investigative research into creating a catalogue of joinery methods, varying in complexity and geometries. At the same time, integrating a new workflow of design to mill fabrication using new components such as D2P & TasMachine to create sophis`iticated digital models and manage complexity.

precedence

first day / manual studies

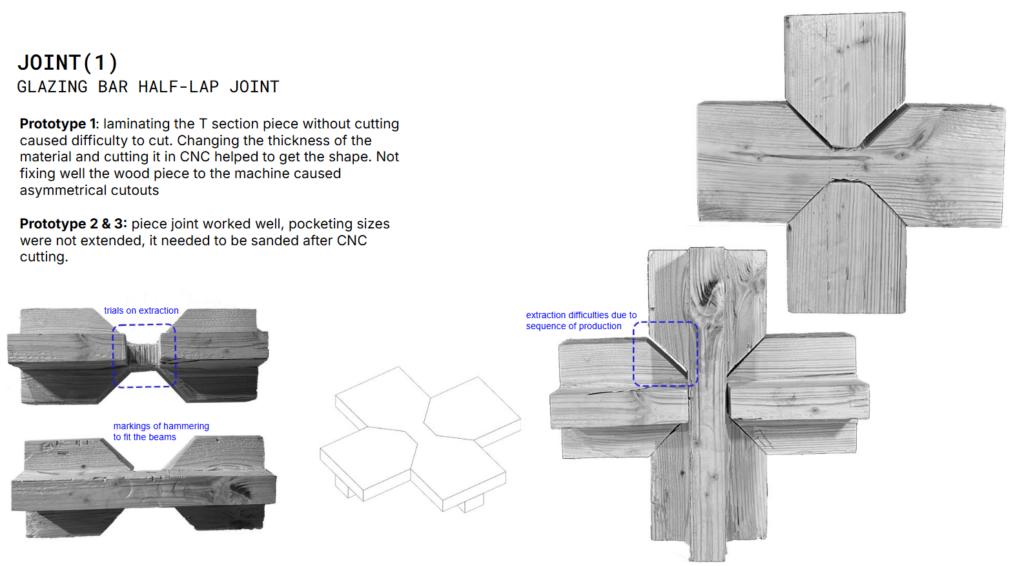

on our first day, we picked a joint to fabricate in the afternoon, only using hand tools and machinery available in the wood shop.

We chose to build a glazing bar half lap joint.

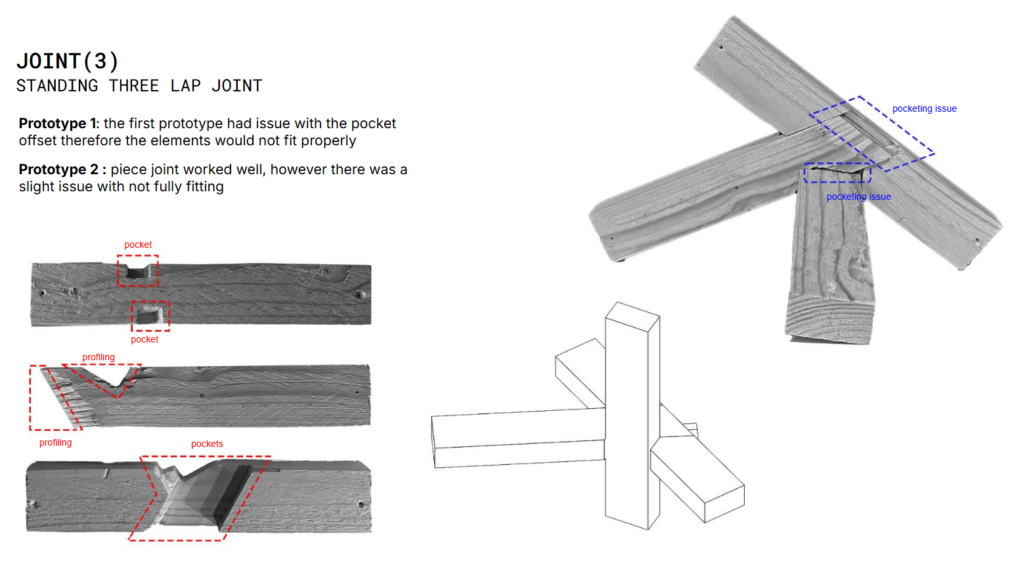

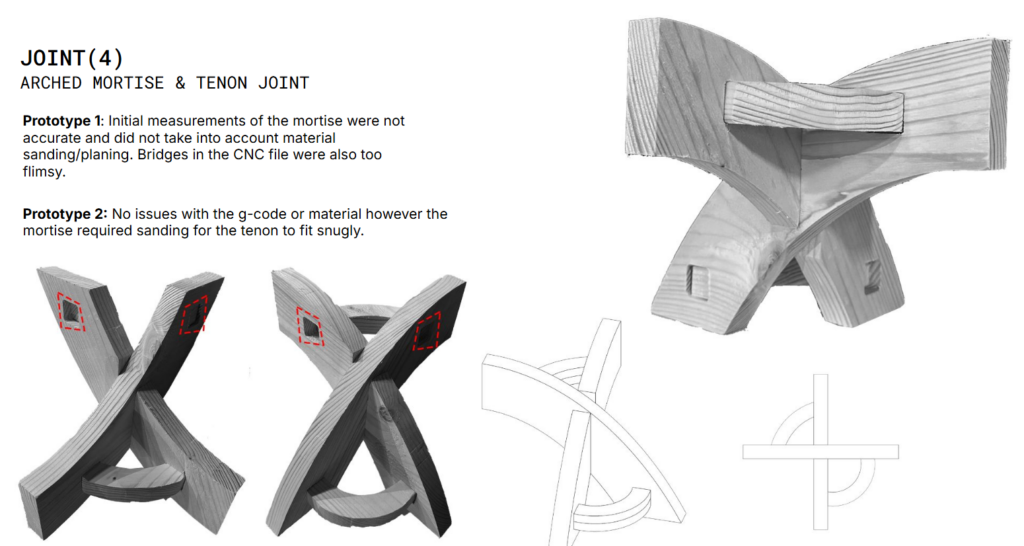

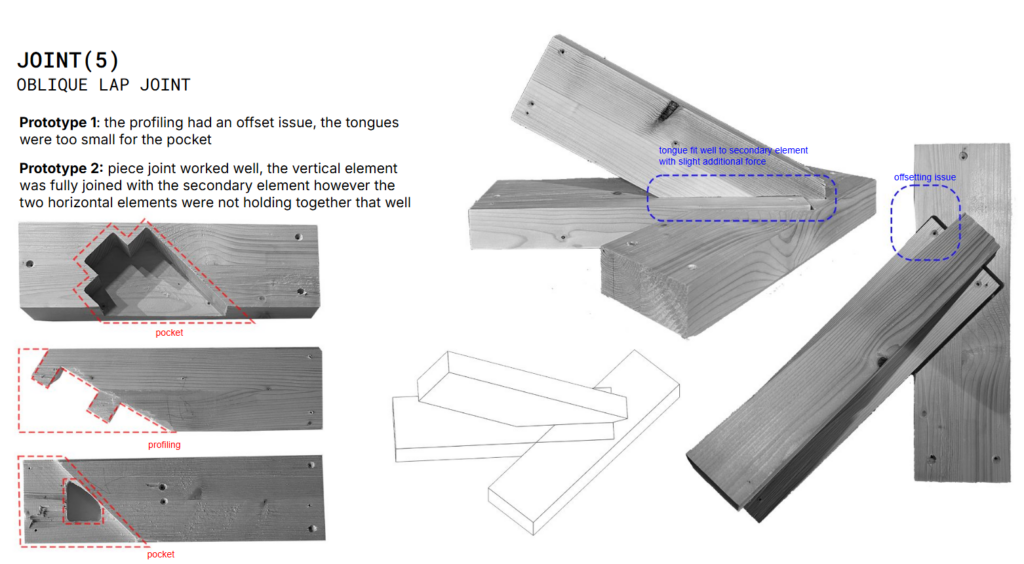

joint fabrication

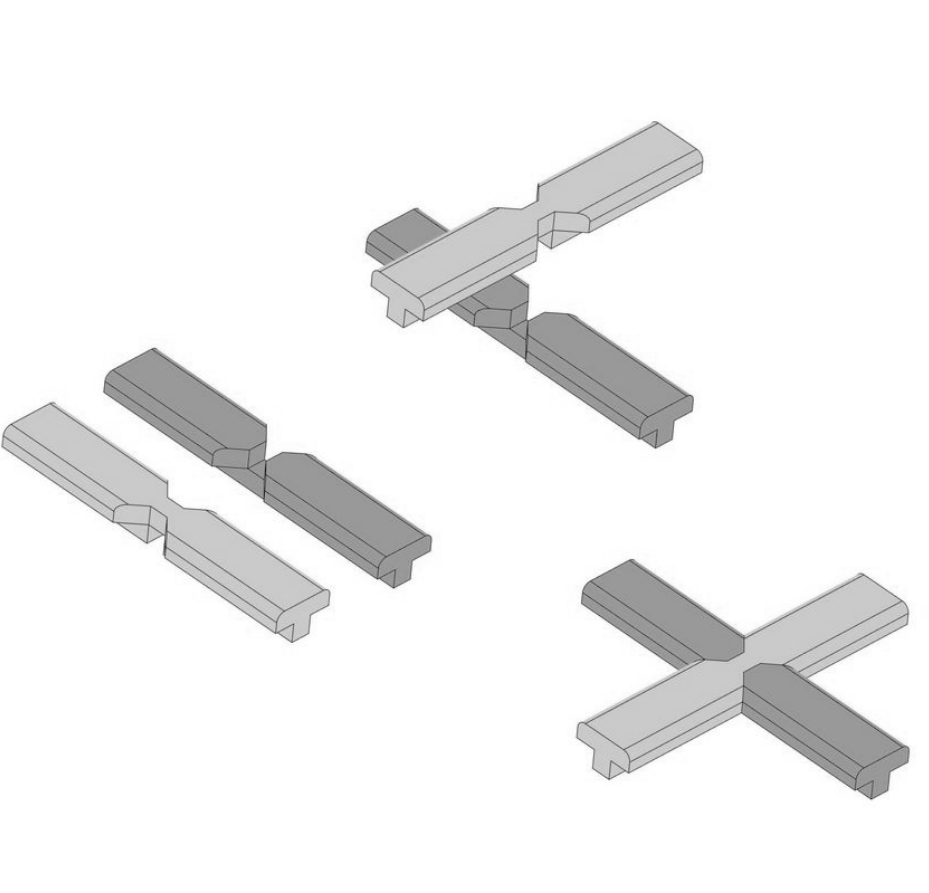

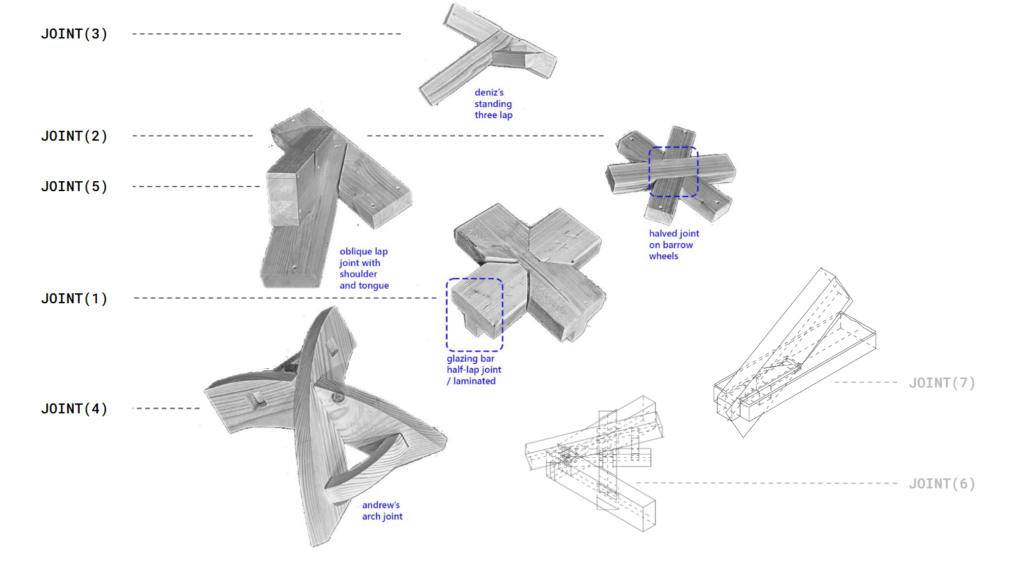

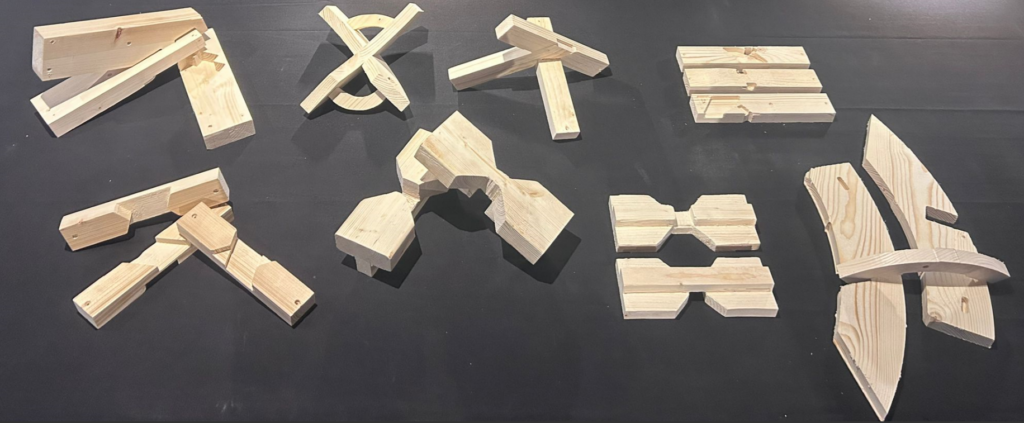

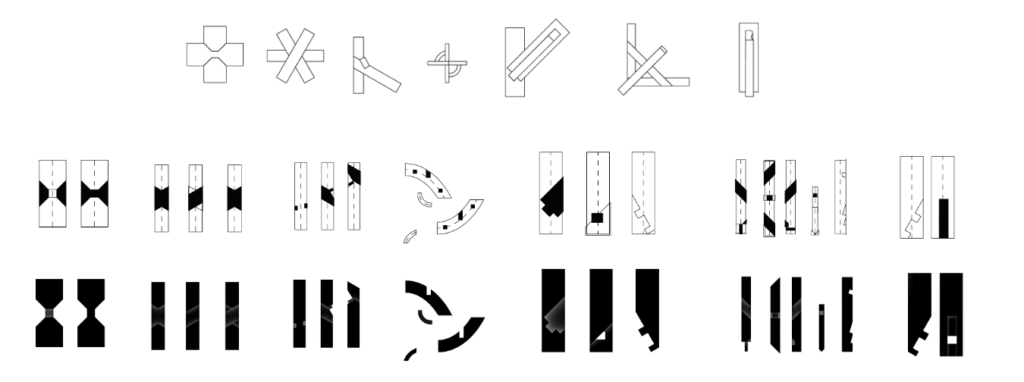

table of joints

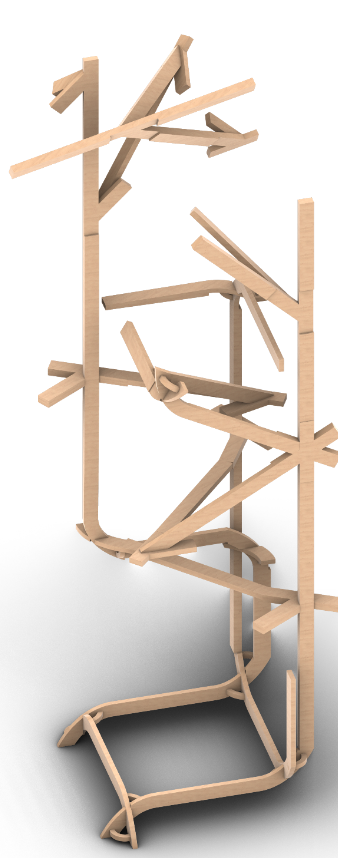

structured model

after the fabrication of the joinery, we performed an exercise in assembling a specualtive structure using our joints, taking advantage of the specific characteristics of each joint. The structured model was also to be the final iteration of our digital studies, each beam and joint in the model was parametricized to be easily extracted and fabricated in seconds, regardless of it’s orientation or location in space.

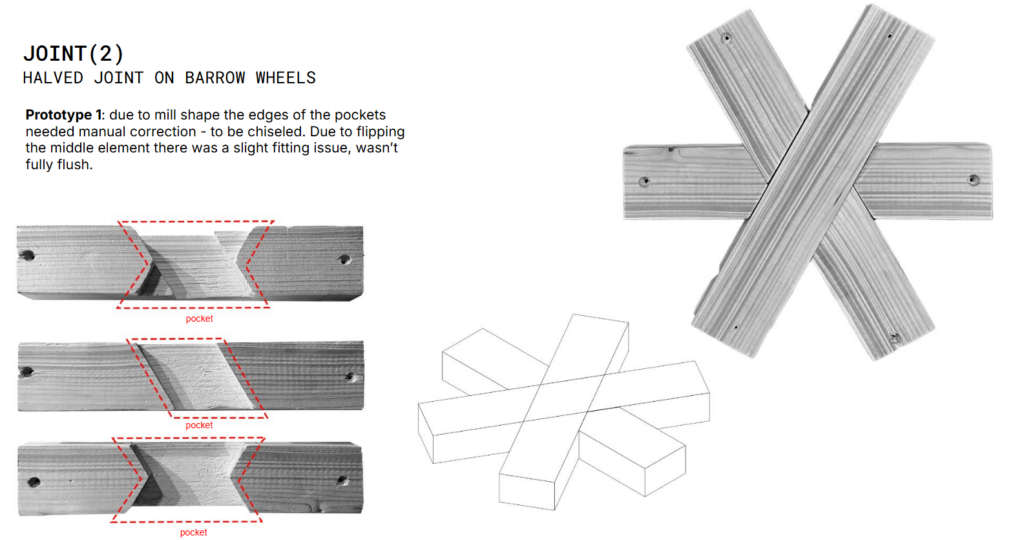

catalogue of joinery

spatial assemblage using joint(4) spatial assemblage using joint(5)

spatial assemblage using all joints

final spatial assemblage using all joineries

conclusions

This seminar, we learned to view “craft” as a holistic design process. One where we aimed to be in control of every single step of the design.

From curves to g-code to a toolpath to a smooth line across wood.

Digitally, we’ve gained a deeper understanding of the relation of a digital file and a work piece.

Just as good architecture focuses on precise details, we believe good fabrication focuses on a precise understanding of the tool, the material and the method.

In our own practice, we are exploring the relation between fabrication, materiality and design and where we can intervene and propose innovative architecture.

many thanks, from the team