In the ever-evolving landscape of architectural innovation, the exploration of materials and construction techniques plays a pivotal role in shaping sustainable and efficient structures. This presentation delves into the fascinating realm of hygroscopic vaults, examining the transformative potential of wood in response to varying moisture content. Through an in-depth analysis of the hygroscopic behavior of wood, we unveil a groundbreaking approach to construction. Drawing inspiration from the HYGROSHELL project and its air-dried panels, we unravel the possibilities of pre-programming wood’s bending capacity to create a bilayer structure that achieves both form and function. Our journey encompasses comparisons between traditional Cross-Laminated Timber (CLT) and hygroscopically bent CLT, showcasing not only the structural advantages but also the environmental and economic benefits of embracing hygroscopic wood. From the scripting process in Rhino to the site-specific considerations in Srinagar, India, this presentation offers a holistic exploration of the hygroscopic vault system, underscoring its potential as a sustainable and adaptable solution for contemporary architectural challenges.

.

Hygroscopic CLT

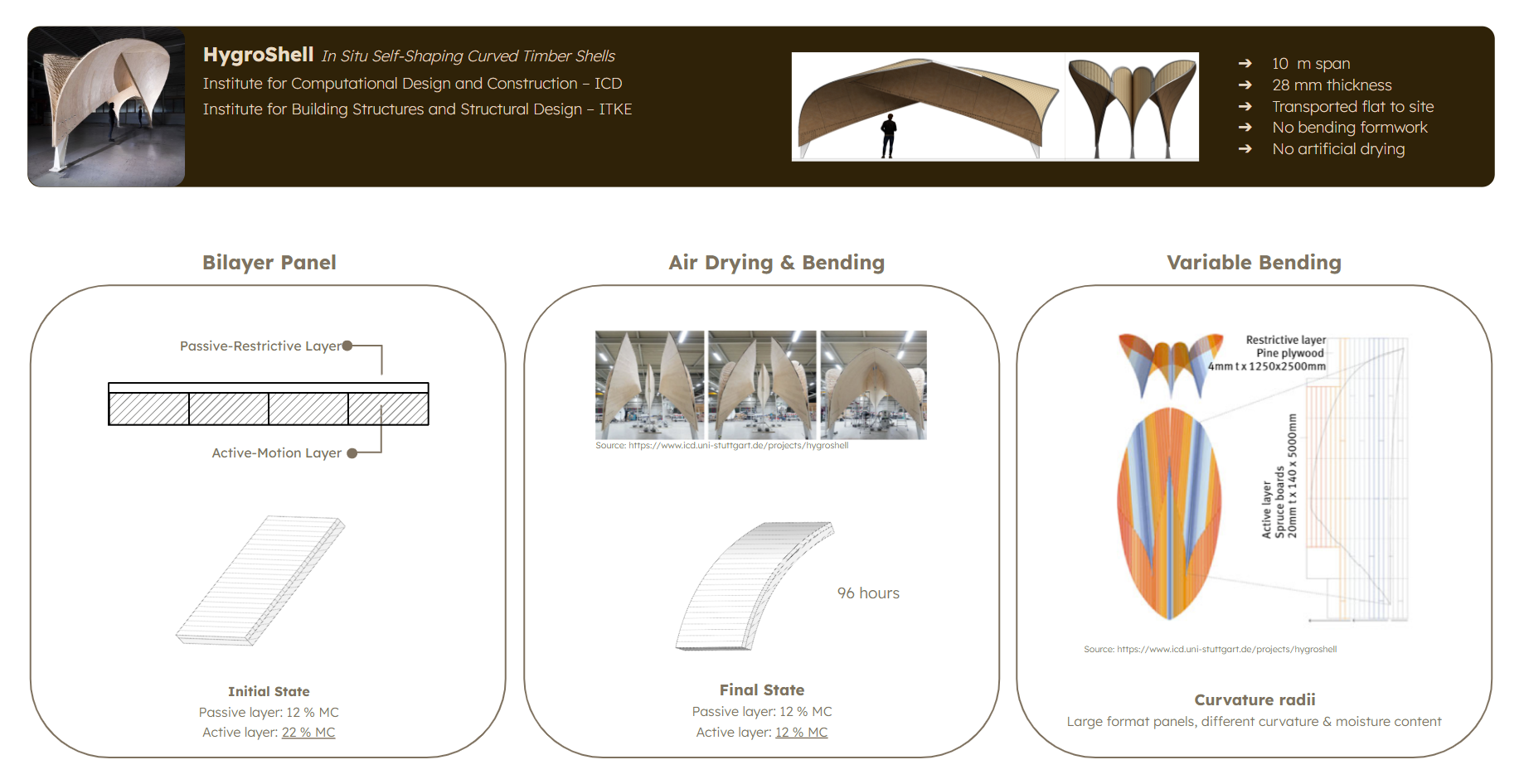

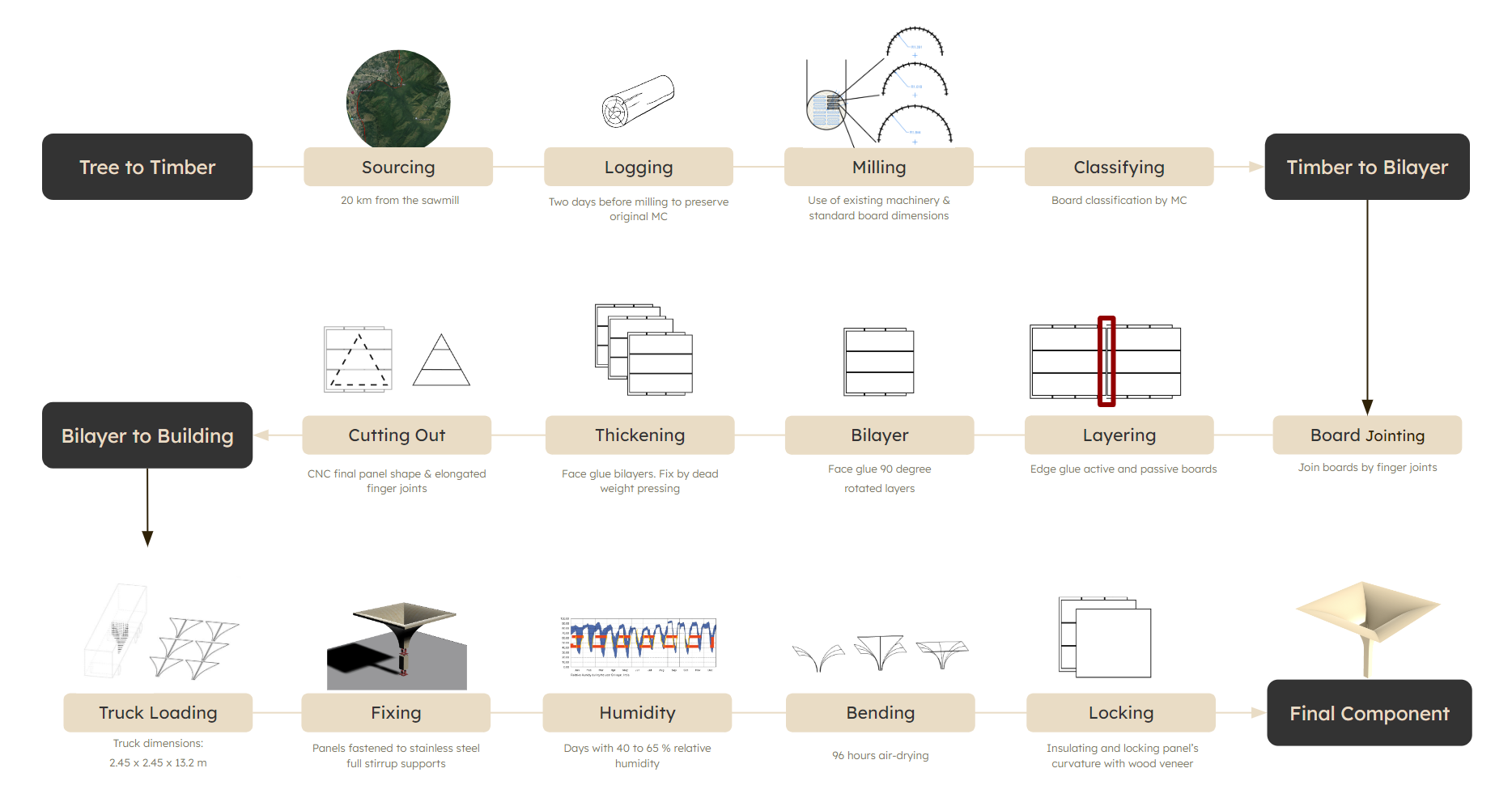

The HygroShell project by Dylan Wood from the ICD is our reference, employing air-dried panels with variable curvature along the central axis, resulting in a covered space with reduced material usage compared to traditional CLT orthogonal floor walls.

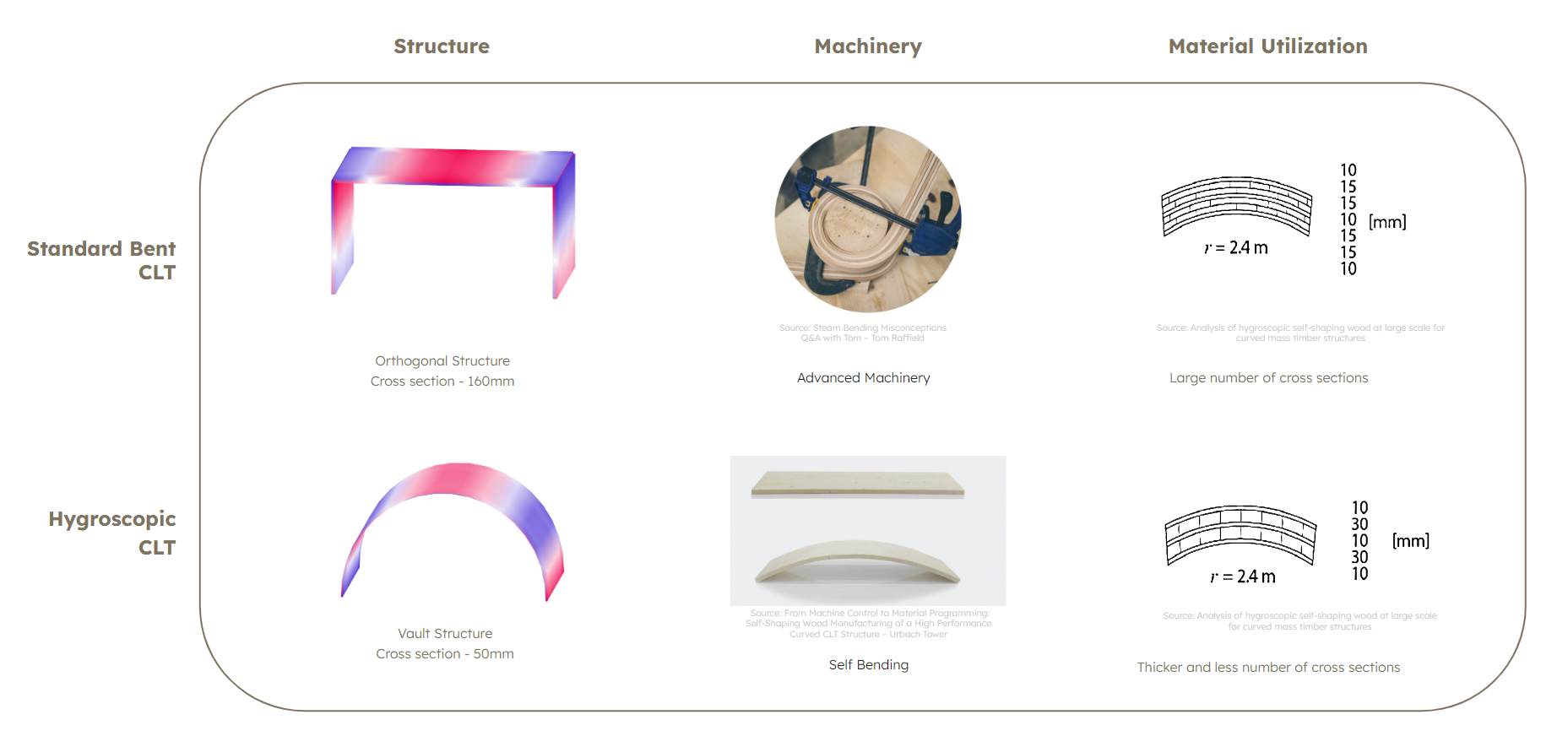

Building upon insights from Hygroshell, we compare standard CLT with hygroscopically bent CLT. Traditional bent CLT demands advanced machinery for formwork, whereas hygroscopic wood employs a natural bending principle with basic raw material processing adaptable to local sawmills. CLT requires seven layers to achieve similar curvature standards, increasing glue application, labour, and time. In contrast, hygroscopic wood uses thicker sections, reducing material waste. Transportation costs are also minimized as hygroscopic wood can be flatly transported and bent on-site using an air-dry process. Comparing CLT orthogonal and vault structures, we find the latter requires half the cross-section size for the same volume.

.

.

Process Parametrization

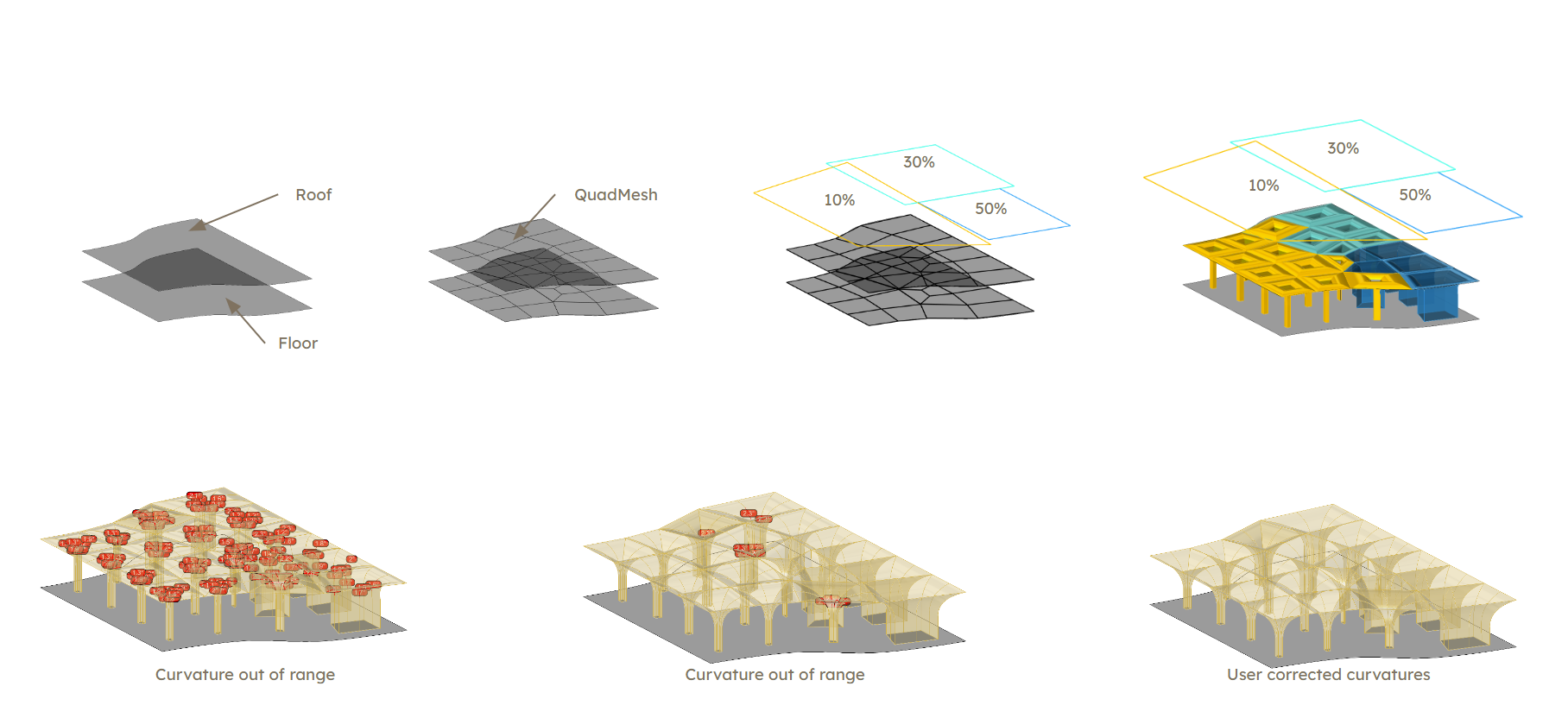

Our Hygroscopic Vault script in Rhino automates the process using pre-existing surfaces. The roof surface transforms into a quad mesh with optimized face sizes. User-defined zones dictate vault placement, with varying percentages for open views, technical rooms, shops, and galleries. Faults are highlighted and adjustable via a slider, allowing users to merge faces for customization.

.

Design Space Iterations

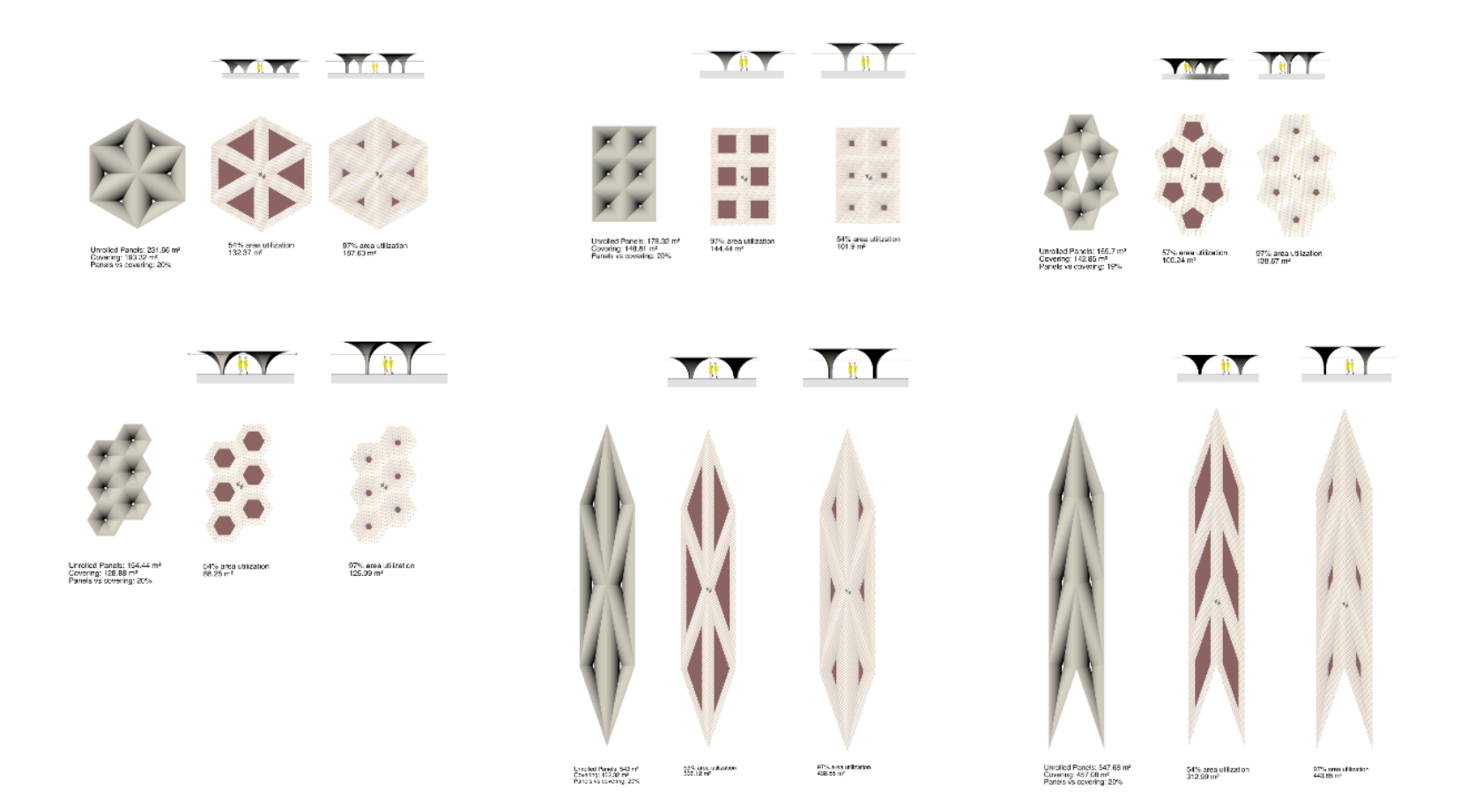

The script calculates viable space with proper headroom by analyzing floor and roof surfaces. Users receive a catalogue of unrolled vault panels and their area requirements. In the image above, three instances test the limits of the system in terms of minimum bending radius and maximum panel length, accompanied by the headroom and panel area calculations.

.

System Materialization

Structural analysis with Karamba reveals a stable structure using a 40mm thick cross-section, with 10mm as the passive layer and 30mm as the active layer. Truck dimensions determine panel size limits for transportation. Construction involves on-site air-drying, with a detailed fabrication sheet providing values for the unrolled panel area and total timber volume.

.

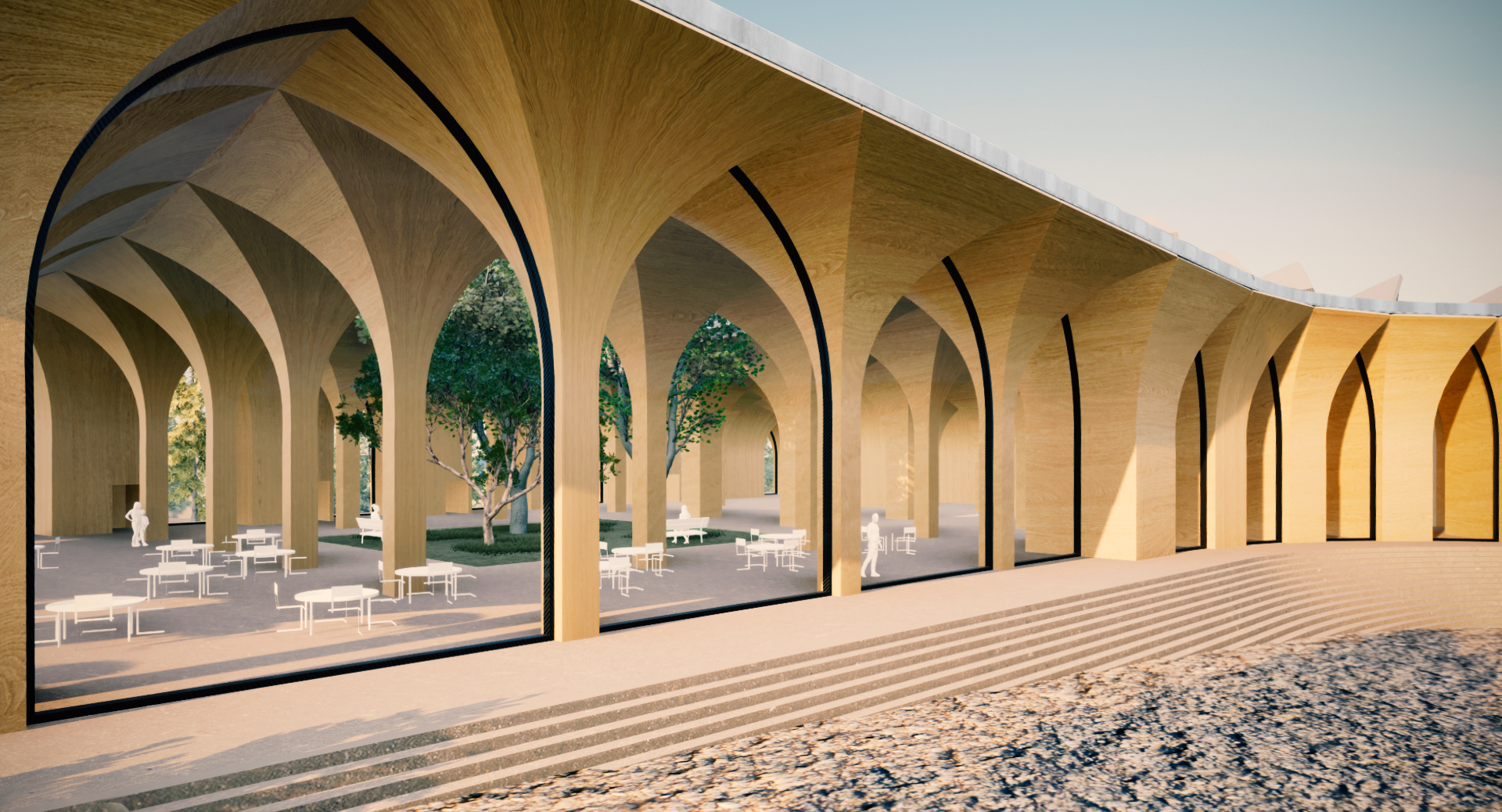

Urban Haat

Project Site

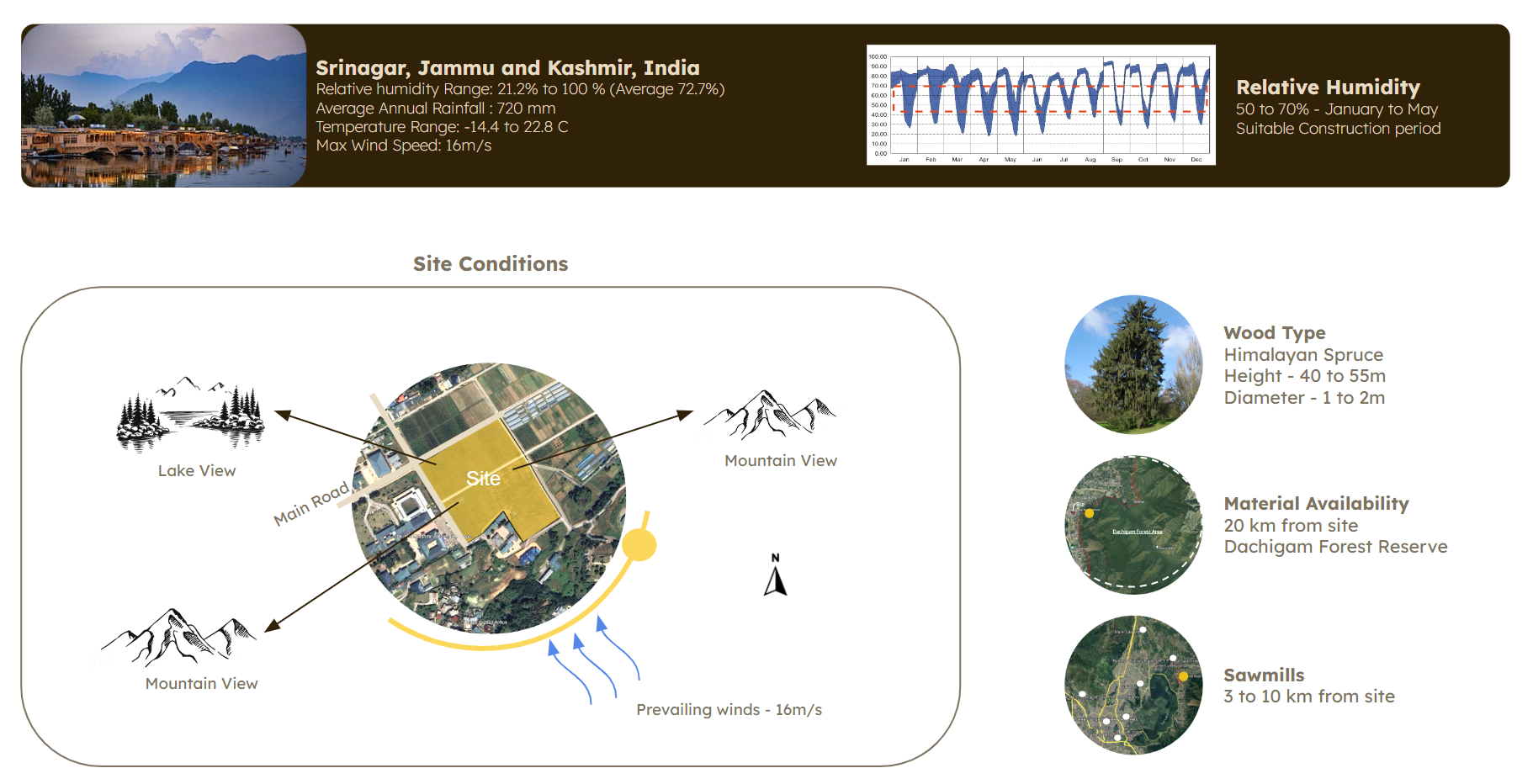

Situated in Srinagar, India, our proposal addresses the decline of traditional handicrafts. Hygroscopic structures are ideal due to the suitable moisture content from January to May. Himalayan Spruce, sourced within 20km, is used, with sawmills as close as 3km. The site’s location and environmental conditions are considered in the design.

.

Project Actualization

The plot, featuring a slope and scenic views, offers a dynamic visitor experience. Spaces within the building are defined by three vaults or “mushrooms,” serving various functions. Skylights and roof slopes enhance natural lighting and precipitation management.

Considering design requirements and topography, the structure is planned with segregated mushrooms for open views, rooms, and service cores. Detailed joinery and connections are presented, showcasing the integration of metal plates in the construction.

.

.

Conclusions

This construction system offers many architectural spaces while efficiently using wood. Vaults do not lend themselves to buildings with multiple levels. However, multiple floors can be contained in a large format vault.

In addition, the hygroscopic vault system presents an environmentally sustainable alternative, minimizing carbon footprint by utilizing locally sourced materials and reducing the need for energy-intensive processes. Our process minimizes CO2 emissions by sourcing materials locally, reducing transportation needs, and avoiding steam for moisture content adjustment. Hygroscopic wood requires half the material of CLT, leading to reduced glue usage and minimal formwork requirements.

Moreover, the adaptable nature of hygroscopic wood allows for cost-effective and resource-efficient construction, making it a viable choice for sustainable architectural projects in diverse geographical locations.