The objective of this project is to expand the capabilities of specific robotic processes in additive manufacturing, known as impact printing, Impact Printing, a novel additive manufacturing Robotic technique that consolidates pliable soft particles through a robotic shooting process. The cohesion among these soft particles arises from the conversion of kinetic energy, acquired during acceleration, into deformation upon impact. Consequently, no extra binding material is required between the soft particles, as the inherent cohesive and self-interlocking properties of the material serve as the primary binding agent.

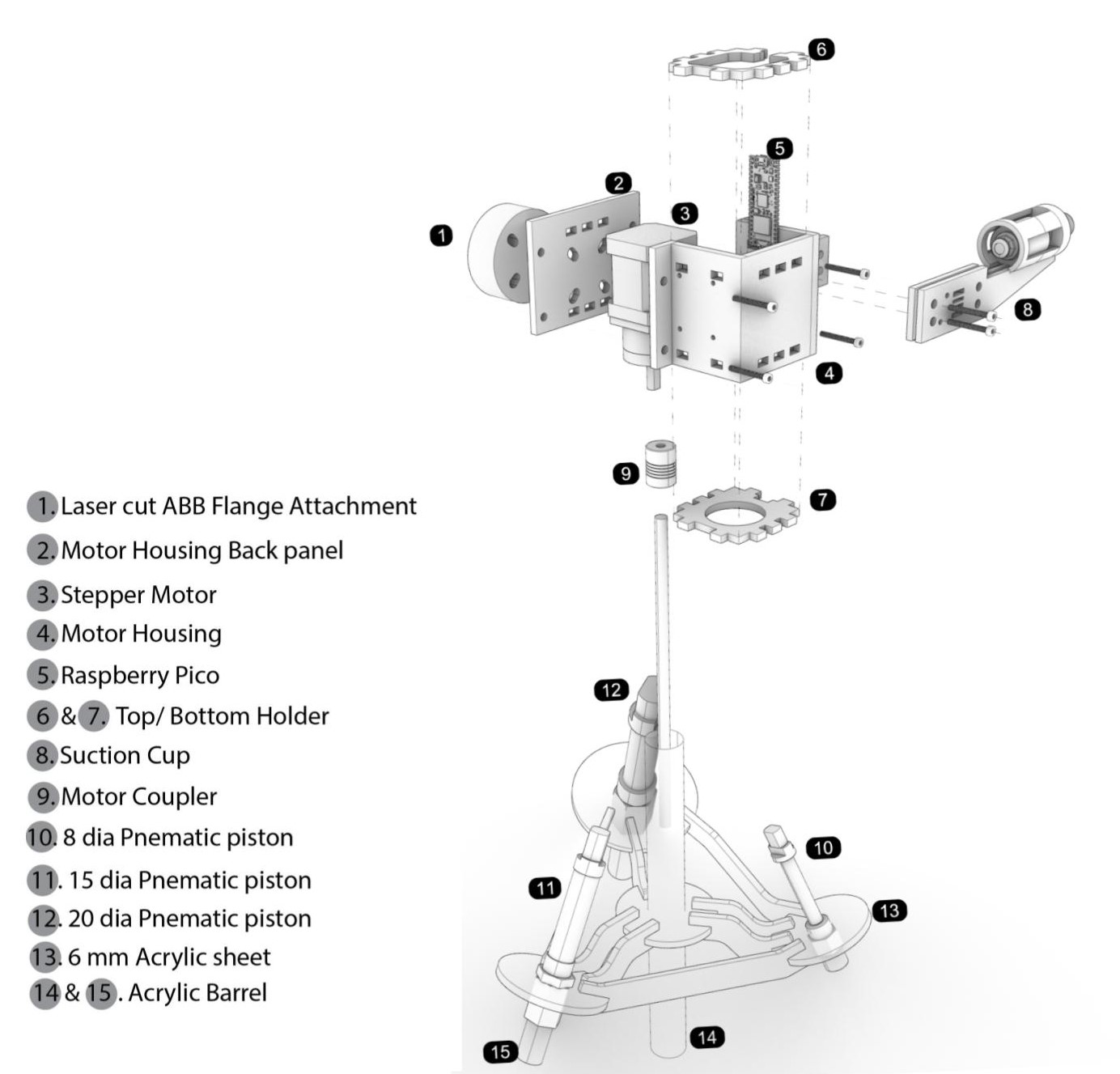

For impact printing we have pneumatic piston with barrel consists of (15mm) in diameter, now we want to include two other pistons with different diameter. This opens another paradigm in additive manufacturing.

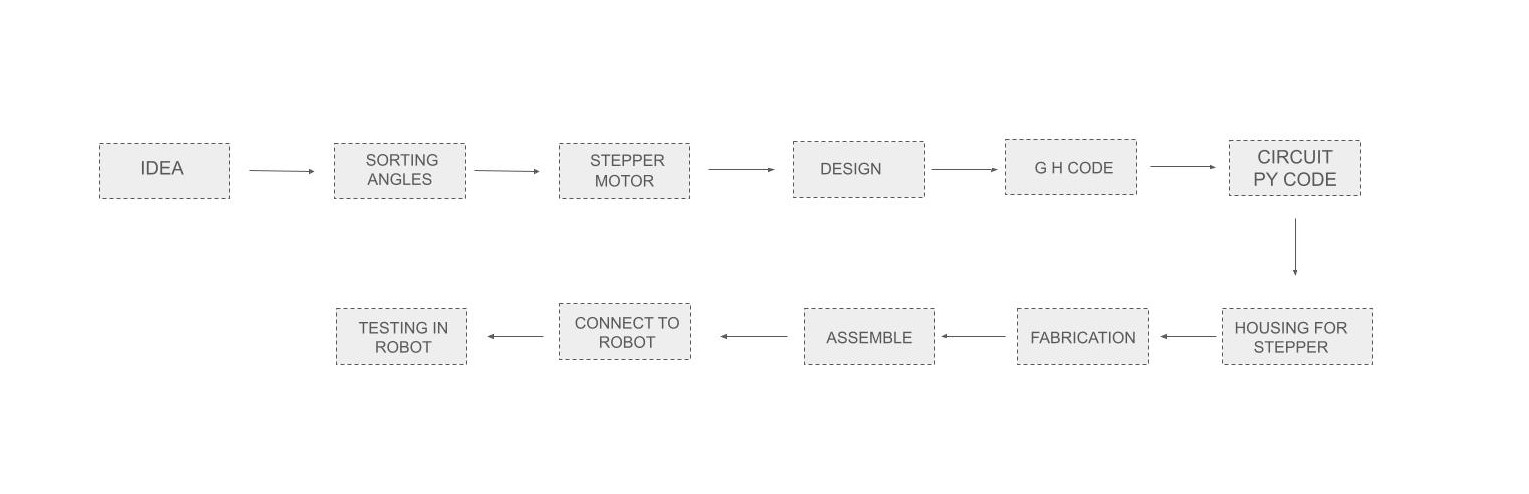

GENERIC WORKFLOW

INSPIRATION

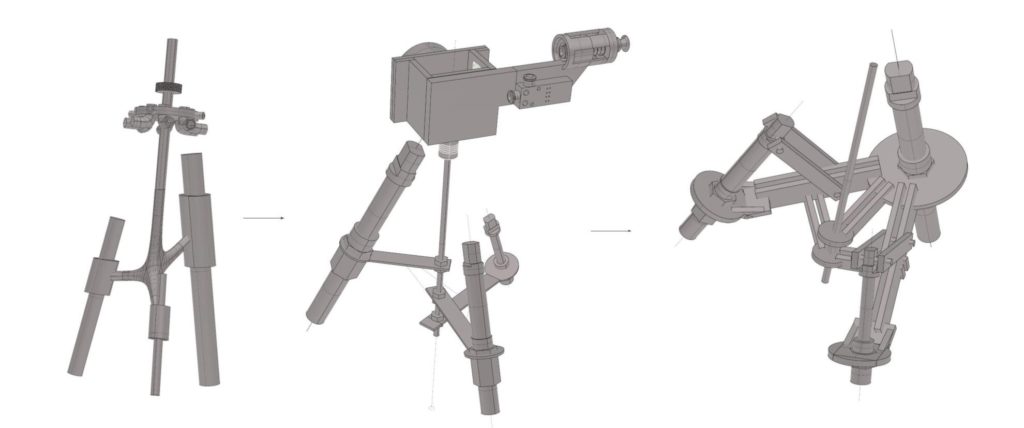

Our initial tactical deployment involved the use of a pistol, as this particular firearm possesses the capability to rotate and discharge projectiles. In the context of developing the rotation tool, it is imperative to maintain a consistent center point within the same plane. Simultaneously, when one piston is in motion, it is essential to prevent any interference with the prototype by providing adequate buffer space. To address this challenge, we drew inspiration from microscope design principles.

DESIGN EVOLUTION

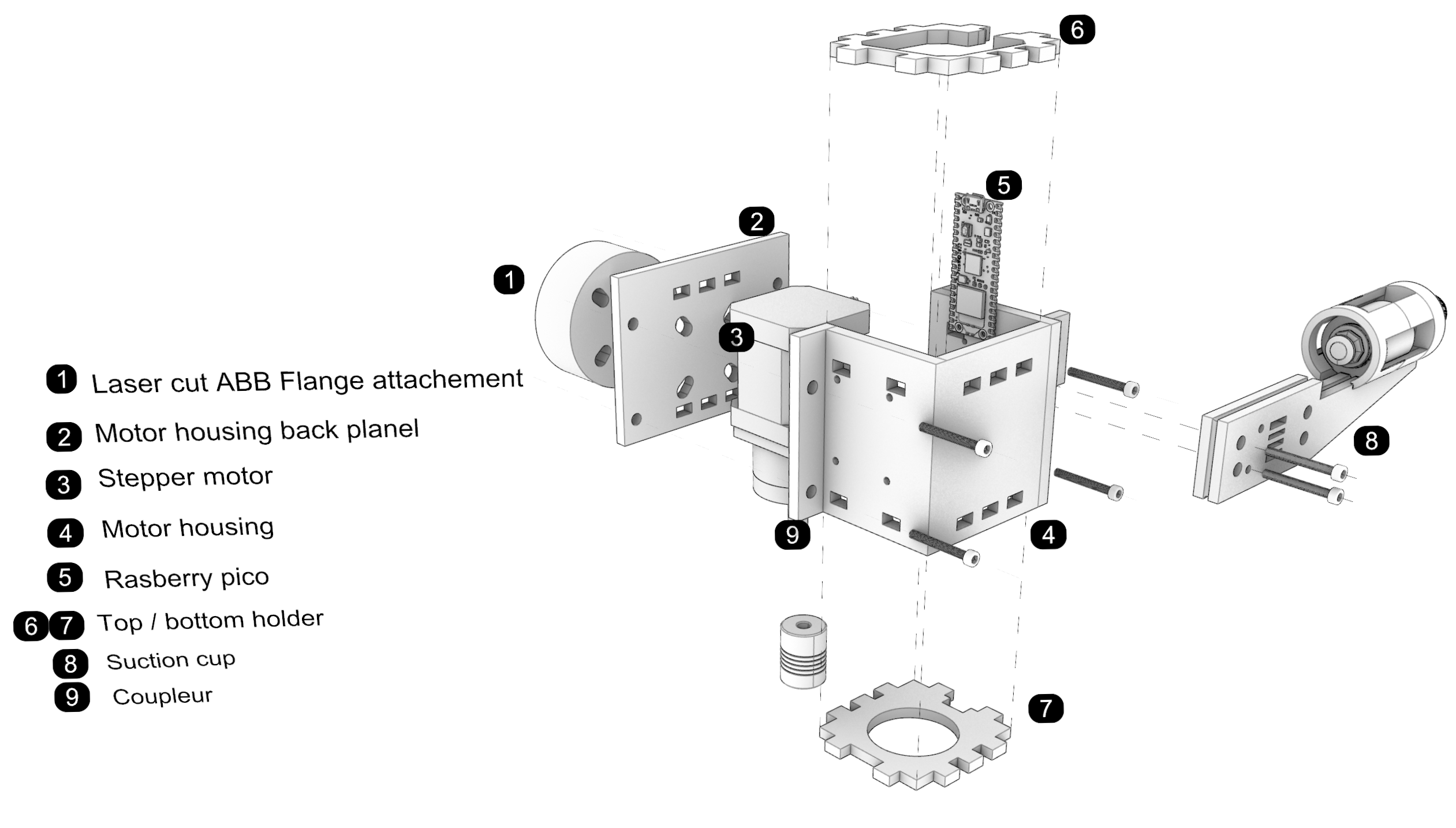

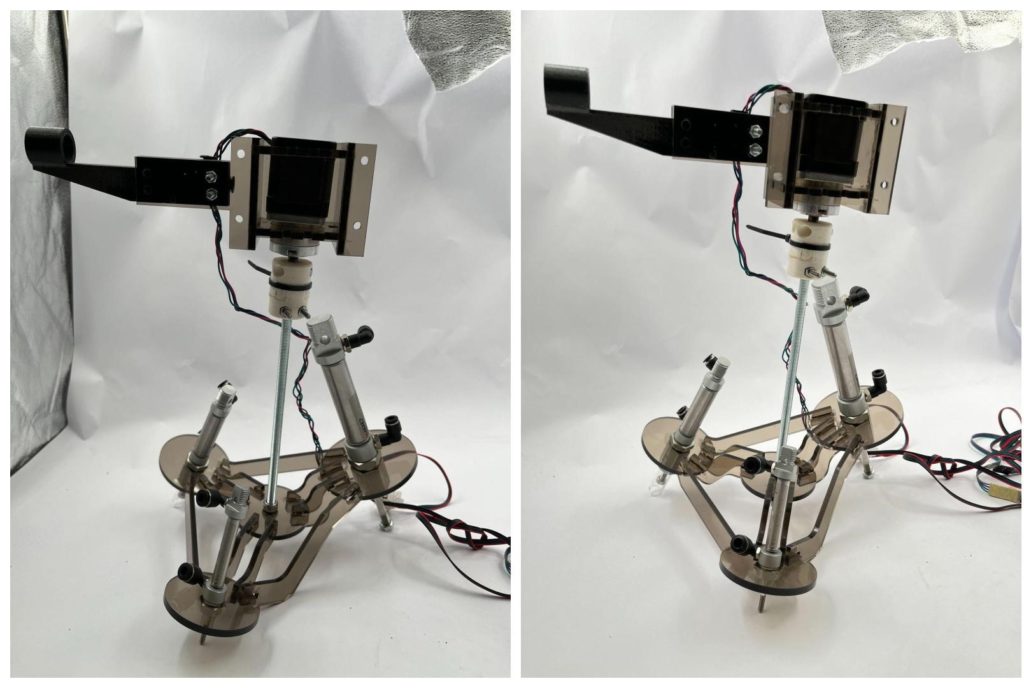

FINAL PROTOTYPE

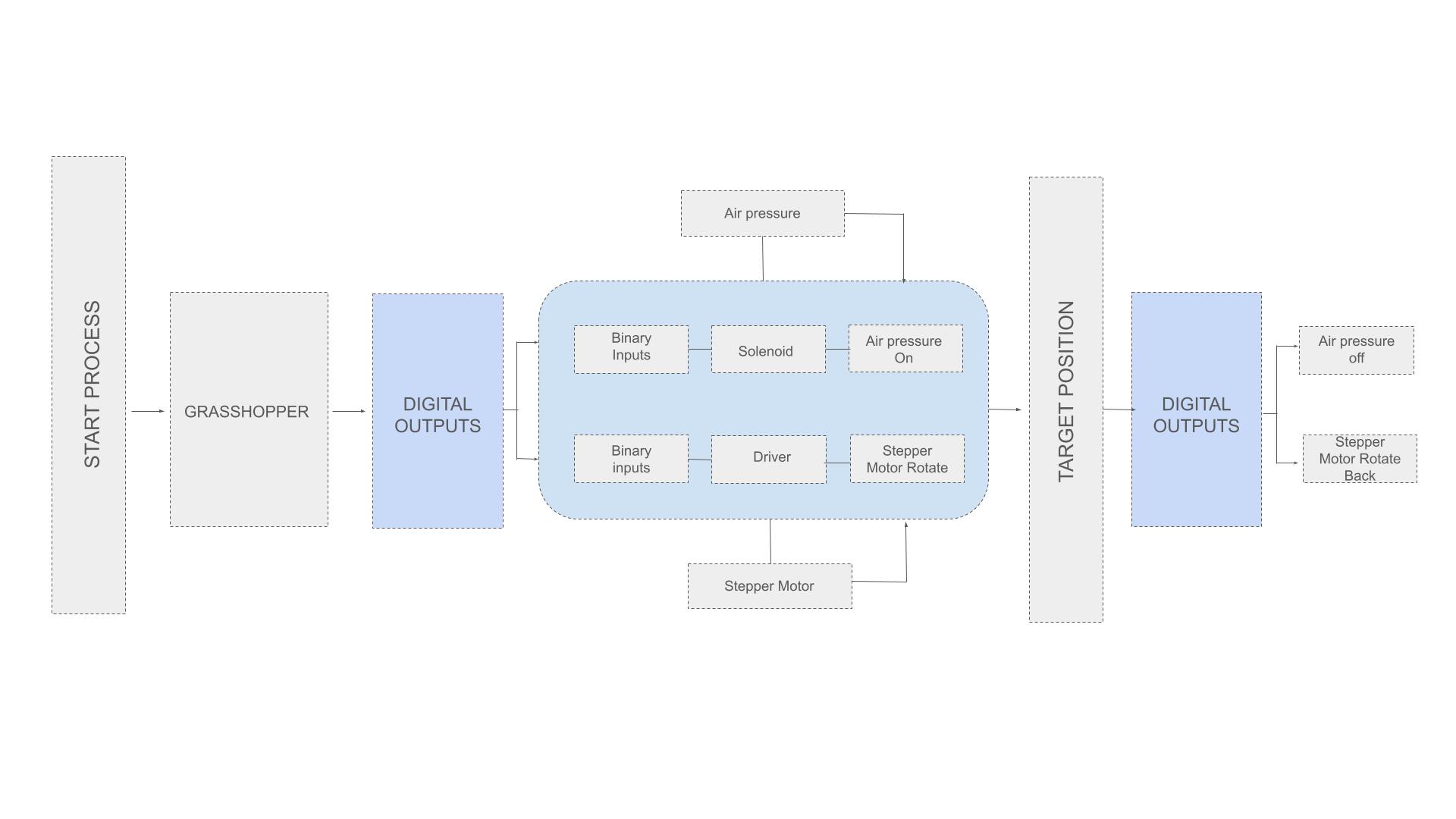

COMMAND WORORKFLOW

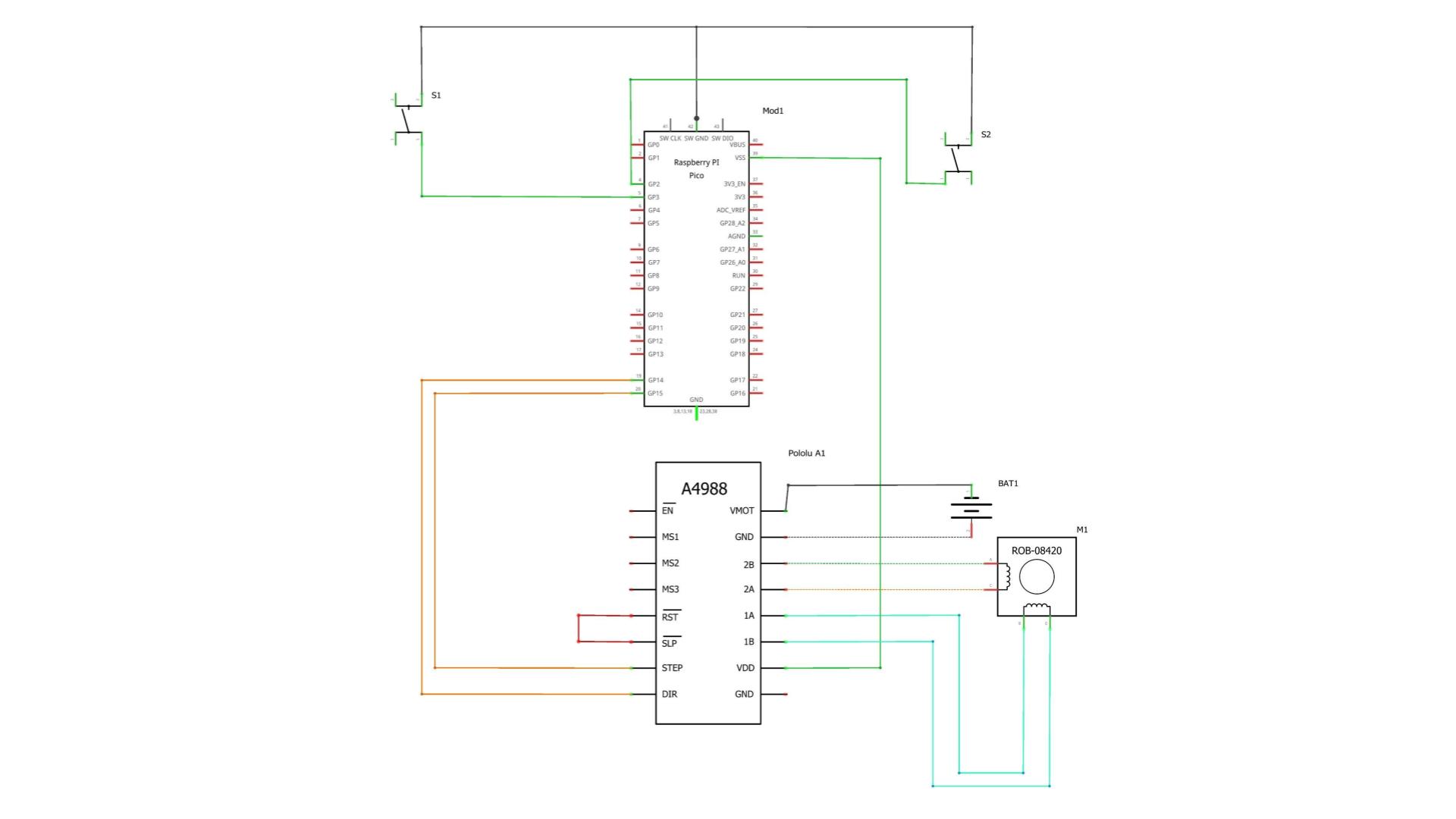

The electronic workflow has been designed to support both Air Pressure to pistons and rotation of the end effector. First Rotation is controlled by two inputs from the robot, these are translated into the number of steps and direction forward and backward with the same equal steps. It is designed in such a way that it comes back to home position after rotation. The diagram below shows how circuit diagram operates.

CIRCUIT SCHEME

SIMULATION

CONNECT TO ROBOT

CONCLUSION

During the prototyping phase, numerous challenges have arisen. Specifically, the current hurdle revolves around the coupler that links the stepper motor and the prototype. Ensuring friction is crucial in this scenario.