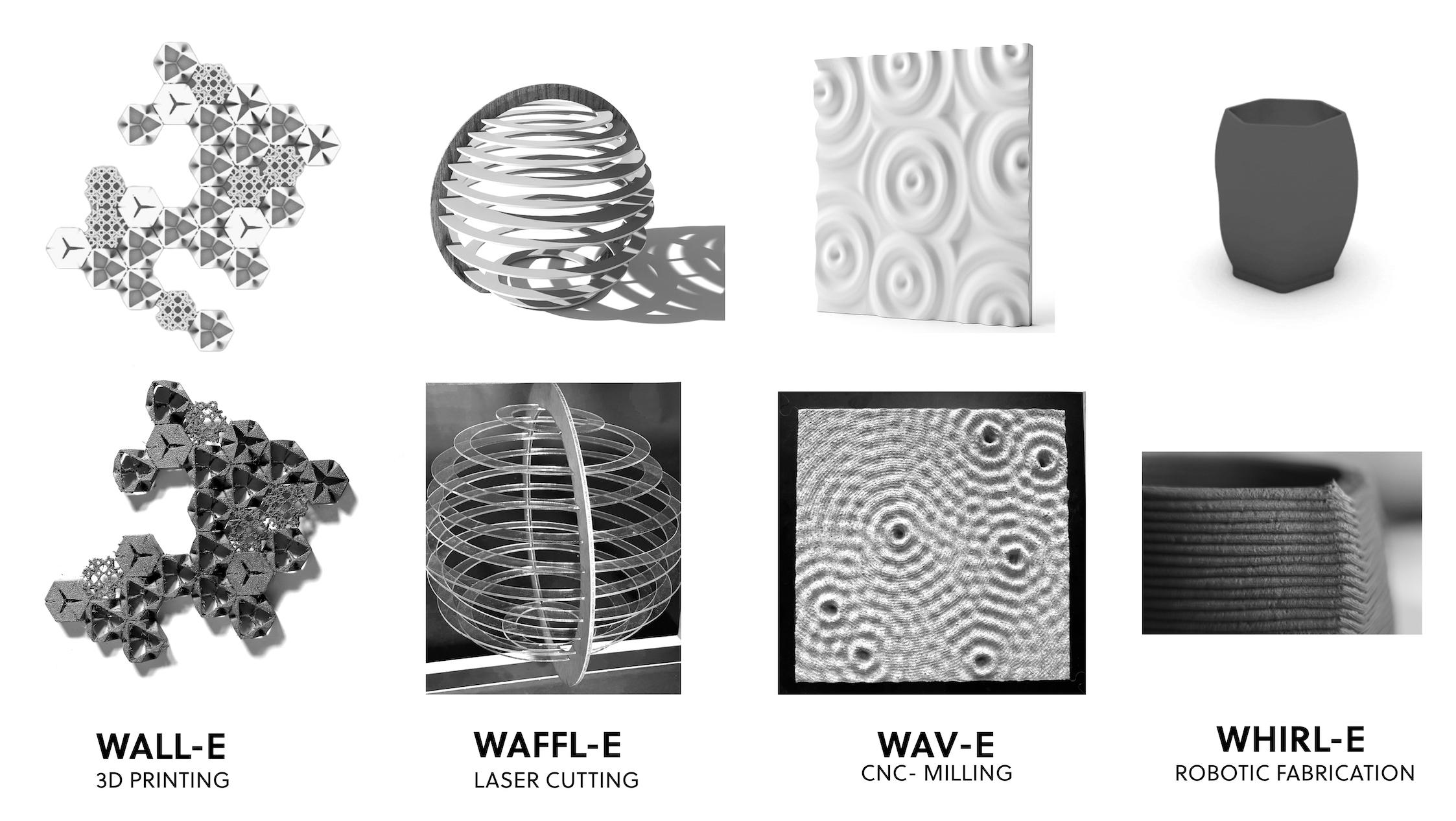

THE W-E SERIES

WALL-E

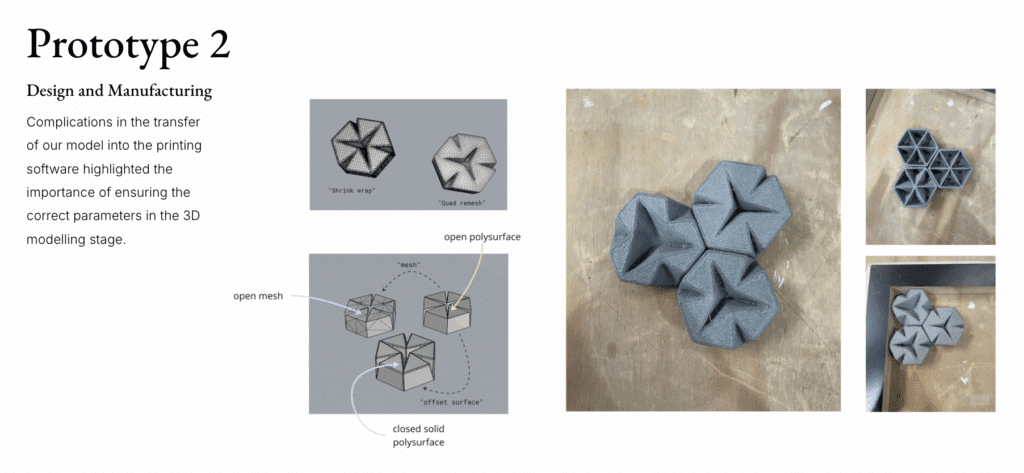

3D PRINTING

DESIGN INSPIRATION

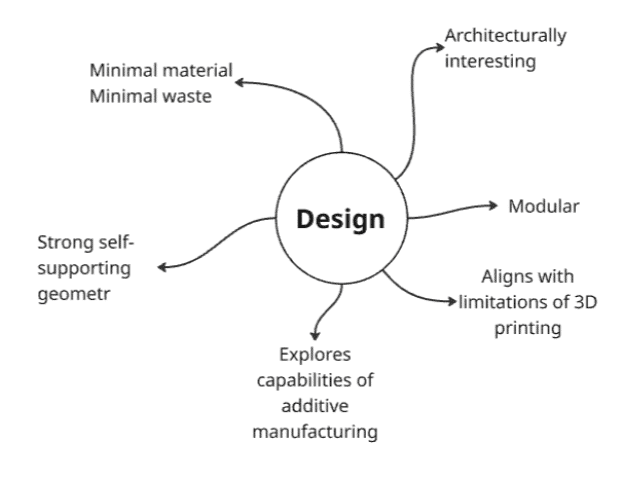

OBJECTIVE

To create a modular vertical element that explores the capabilities of 3D printing and is simultaneously architecturally attractive, is structurally strong whilst using minimal material.

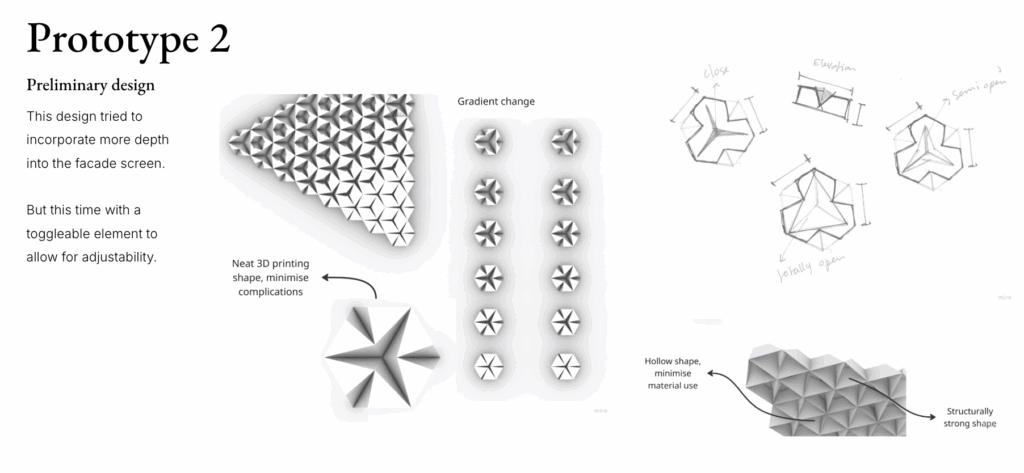

DESIGN OPTIONS

FINAL DESIGN

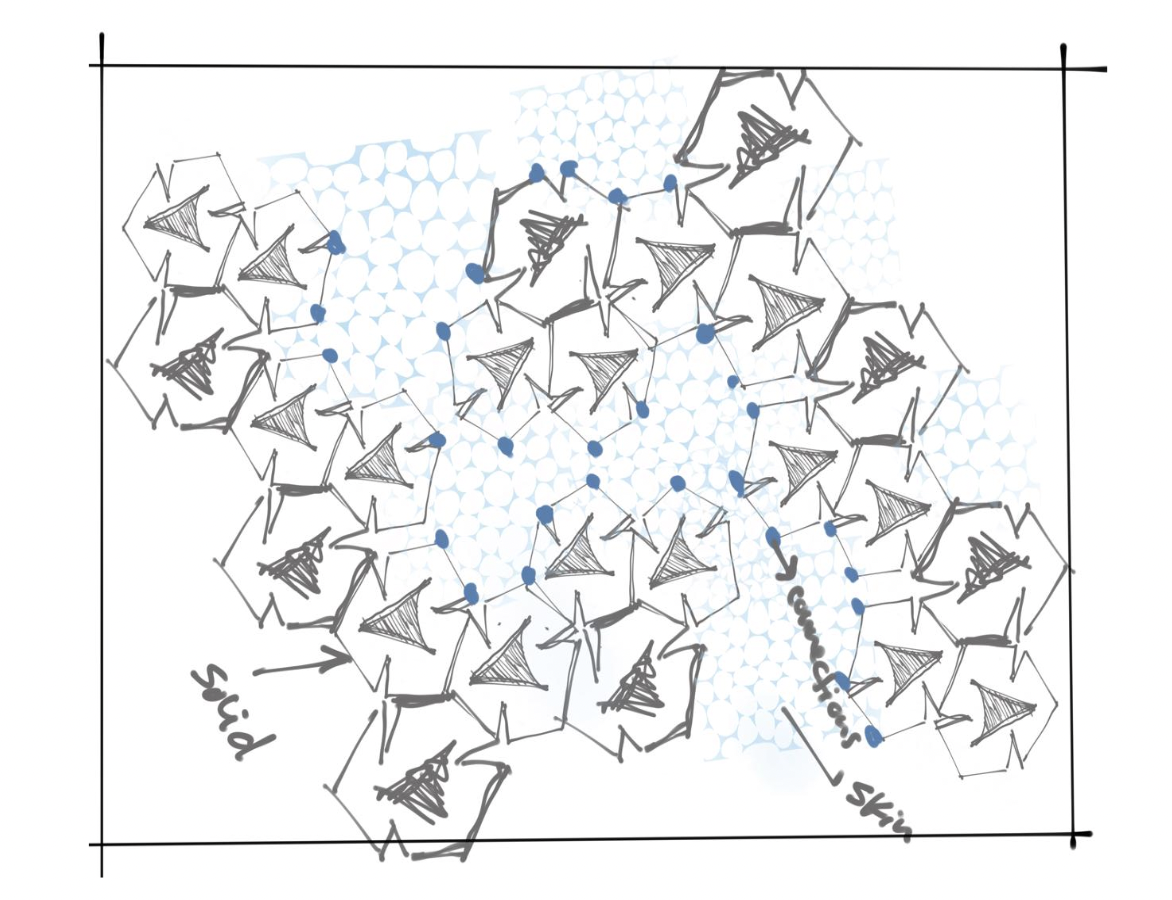

CONCEPT

By blending elements from previous prototypes, the final piece combines 2D and 3D forms to exploit capabilities of 3D printing.

By selectively removing parts of the panels to break the continuous solid field, this reduced the production time whilst the lattice base still maintained the screening element of the facade with less manufacturing time.

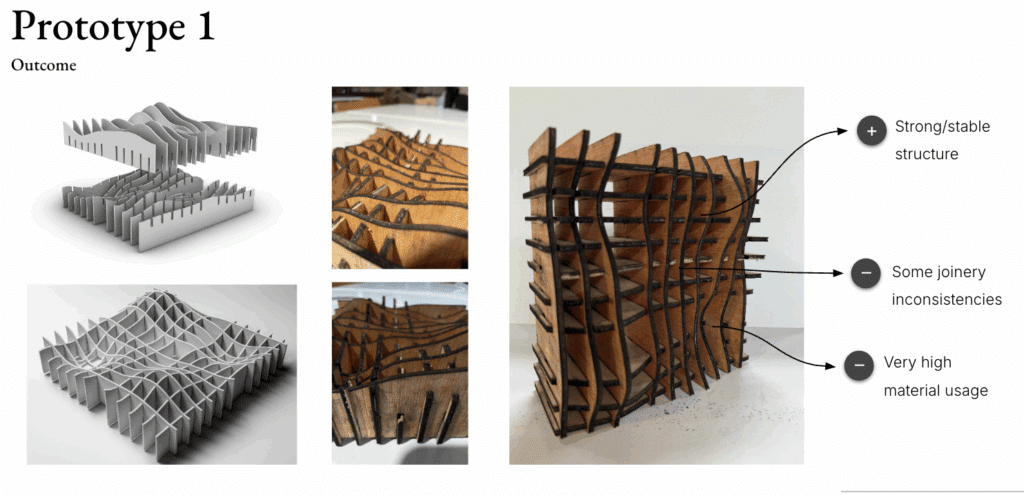

WAFFL-E

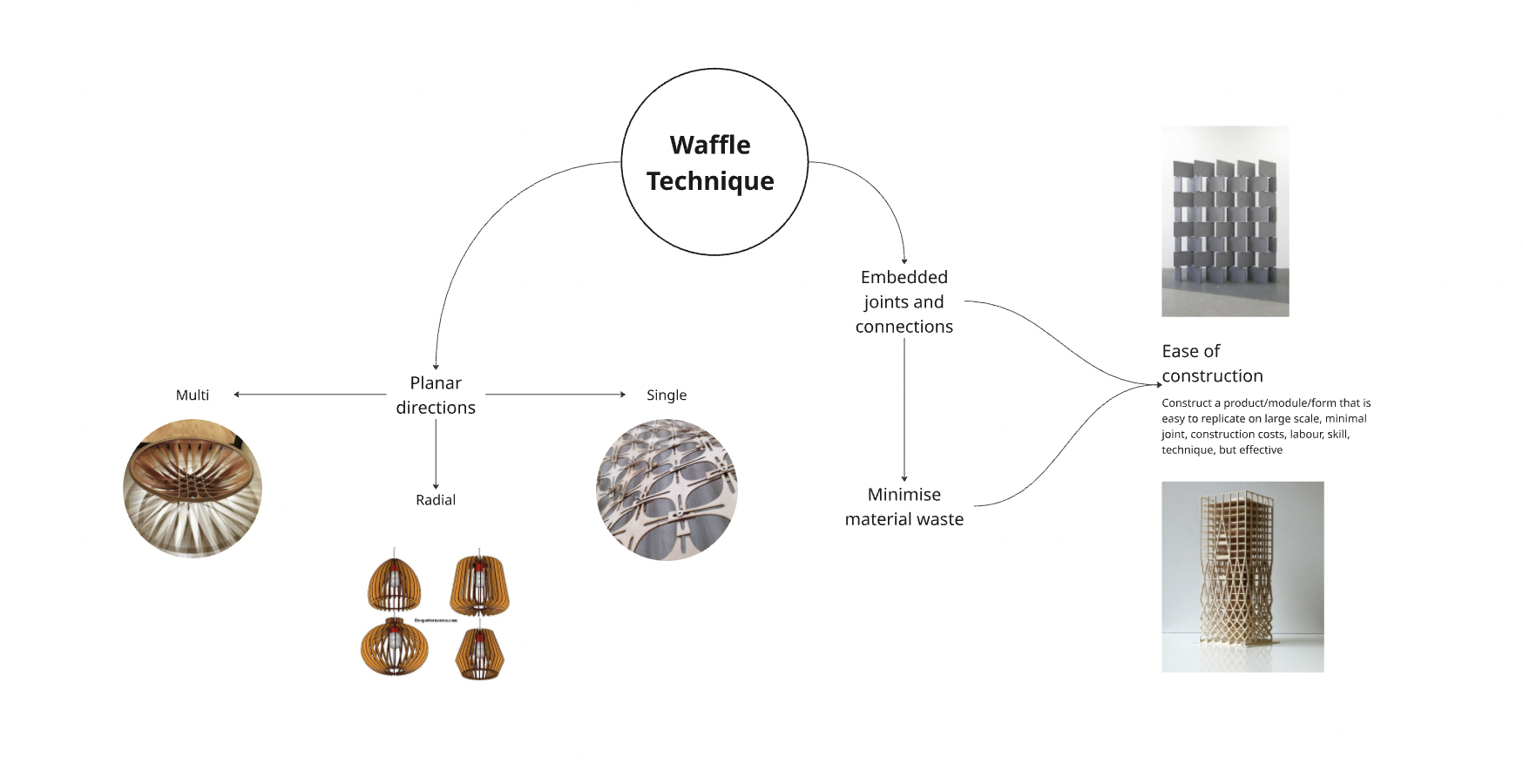

LASER CUTTING

DESIGN SKETCHES

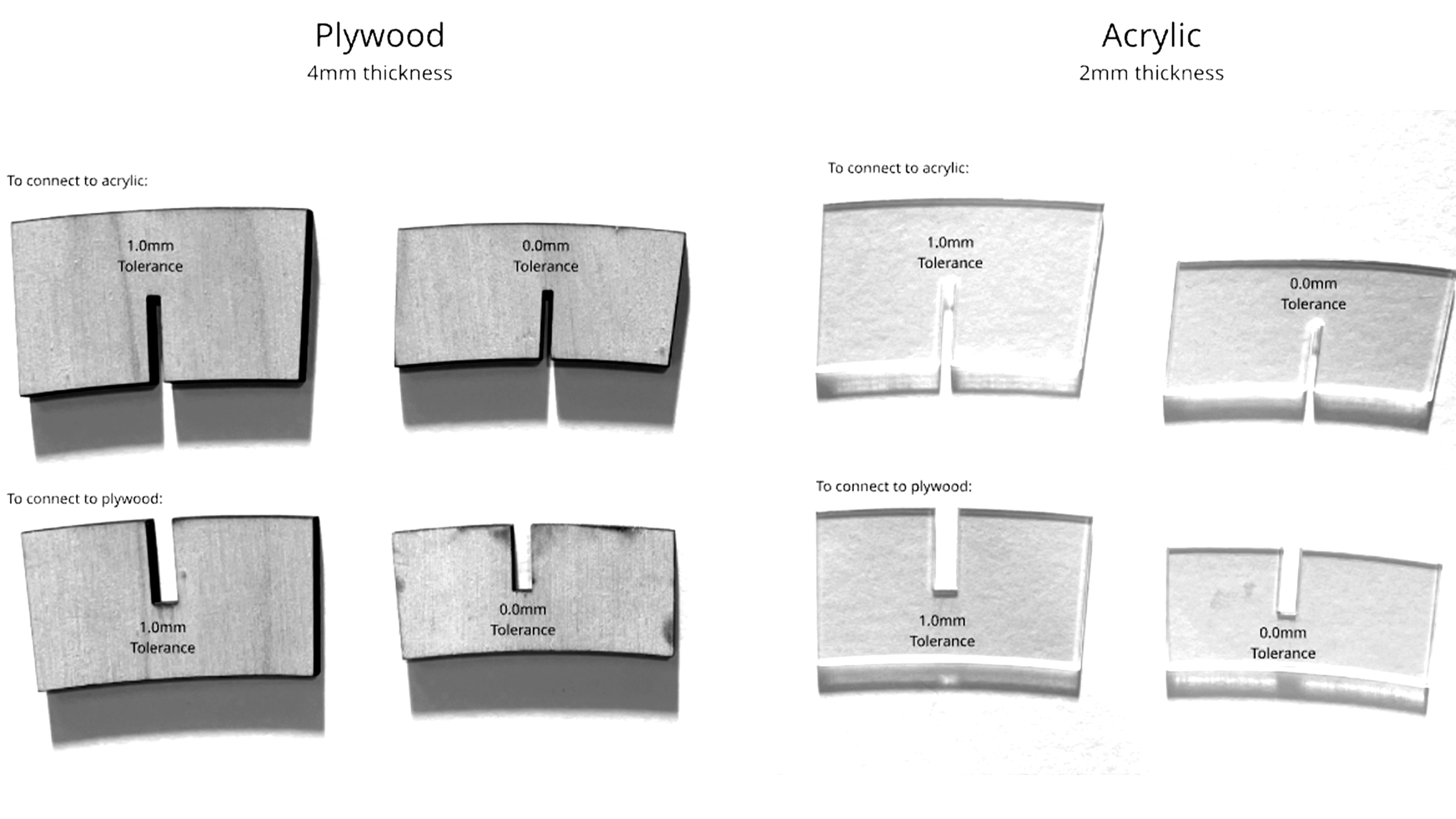

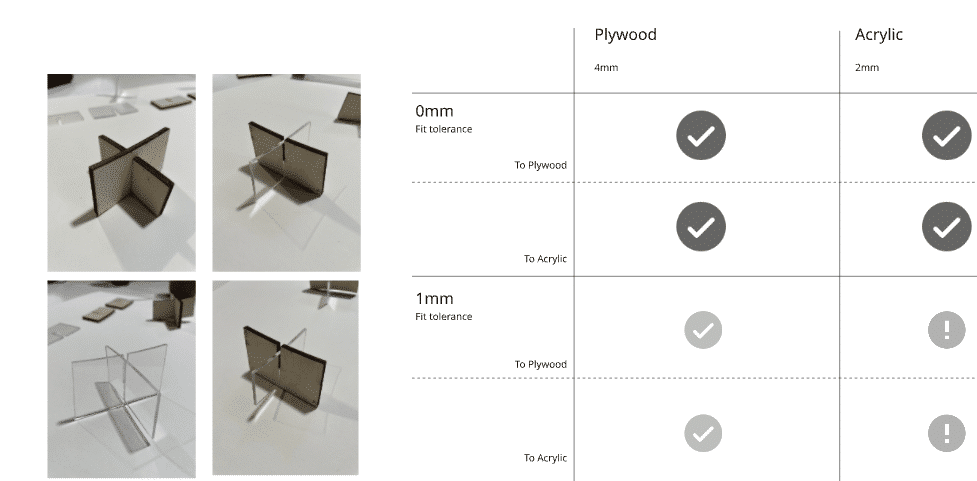

TOLERANCE TESTING

With the potential to use multiple materials, the design aims to combine multiple materials to create a composite product that will be both more aesthetically pleasing and structurally stronger.

Gap Tolerances

As a limitation of laser cutting is its lack of accuracy and inconsistancy across different materials, a mini test study was conducted to establish the optimum dimension parameters in order to have different materails slot together effectivly.

AIM

Test multiple materials and gap tolerances

FAILS

The overall pieces had issues fitting

NEXT STEP

Have clear translation of 3D model to 2D drawing layout

FINAL DESIGN

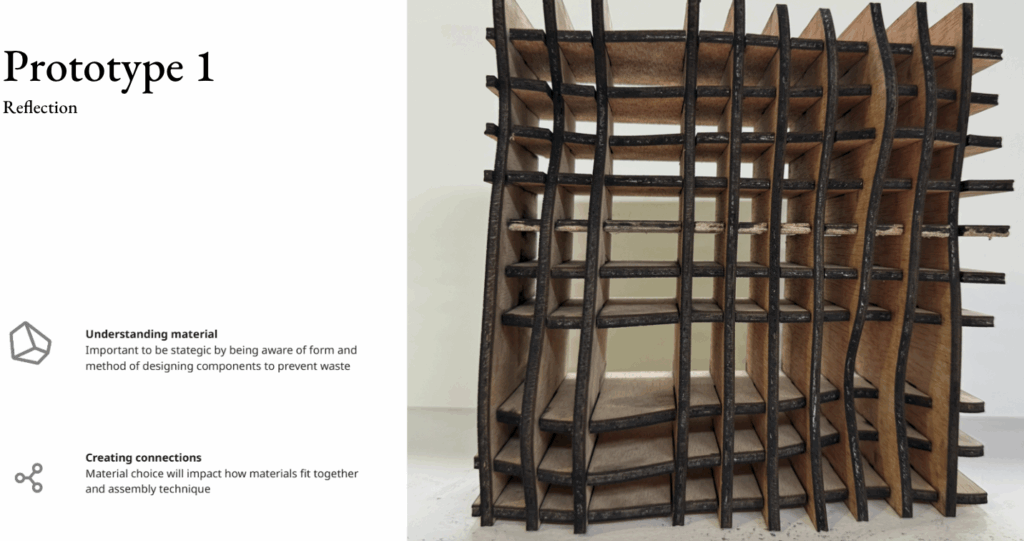

REFLECTION

Our brief was to explore the potential of waffle construction in laser cutting.

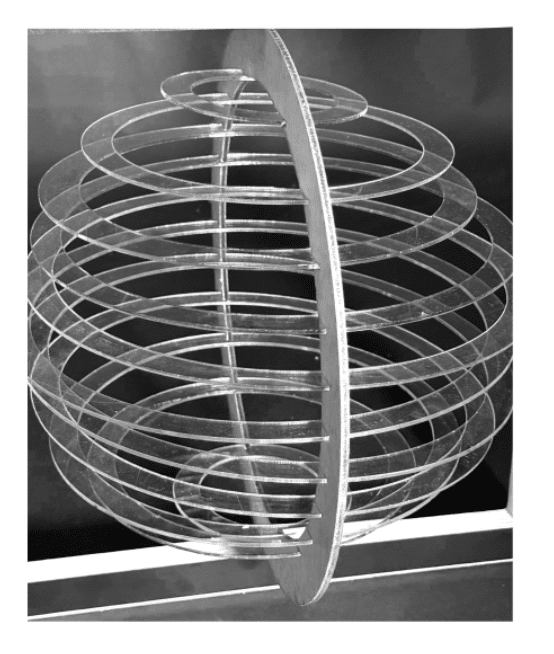

Our piece combined plywood and acrylic in circular ring frame with radial interlocking ribs, forming a lightweight, spherical structure to produce a visually expressive and structural strong product.

Optimised for fabrication efficiency, the design was based on achieving minimal waste while maximising the scale of the final form. The process of interlocking the various materials required experiments into tolerance studies to establish material behavior and how the connections could be made successfully.

Lastly, the 3D element is fully collapsible, allowing for ease of portability as well as the potential to reuse the materials in the future.

WAV-E

CNC – MILLING

DESIGN INSPIRATION

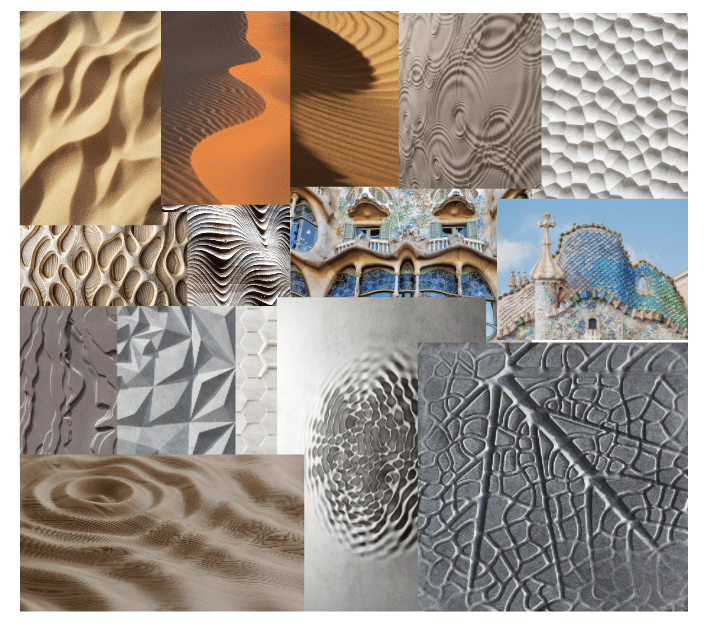

- Inspired by organic forms

- Subtractive milling effective for producing flowing continuous geometry

- Subtractive quality can replicate erosive effects of natural processes

- Leaves behind texture which can be integrated into the design

- Constraint, can’t do sharp edges, nature rarely has sharp forms

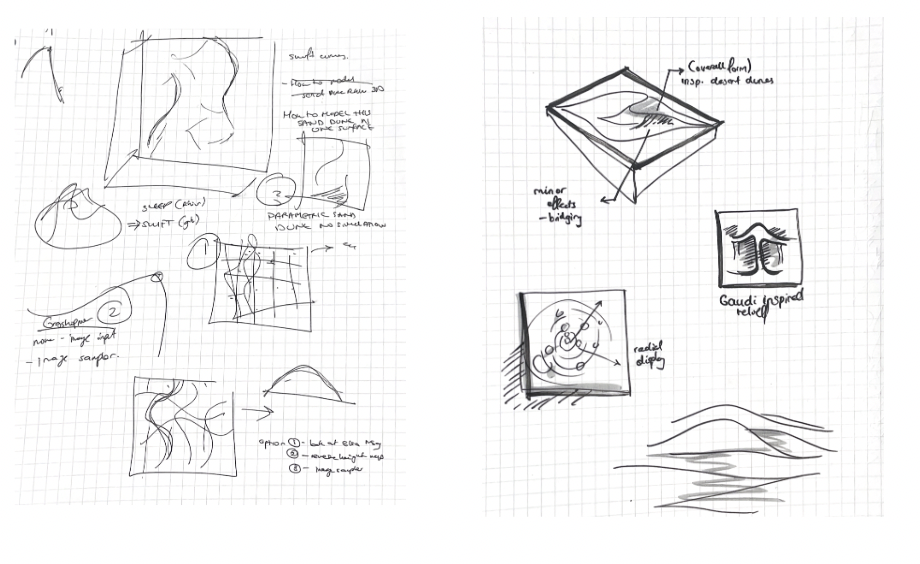

SKETCHES

- Forms that resembled curves; desert dunes, waves on water

- Wanted to play with contrast between cutting texture and curvature patterns

- Combining multiple textures to make more tactically interesting for touch as well as observation

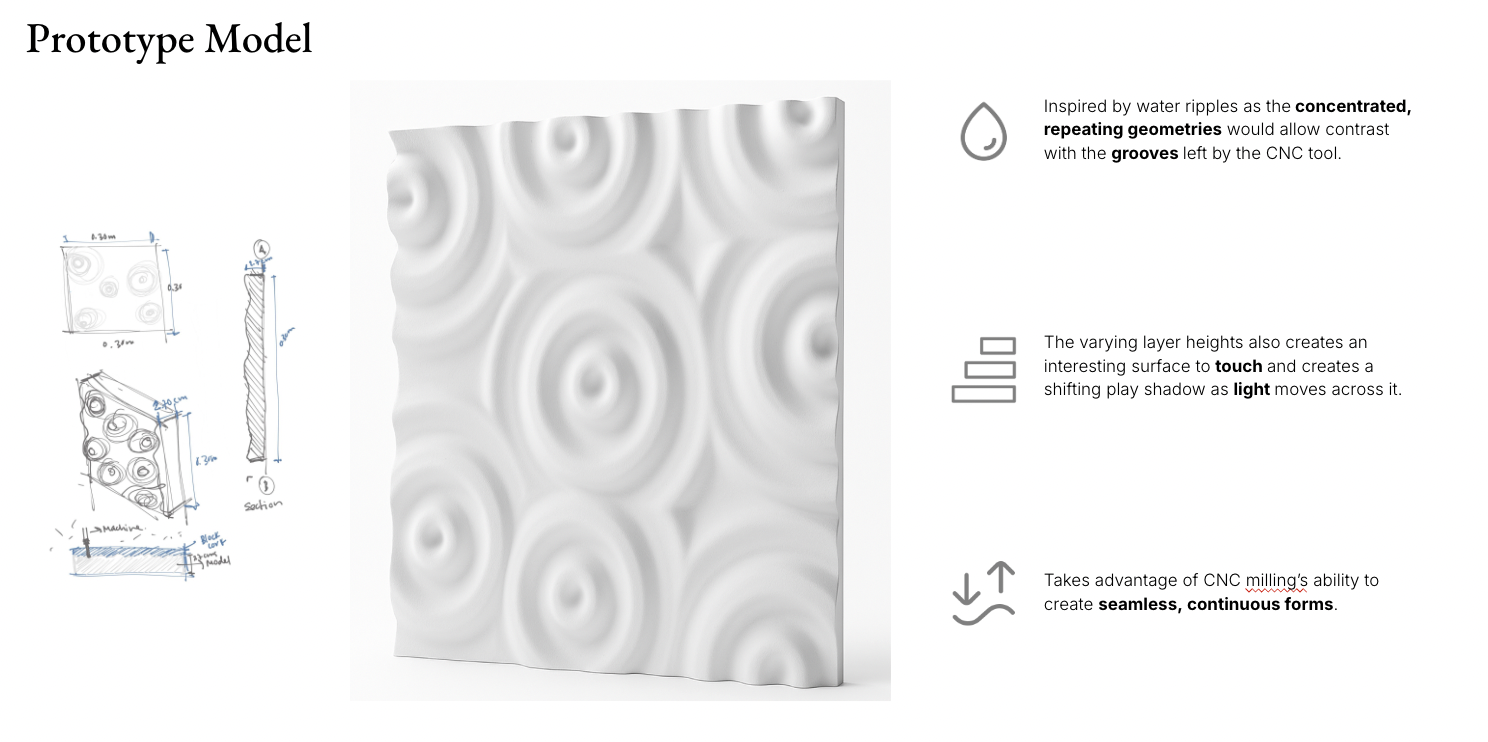

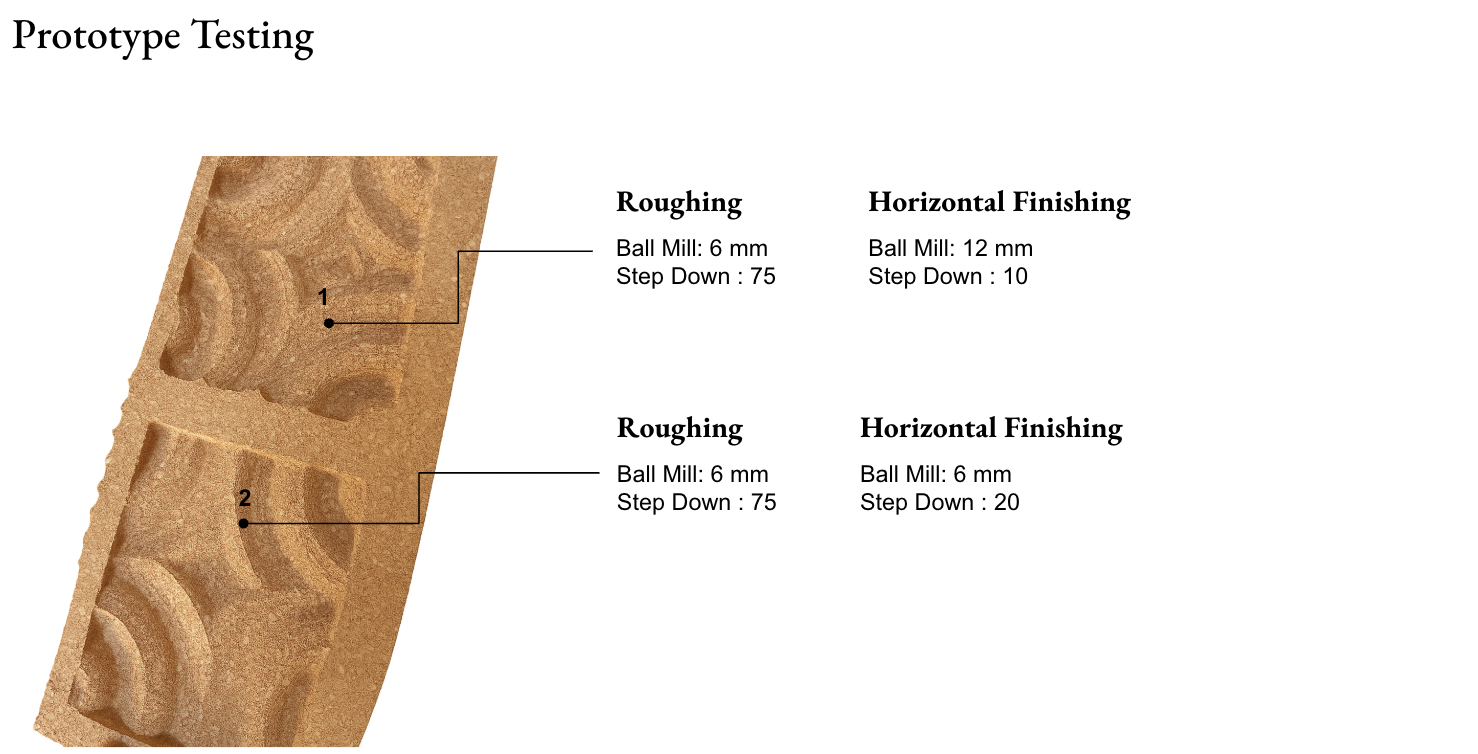

FINAL DESIGN

REFLECTION

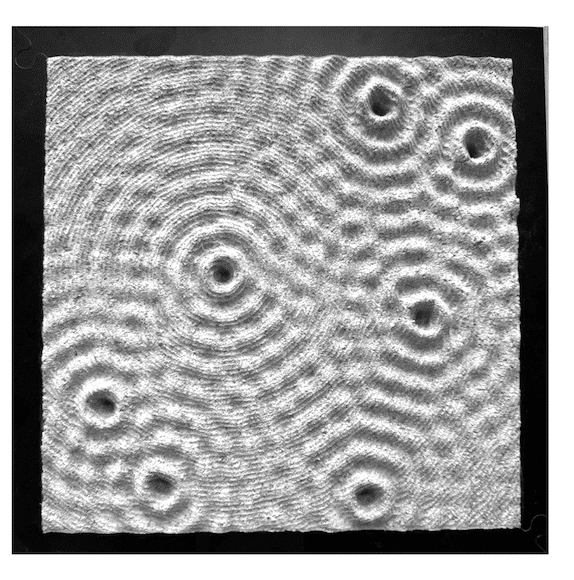

Our final piece translated a natural ripple form through CNC machining, creating an interesting narrative of natural forms being replicated using automated machining procedures.

The spiral finishing produced an intricate texture that plays with the concentric waves of the ripples, whilst the cork material effectively reveals the surface undulations and depth variations in certain lighting through shadowing that would be less visible with another surface pattern on the same material.

The simplicity of the geometry also enabled both roughing and finishing to be completed with the same large mill bit, significantly reducing milling time and eliminating the need for tool changes.

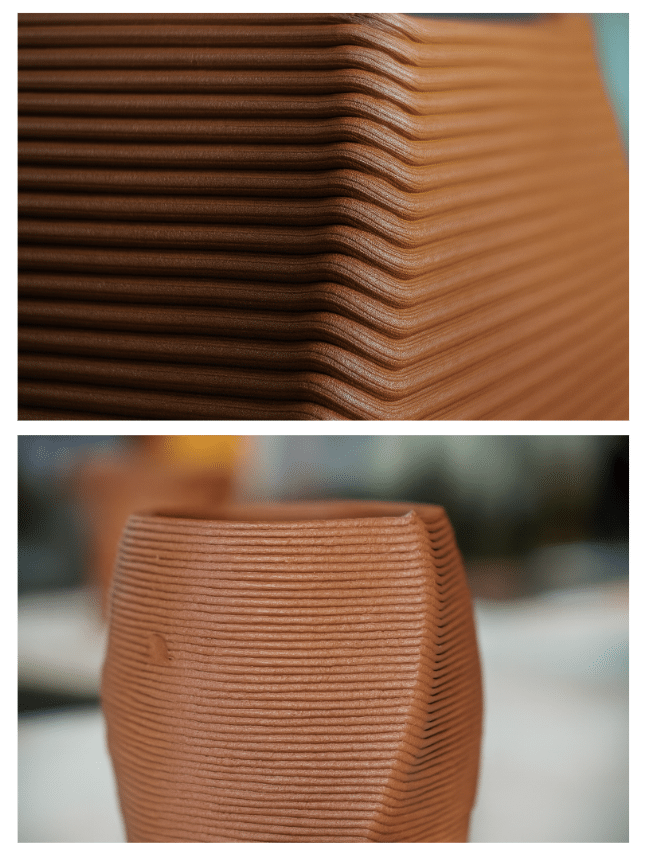

WHIRL-E

FINAL DESIGN

REFLECTION

Our final design reflects a careful balance between vernacular craft and robotic precision

. Inspired by traditional Mexican and Guatemalan clay cups, the piece captures organic curvature while embracing the layered logic of robotic extrusion.

Throughout testing, we refined the geometry to ensure the wet clay could be deposited without collapsing, resulting in a form that is structurally stable yet still expresses the subtle imperfections and material behaviour visible in handcrafted pottery.

The final model demonstrates how robotic fabrication can reinterpret traditional craftsmanship while preserving its tactile authenticity.