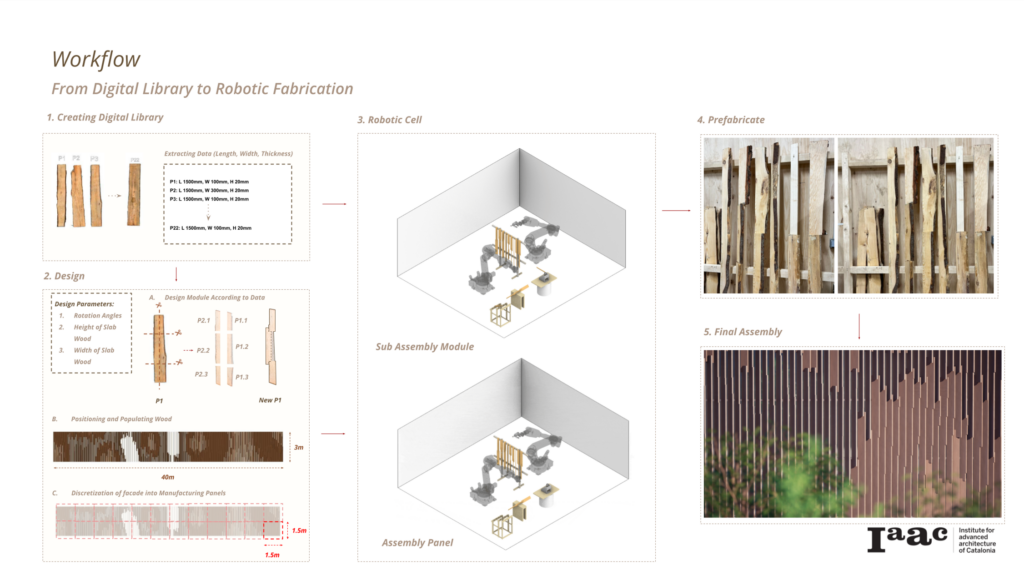

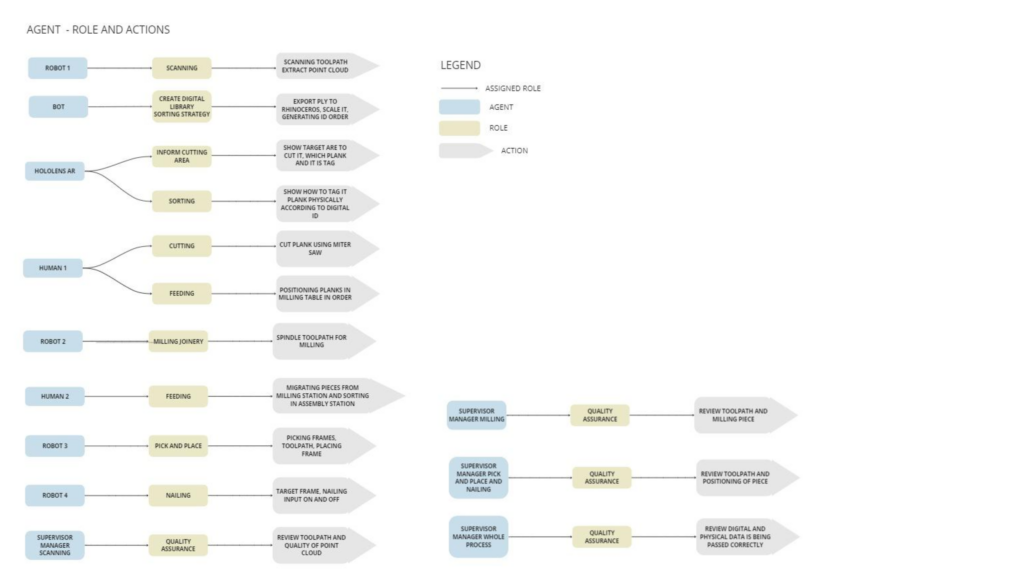

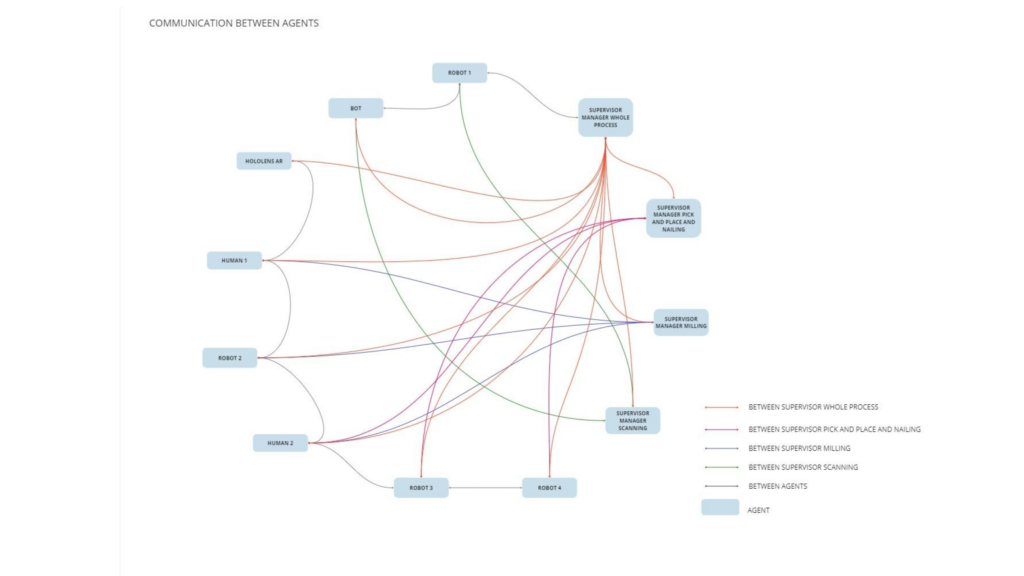

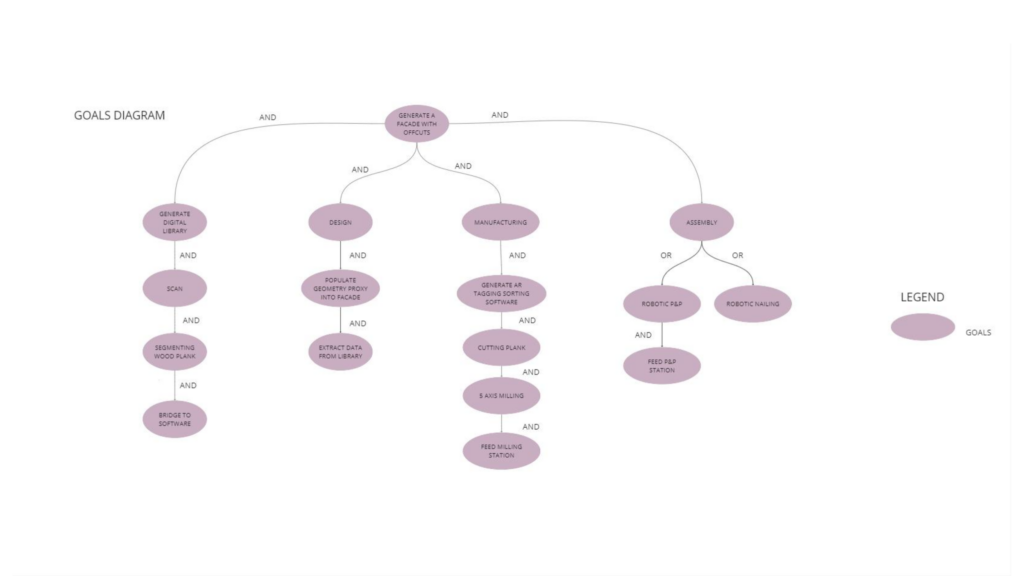

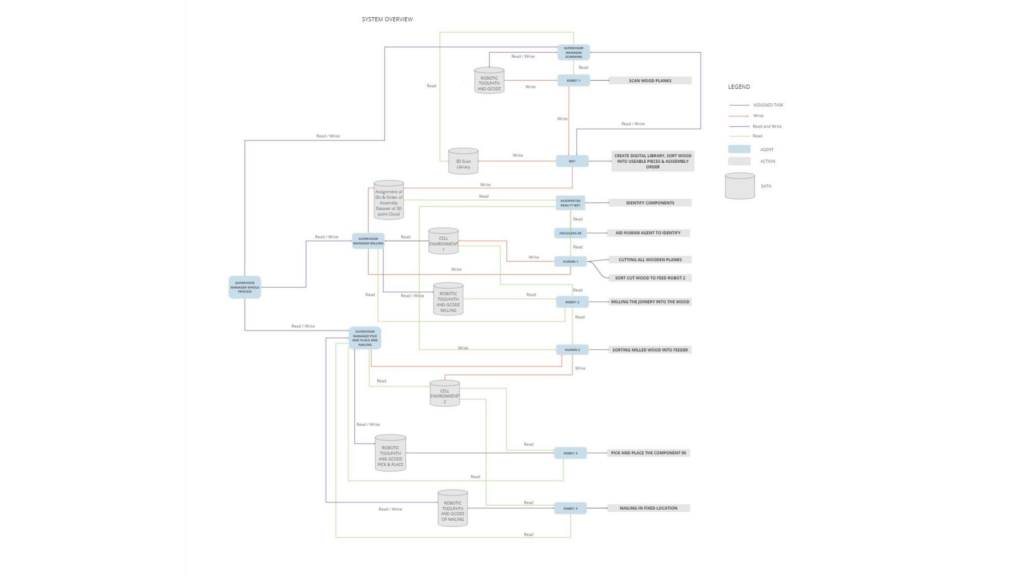

The aim of this Seminar was to imagine a scenario where the Studio Project could be imagined on an industry floor with full automation. In order to understand the workflow and position of each station to fabricate a facade made from raw edge sticks an an agent based system was sketched as diagrams in order to understand all parts of the system workflow and its roles so a hybrid scenario on a industry floor could be imagine: both linear and circular. Circular inside each specific phase (generating the library, scanning, sorting, depositing and generating the quality assurance on this phase). Once this phase is done the chosen sticks are passed down to the other phase which is adapted to the design aim, pre processed (cutted by human as an agent), then it is passed down to the robotic manufacturing cell where the data, the robotic toolpath and quality assurance of the process needs to be evaluated on their own loop then passed down to the other sequential phases.

Overall the seminar helped us understand the roles of each agent, how they related to each other and the data necessary for each phase and how to evaluate. If this experiment was to be developed further we could input a test in a space of a factory floor and test it utilizing ABxM with each agent and as well as testing how to optimize the position of each cell on the factory floor plan utilizing multi fitness criteria engine such as wallaceix.