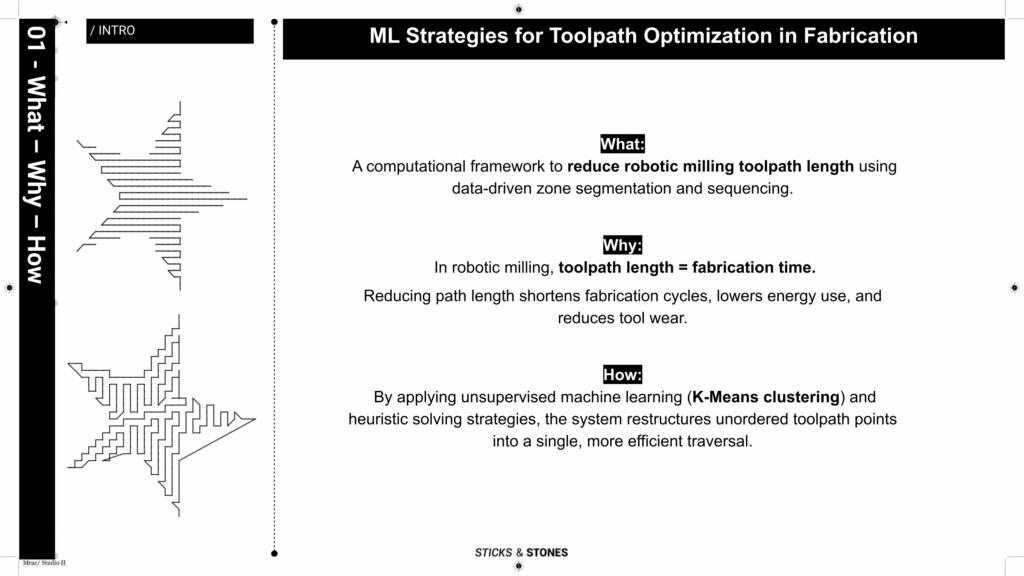

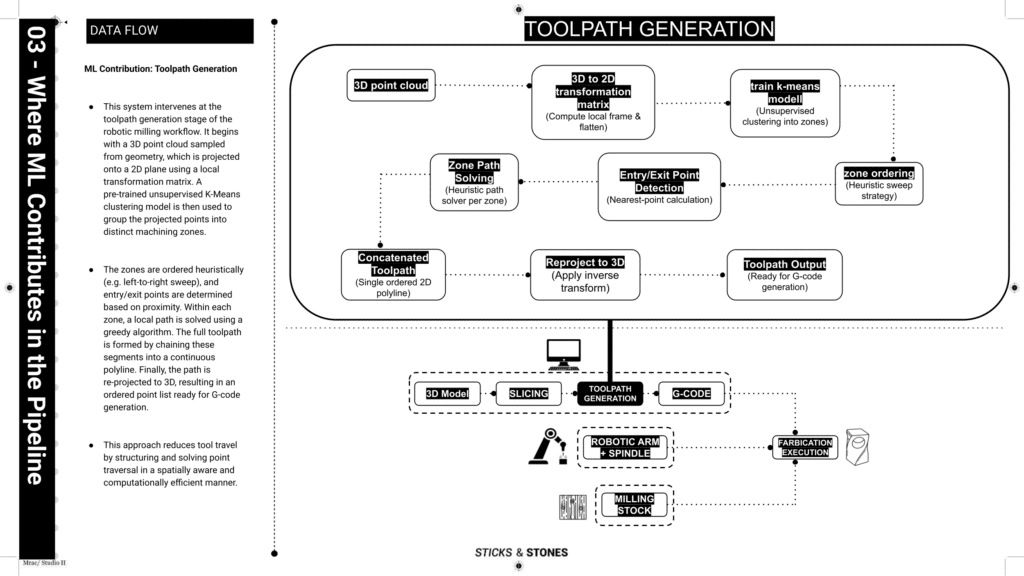

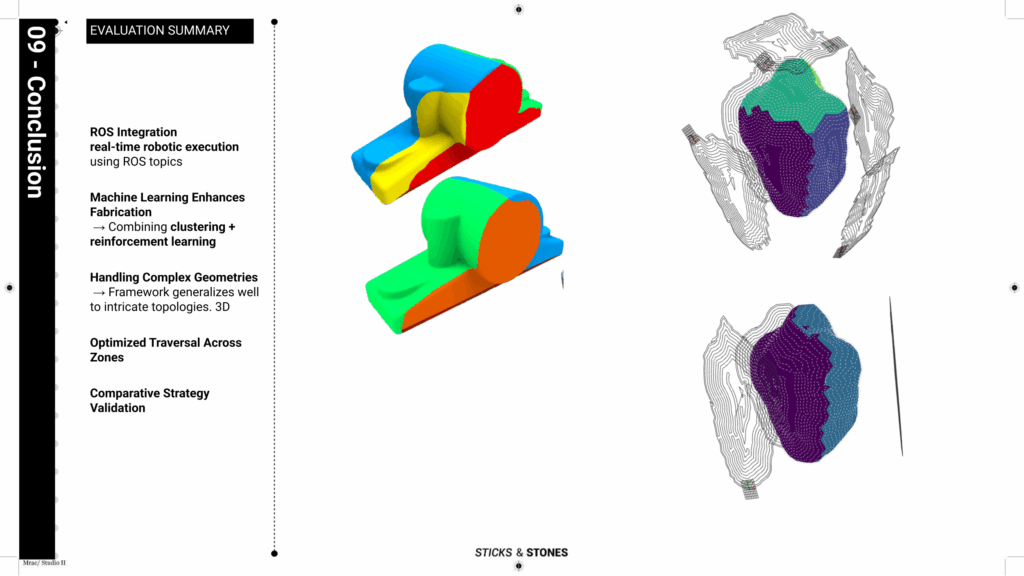

In the ongoing pursuit of efficient toolpath generation, we set out to build a modular, logic-driven system capable of planning subtractive manufacturing strategies. The framework integrated zonal segmentation, directional movement, and dynamic state awareness; its goal was adaptability and long-term scalability. While we achieved full system functionality, this initial iteration exposed the distance between a working system and a truly optimised one. What follows is a reflection on that gap, the insights gained, and the possibilities that remain open.

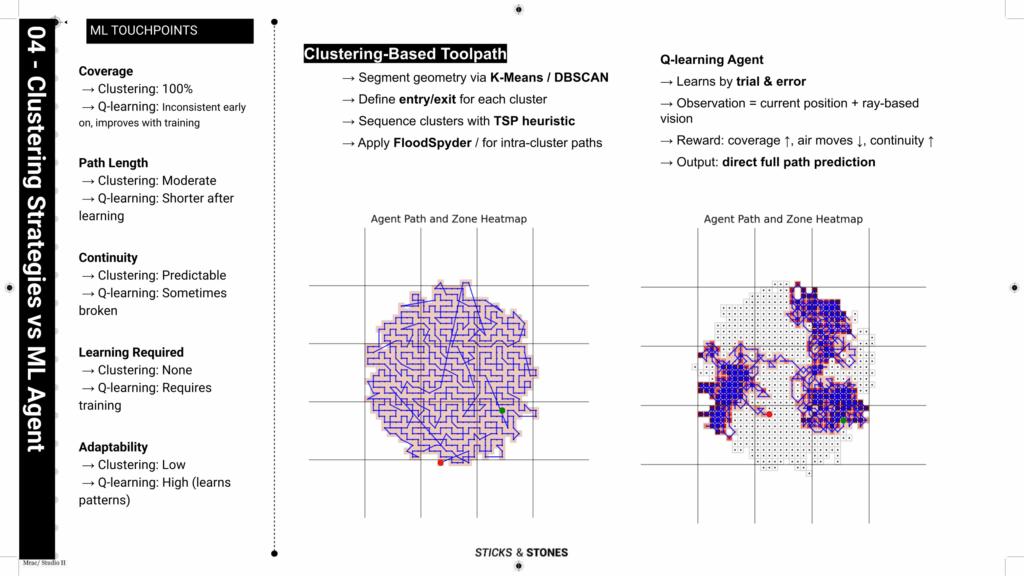

All systems were eventually brought online and functioned as intended, but optimisation remained a missing layer. Key logic elements such as efficient search patterns and intelligent endpoint chaining between layers were either underdeveloped or entirely absent. The system also relied too heavily on manual clustering, where an automatic, data-driven approach would have yielded more consistent results. Despite its modularity and potential, the outcome was still outperformed by established solutions like RhinoCAM; this suggests that raw efficiency may not be the most appropriate metric for judging its value. Instead, its promise may lie in tackling irregular or complex surfaces that traditional workflows are not well suited for, which could define the direction for future development.