Abstract

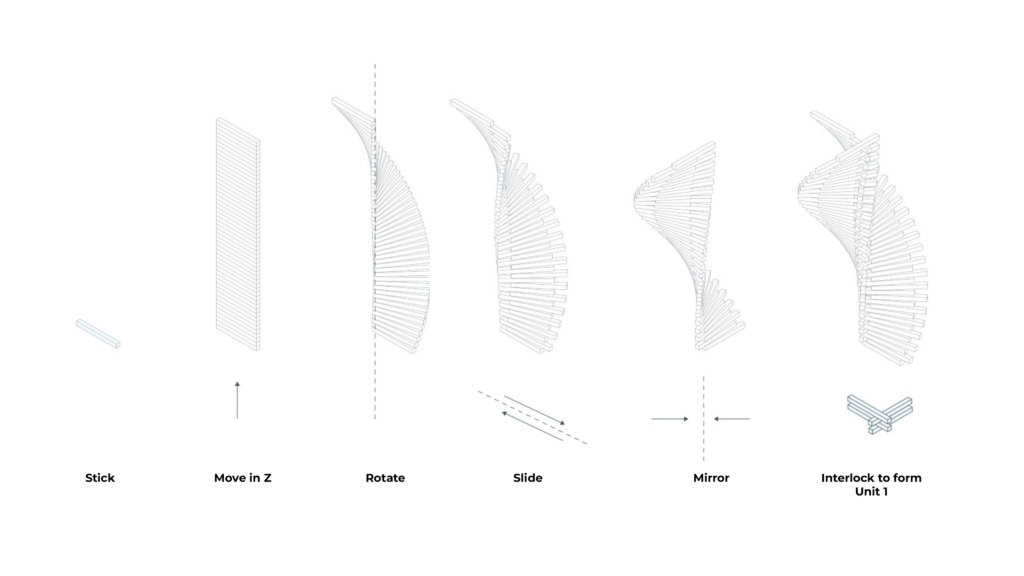

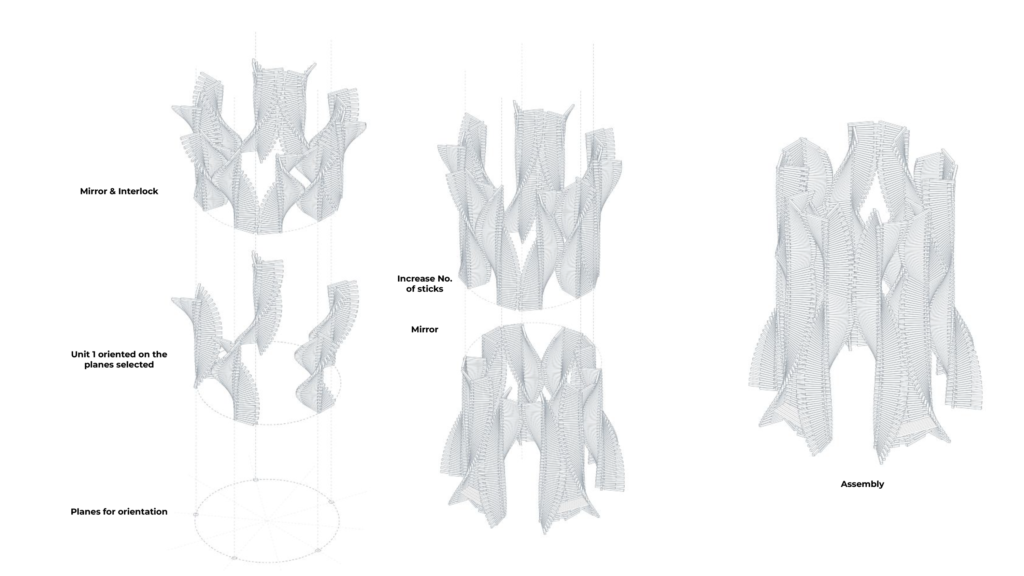

This project will focus on using the pick & place operations to develop column geometries stacked out of timber elements. Below we present the development of a parametric system capable of integrating fabrication constraints and architectural goals. The aim was to create a natural geometry with a simple linear element, a catalog of multiple forms based on geometrical terms, the robotic limits, and the desired aesthetic. We produce variables of modules and types in order to fabricate the final module which can produce also architectural applications, such as a pavilion or shell structure.

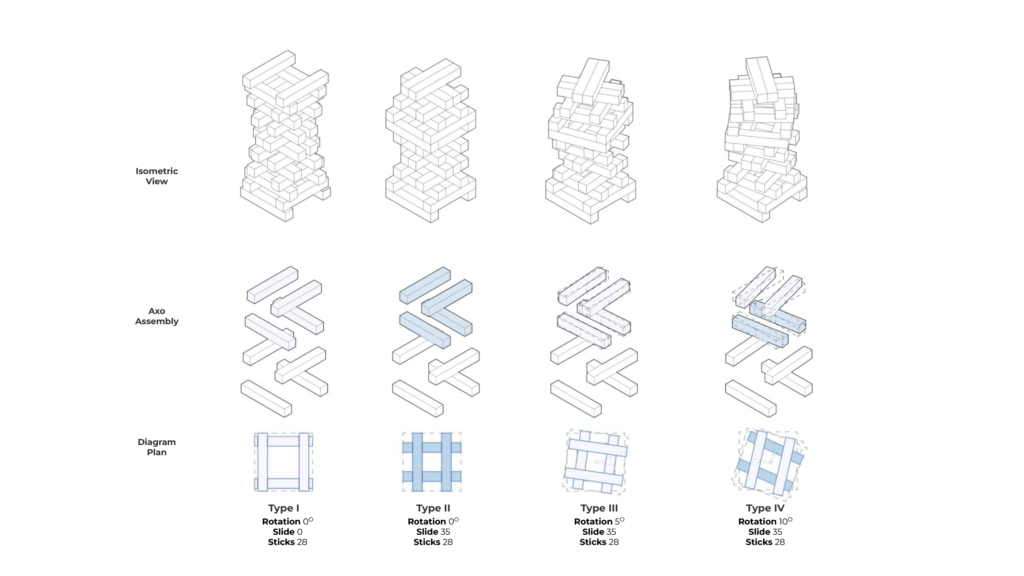

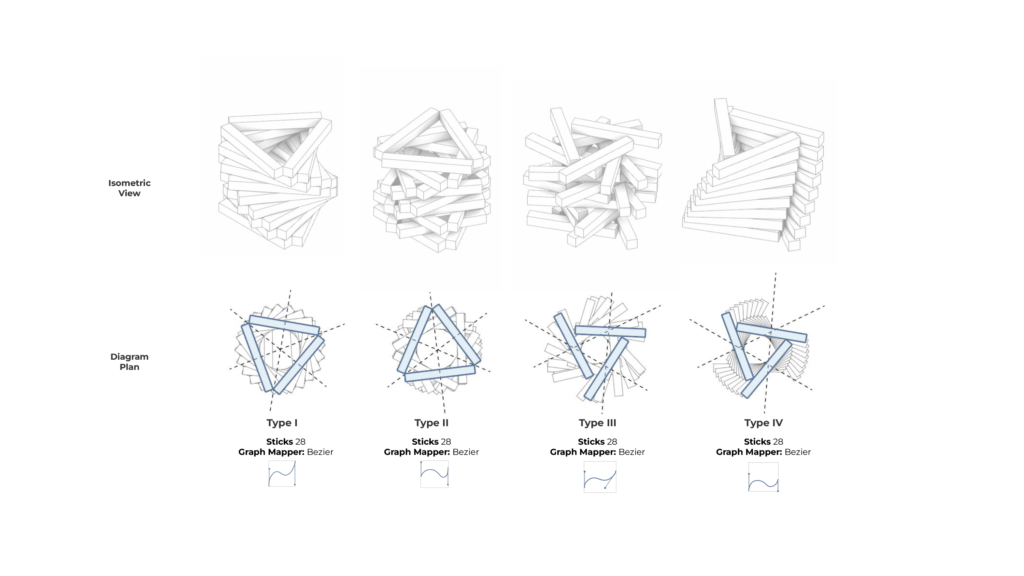

Catalogue of Module A

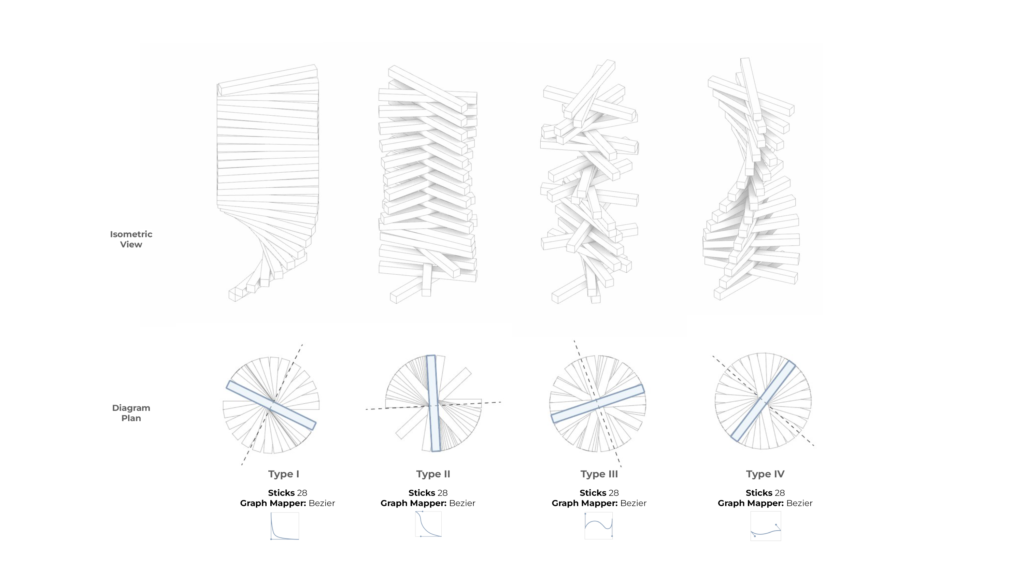

Module B_Type I: one stick per layer

Week 1

Module B_Type II: two sticks per layer

Module B_ Based on two wood sticks in base

Week 2

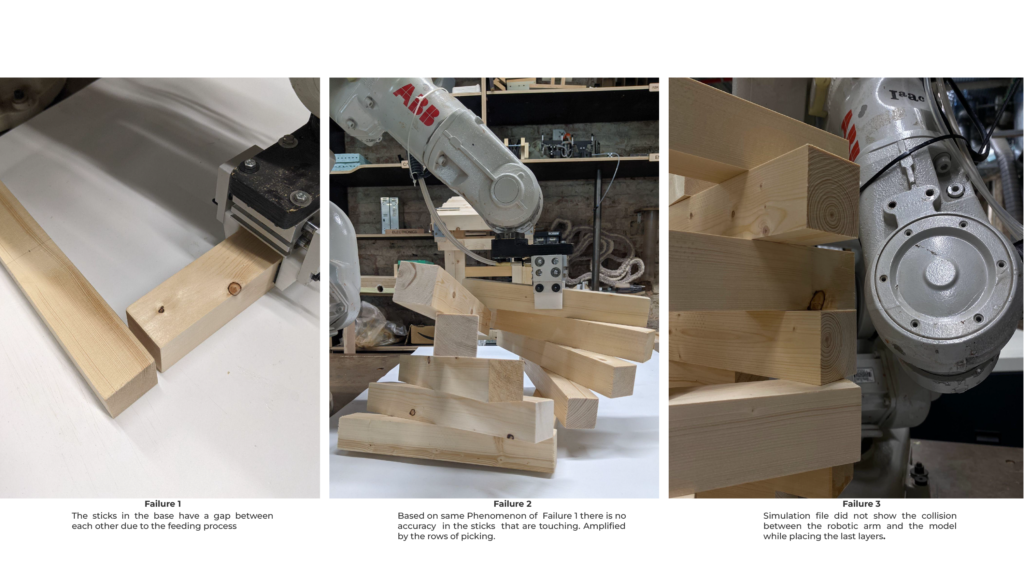

Catalogue of Failures

Type III: three sticks per layer

Type IV: four sticks module

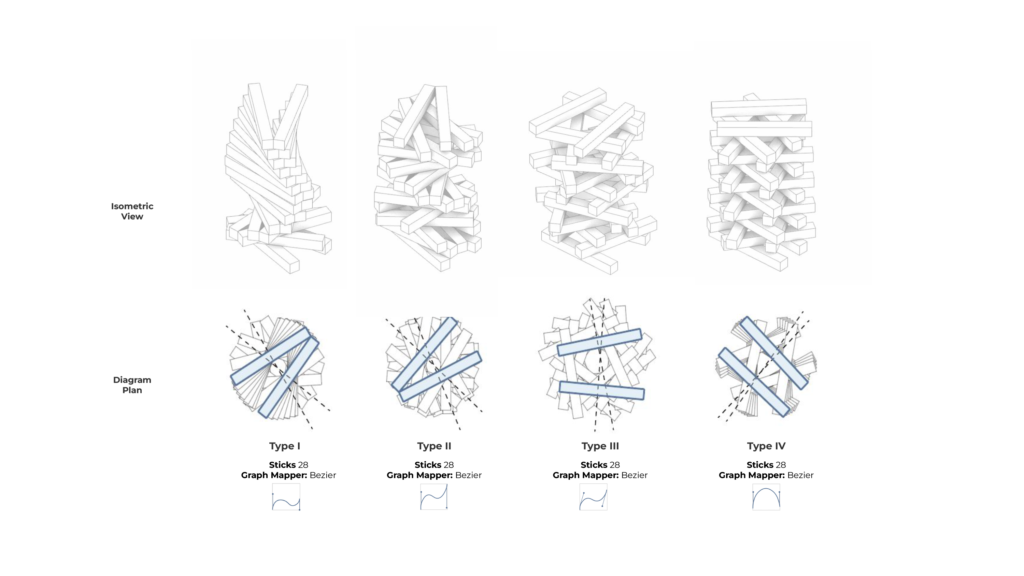

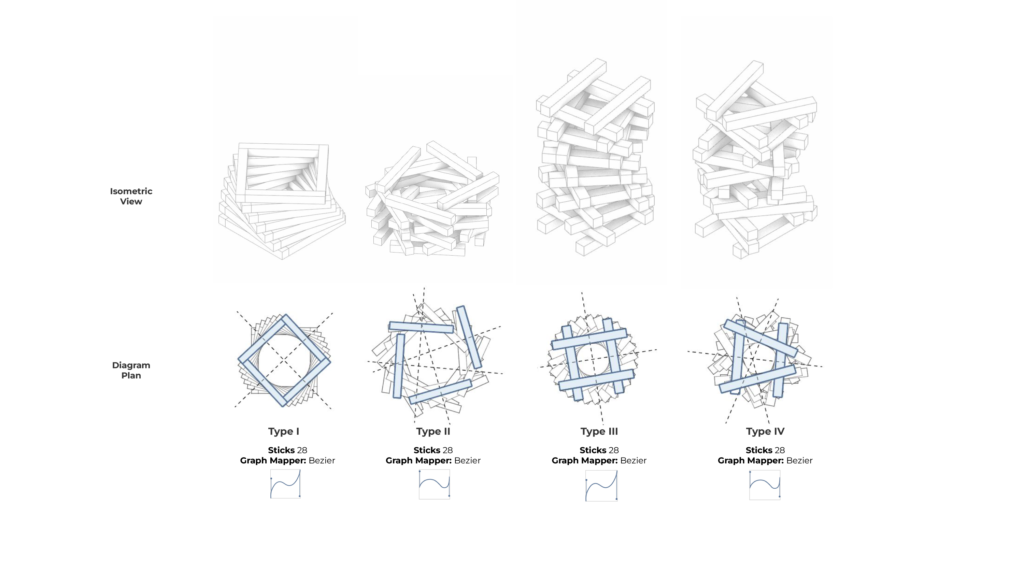

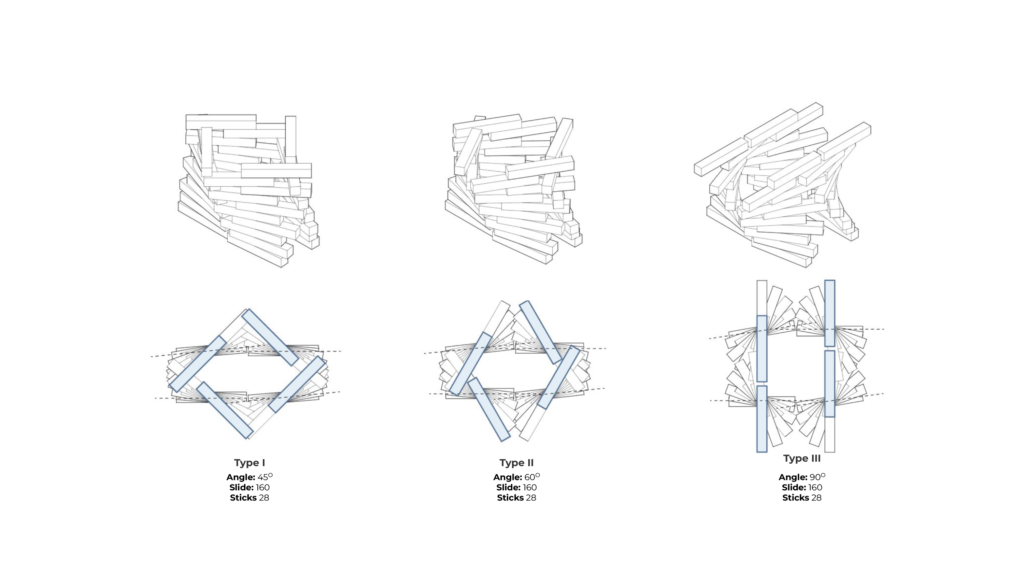

Module C_Type I, II, III: four sticks per layer

Week 3

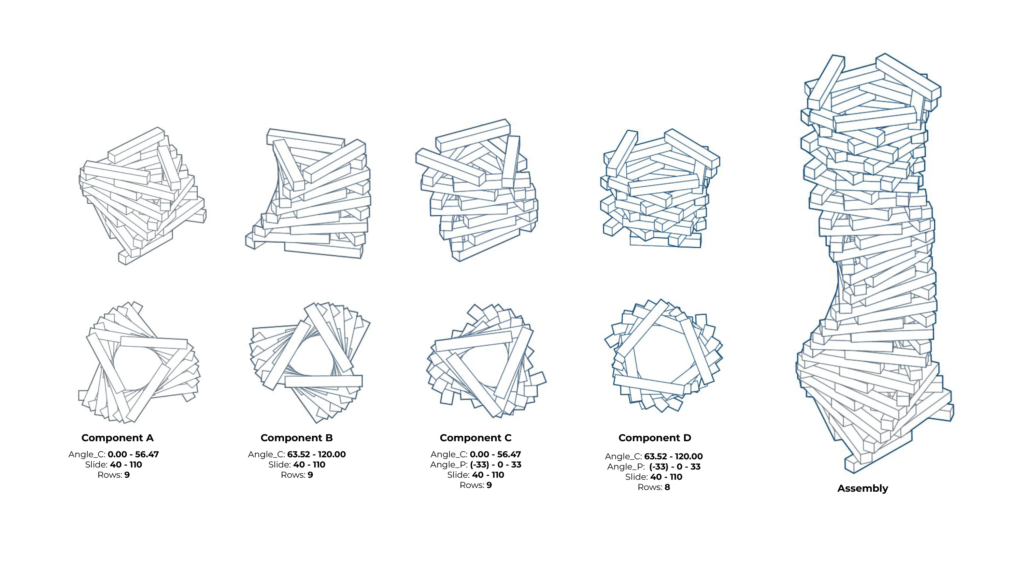

Module D_Component A-D: three sticks per layer

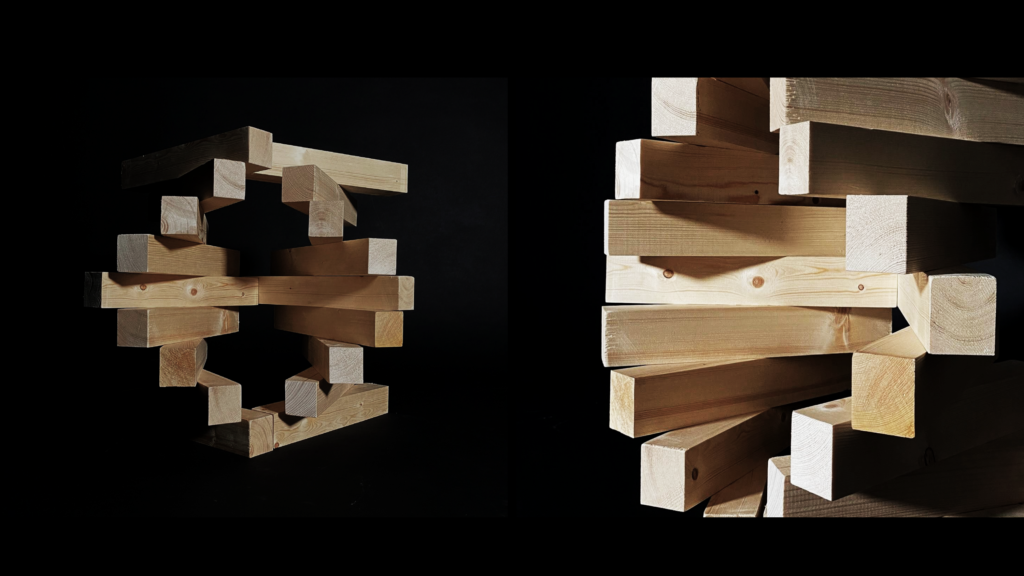

Final Model

Week 4

New rules for a Furniture System

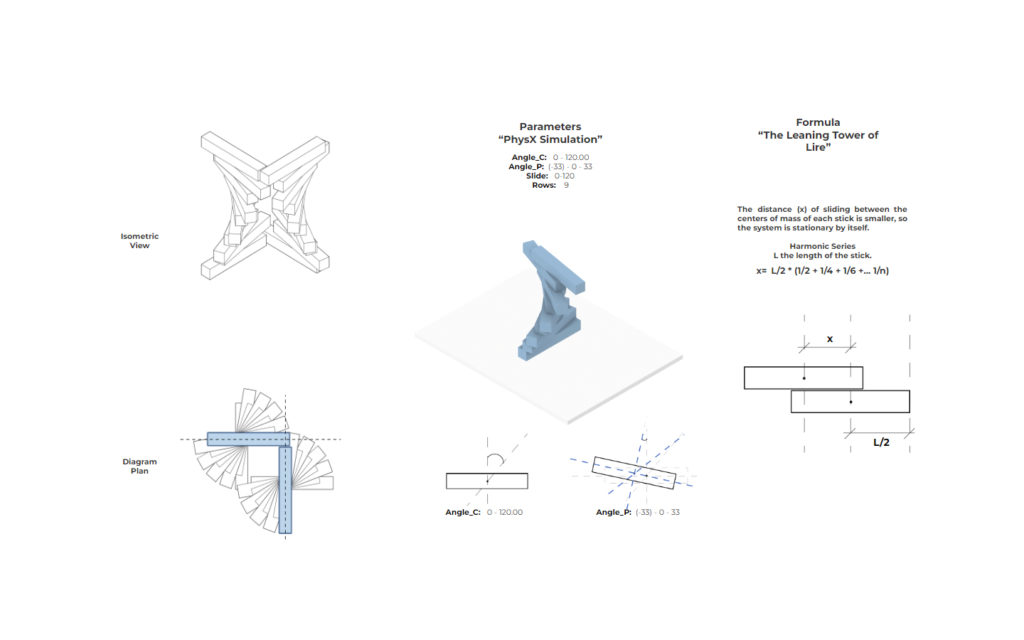

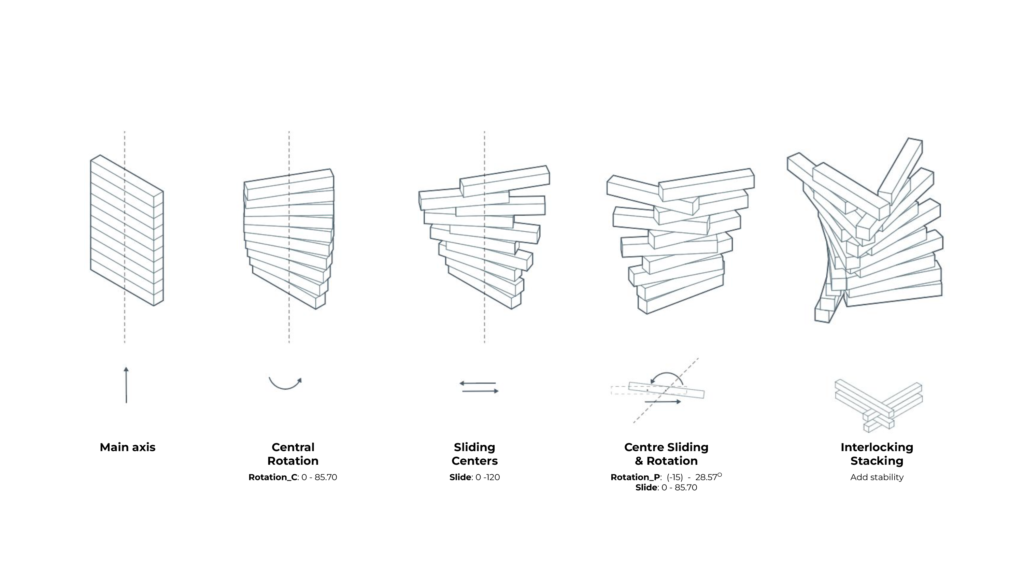

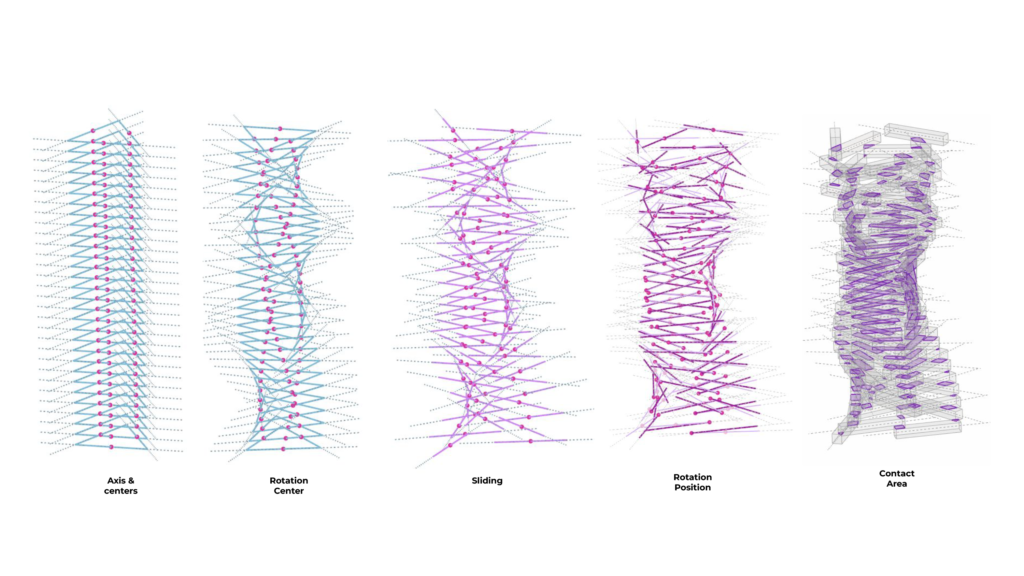

Rules of code

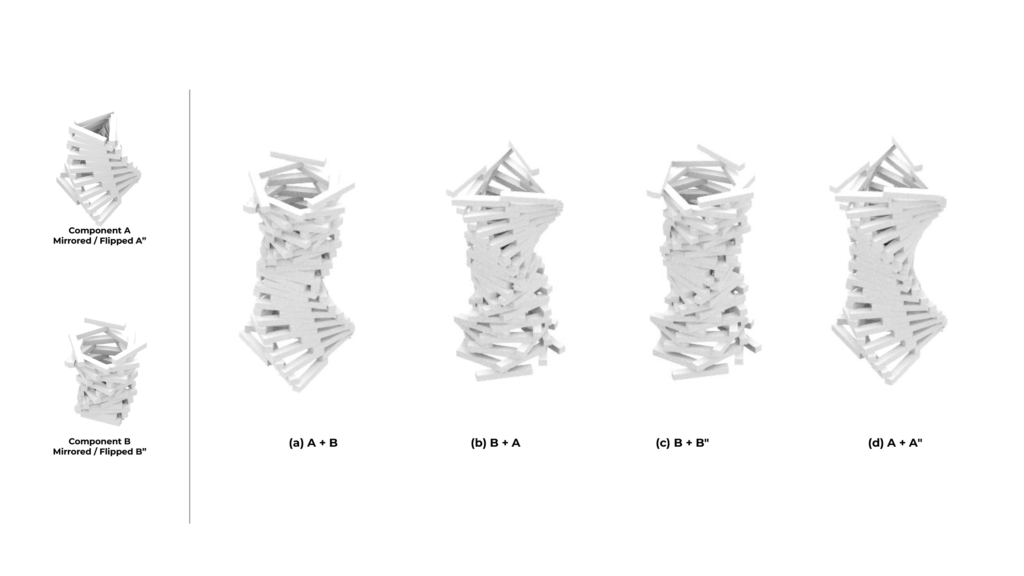

Possible columns

Difference with physic tools simulation

Week 6

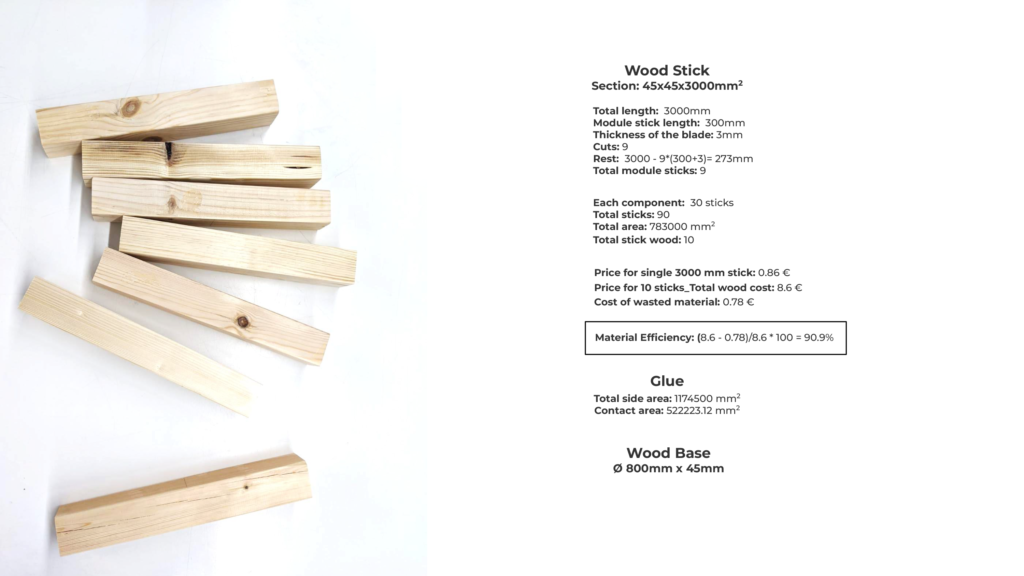

Calculations

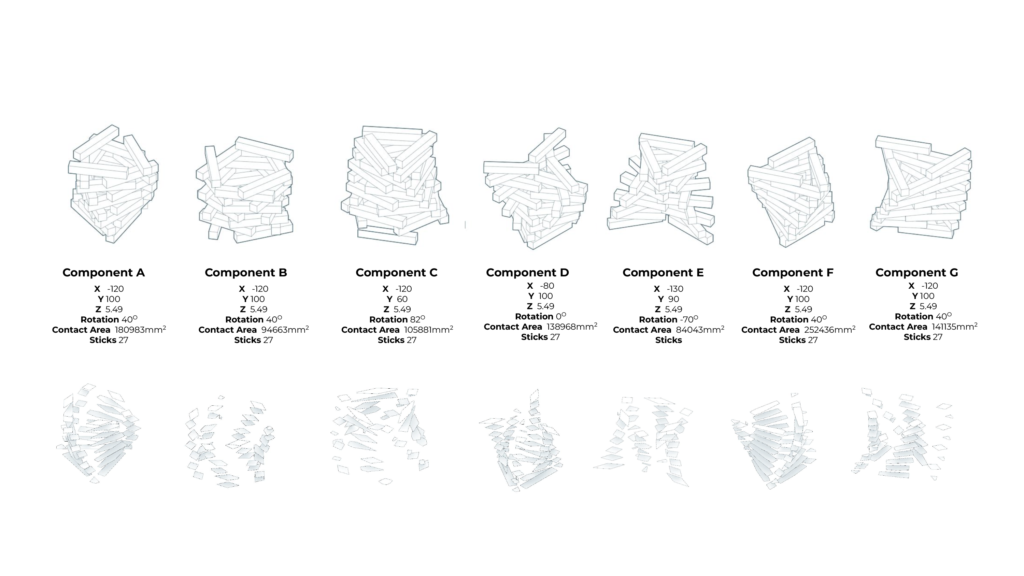

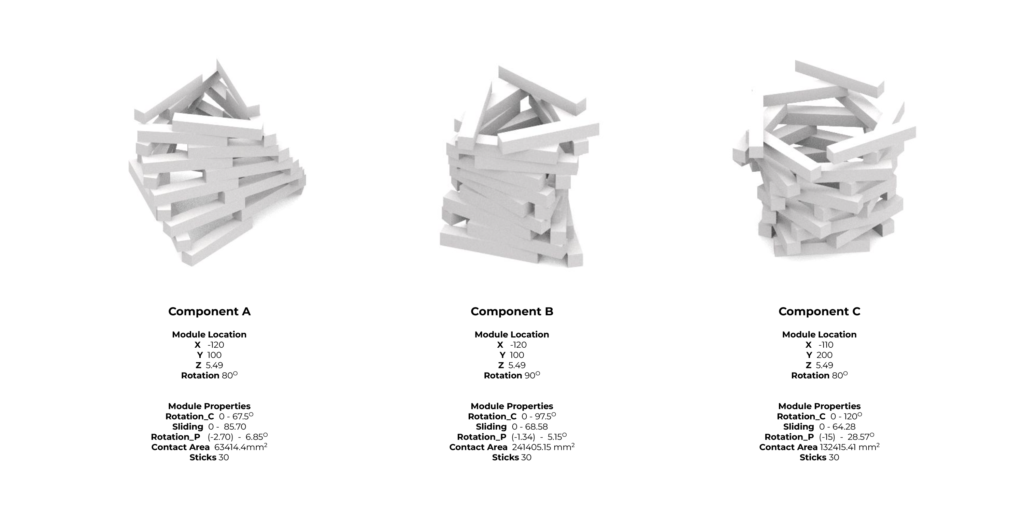

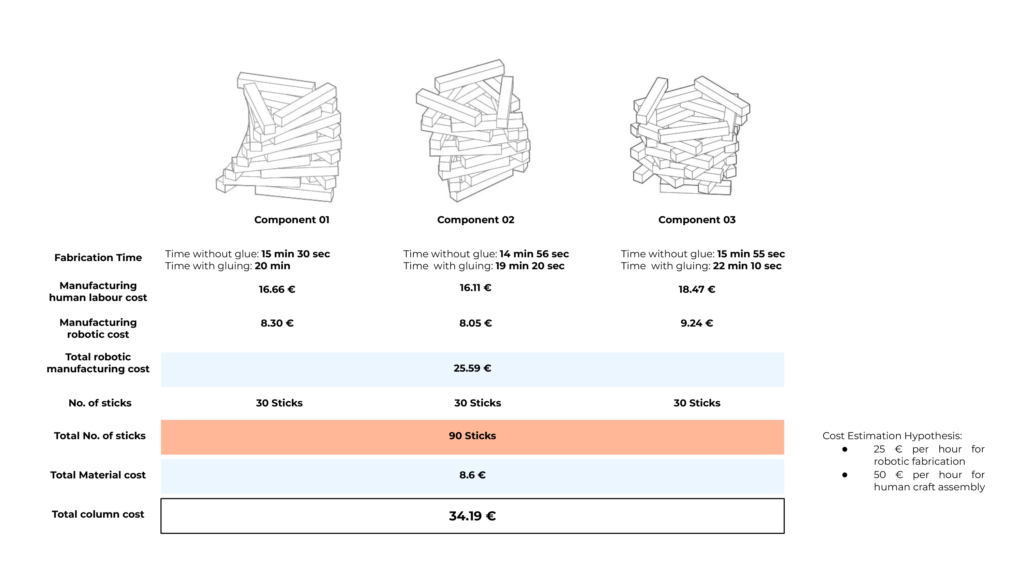

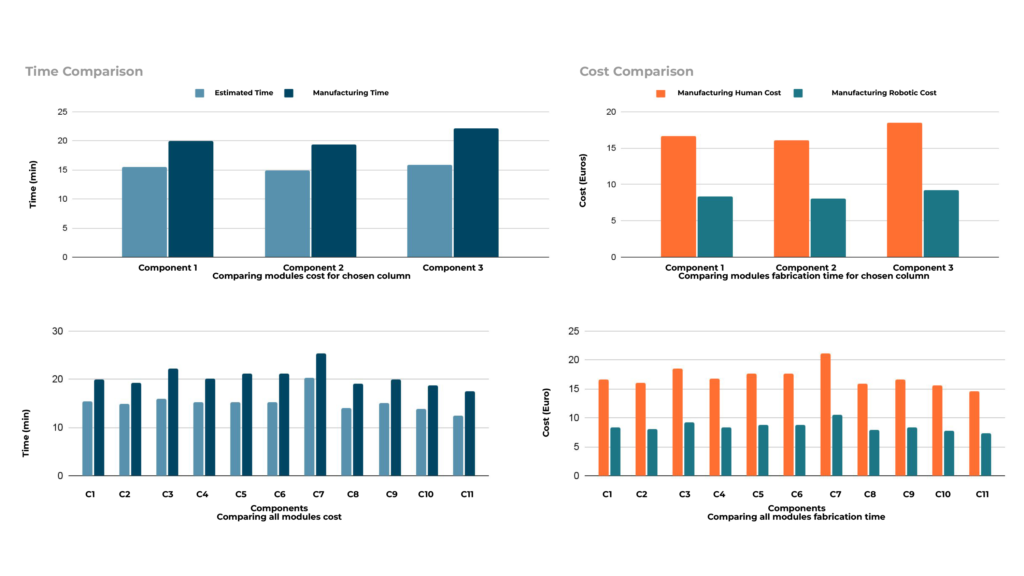

Efficiency of Column Components

Efficiency of Column Components

Efficiency of Column Components

Rules for Architectural Application

Module Analysis