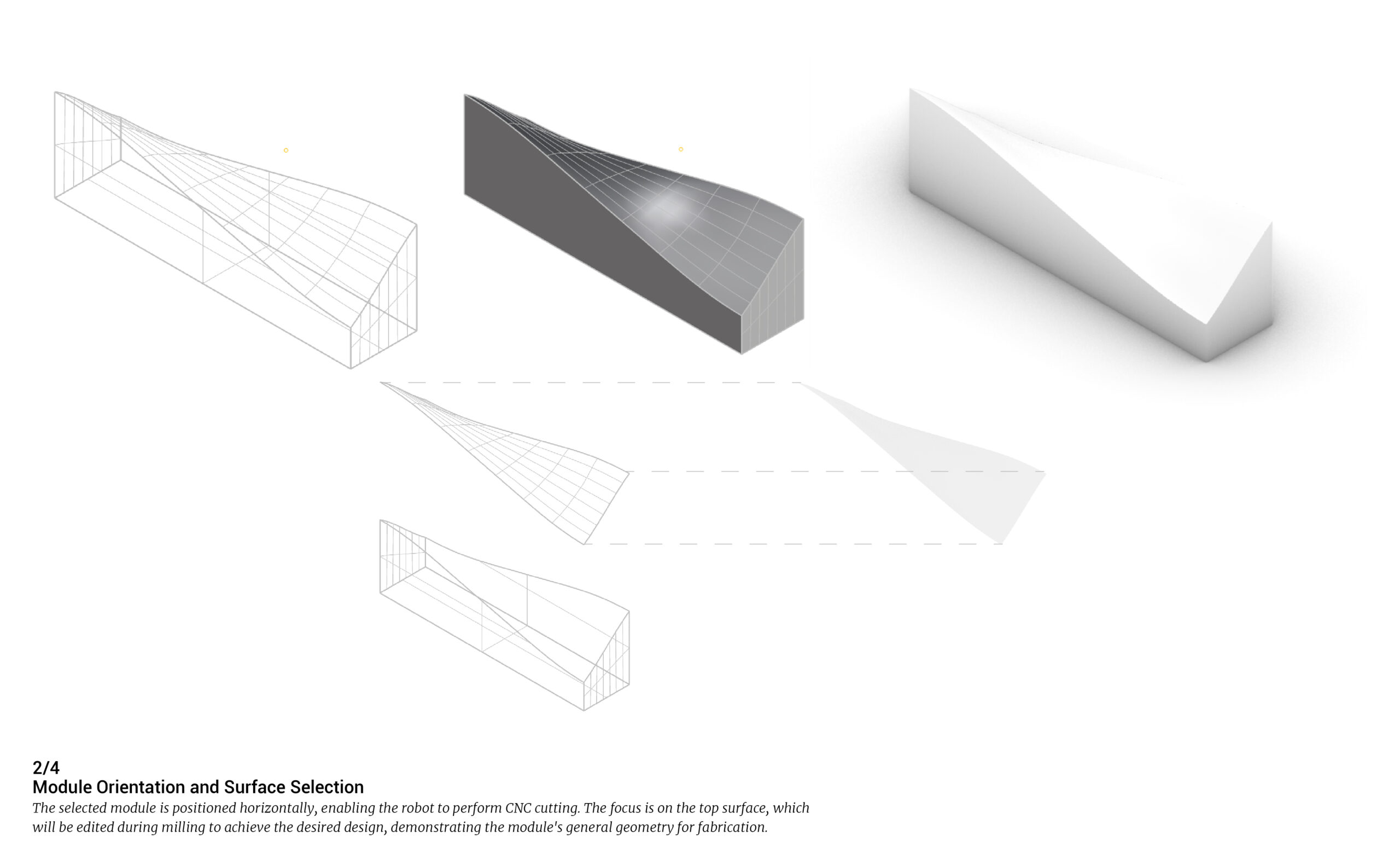

2.Module Orientation and Surface Selection

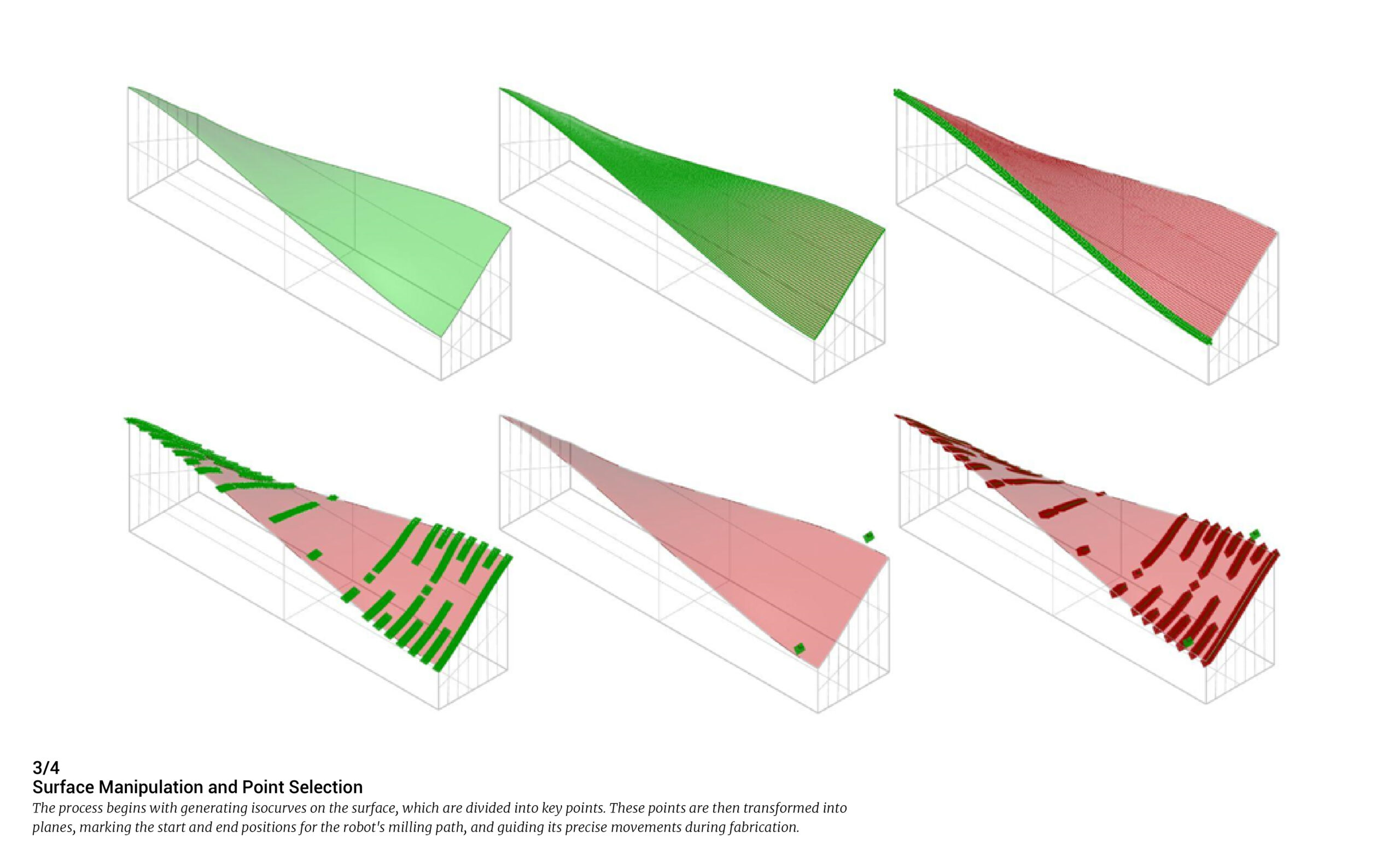

3.Surface Manipulation and Point Selection

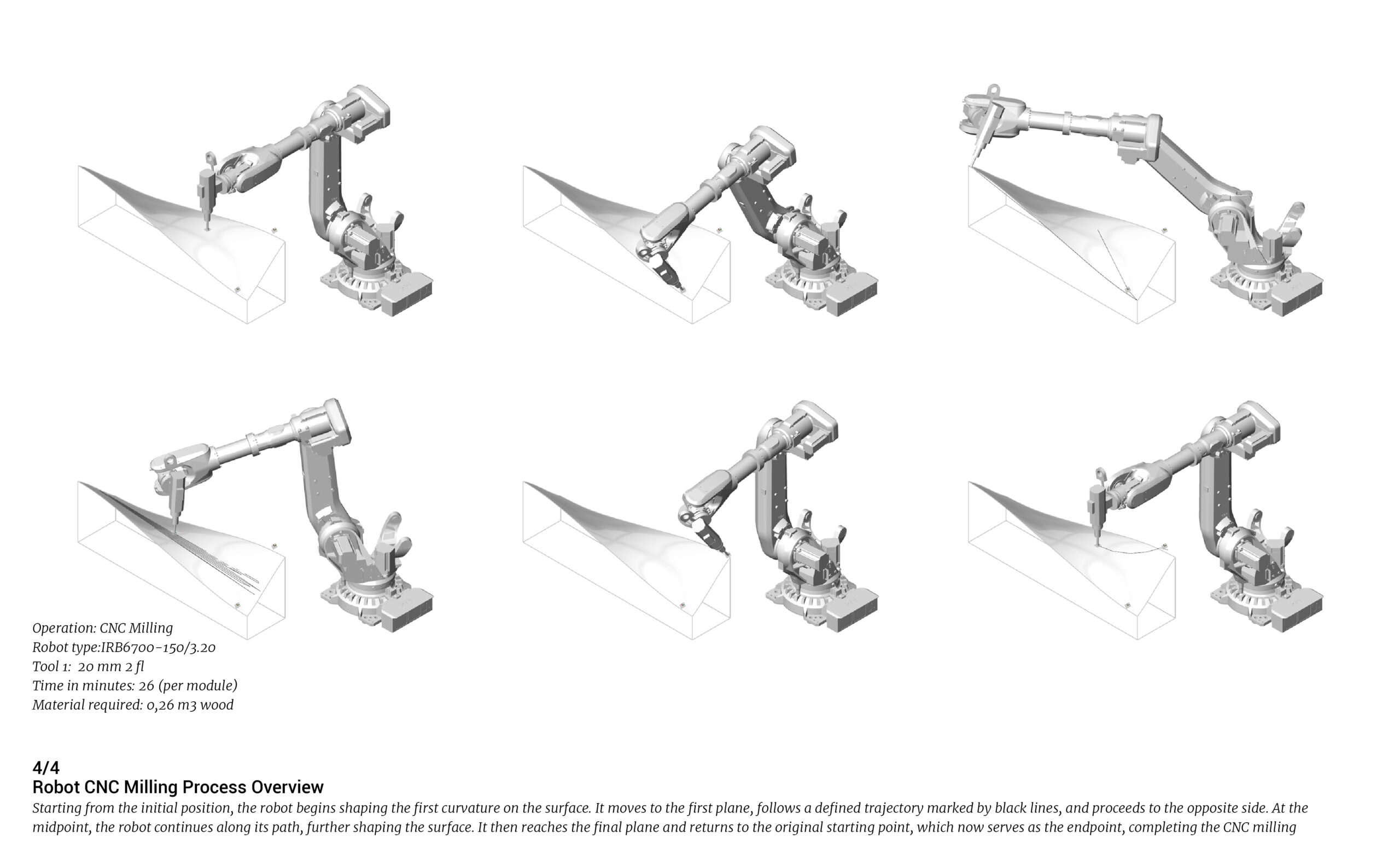

4.Robot CNC Milling Process Overview

5.Render