INTRO

This study investigates innovative joinery solutions for modular evaporative cooling systems using 3D printed clay. With the rising global temperatures and subsequent increased demand for energy-consuming air conditioning systems, there is a crucial need for sustainable cooling alternatives. The research focuses on addressing the challenges of material shrinkage and joinery reliability in 3D printed clay structures, aiming to enhance assembly integrity and performance. The study utilizes experimental methods to compare traditional and novel joinery designs and evaluates the effectiveness of 3D scanning and edge detection in capturing detailed geometric data for precision joinery.

CONTEXT

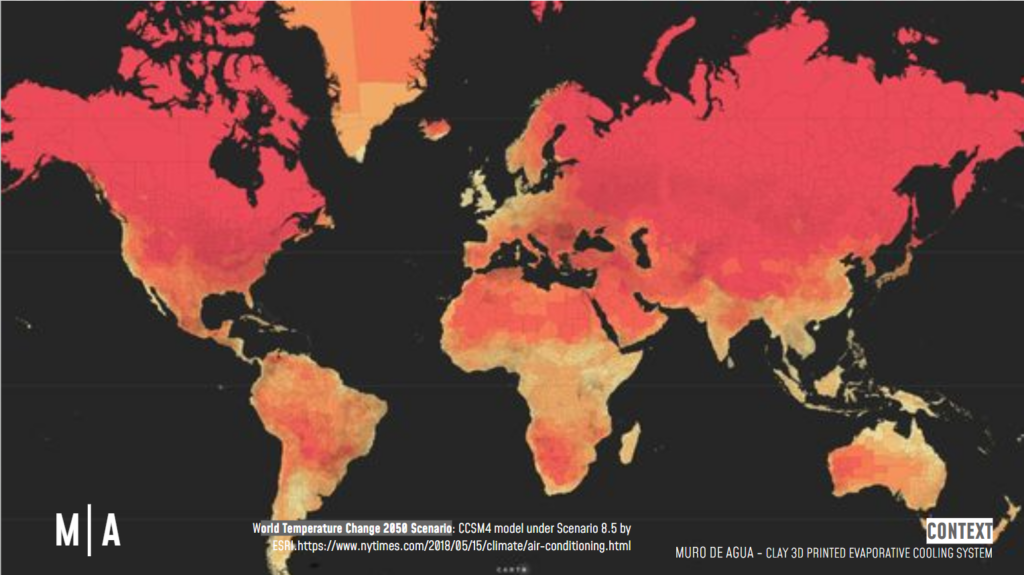

The escalating effects of global warming have led to increased temperatures worldwide, significantly raising the demand for cooling systems in residential and commercial buildings. This trend poses a challenge due to the high energy consumption associated with conventional air conditioning, which in turn contributes to further environmental degradation.

HISTORICAL COOLING TECHNIQUES

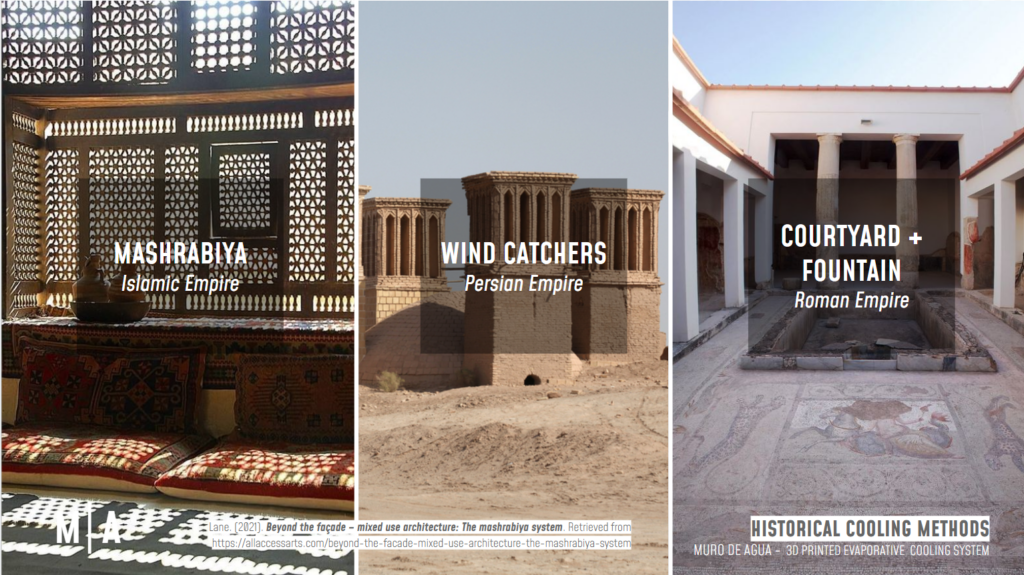

Throughout history, various civilizations have innovatively designed spaces to stay cool without modern energy. These designs harnessed natural elements like shadow and airflow. For instance, Mashrabiya (ornamental latticeworks) not only provided privacy but also facilitated air movement and shading. Wind catchers, towering structures, funneled cool breezes into buildings. Similarly, courtyards with central fountains enhanced evaporative cooling, creating refreshing microclimates.

MODERN EVAPORATIVE COOLING

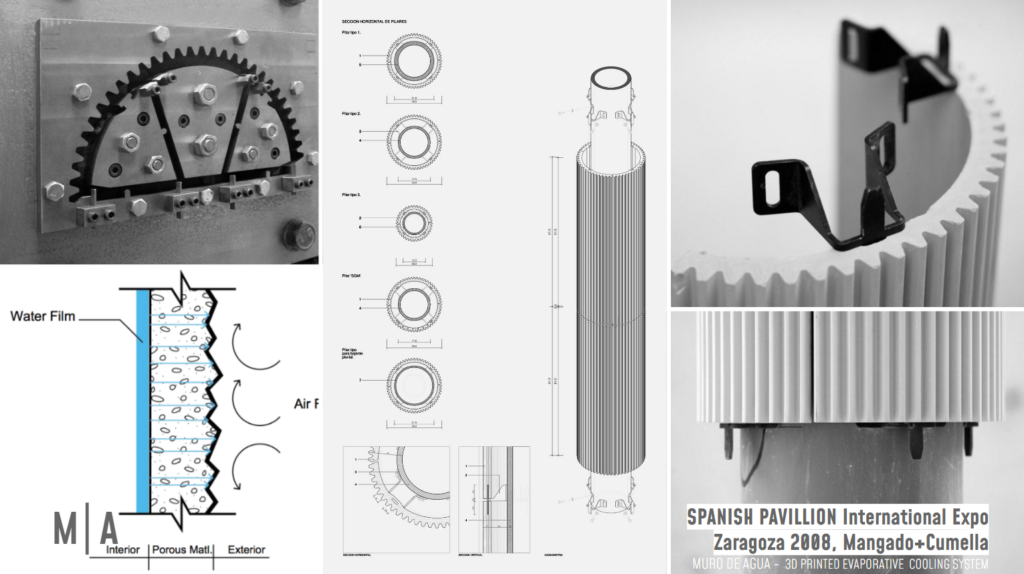

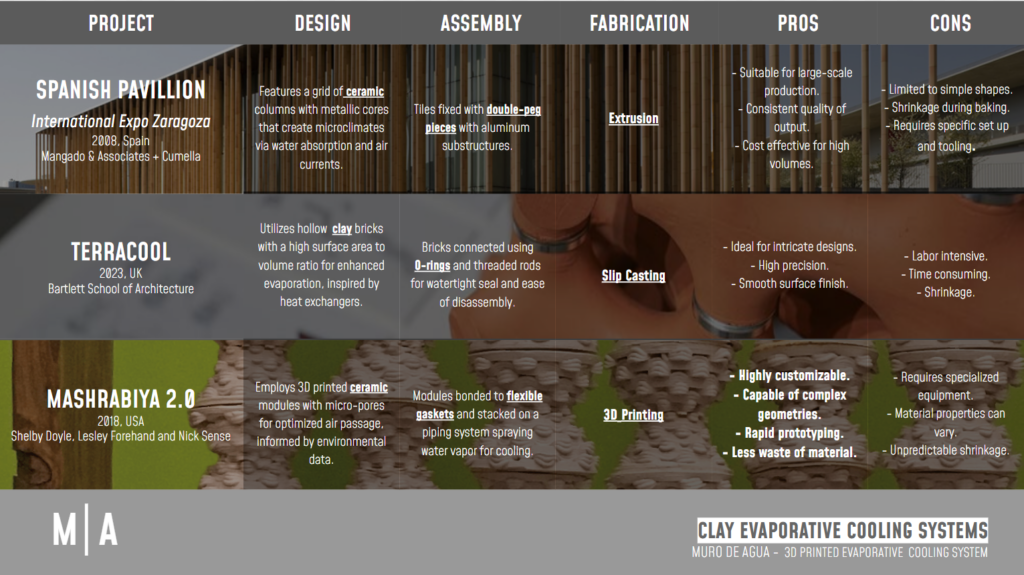

SPANISH PAVILION, ZARAGOZA 2008: The Spanish Pavilion of the international expo of Zaragoza in 2008, was commissioned to Francisco Mangado. He materialized an exposition space surrounded by a forest of columns resting in a water body. The fabrication of the Microclimate Generator Pillars was handled by Cumella. The terracotta tiles were made through extrusion and assembled into metal columns using double-peg pieces to keep them in place. The ceramic pieces are then constantly sprayed with water from the inside to promote water absorption.

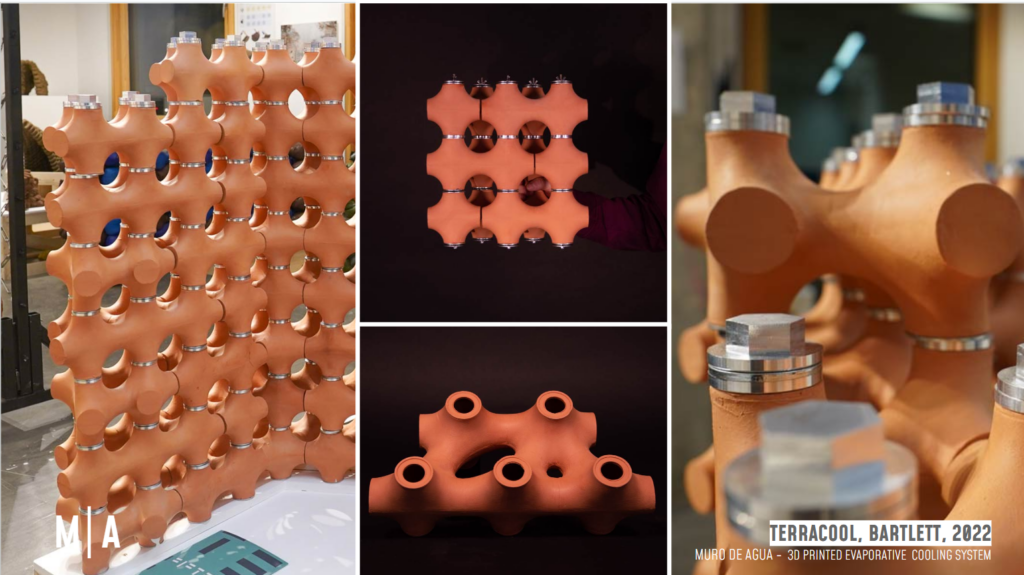

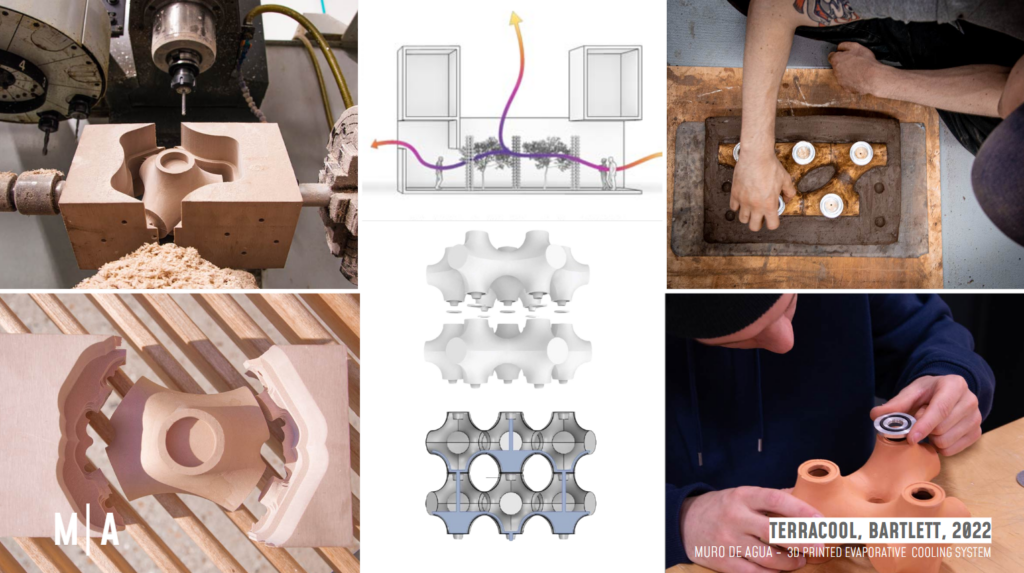

TERRACOOL : Terracool is a project by students at Bartlett. Inspired by heat exchangers, they created hollow bricks with minimal surfaces, forming a modular system that integrates evaporative cooling into architecture. They used subtractive and additive methods to create controlled molds for managing slip-cast clay. This ensured precise assembly, utilizing O-rings and threaded rods for watertight seals, allowing water to flow throughout the structure.

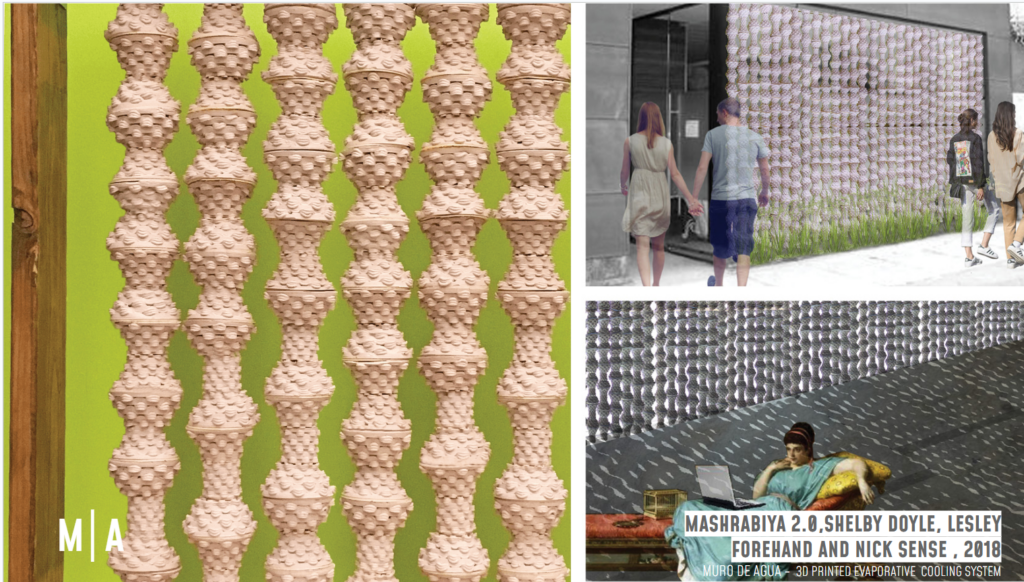

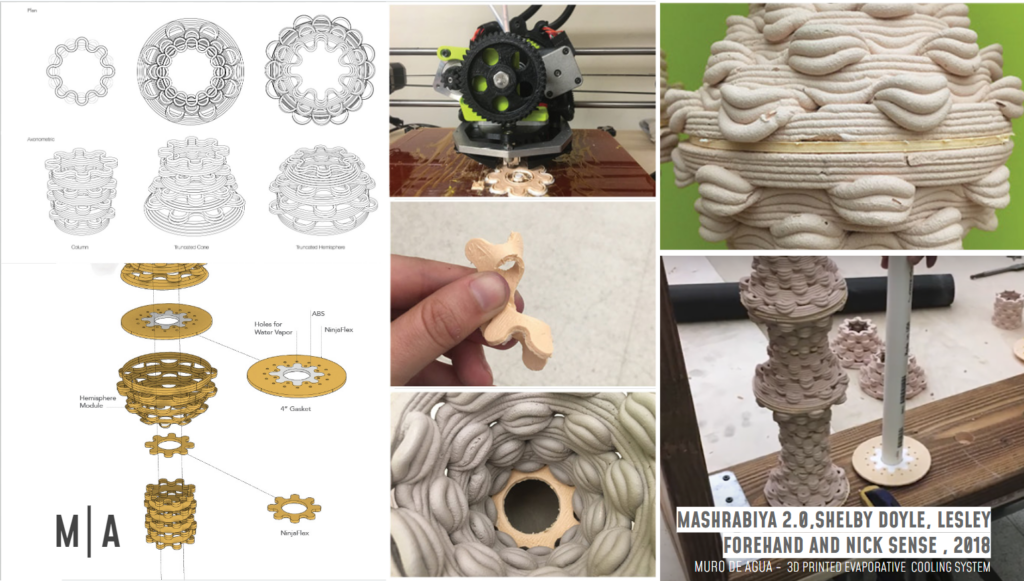

MASHRABIYA 2.0: Mashrabiya 2.0, inspired by the traditional Egyptian mashrabiya, proposes a series of ceramic modules to provide evaporative cooling instead of using a traditional wooden screen. These ceramic modules were 3D printed using a clay woven pattern that produces micropores, allowing air to pass through the screen. The modules are then stacked with spacers made of flexible material, covering a pipe that actively sprays water.

Despite their different approaches of fabrication, they face common challenges, shrinkage. While extrusion and slip casting can control it, they are limited in design flexibility, whereas in 3D printing despite its unpredictable shrinkage provides customization and rapid prototyping capabilities.

RESEARCH PROBLEM

3D printed clay elements for evaporative cooling systems often deform during the manufacture process, (shrinkage, over extrusion, etc). These deformations compromise the integrity and fit of assembled structures, making reliable joinery difficult.

RESEARCH GOAL

To develop joinery solutions that accommodate the shrinkage and deformation of 3D printed clay elements, ensuring precise fit and reliable assembly in evaporative cooling systems.