The objective of this studio was to implement an automated robotic process for the efficient fabrication of modular cork blocks, essential components of a doubly curved acoustic surface. The key objectives encompassed the following:

- Exploration and comprehension of robotic workflows and semi-automated manufacturing processes, taking into account the unique material properties of cork and their alignment with specific design concepts.

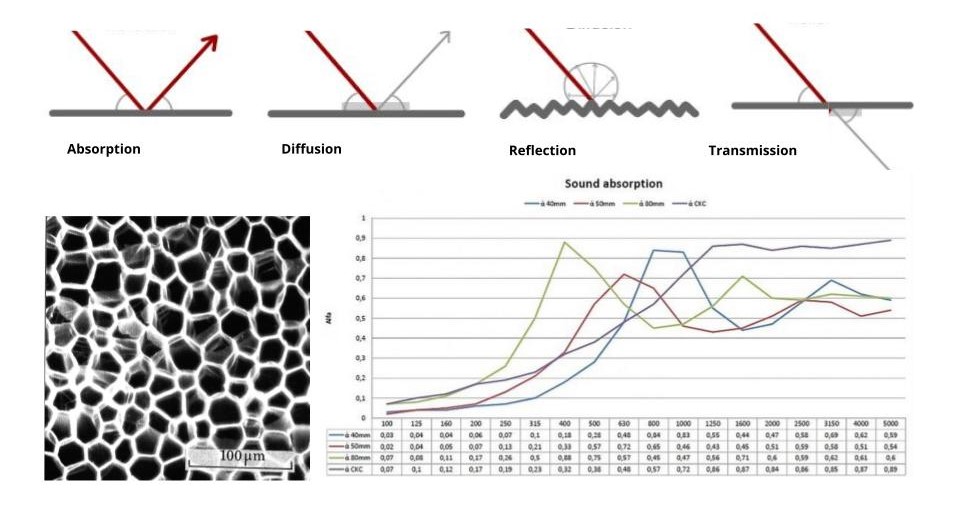

- Designing an interior surface system that not only amplifies the inherent acoustic qualities of cork but also aligns with the fabrication capabilities and limitations of machines and robots involved in the process.

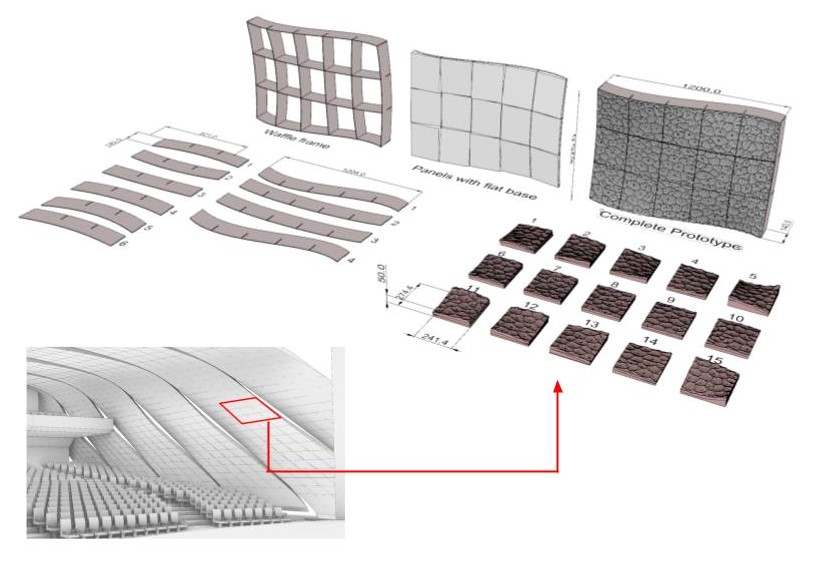

- Investigating various discretization strategies for the fabrication of a textured double curved surface, considering the available material dimensions.

- Generating innovative ideas for the panelization and assembly of a double curved surface utilizing a waffle structure that can be effectively scaled up and optimized for larger interior spaces.

By addressing these objectives, the studio aimed to advance the field of robotic fabrication while emphasizing the acoustic potential of cork and its application in creating immersive interior environments.

This project focused on the fabrication of a chosen design for a modular cork block system, derived from an auditorium interior, while emphasizing efficient robotic workflows and cork material properties, rather than generating acoustic designs from scratch.

For our prototype, we employed a square-based discretization approach and devised a straightforward assembly strategy for the panels. To enhance both the acoustic performance and aesthetic appeal, we incorporated a Voronoi pattern onto the textured surface of the prototype.

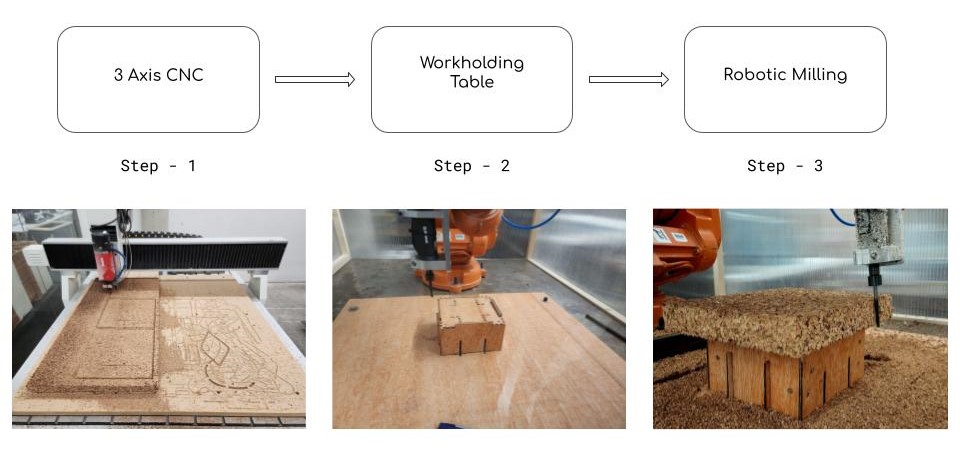

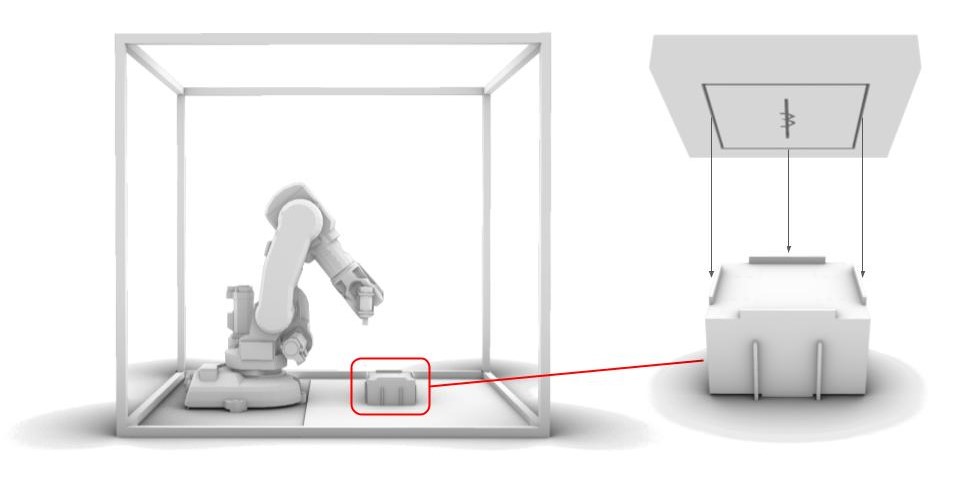

Our manufacturing workflow involved the utilization of CNC and robotic arm technologies. Initially, the CNC machine was employed to cut out the near net shape from cork panels, while also conducting engraving and labeling to facilitate precise placement of the pieces on the custom-made work-holding table designed for the robotic fabrication process. The labeling proved particularly helpful during the panel assembly stage.

To generate the milling tool path, we utilized the Robots plugin within the Grasshopper environment. Subsequently, the tool path was exported into a G-code format by leveraging a custom plugin developed specifically for this purpose.