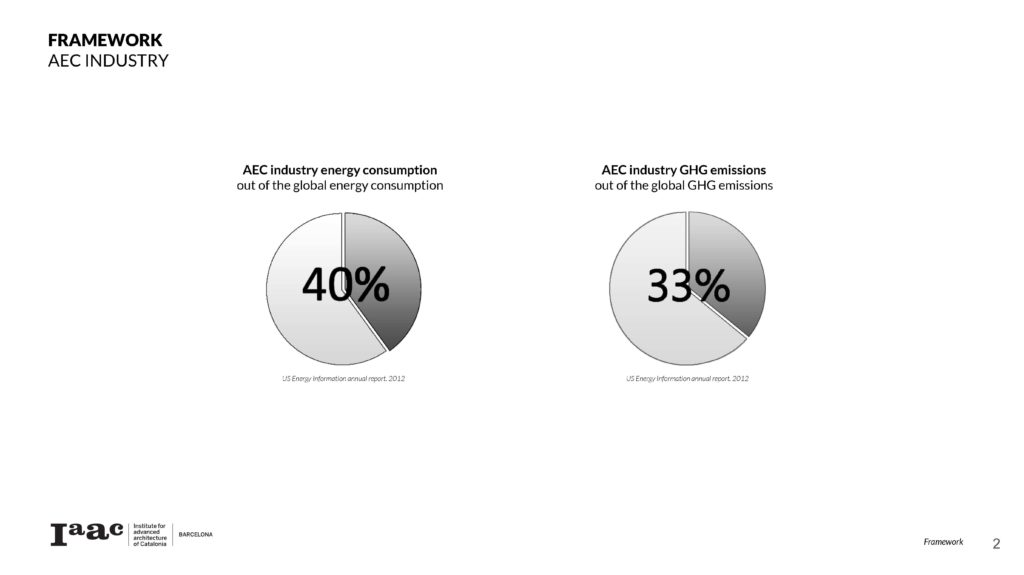

The AEC industry consumes 40% of global energy and emits 33% of greenhouse gases, which contributes heavily to climate change.

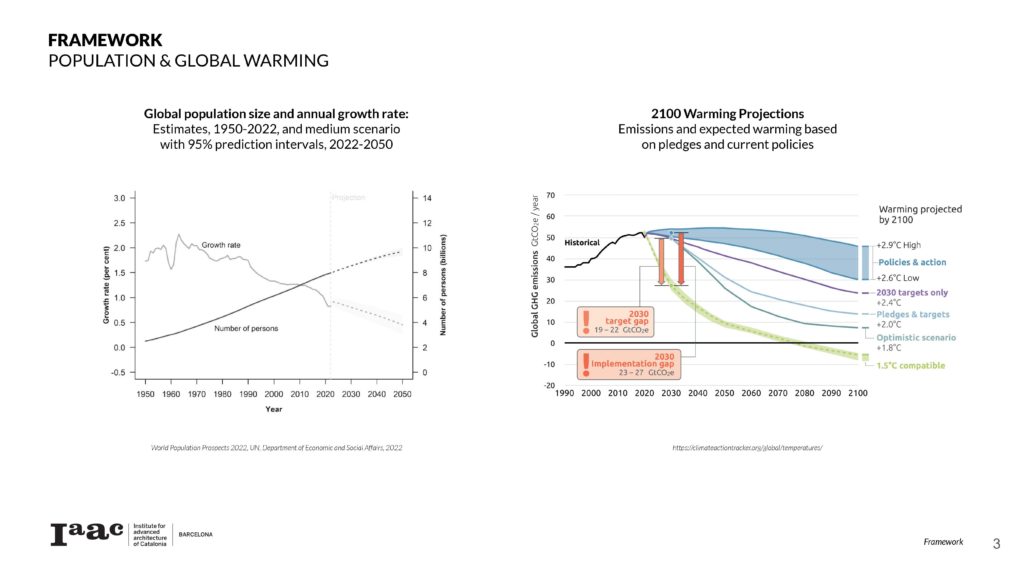

Additionally, by the year 2050, the population will grow up to 10 billion people of whom the two-thirds are going to be living in cities.

Which means a lot more building will need to be built.

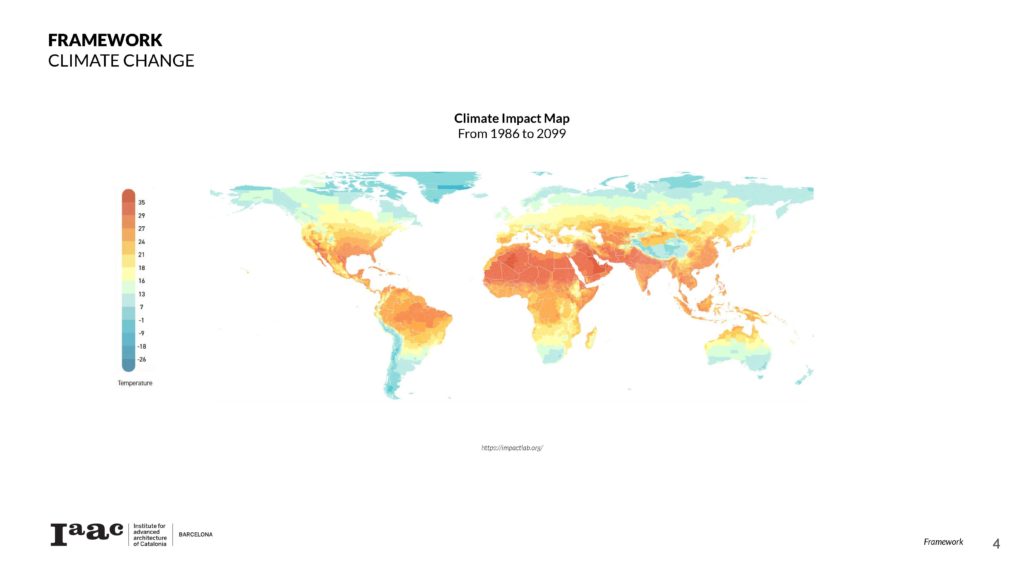

Meanwhile the global warming projections are concerning and indicate that our planet is experiencing significant changes that could have devastating effects on our environment, ecosystems, and human societies.

The planet is heating up.

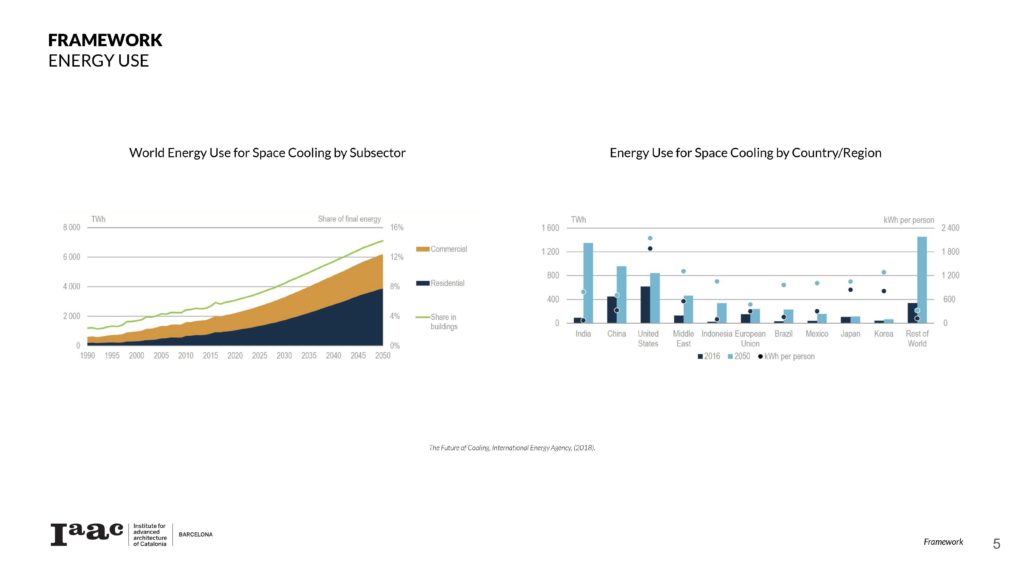

and numbers show that energy consumption for air conditioning will increase in residential and commercial buildings through 2050, as we move towards warmer climates.

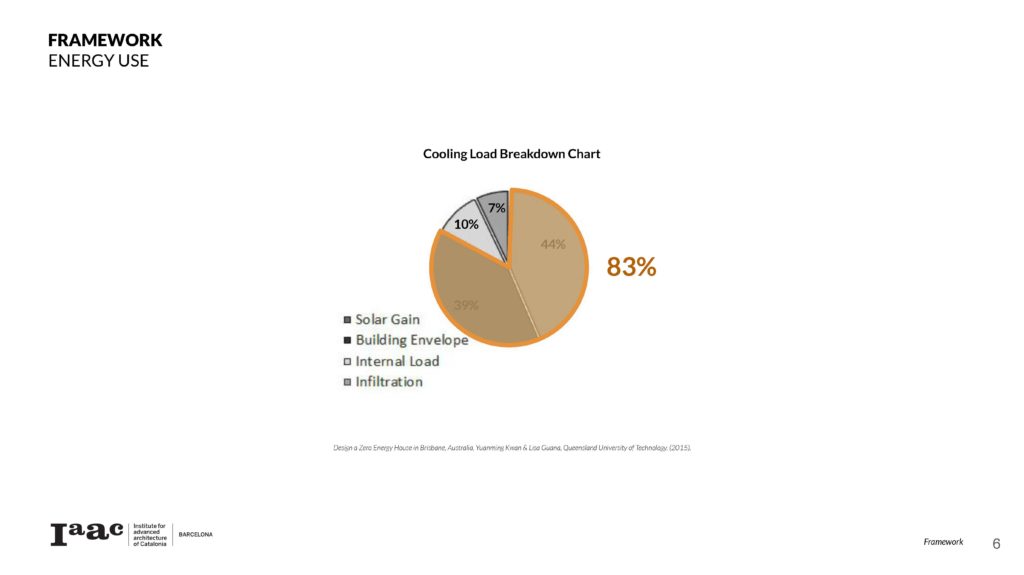

As we do the breakdown of the cooling load, it appears that a majority of the cooling requirements for buildings are caused by poorly performing building envelopes, which results in higher solar gain. This accounts up to 83% of the overall cooling load.

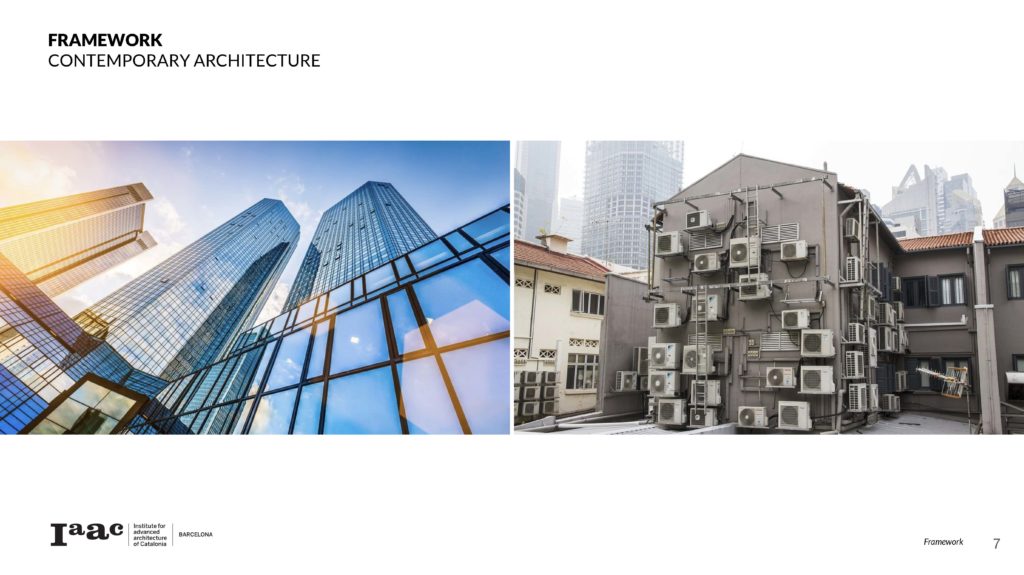

Yet we keep on building glass towers and cheap constructions that contribute to high energy consumption and carbon emissions due to their poor design, perpetuating a damaging feedback loop.

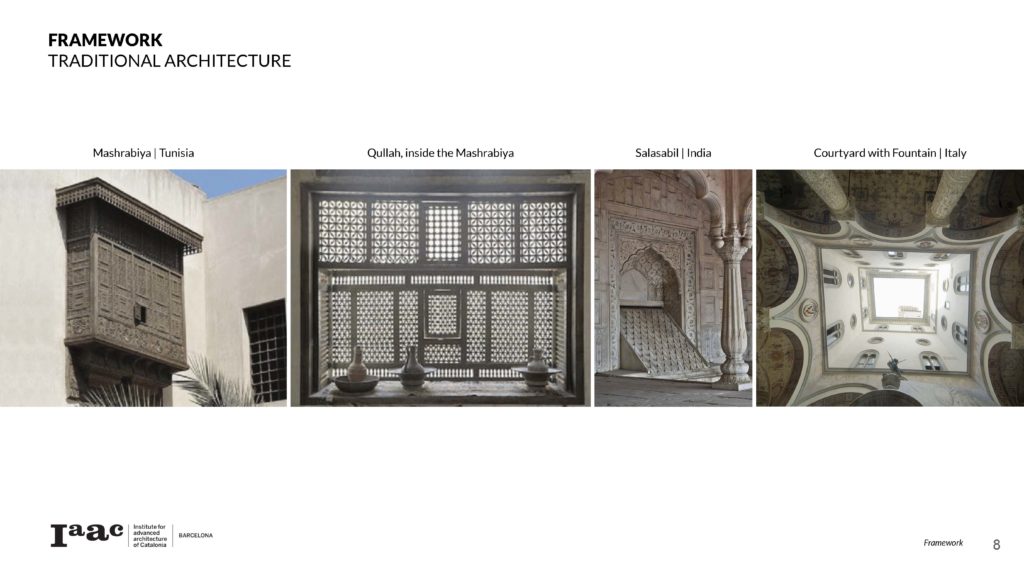

But, by examining traditional architecture, we can observe that solutions for contemporary challenges have existed for centuries.

Traditionally, passive cooling systems have been part of architecture in different regions of the world to provide thermally comfortable living spaces in hotter climates through passive means.

- Mashrabiya: creates shading and lets the wind pass

- Qullah: set inside the mashrabiya to cool interiors. Porous pottery maximizes the area for evaporation. The designs of the latticework usually have smaller openings in the bottom part and larger openings in the higher parts, hence causing the draft to be fast above the head and slow in lower parts.

- Salasabil: is a type of fountain that maximizes the surface area of the water, and thus evaporative cooling of passing drafts

Courtyard with fountain: Evaporative cooling cools the air down as it passes through the courtyard.

As we notice, most solutions incorporate clay, wind, water and shade!

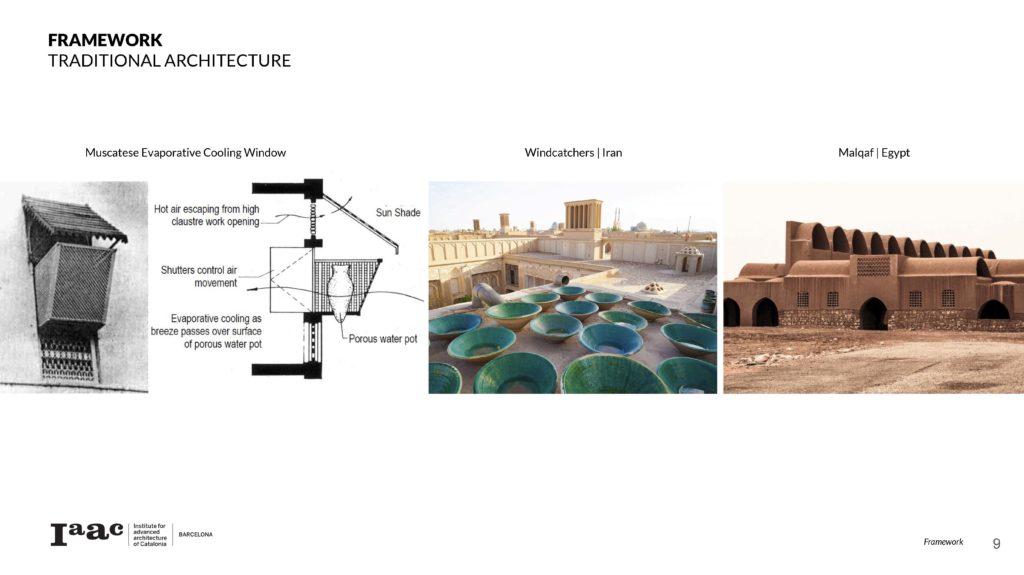

- Muscatese evaporative cooling window which is similar to the clay jars inside the mashrabiya

- Windcatchers: with bowls of water placed strategically in front of them

- The Malqaf: as we see in Hassan Fathy’s work, used to create cross ventilation and passive cooling by bringing the higher cooler winds down into the house

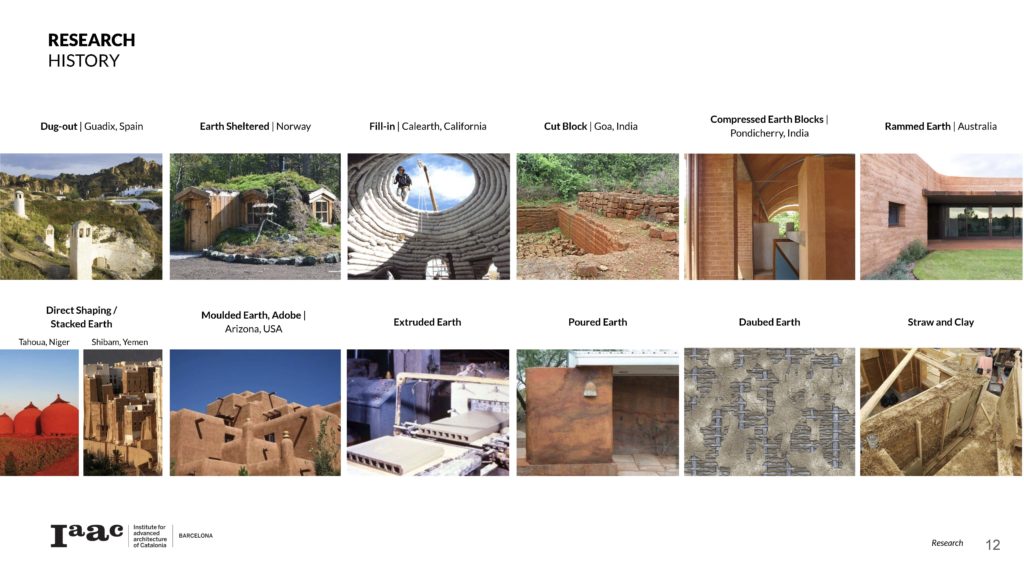

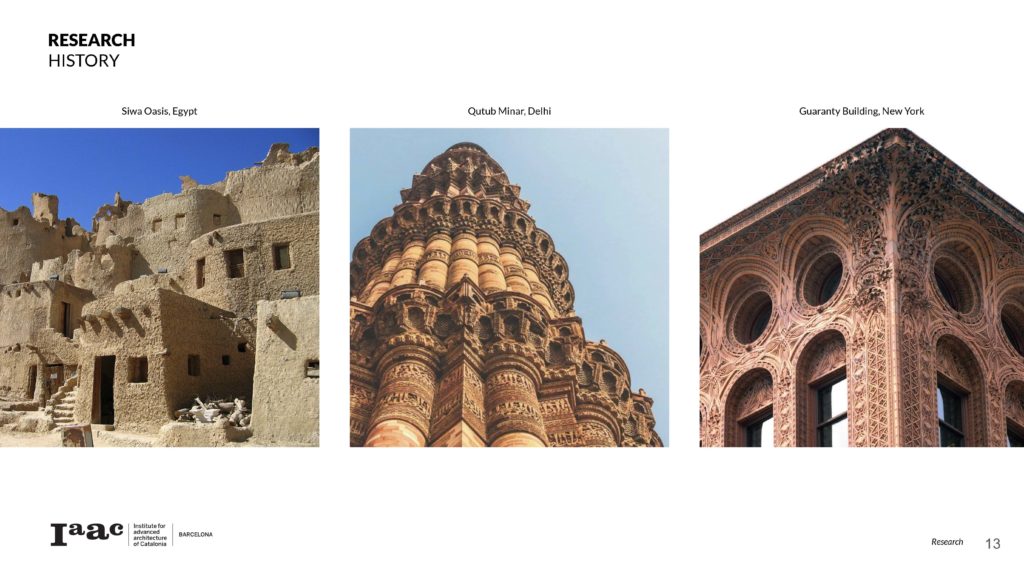

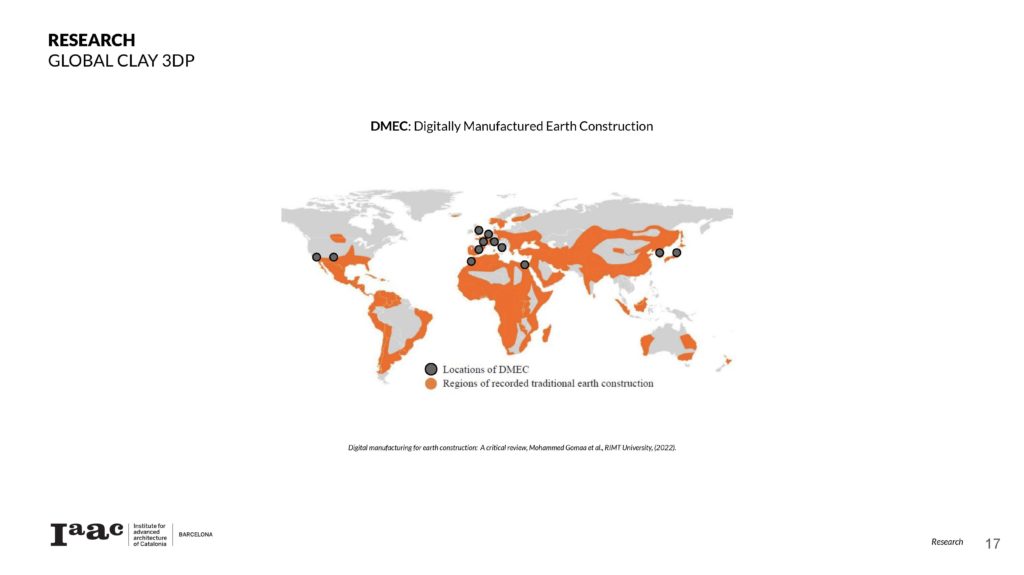

Clay is one of the oldest and most abundant construction material in the world

Over 1/3 of the world’s population live and work in earthen structures that have been developed through 12 traditional techniques

These structures range in complexity from fairly simple to highly complex geometries.

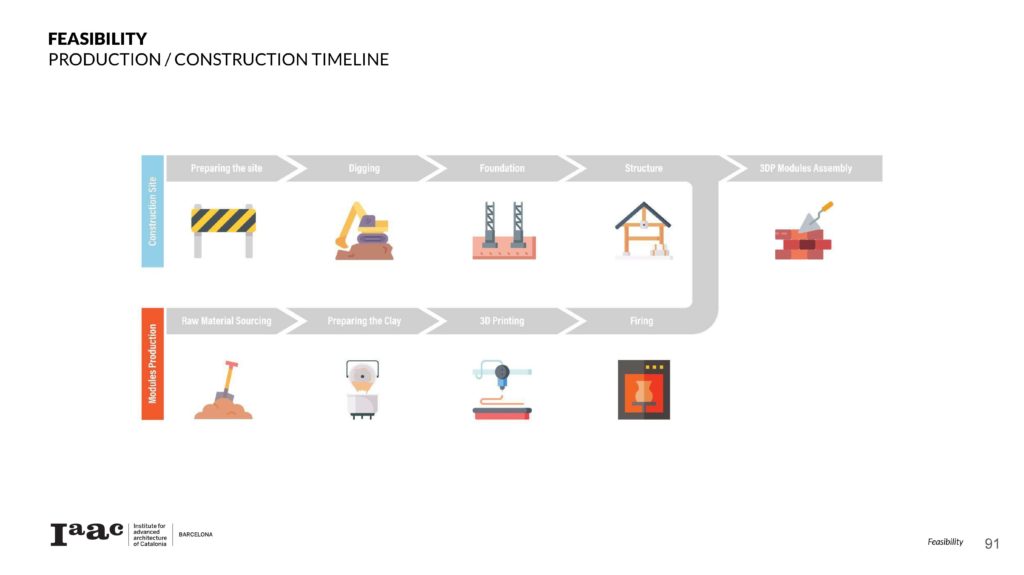

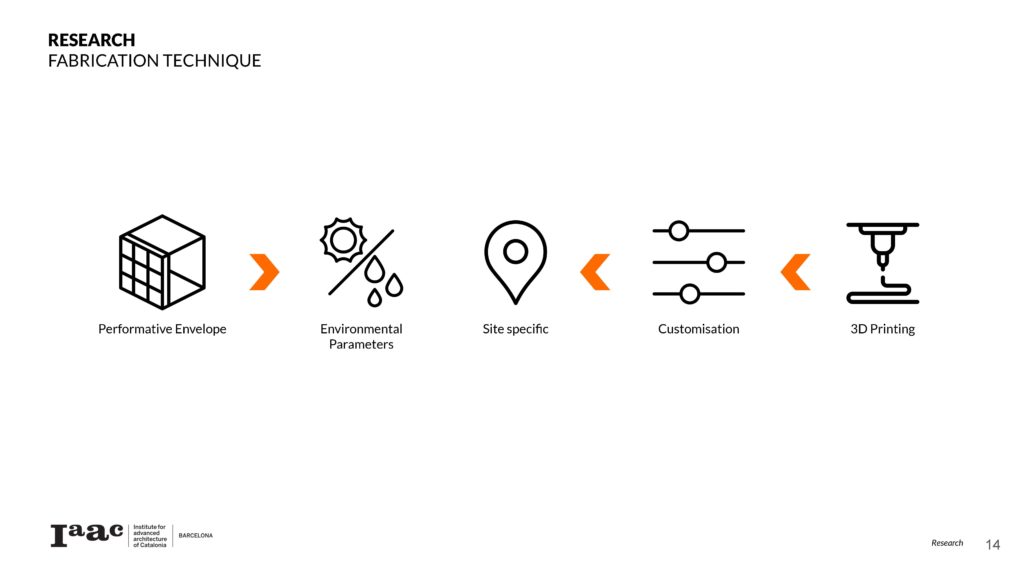

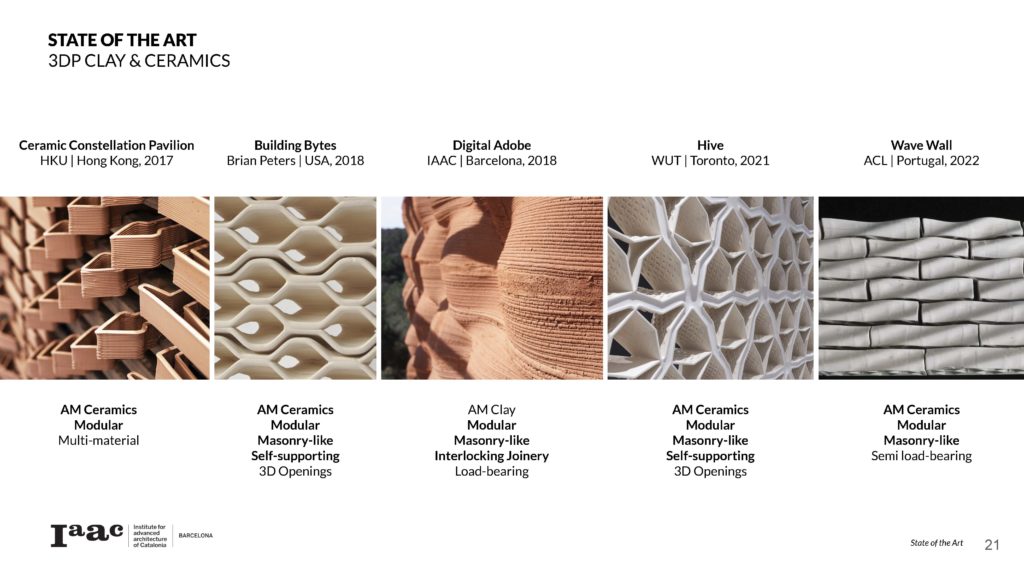

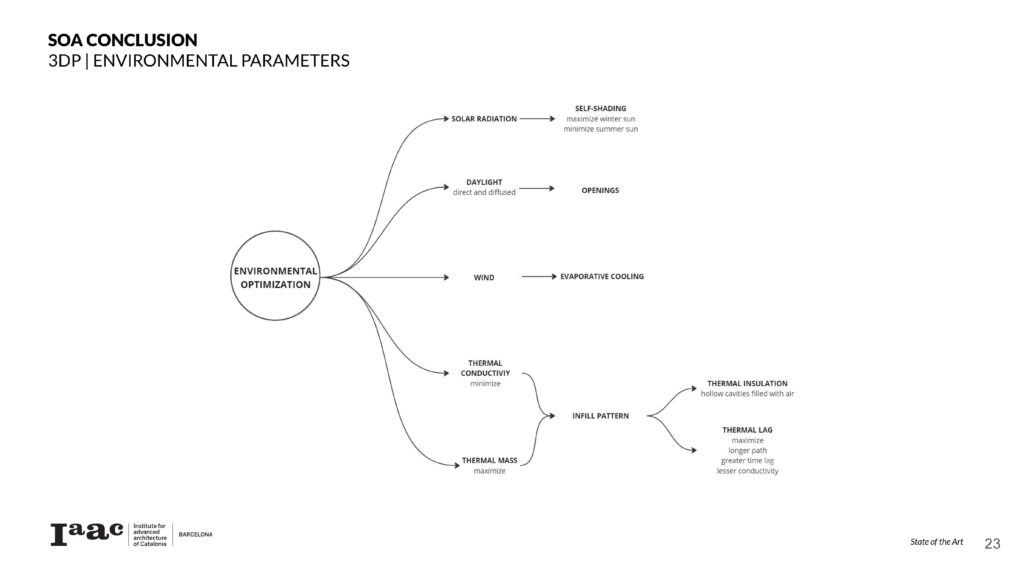

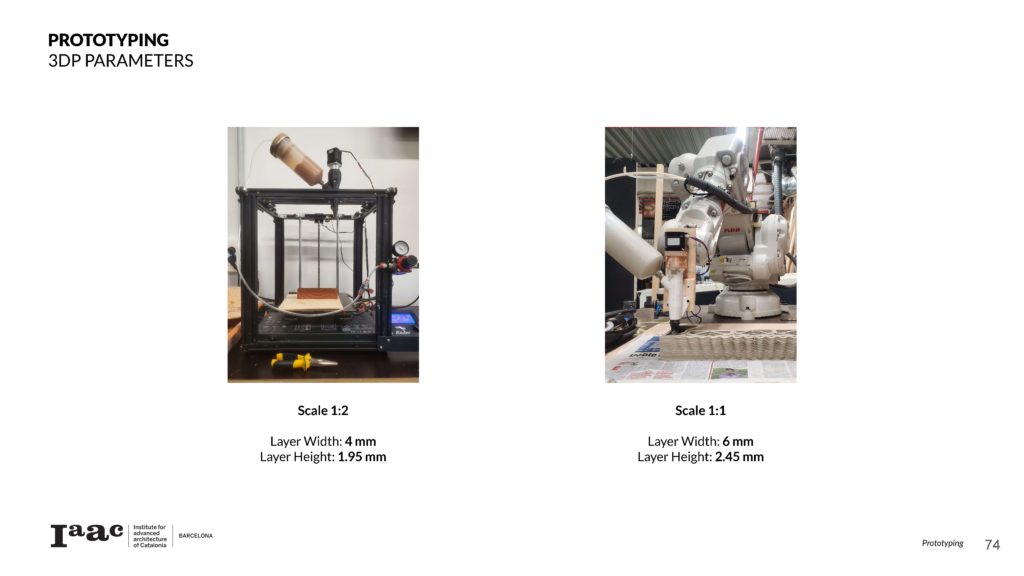

The performative envelope relies on variable environmental parameters and is therefor site specific, this requires the use of a fabrication technique that allows for easy customization. Therefore 3D printing is the adopted method for the fabrication of the system.

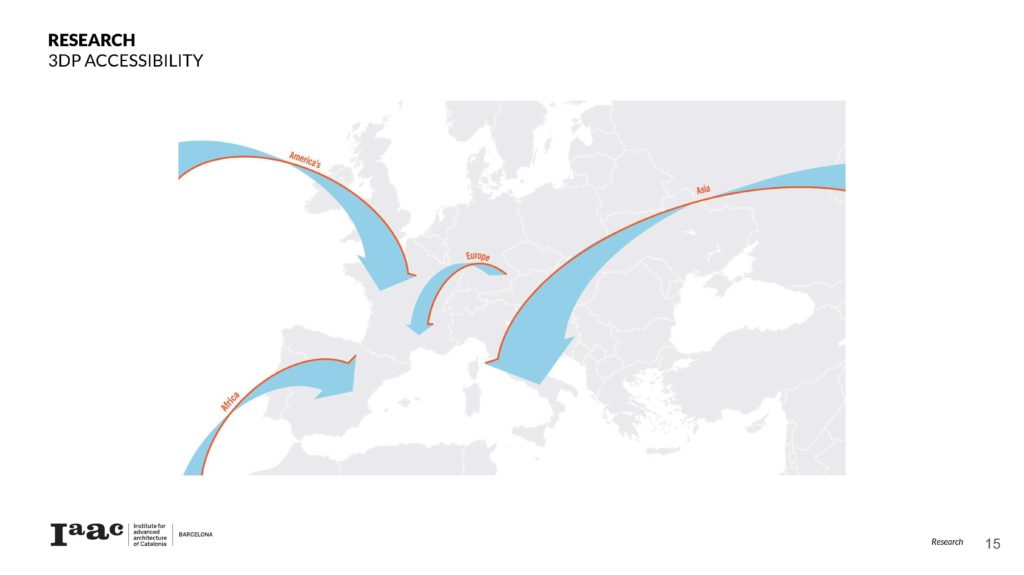

Although 3d printing is slow, it is a more accessible and distributable mode of production.

It eliminates the need and dependency on a large manufacturer and promotes local production.

With more research and innovation, it has the potential to become mainstream

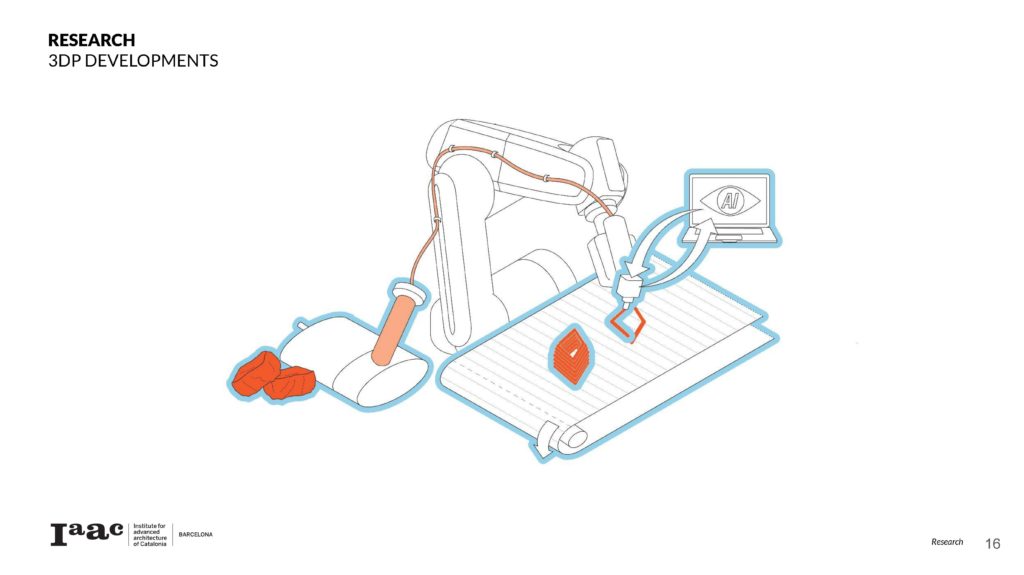

- material research

- Continuous feeding systems

- Rolling beds

- And AI powered computer vision integration for real time feedback and auto-correction

And we see this research already happening around the world, and mostly in Europe.

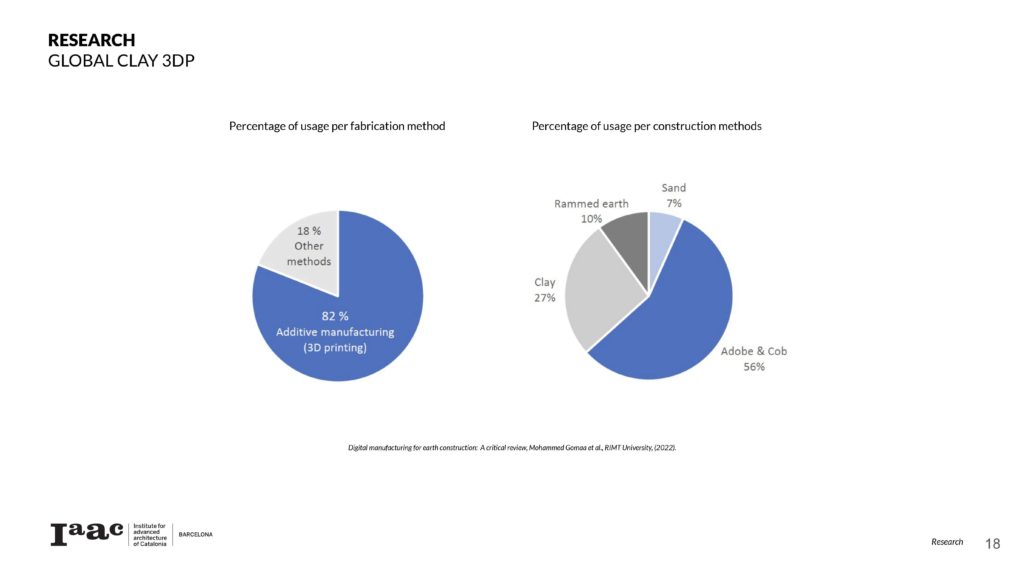

And most of the research is going into 3d printing with clay and adobe.

And in fact 3d printing clay resembles a lot to the ancient technique of coiling clay.

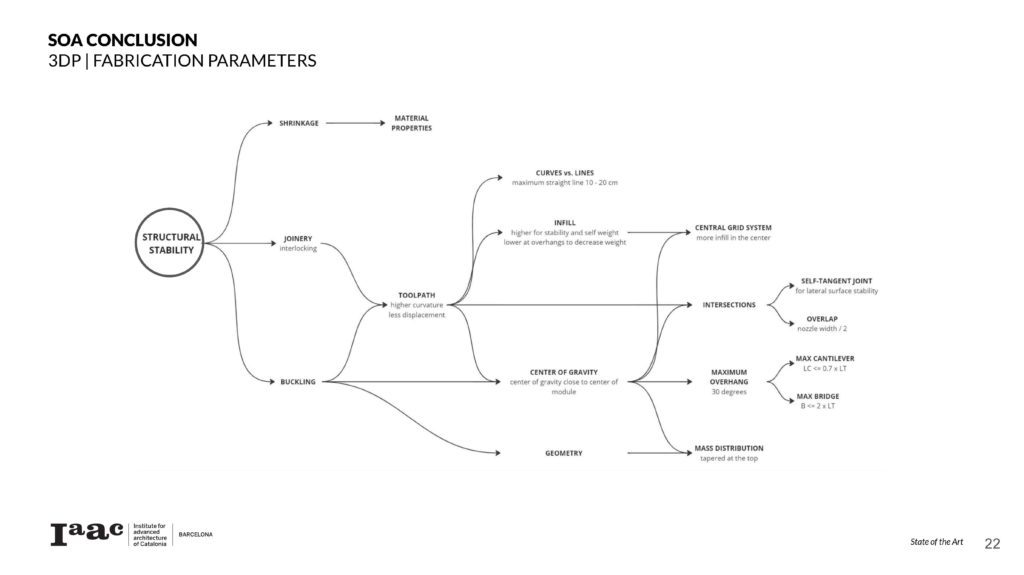

This chart is a map of the understanding of the structural and material opportunities and challenges.

3D printing allows for the creation of complex geometries, but the environmental optimization techniques that could be incorporated into the design are what give it intelligence.

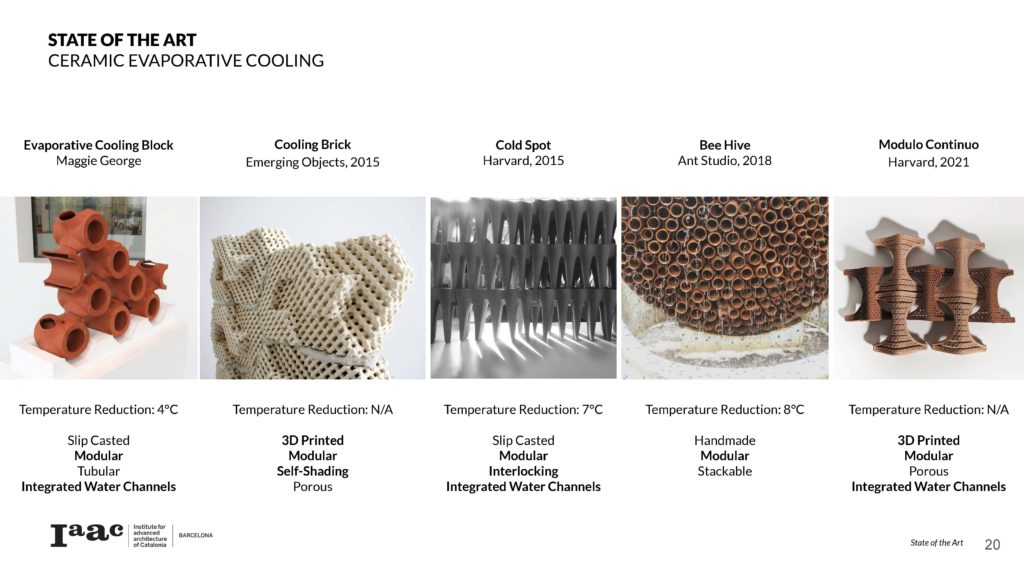

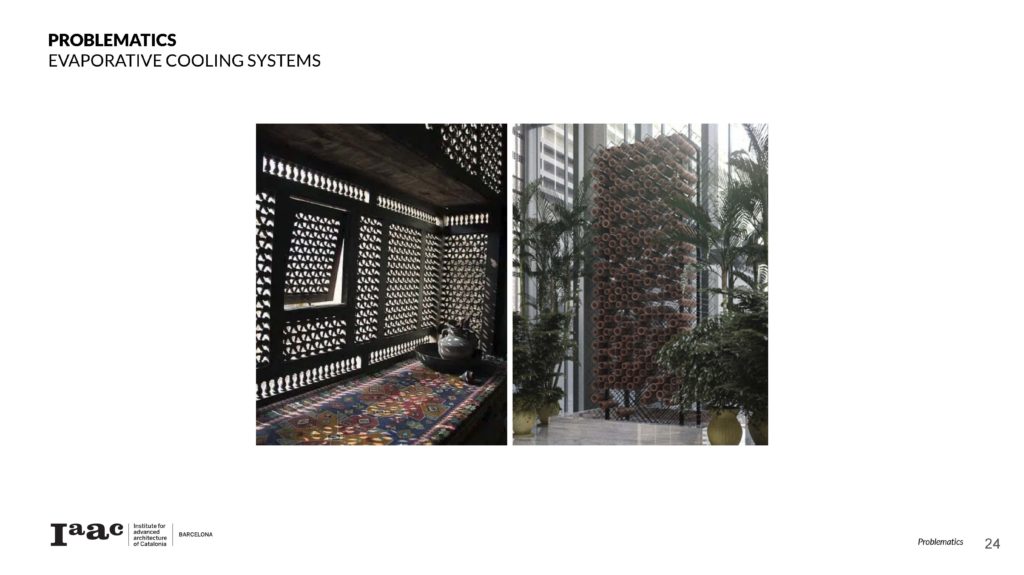

Even though evaporative cooling shows that it works, it doesn’t come without its problems.

In traditional architecture and contemporary examples, systems like this on a building facade obstruct the view and keep the daylight from reaching in.

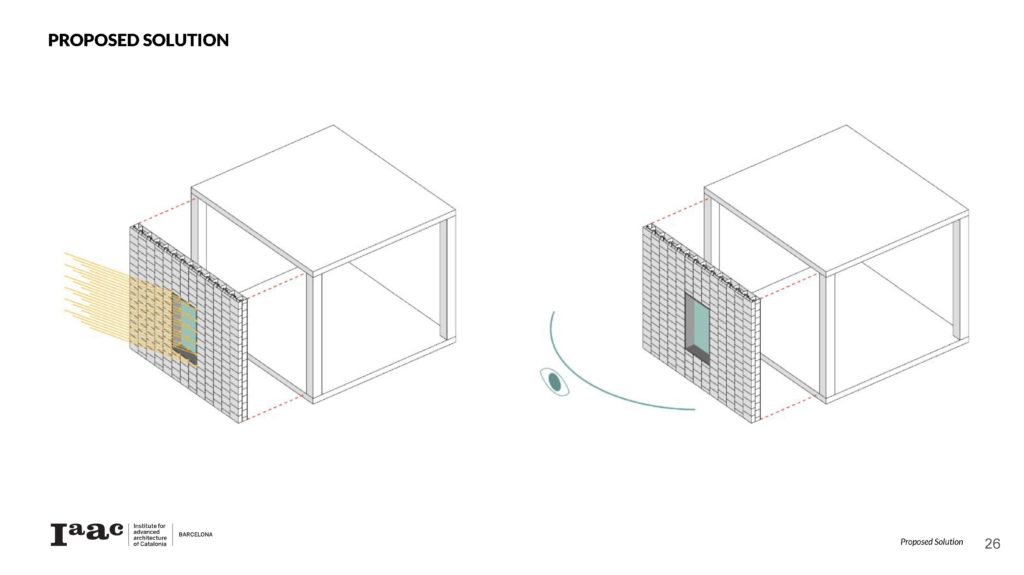

So I propose to design a building envelope that integrates this system within it without sacrificing the view and the daylight.

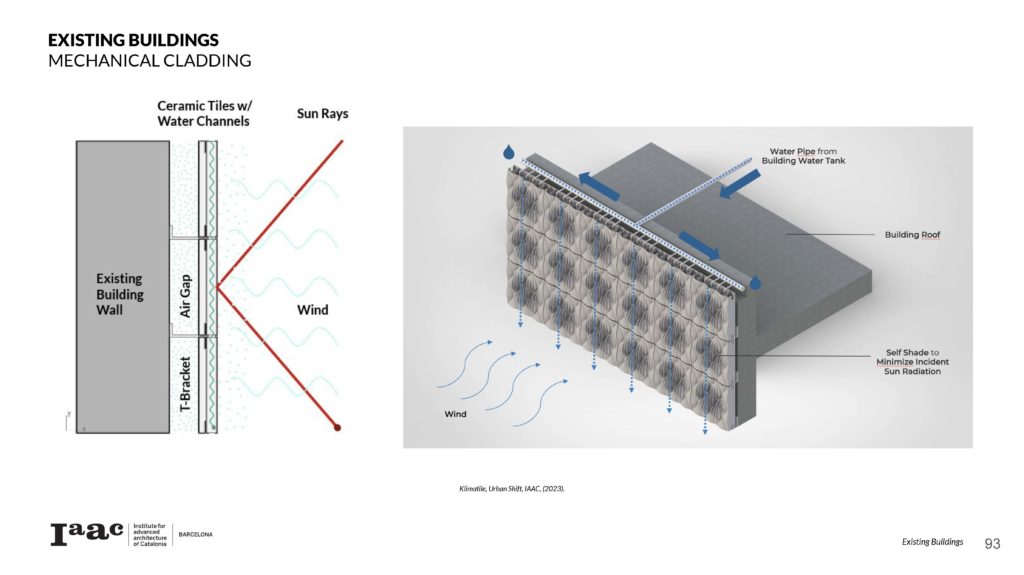

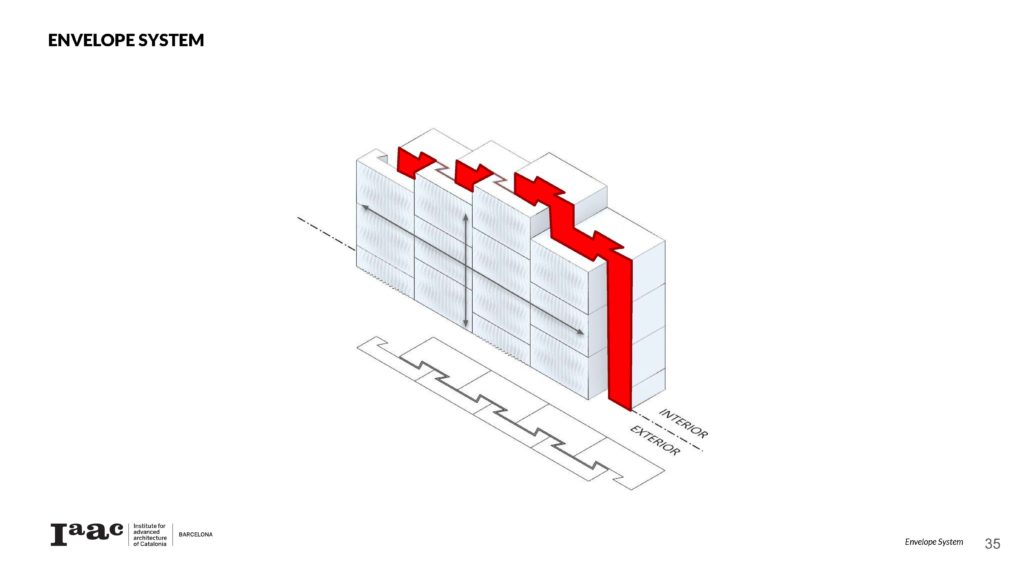

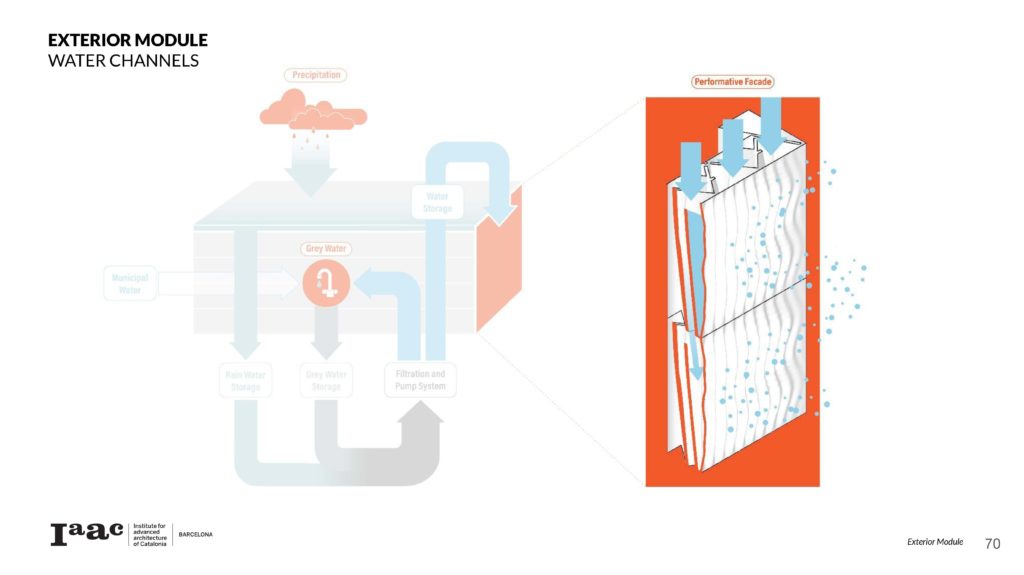

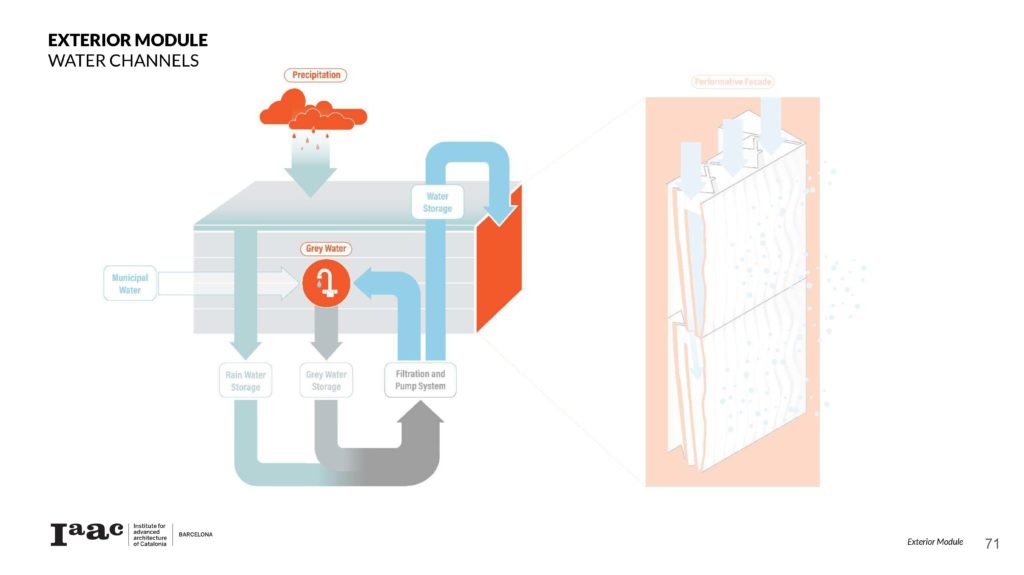

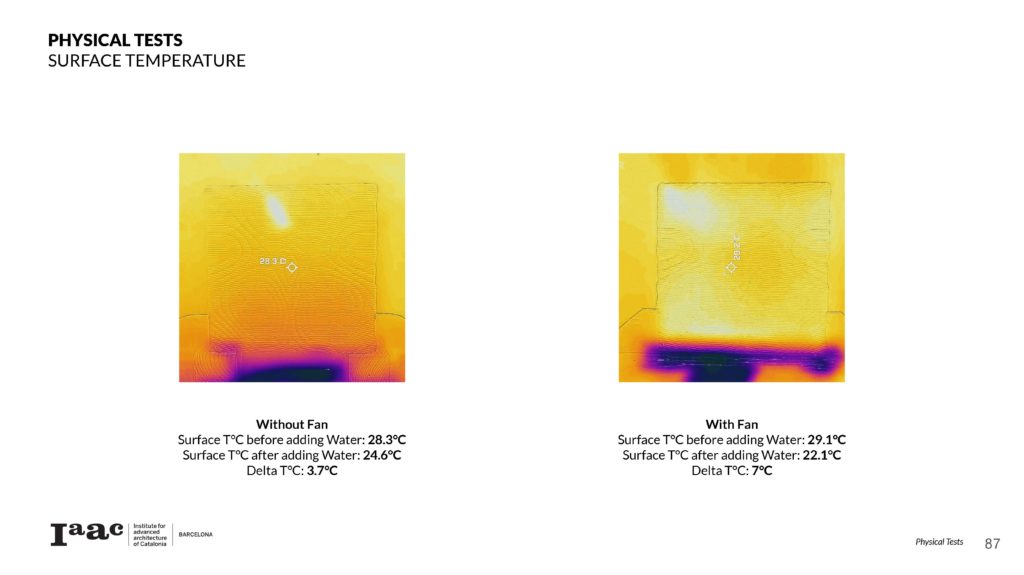

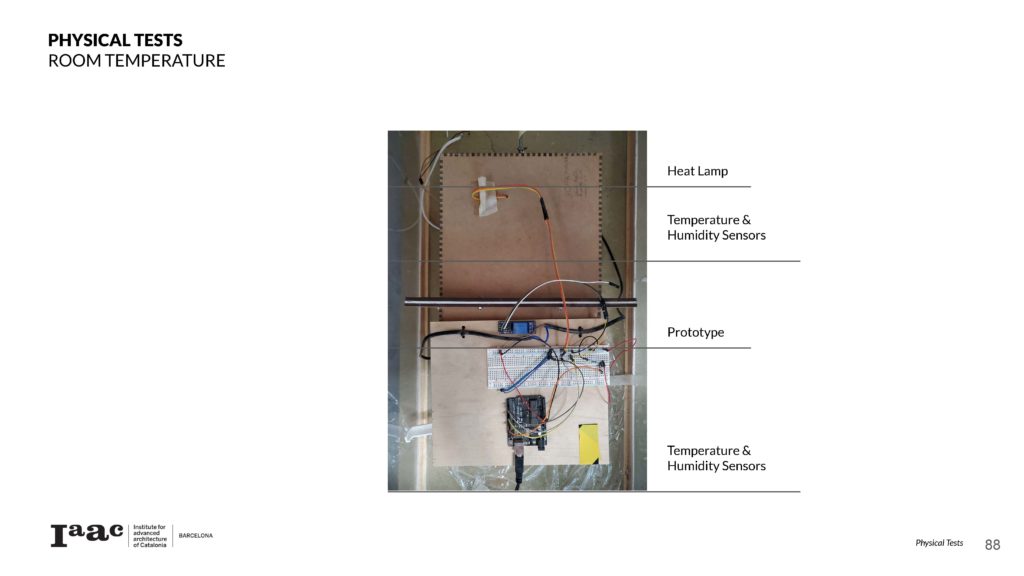

The building envelope employs a double wall system, with the interior wall serving as insulation and the exterior wall designed for cooling purposes. As water flows down the exterior wall, it is absorbed by the surface, while the wind interaction induces evaporative cooling. This process generates a cooler microclimate shield around the building, effectively reducing the temperature gradient between the interior and exterior, thus minimizing heat transfer. Consequently, the exterior and the interior of the building are cooled down.

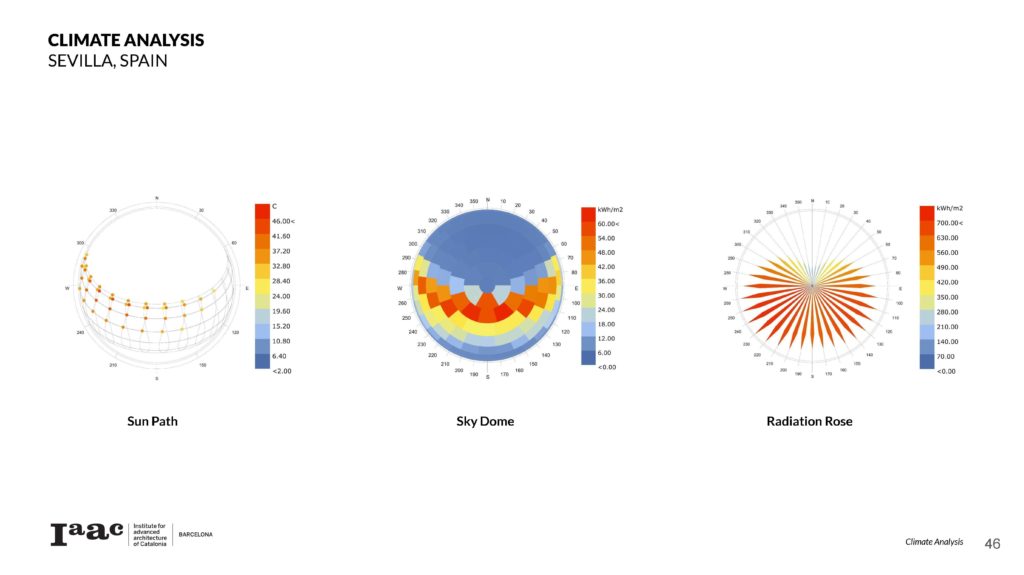

The blue areas correspond to hot and dry and mild temperature climates, between subtropical and temperate zones.

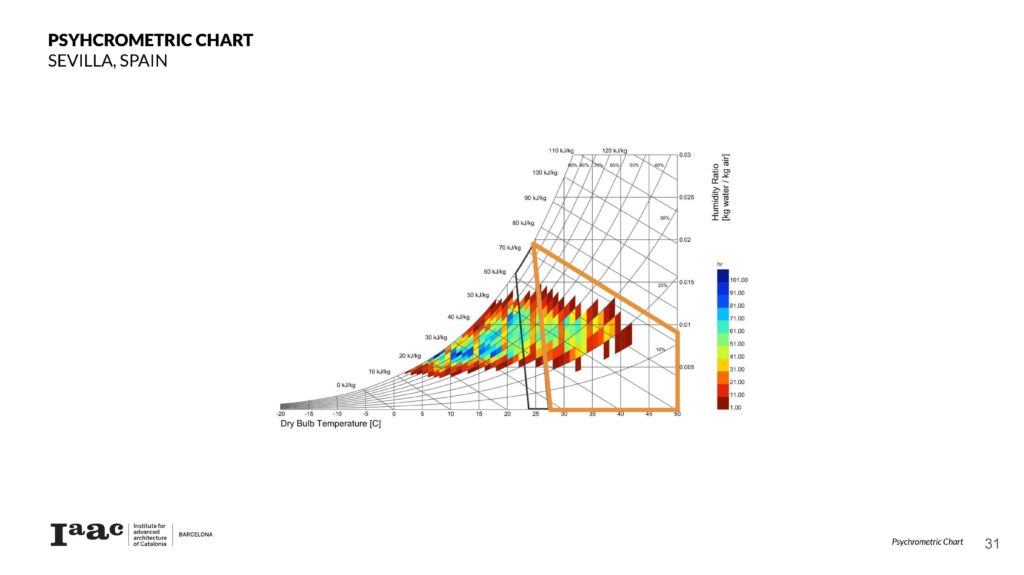

Sevilla, Spain was chosen for the case study.

Time of the year where the temperature is above 26 and the humidity levels below 70%.

And with a psychrometric chart we see how evaporative cooling can cover all the cooling needs and potentially eliminate the use of air conditioning.

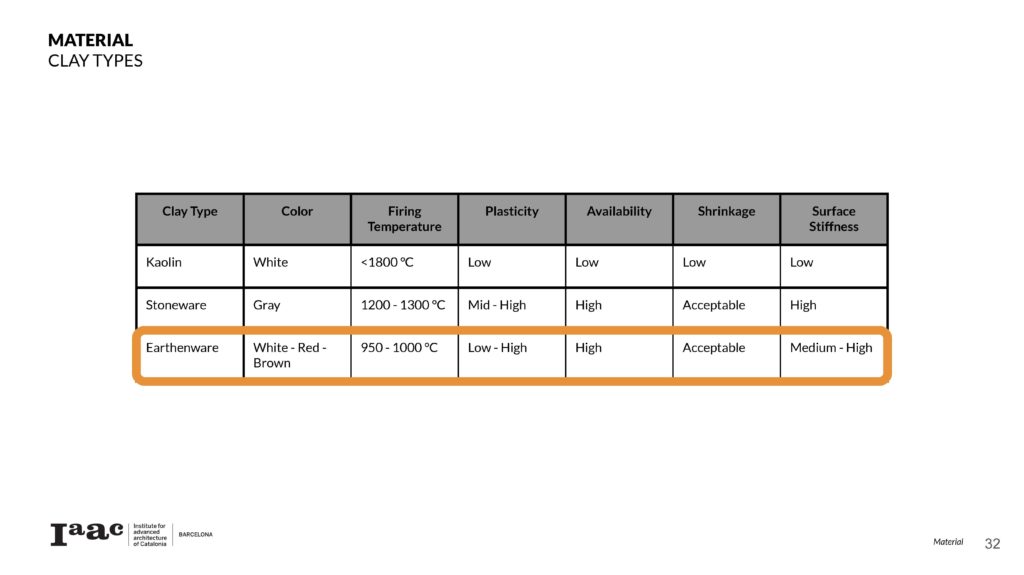

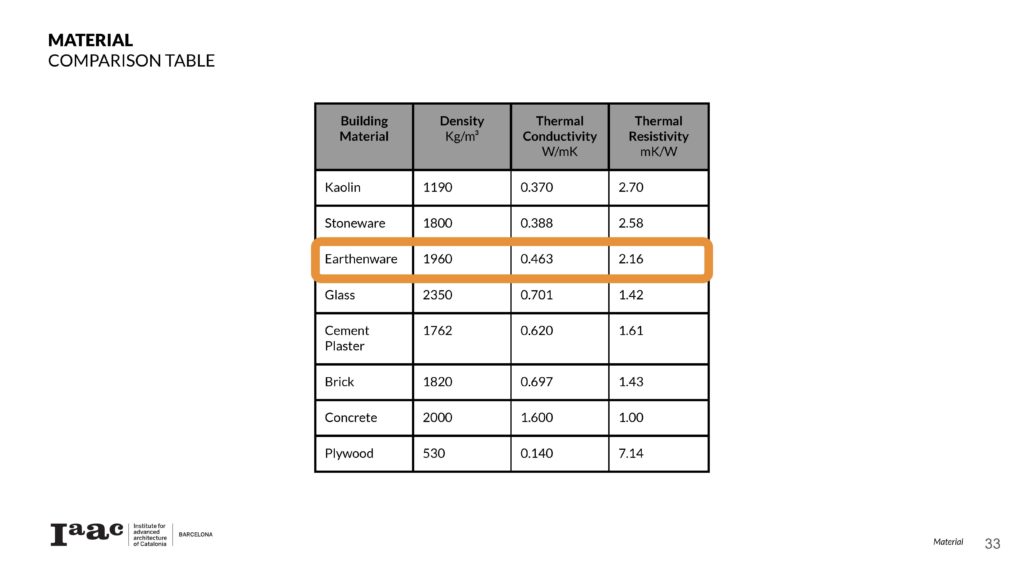

For the materialization of the proposal, 3 types of clay were taken in consideration, of which earthenware was chosen, due to its high availability, acceptable shrinkage, plasticity and lower firing temperatures.

Earthenware is not the best among the clays, but it still has much lower thermal conductivity and more thermal resistivity than other non-wood building materials.

White was chosen for maximum reflectivity.

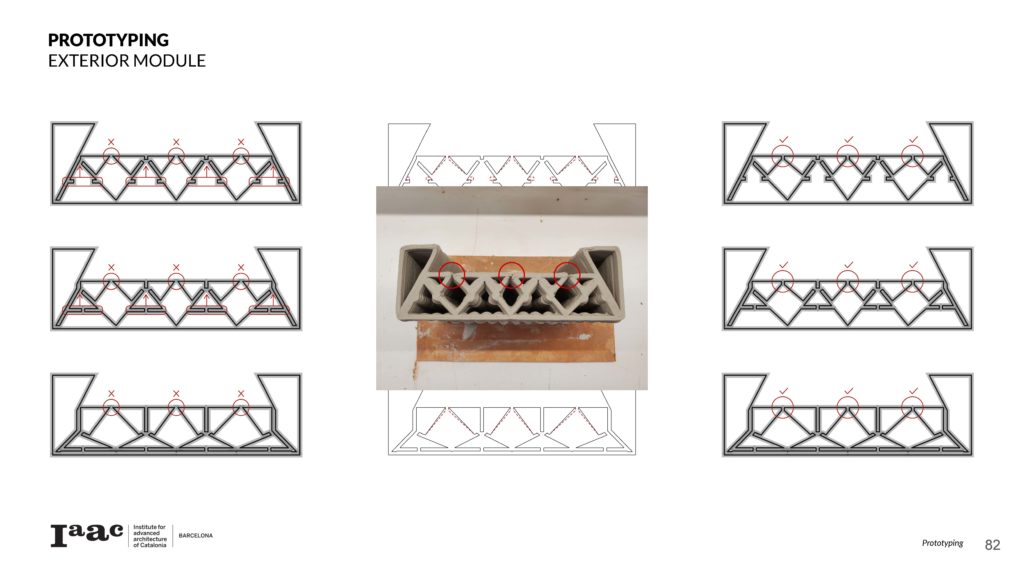

- The modules slide in with interlocking joints

- They get staggered vertically, with mortar in between

- Clear separation between interior walls (insulation) and exterior (cooling)

- Seamless continuity of the surface texture

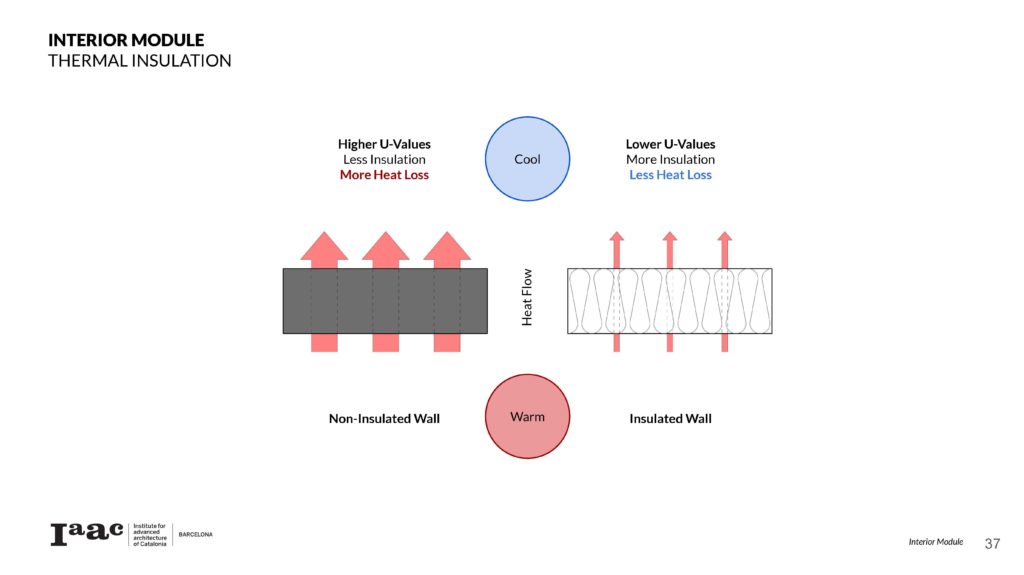

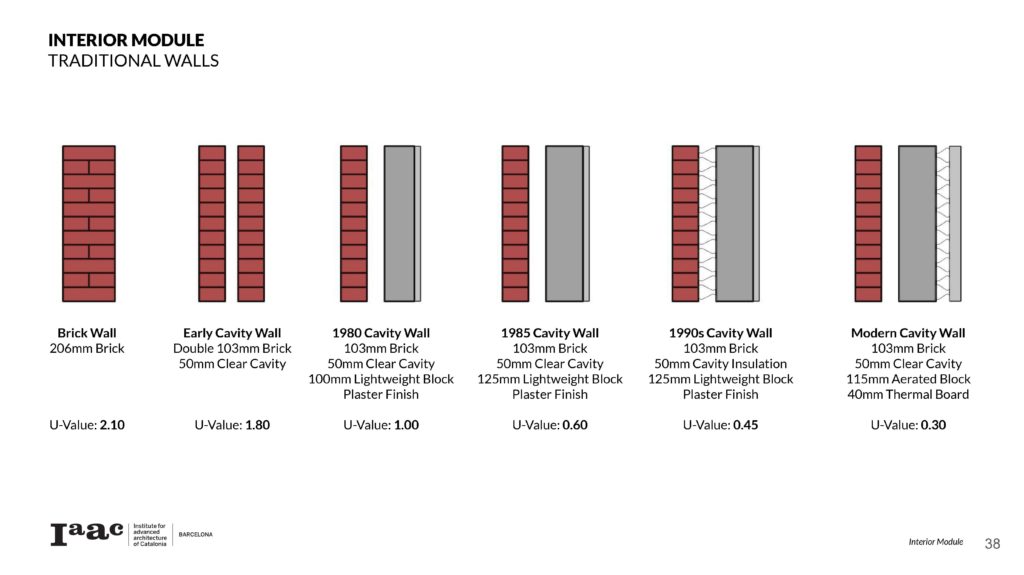

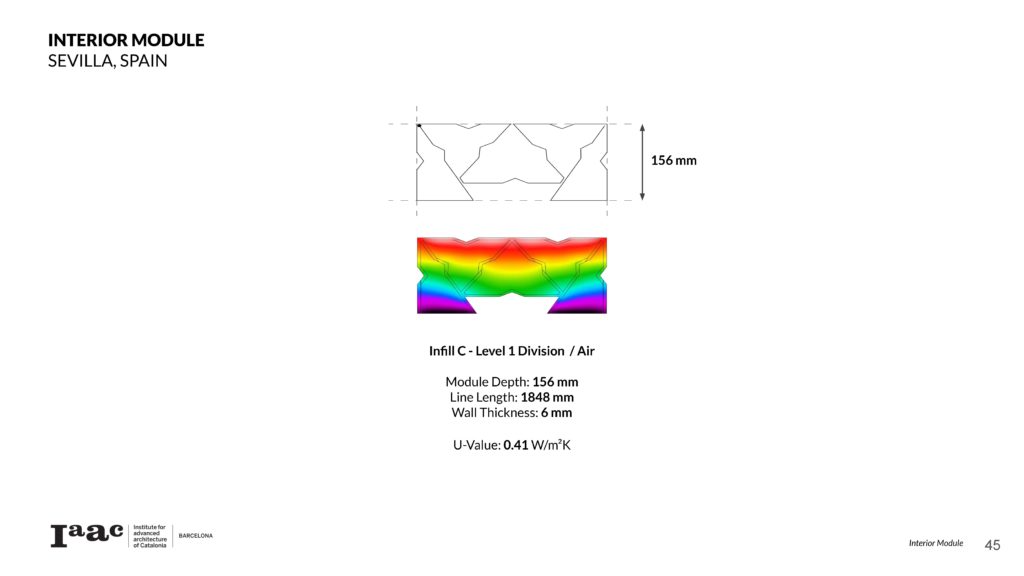

The U-Value is the measure of how effective a given material is as an insulator.

The lower the U-Value, the better a material is as a heat insulator.

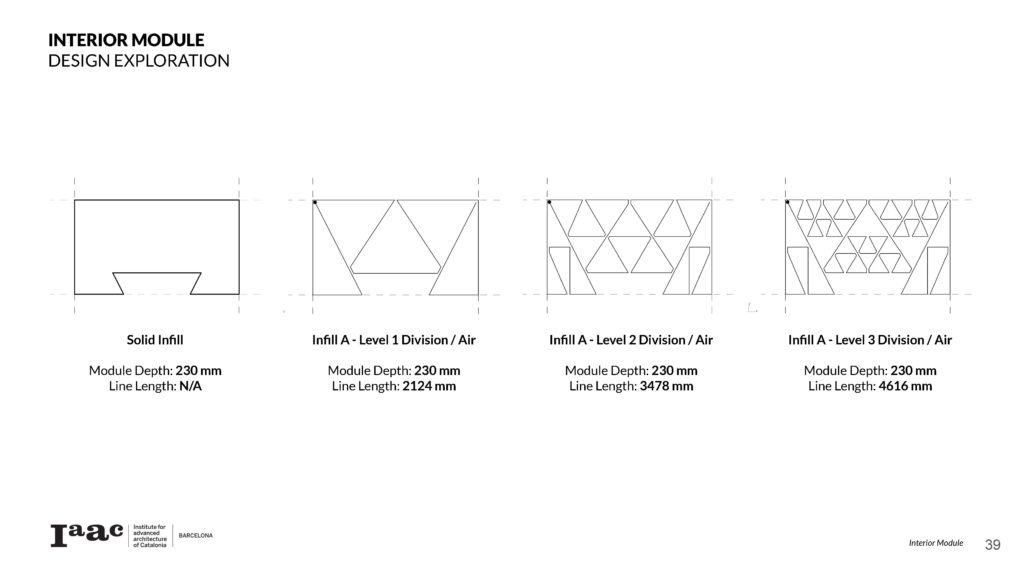

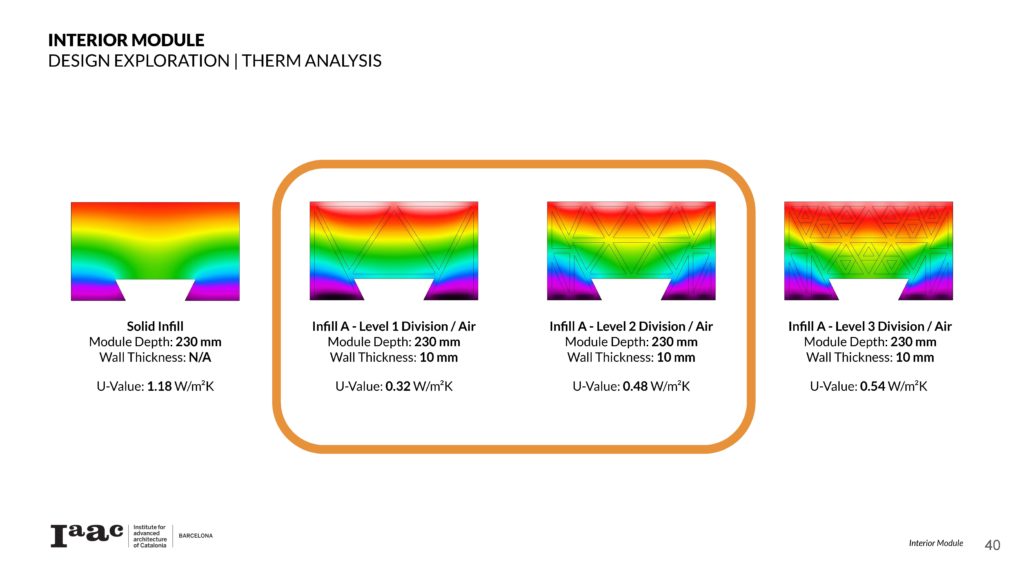

Exploration elements were:

- Subdivision levels of the infills

- Thickness of the walls

1 cm wall thickness

6mm wall thickness, because that was going to be the 1:1 scale 3d printed wall size.

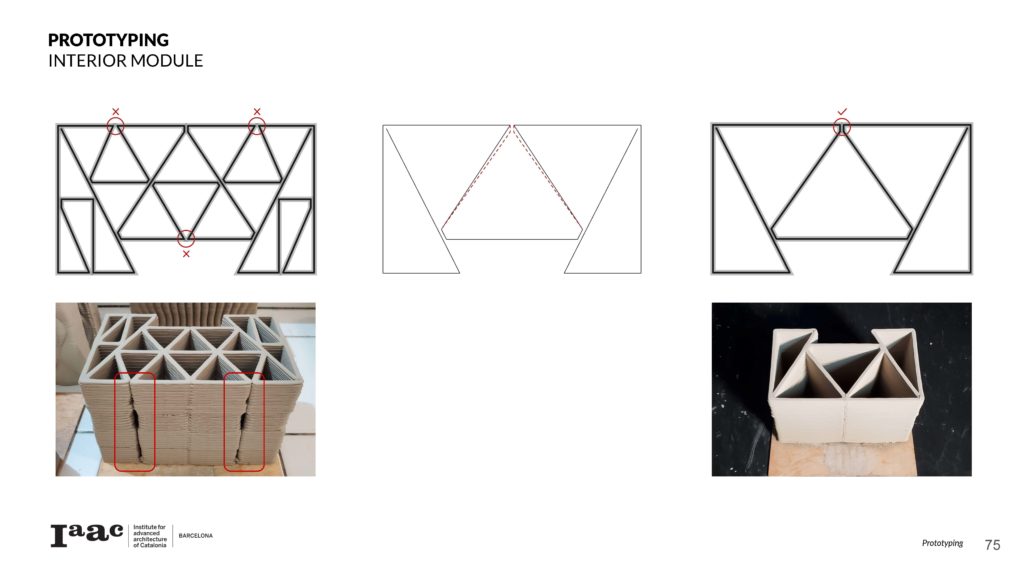

Had to add structural walls / kinks, because in scale 1:1 the length of the straight wall would be larger than it should, per the previous research, so the long lines had to be broken down.

The reason of the choice is that infill C- Level 1 has good enough U-value while having the least material, which also means less weight and printing time.

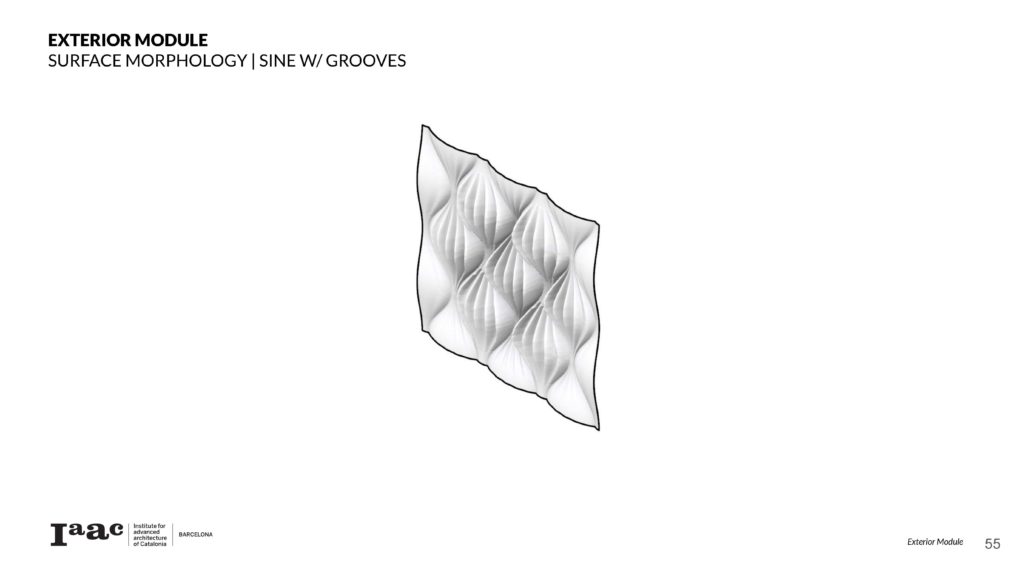

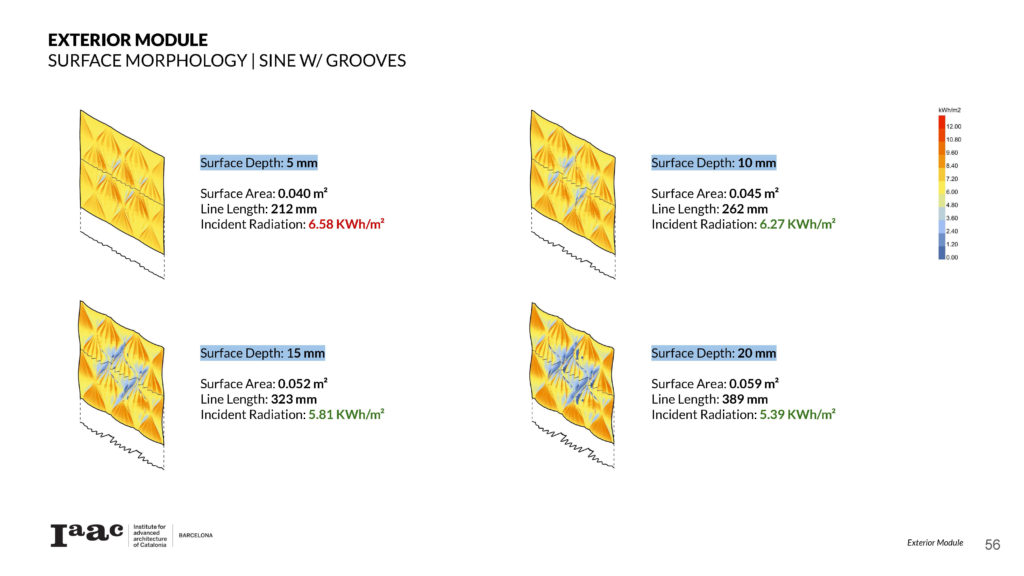

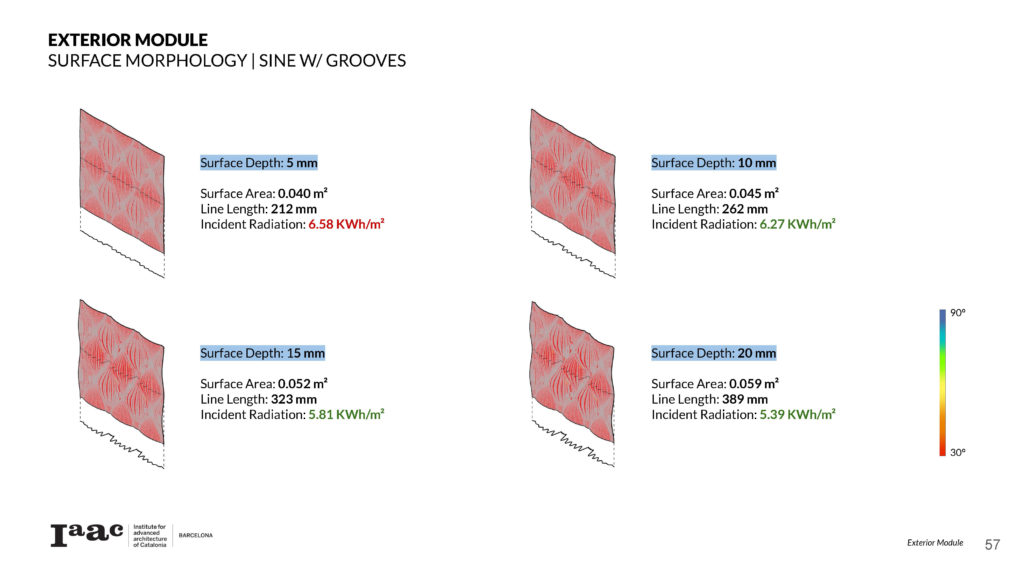

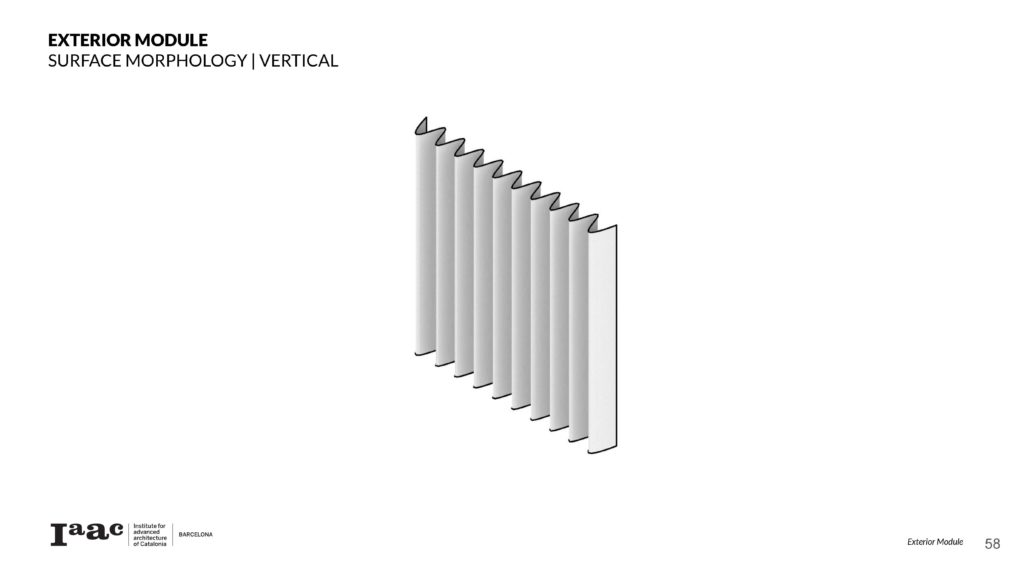

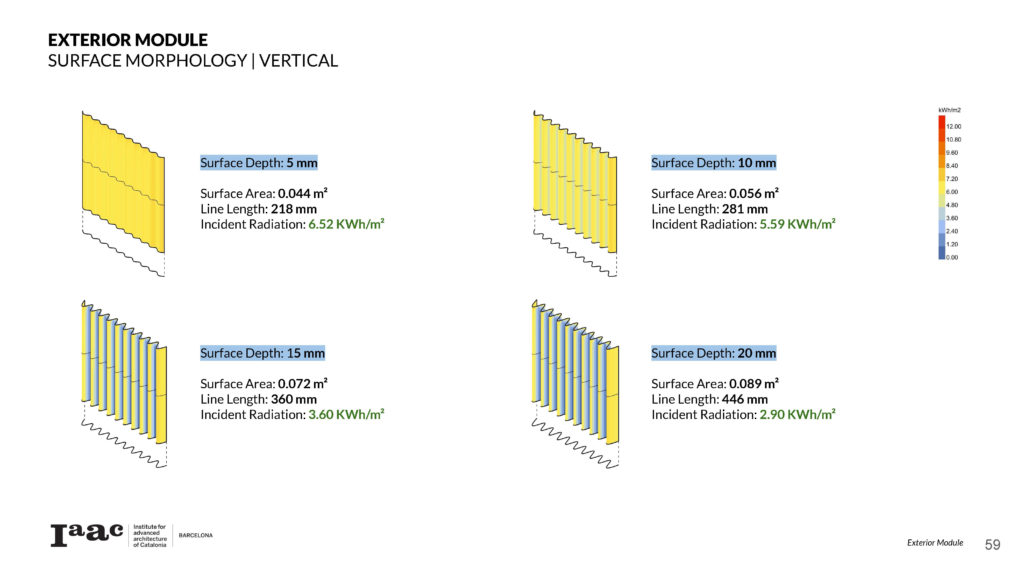

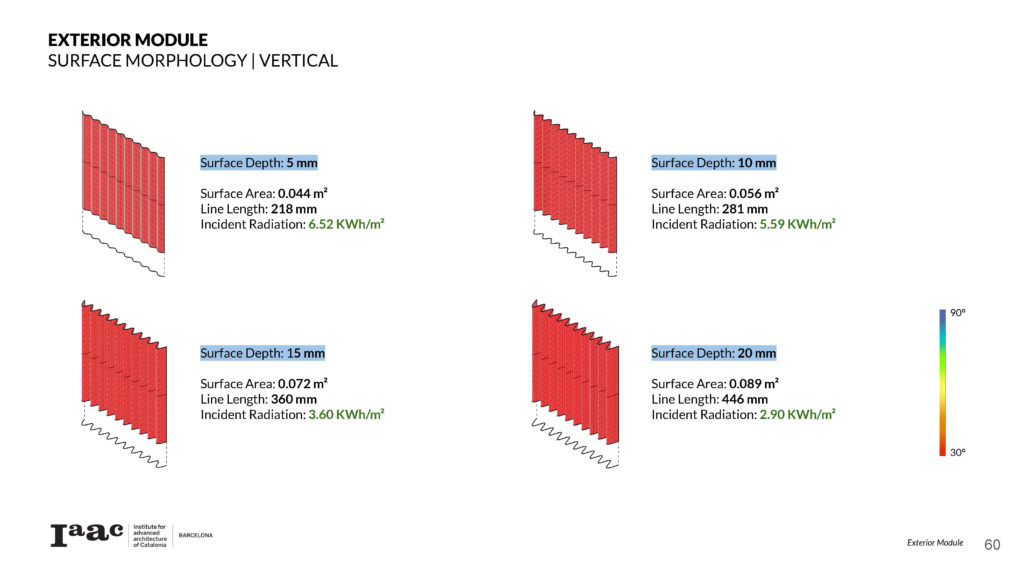

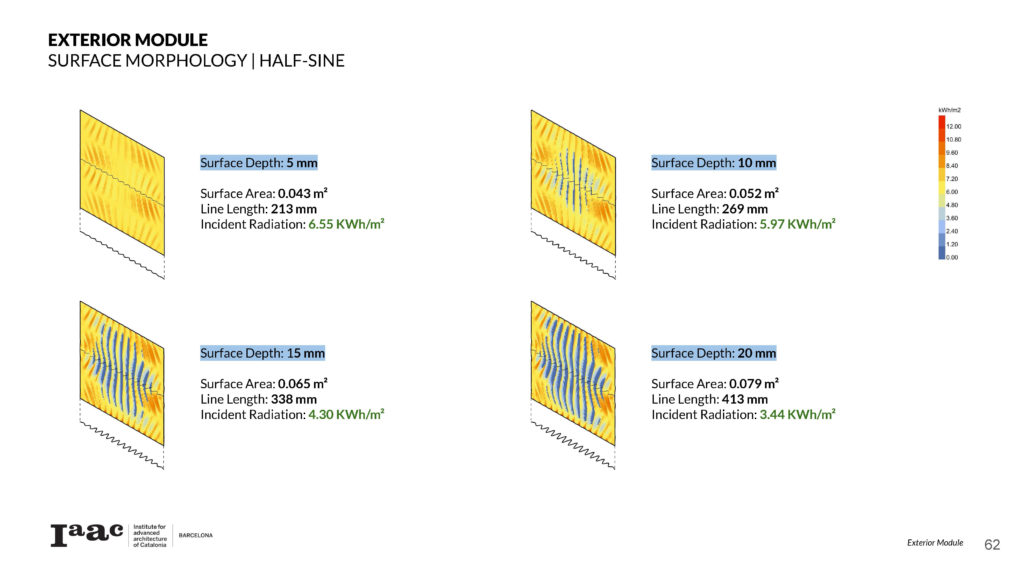

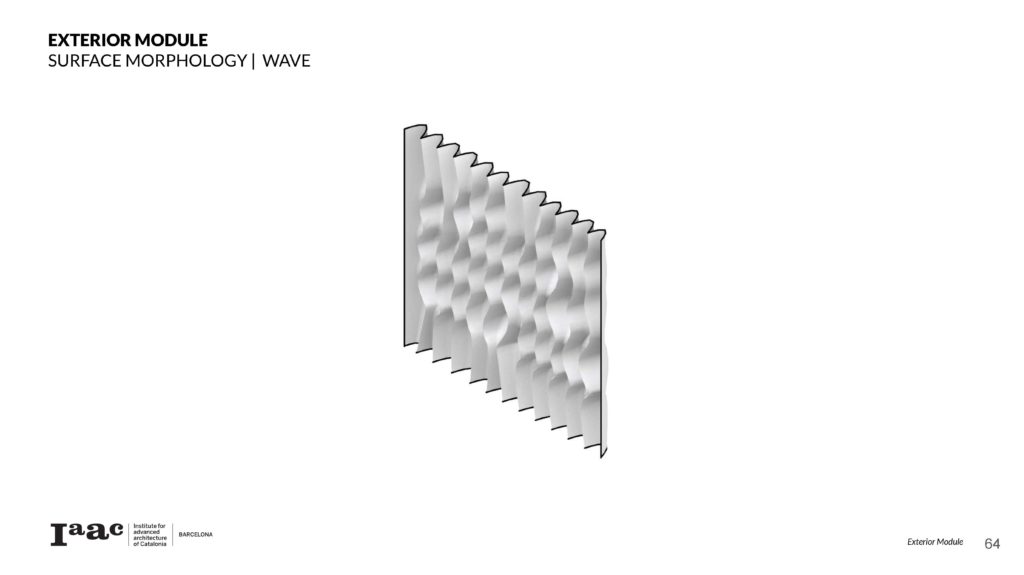

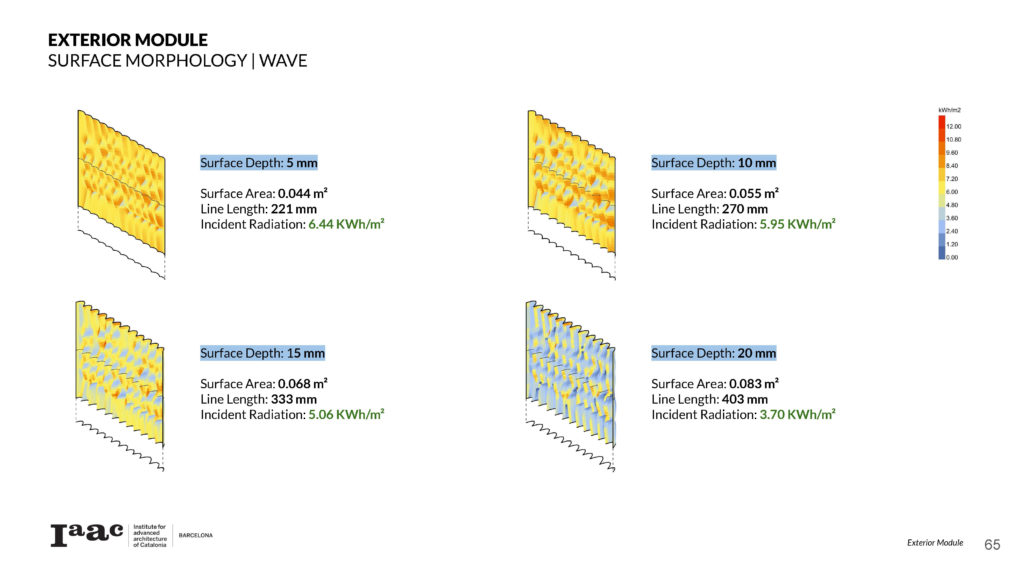

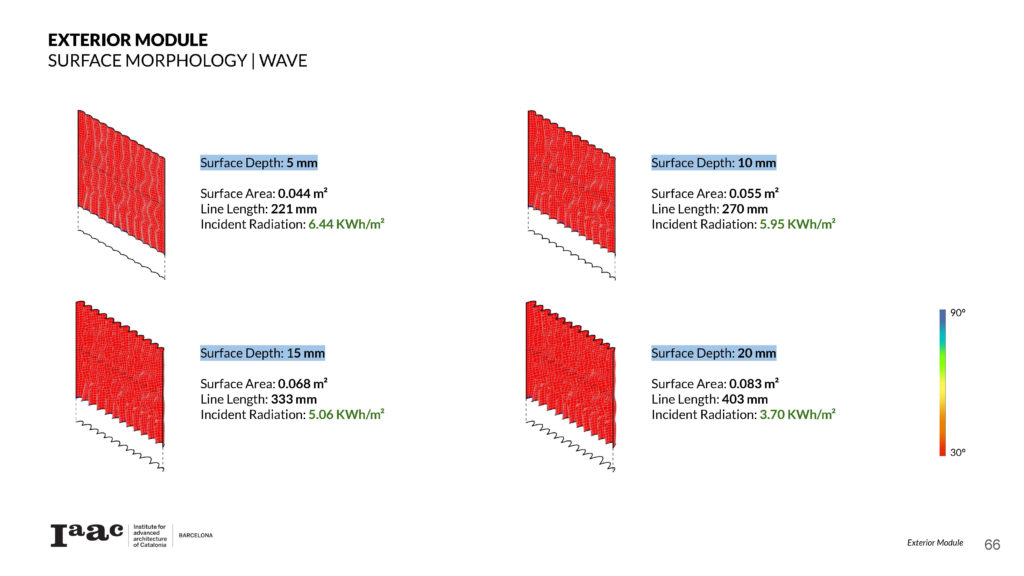

Sun path and radiation analysis, for the surface texture.

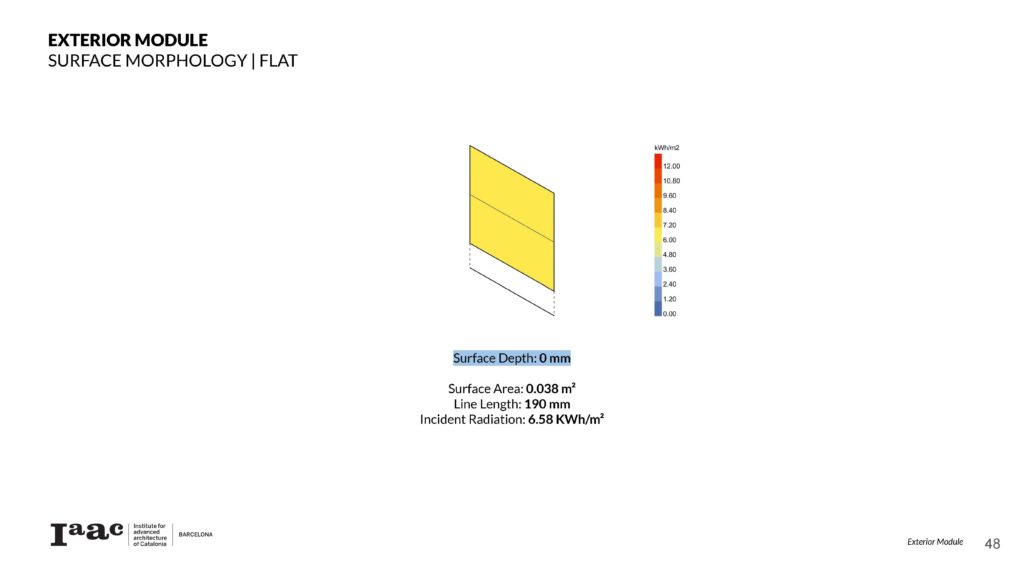

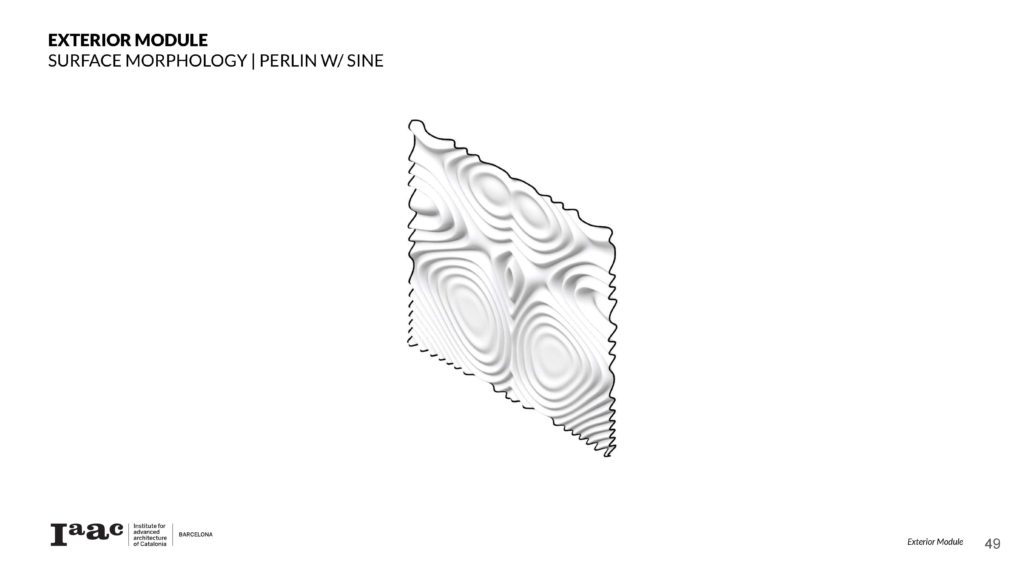

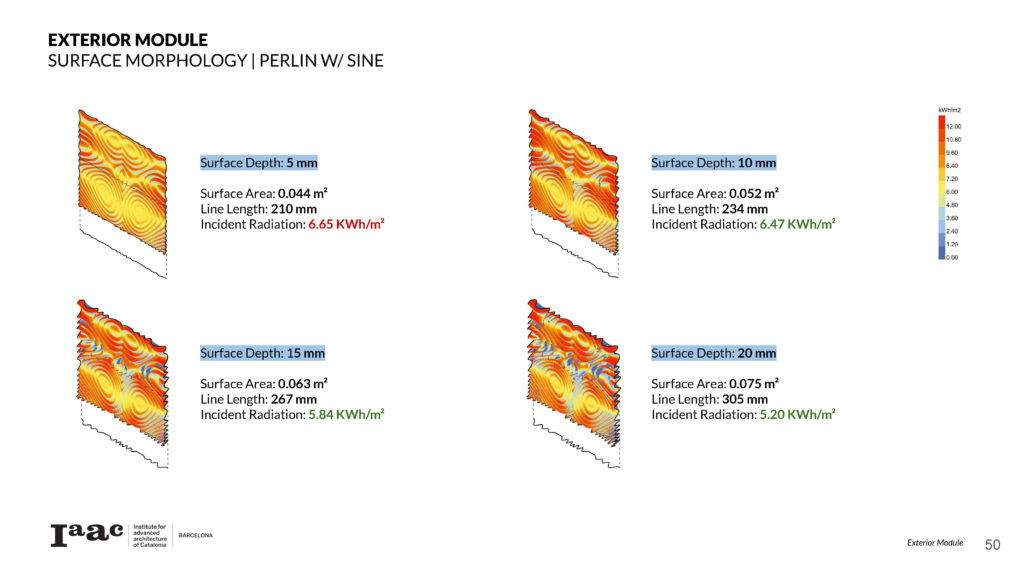

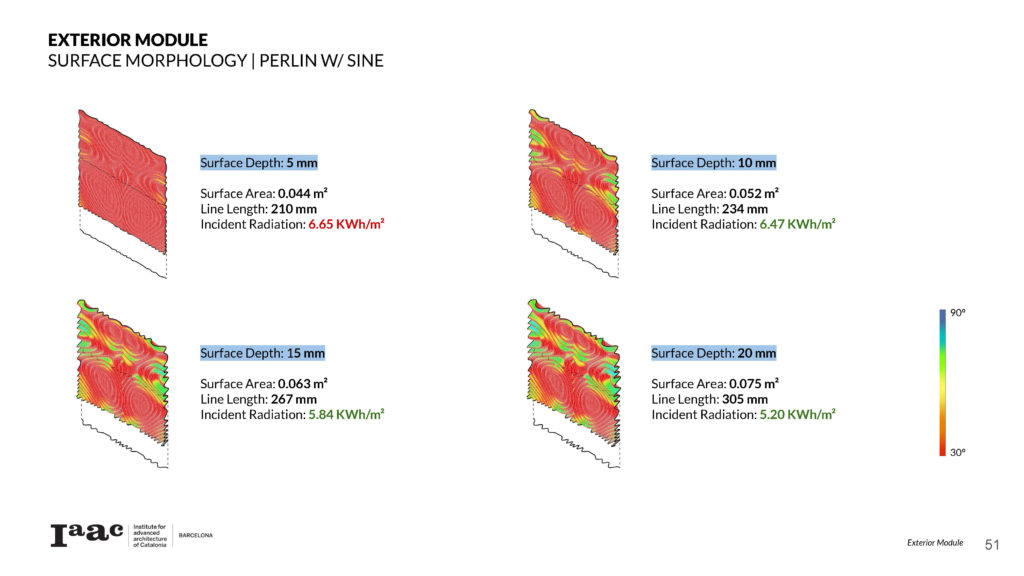

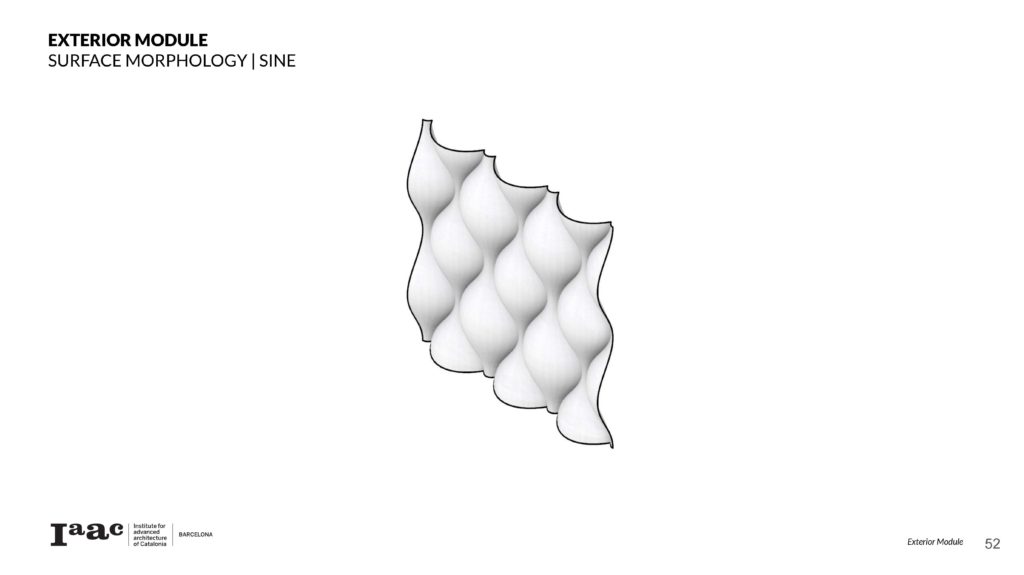

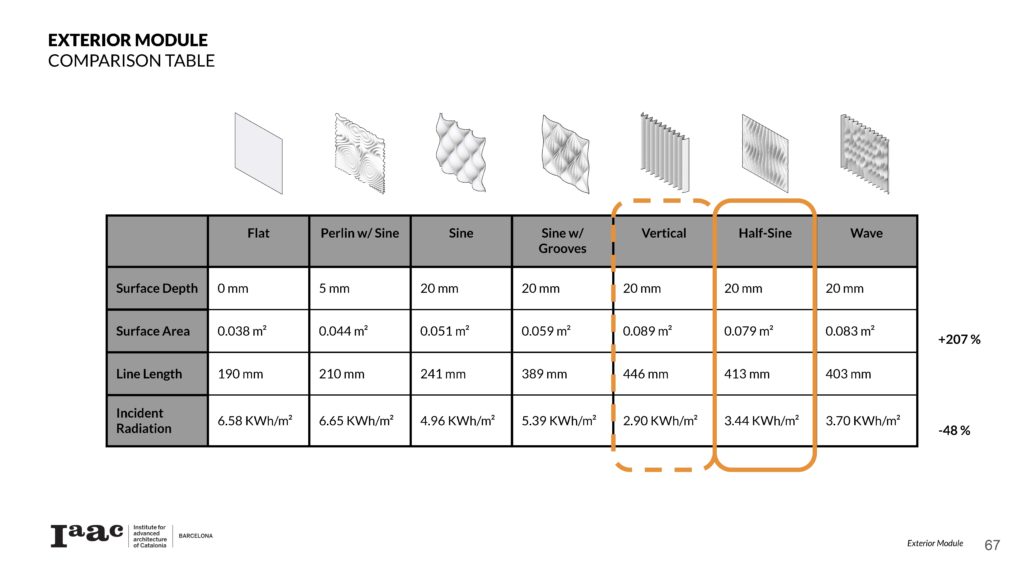

All other surfaces will be compared to this baseline. What we want is to increase the surface area while decreasing the incident radiation on the surface, which means the geometry will have more self-shading, therefore the creation of grooves.

At the same time we will be looking at the printability of each surface texture.

4 different surface depth will be compared: 5mm, 10mm, 15mm, 20mm.

Comparing all these surfaces together, the vertical one proves to be the most effective but the half-sine was chosen as it was close enough to the vertical one data wise, but aesthetically more interesting.

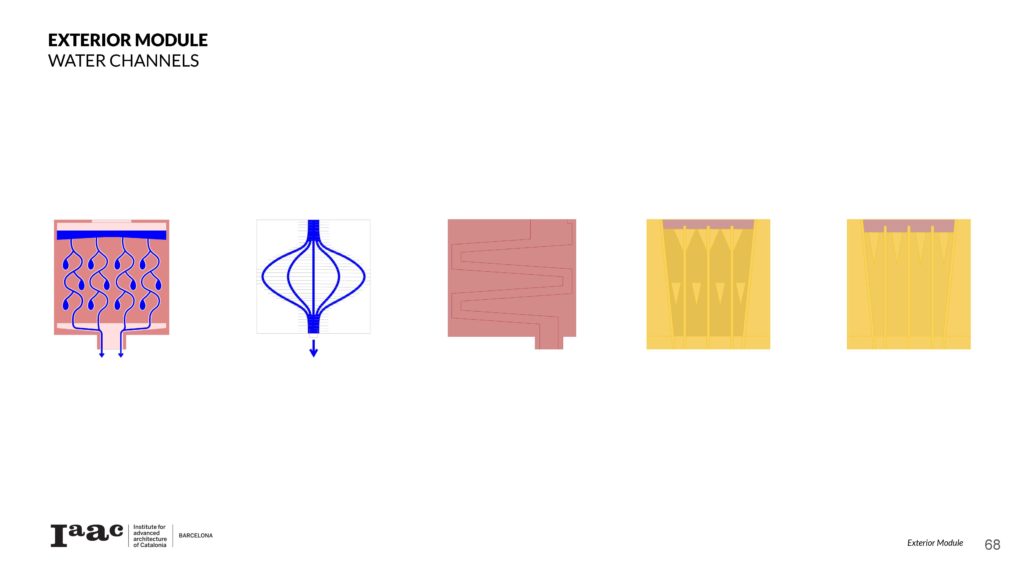

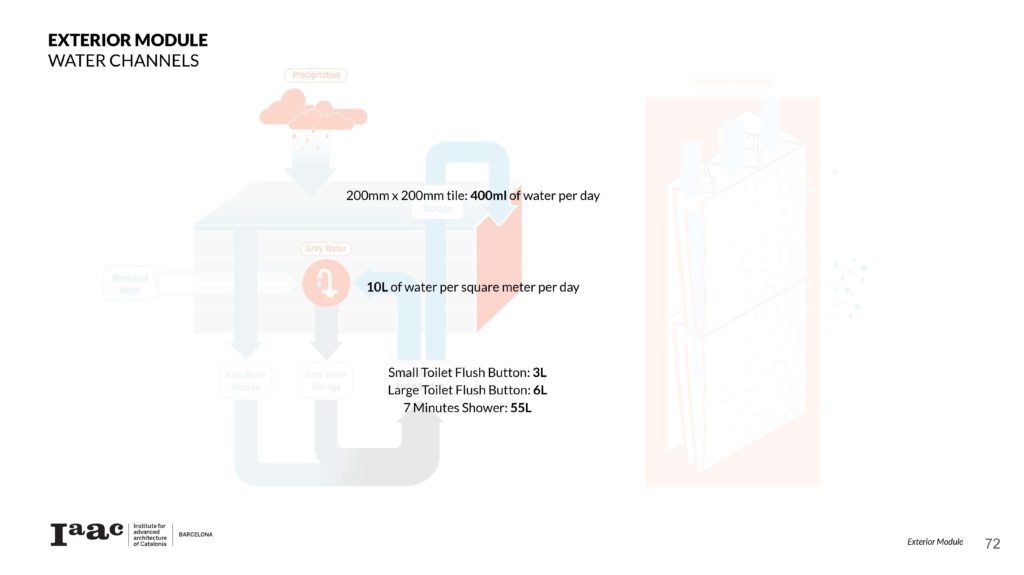

As for the water channels, after some exploration…

The final design was achieved.

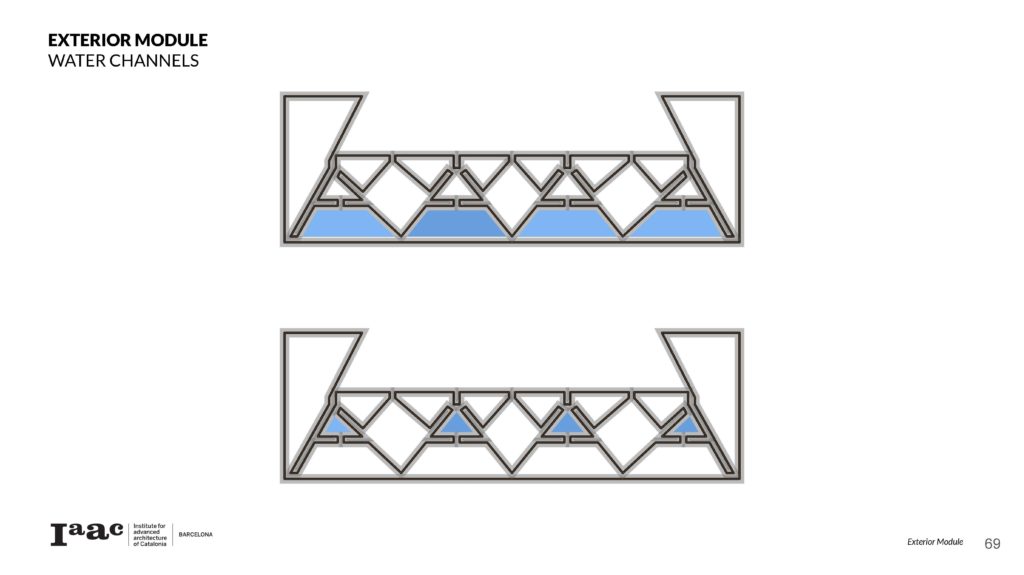

The water fills the front channel of the wall and it overflows into the back channels.

Section showing the water channels.

Water source proposal diagram.

And just for reference…

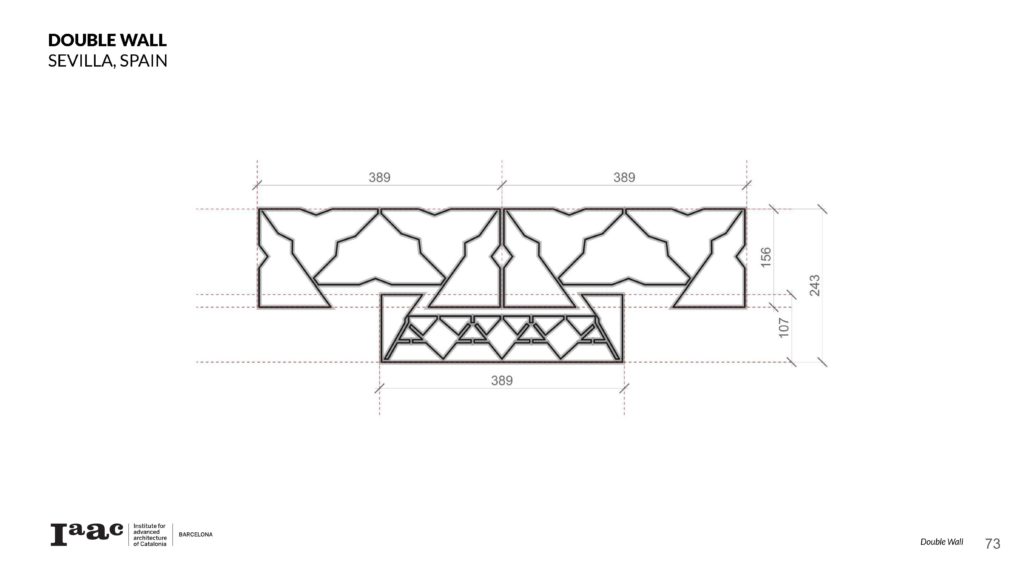

For sevilla, this would be the double wall system dimensions.

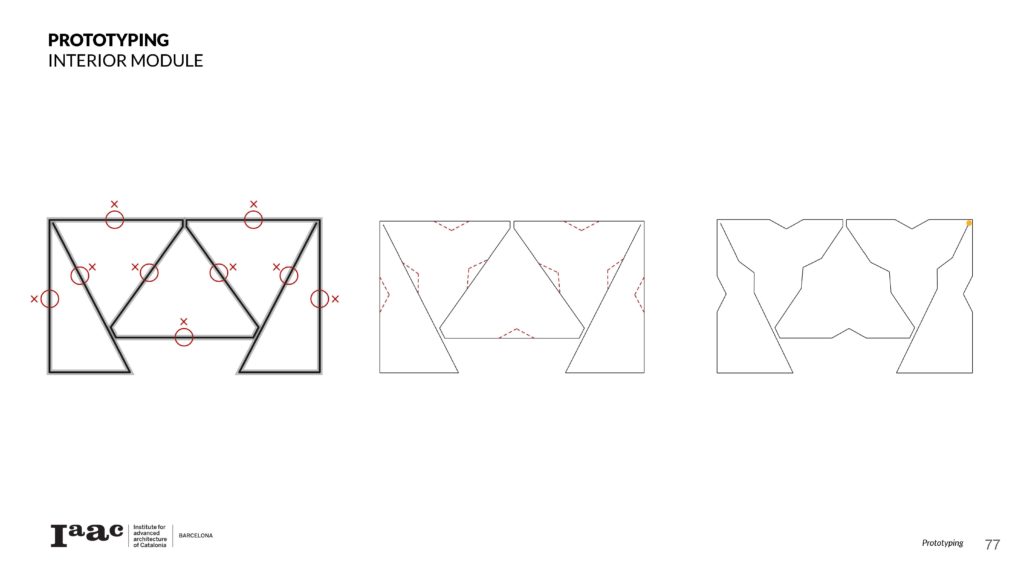

Fixing the angles.

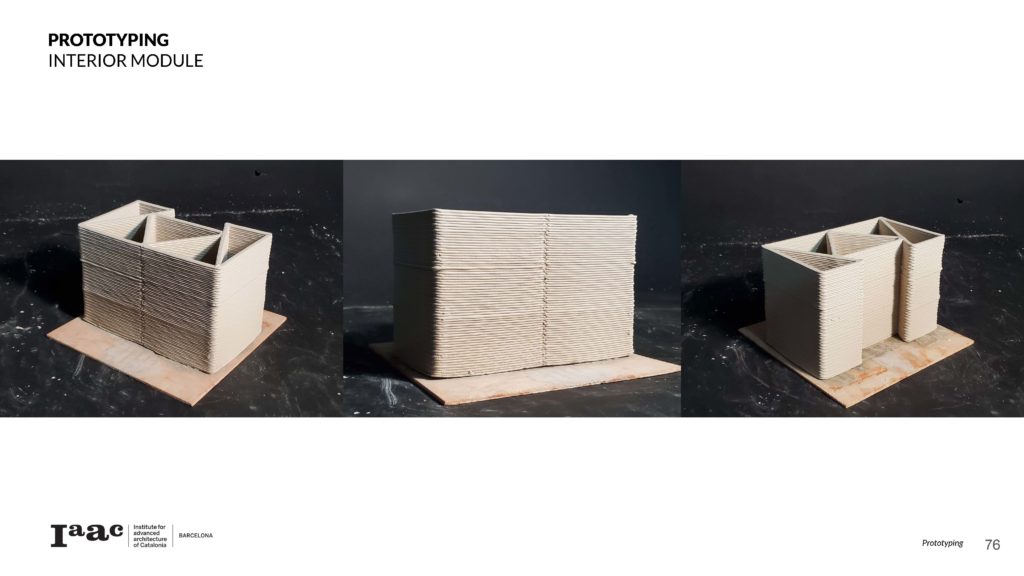

Bi directional printing, each layer prints the opposite direction of the previous one.

Adding structural kinks.

Fixing the angles

Pushing back the channel walls.

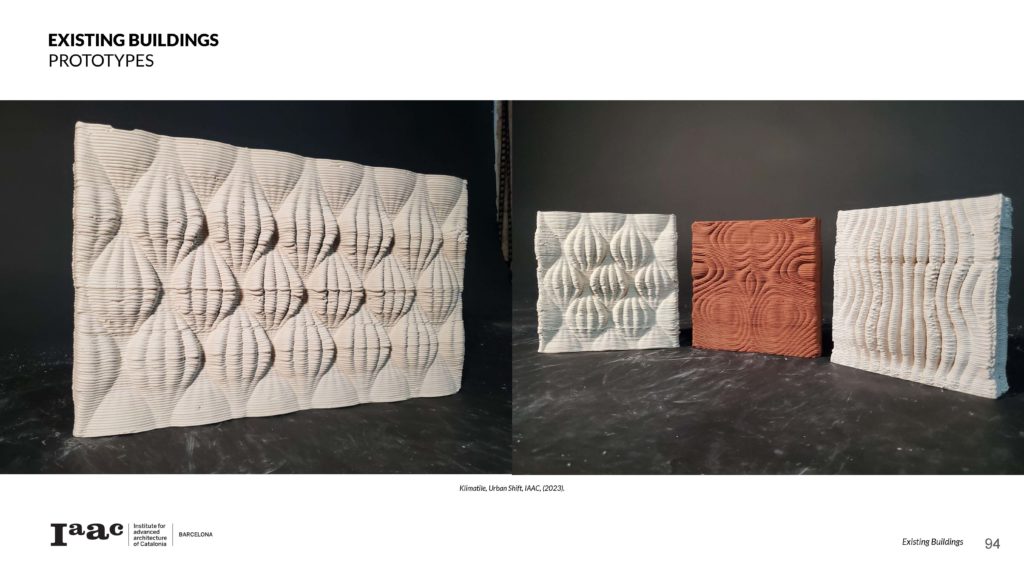

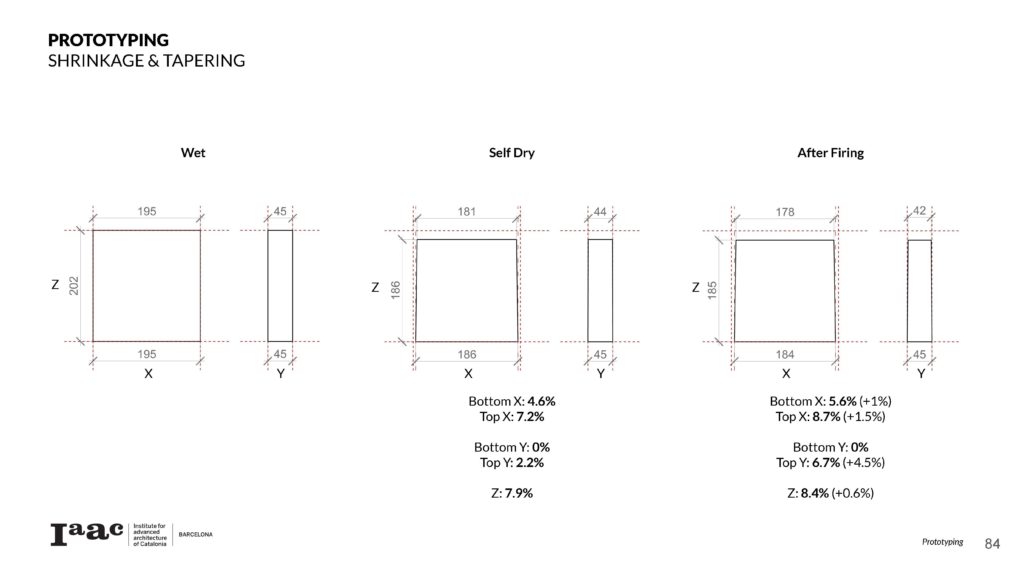

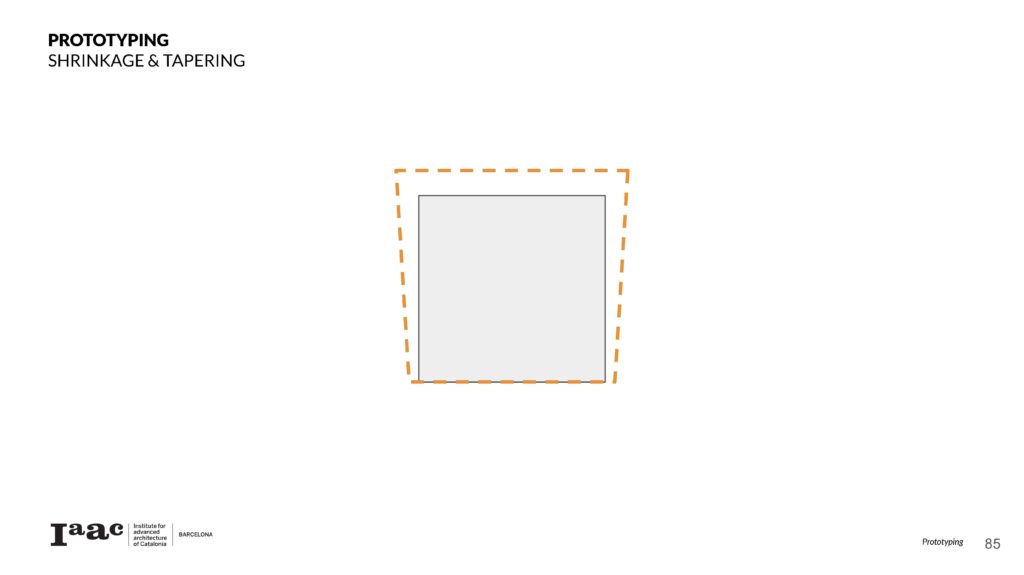

Shrinkage observations:

- Most shrinkage happened in the top x axis and z axis of the prototype

- This caused tapering at the top

Therefore in future explorations these tolerance could be the input to the digital model.

If we wanna print a square.

We need to 3d model a trapeze.

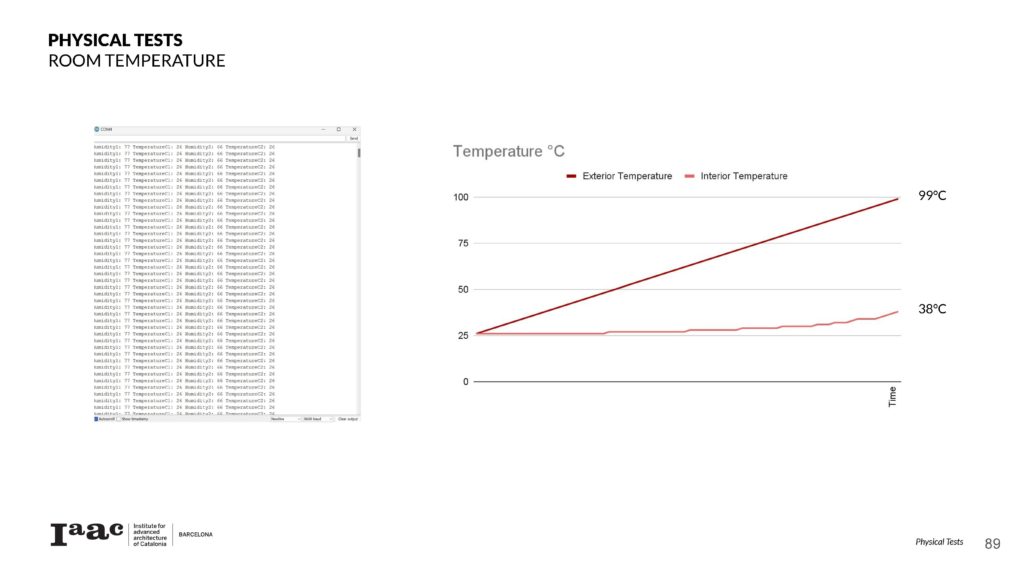

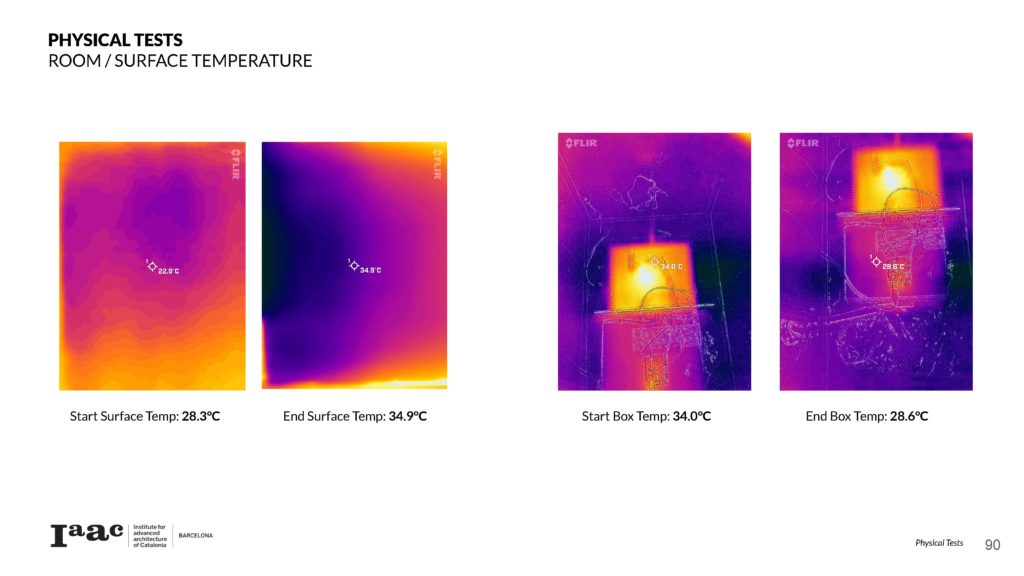

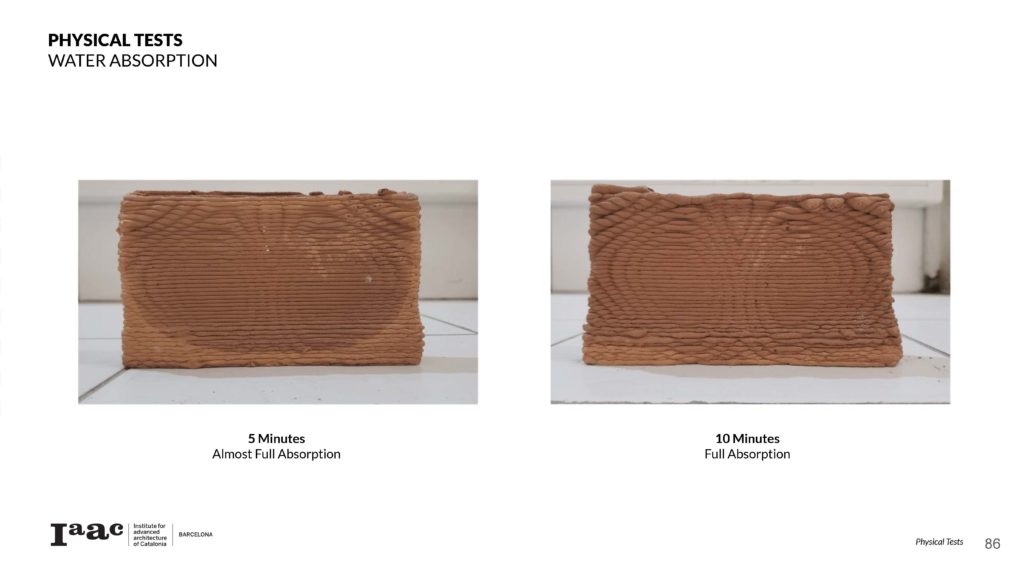

Test conducted with a device that was built during the 2021 3DPA program.