Our digital fabrication journey unfolds through four experiments that explore how material, geometry, and technology negotiate form. Each project challenges a different fabrication technique: laser cutting, CNC milling, 3D printing, and robotic manufacturing, while asking a deeper question: How does digital logic reshape the language of craft?

Laser Cutting

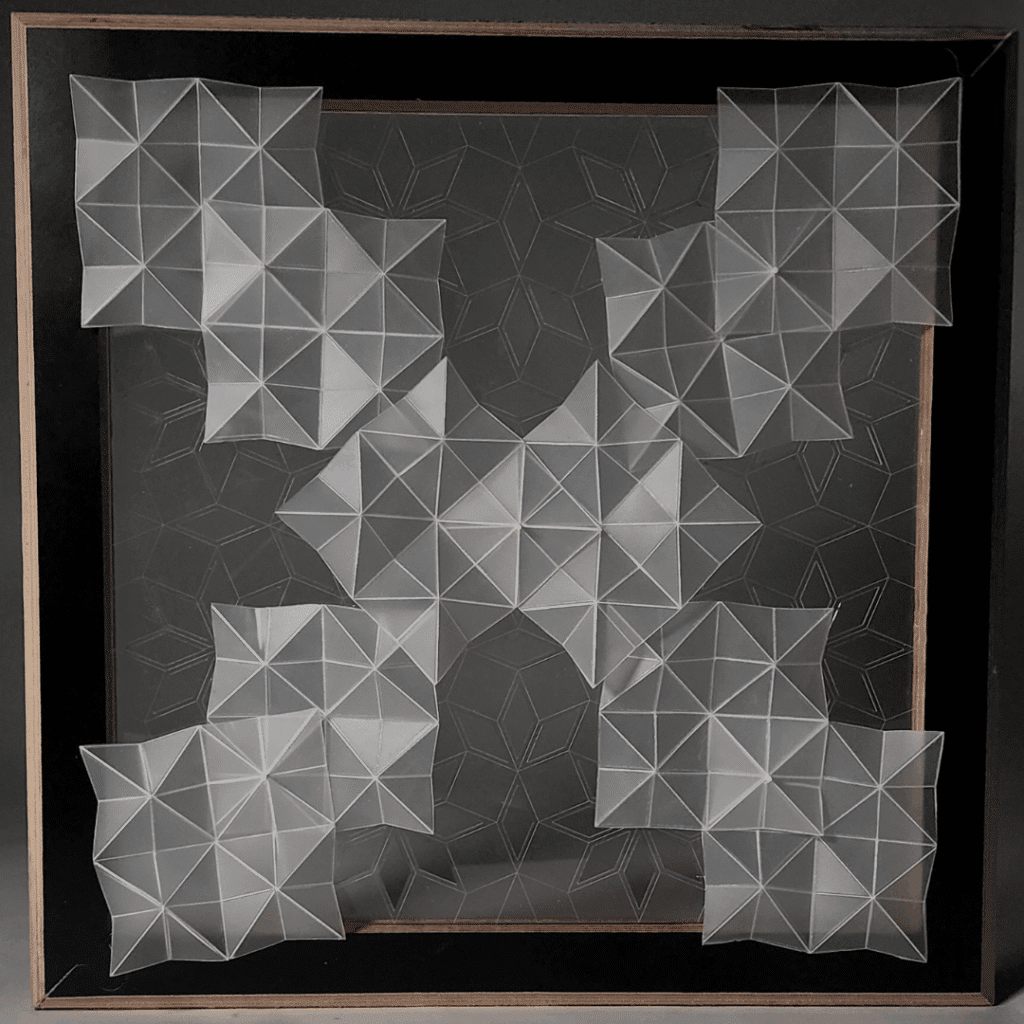

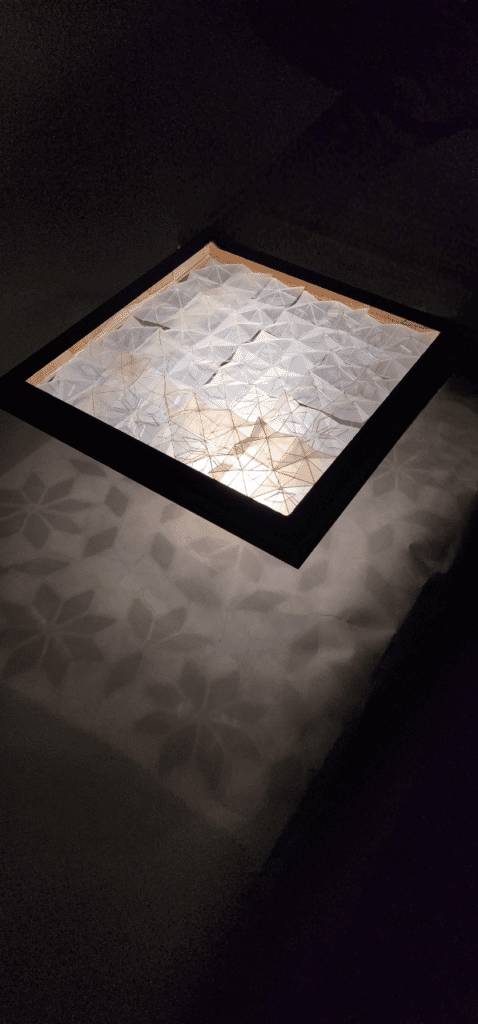

Tessellated Lightfield

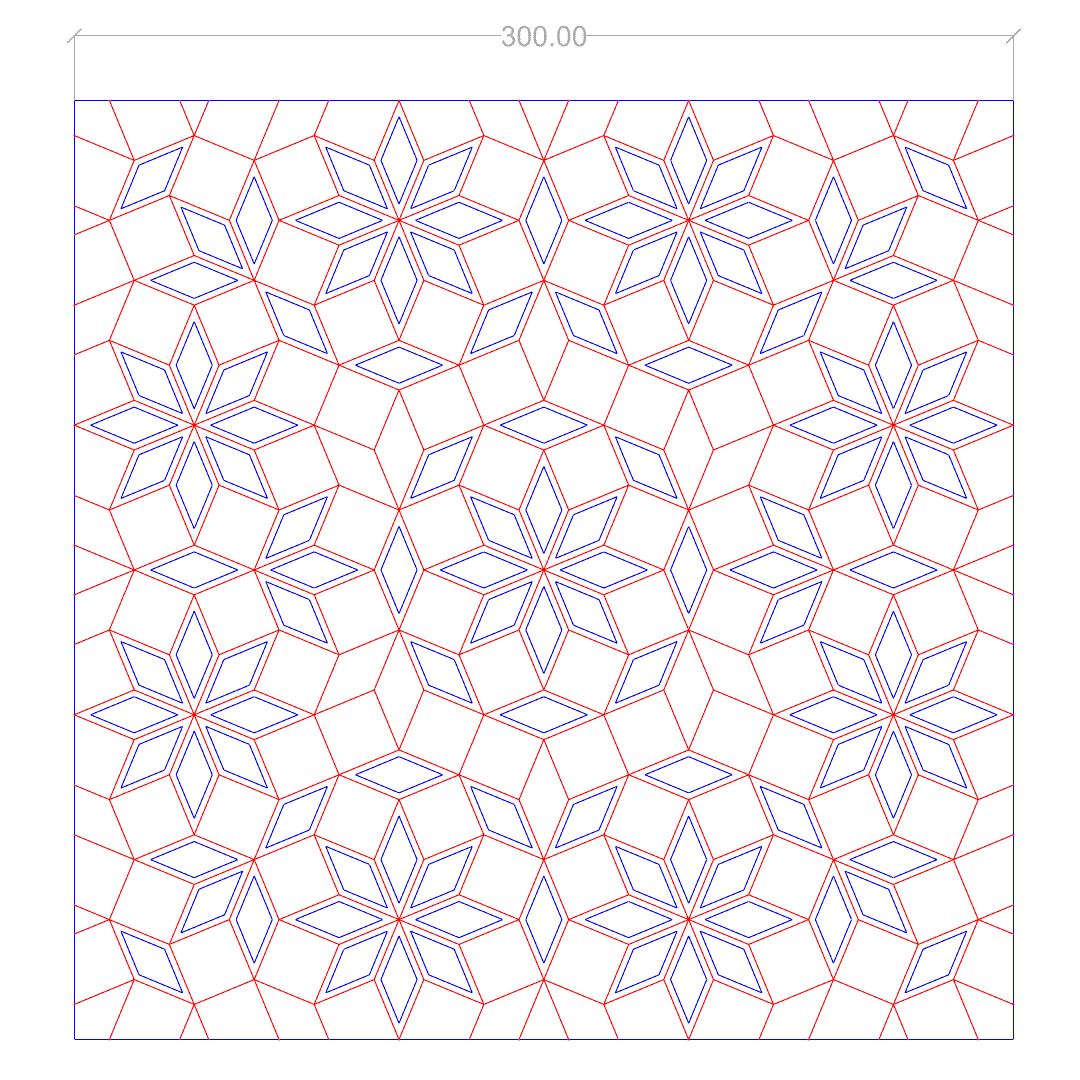

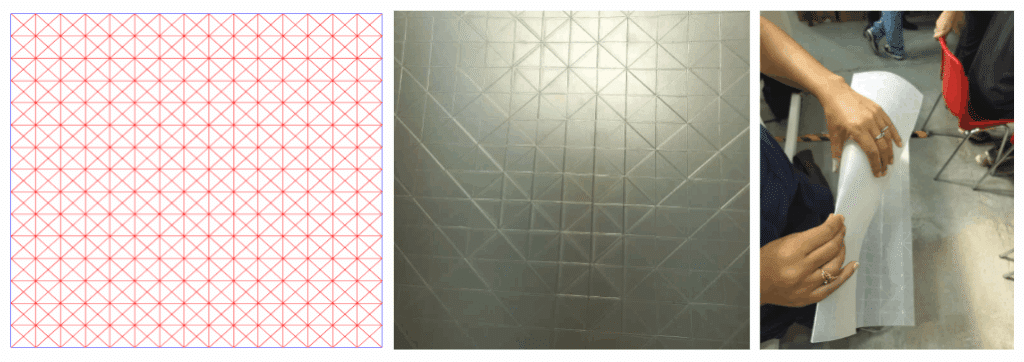

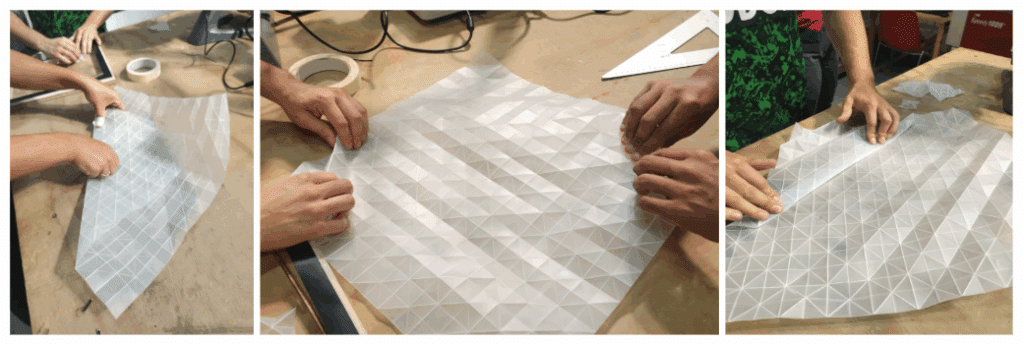

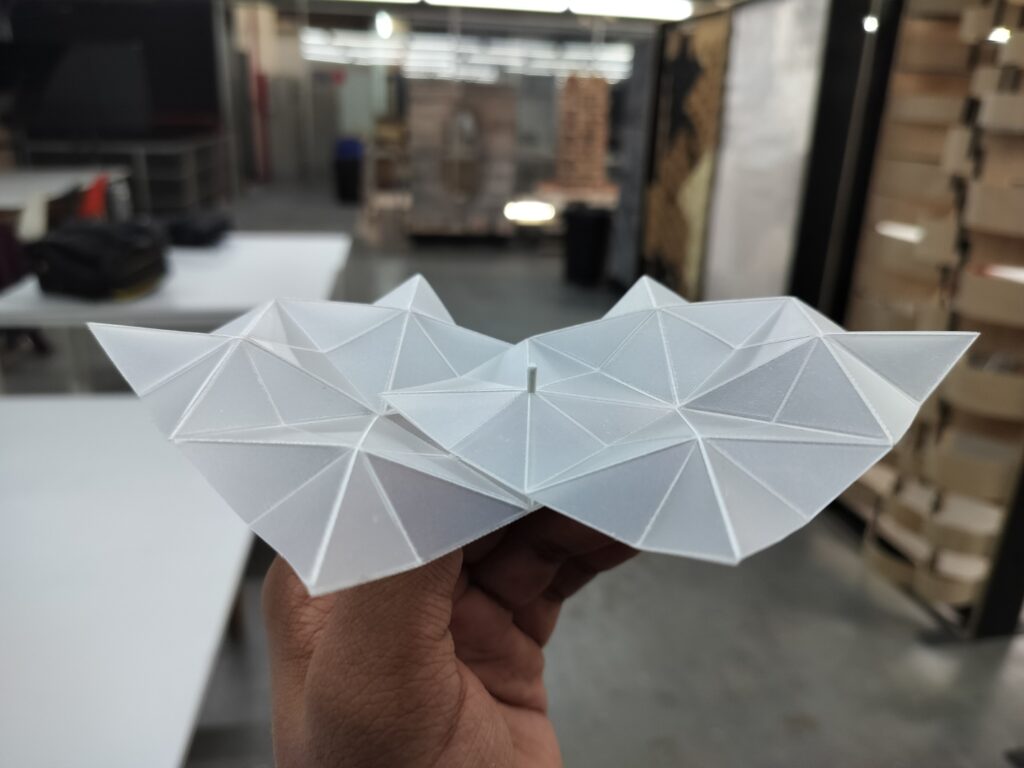

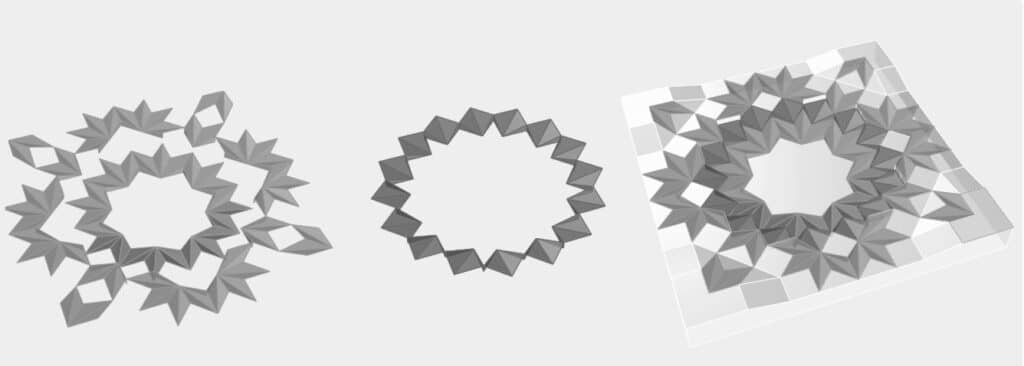

This project explores the spatial potentials of laser-cut geometry, folded surface manipulation, and layered translucency through a three-dimensional modular relief. The piece combines engraved background geometry with floating, volumetric surface assemblies to create an interplay of depth, light, and pattern.

The design is derived from a triangular tessellation system generated through parametric modeling. Each module is laser-cut from translucent polypropylene and manually folded to produce a low-relief topography of peaks and valleys. These folded units are strategically arranged across the frame to form a centralized, symmetrical field, suggesting growth, aggregation, or crystalline emergence. The base acrylic layer features a subtle, laser-cut version of a different tessellated pattern, establishing a calm, two-dimensional base that anchors the raised modules.

Light becomes an active element of the composition: the translucent facets diffuse illumination, while the varied angles of the folded surfaces cast shifting shadows throughout the interior of the frame. This dynamic interaction emphasizes the contrast between the precision of digital fabrication and the expressive dimensionality of hand-formed material. The work operates simultaneously as a material study, geometric investigation, and spatial composition, demonstrating how computational patterning and fabrication technologies can produce nuanced, atmospheric physical forms at architectural scale.

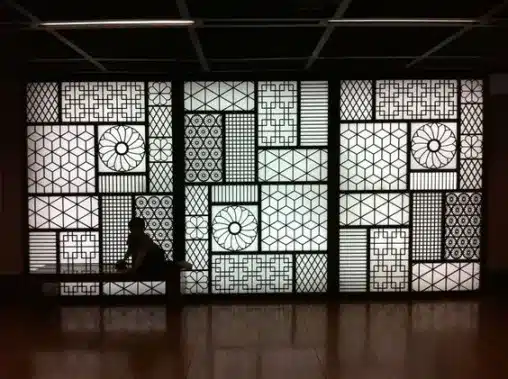

Inspiration

A traditional mashrabiya is an architectural feature consisting of a projecting oriel window with a carved wooden lattice screen, common in Islamic architecture, especially in the Middle East and North Africa. It serves the dual purpose of providing privacy by obscuring the interior while allowing filtered light and airflow to enter, and of facilitating passive cooling by catching wind and holding water jars that use evaporative cooling. Origami symmetrical patterns were also an inspiration for the folds.

Parameters for Laser Cutting

Folding:

Material used: Polypropylene

Machine: Rayjet400

Workpiece: .5mm x 60cm x 60cm

Settings:

Marking

Power: 30%

Speed: 100%

Frequency: 2500

Cutting

Power: 80%

Speed: 50%Frequency: 2500

Acrylic Base:

Material used: Acrylic sheet

Machine: Rayjet400

Workpiece: .5mm x 60cm x 60cm

Settings:

Marking

Power: 10%

Speed: 100%

Frequency: 500

Cutting

Power: 80%

Speed: 6%Frequency: 5000

The Process

3D PRINTING

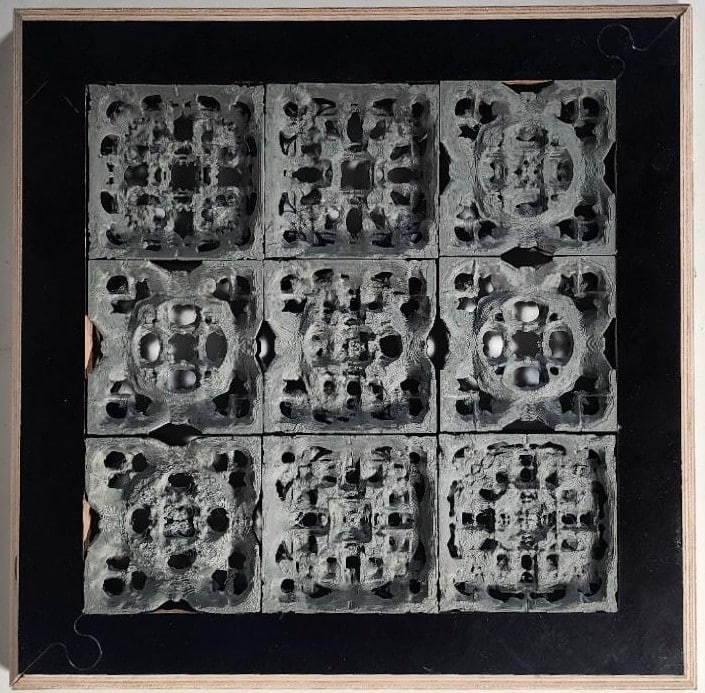

Kosmos: chaos and order

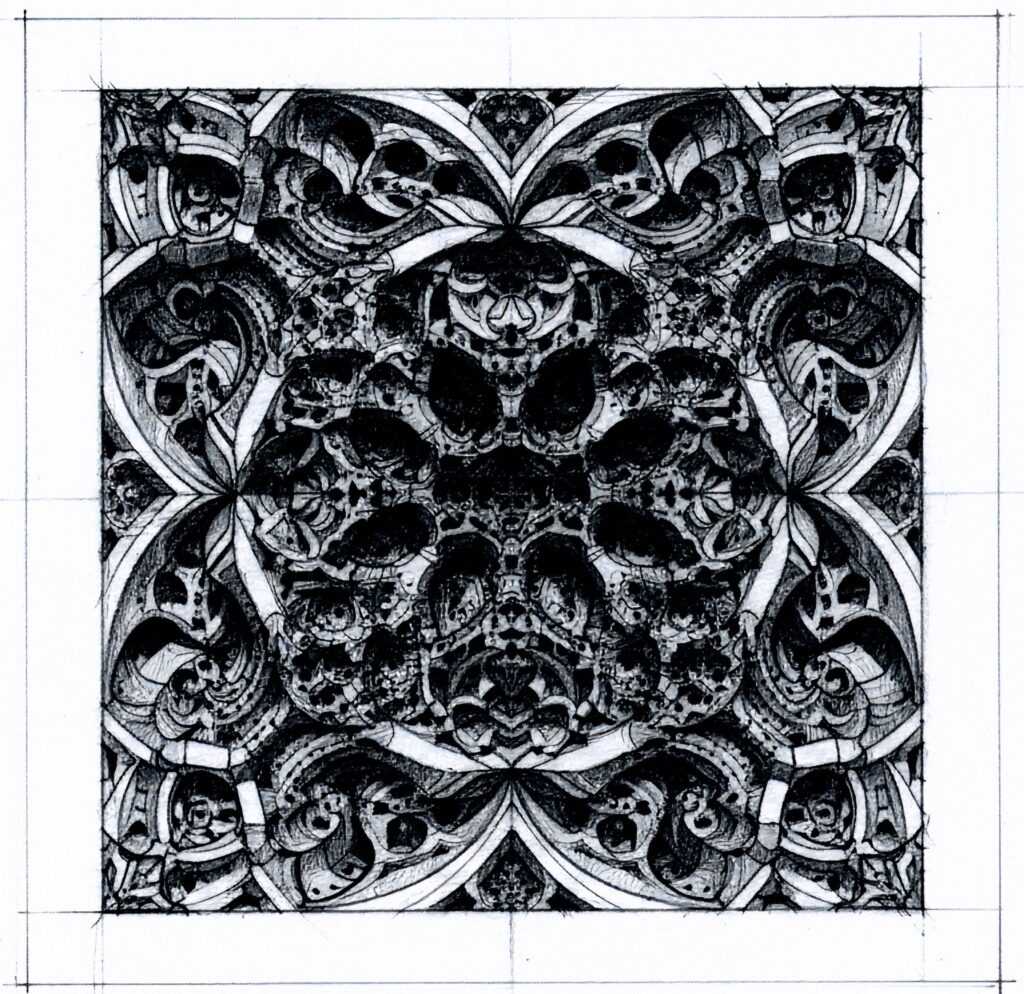

Kosmos explores the inherent tension between the unpredictable and the structured between natural disorder and human attempts to impose geometry and rhythm. The name comes from the ancient Greek word κόσμος, meaning “order,” but also the root of “cosmos,” the vast universe born from chaos.

The façade becomes a physical metaphor for that duality. Each kinetic module behaves like a fragment of disorder responsive, shifting, never fully still, yet collectively, they assemble into a coherent field of movement. This tension forms a living equilibrium, where chaos is not erased but orchestrated.

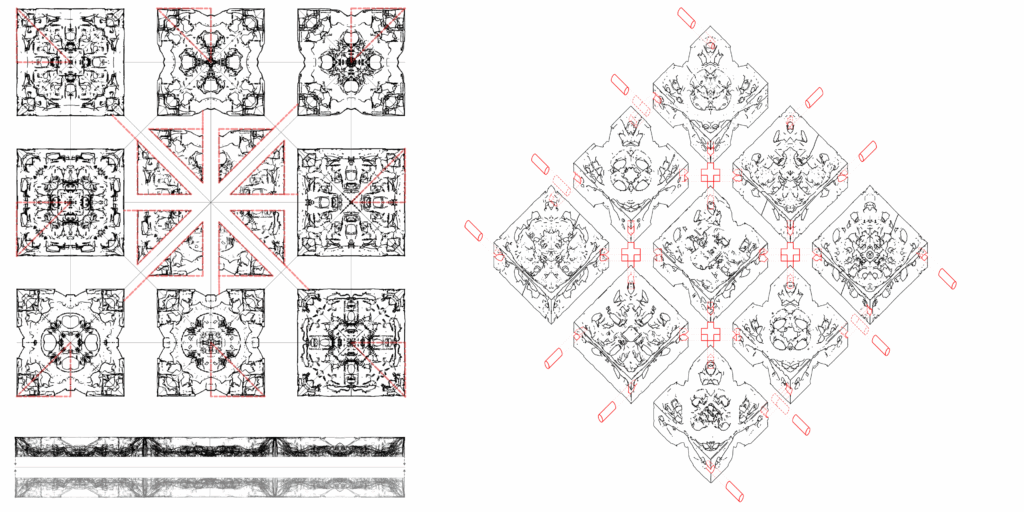

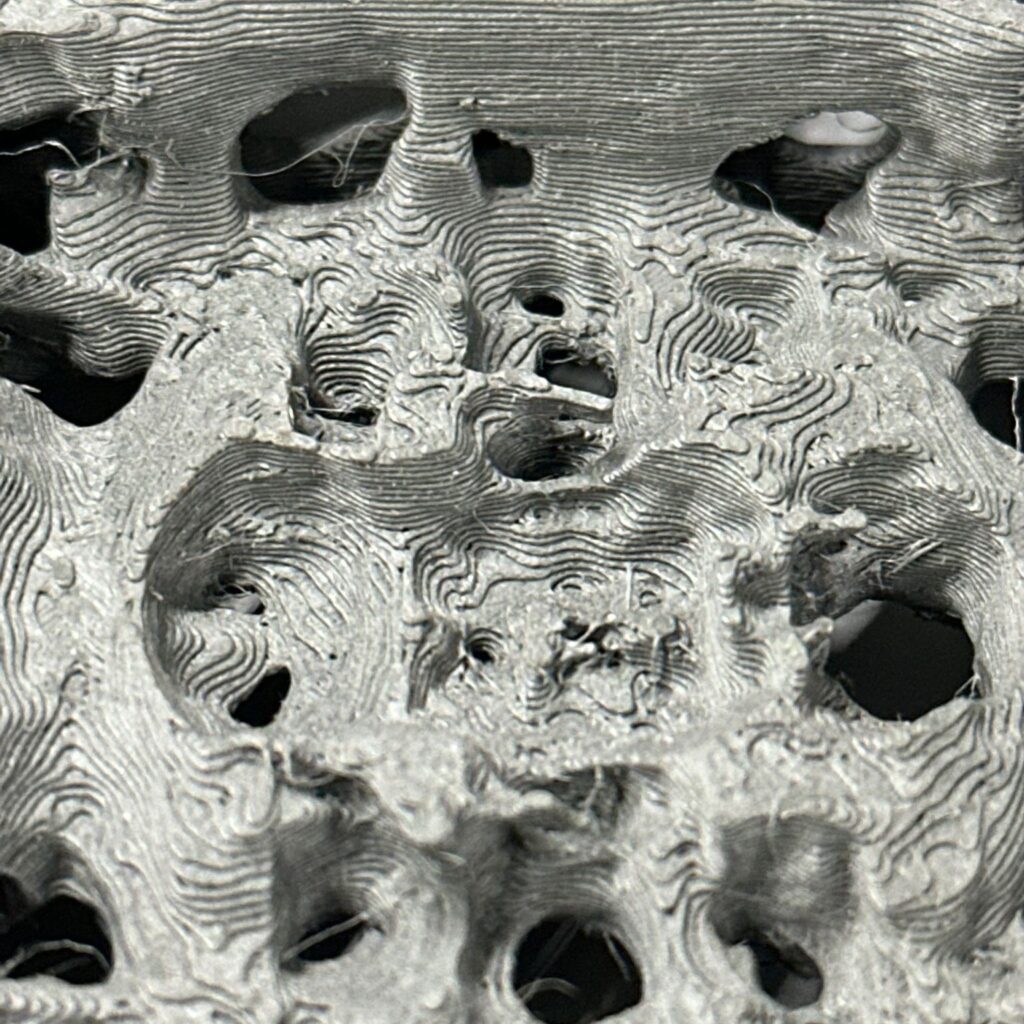

The tile geometry originates from an intentionally chaotic and irregular initial morphology. This seemingly disordered form was then subdivided into eight equivalent segments, whose systematic mirroring generated a coherent set of eight regular tiles. In this way, an ordered configuration emerges directly from the manipulation of the initial chaotic geometry.

The structural system is maintained through two distinct types of dowels. Cylindrical dowels anchor the peripheral tiles to the wooden frame, while cross-shaped dowels connect the central tile to the surrounding tiles at each corner, reinforcing the overall ordered assembly derived from the original irregular form.

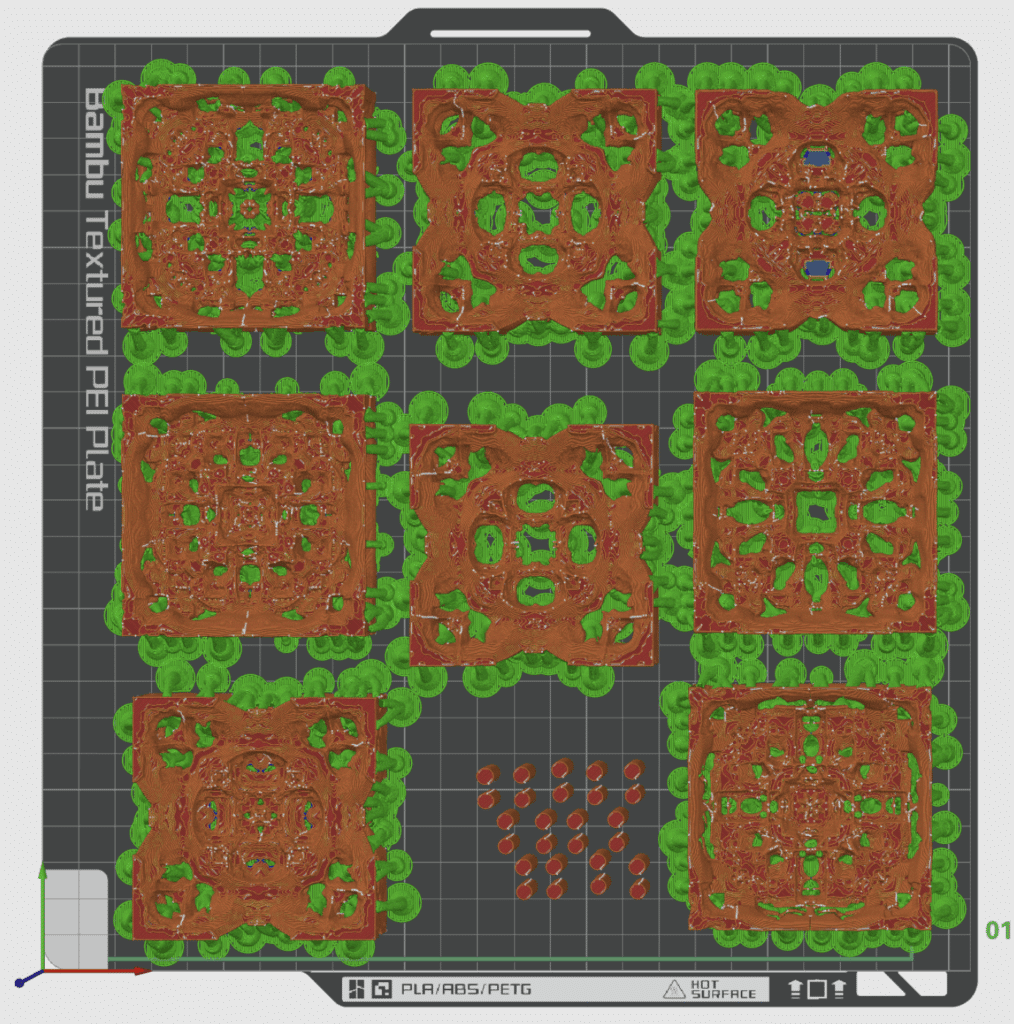

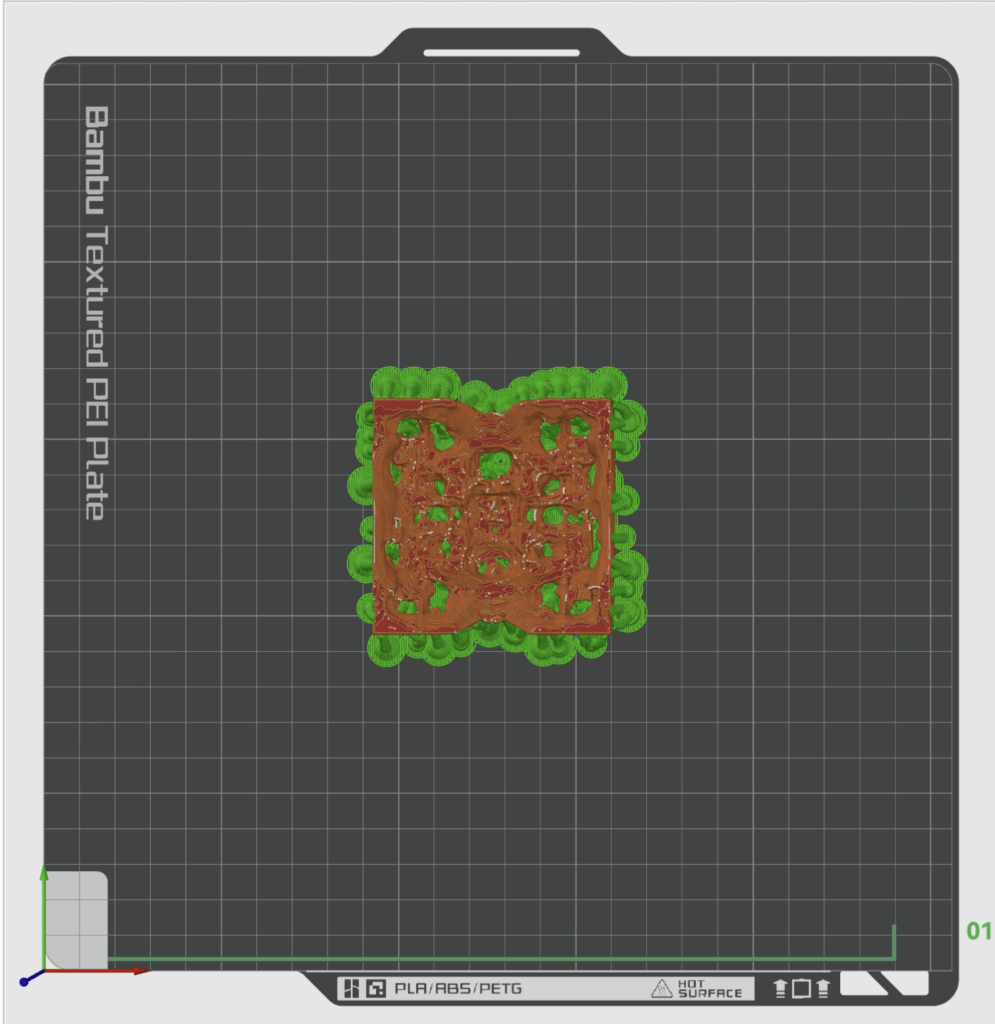

Parameters per tile

- Material: PLA

- Workpiece volume: 66 x 66 x 20 mm

- Machine: Bambu Lab P1S

- Total Filament: 24.02 g

- Model Filament: 18.30 g

- Layer Height: 0.2 mm

- Total Time: 2h37m

Global parameters

- Workpiece volume: 200 x 200 x 20 mm

- Total Filament: 267.29 g

- Model Filament: 187.24 g

- Layer Height: 0.2 mm

- Total Time: 20h19m

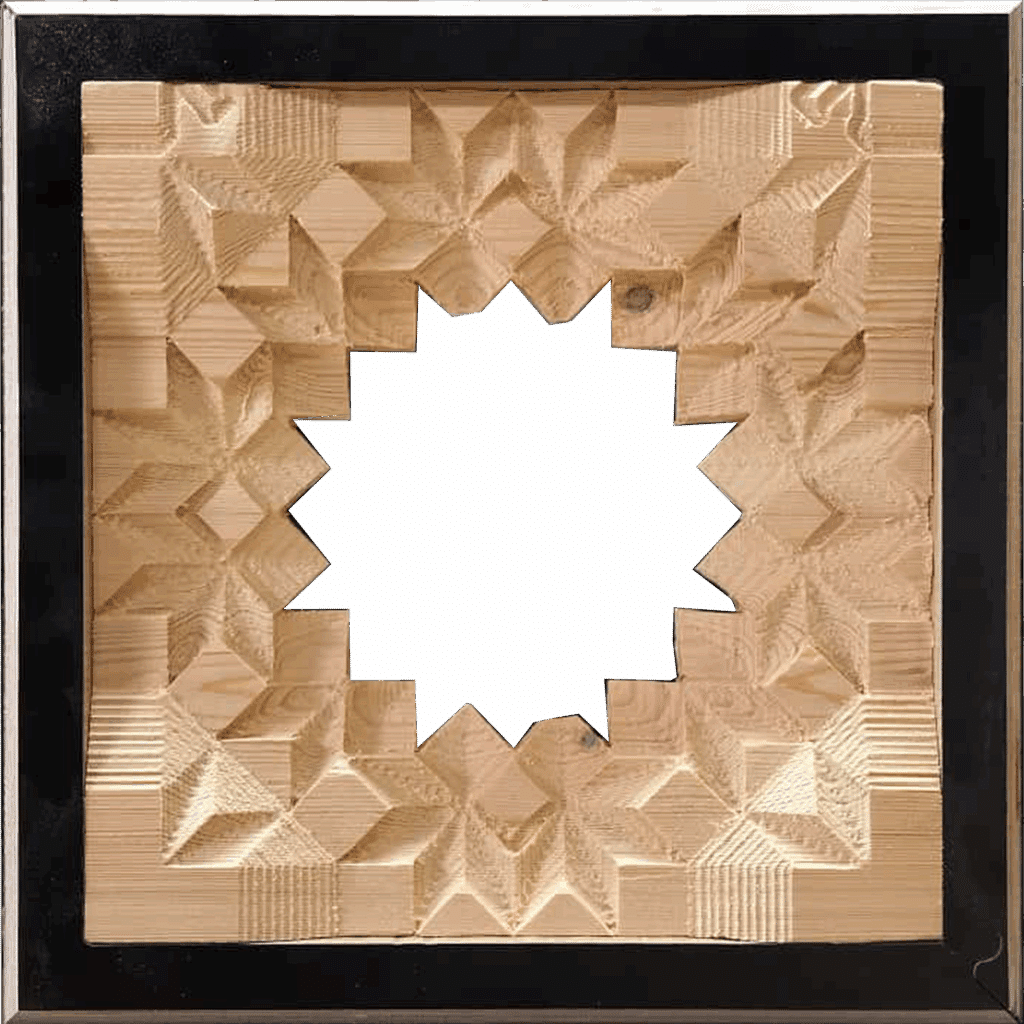

CNC MILLING

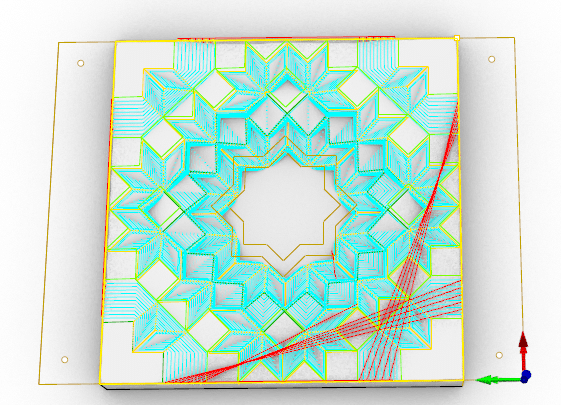

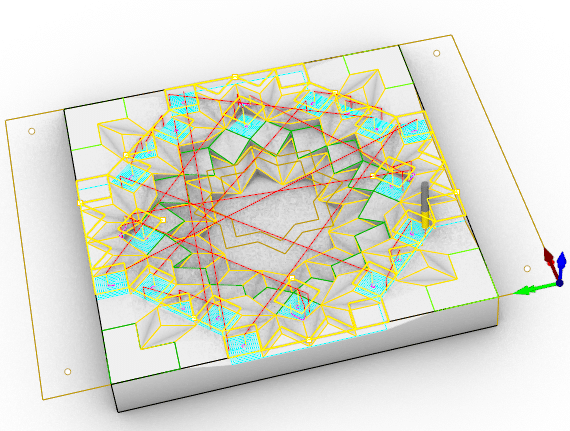

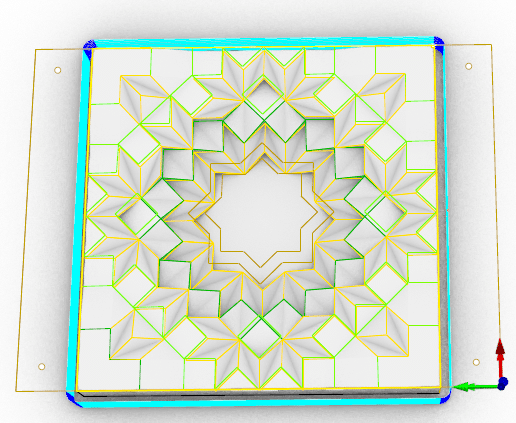

The Muqarnas: A three-dimensional geometric composition

Subtle mixtures of geometry and rhythm also characterised the muqarnas or stalactite vault, which is distinctive to Islamic architecture and decoration. The muqarnas is both a structural element that fills the zones of transition between walls and domes and a decorative element that copies the same structural composition.

Fabrication Strategy

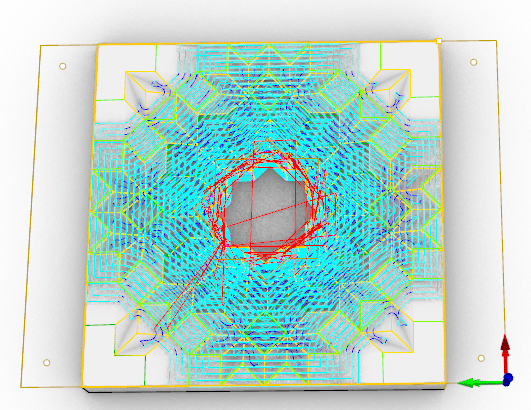

Rhinocam setup

- Material: MDF

- Machine: T -rex

- Porst Processor:

- Workpiece volume: 150x150x30mm

Horizontal Roughing

Flat Mill

- Flute: 2

- Diameter: 8

- Spindle Speed: 12000

- Cut Direction: Upcut

- Stepdown Control (dZ): 50%

- Stepover Distance: –

- Total mill time: 27.44 minutes

- Stock: 1.5

Horizontal Finishing

Ball Mill

- Flute: 2

- Diameter: 6

- Spindle Speed: 12000

- Cut Direction: Downcut

- Stepdown Control (dZ): 13%

- Stepover Distance: –

- Total mill time: 24.14 minutes

Clear Flat Tops

Flat Mill

- Flute: 2

- Diameter: 6

- Spindle Speed: 12000

- Cut Direction: Downcut

- Stepdown Control (dZ):-

- Stepover Distance: 25%

- Total mill time: 7.75 minutes

Axis Profiling

Flat Mill

- Flute: 2

- Diameter: 6

- Spindle Speed: 12000

- Cut Direction: Downcut

- Stepdown Control (dZ): –

- Stepover Distance: -Total mill time: 8.31 minutes

1st Trial with Pinewood

Final Results with MDF

ROBOTICS

The robotic-printed cup uses Grasshopper and Kangaroo to prototype a self-supporting organic structure. The form adapts to material behavior, demonstrating how parametric simulation can guide geometry toward stability while retaining a natural, folded aesthetic.